In the realm of agricultural equipment, comprehending the intricate relationships between various elements is essential for optimal performance and maintenance. Each machine consists of numerous interconnected pieces that work in harmony to achieve efficiency in farming tasks. This knowledge empowers operators and technicians to troubleshoot issues effectively and ensure longevity of the equipment.

One particularly noteworthy model has garnered attention for its reliability and robust design. By exploring the intricate configuration of its components, users can gain valuable insights into their functionality and interdependence. This understanding is crucial for both routine upkeep and addressing any potential complications that may arise during operation.

Delving into the layout of these essential components not only enhances operational proficiency but also fosters a deeper appreciation for engineering ingenuity. As we examine the specifics, it becomes clear how each section contributes to the overall efficiency of the machine, enabling smoother workflows on the farm.

Understanding the Ford 1900 Tractor

This section aims to explore the essential aspects of a specific agricultural machine renowned for its reliability and efficiency. Grasping its fundamental components and functionalities can enhance user experience and maintenance practices.

Key features include:

- Powerful engine performance

- Versatile attachments for various tasks

- User-friendly controls

To appreciate its value, consider the following maintenance tips:

- Regularly check fluid levels

- Inspect belts and hoses for wear

- Keep the exterior clean for optimal performance

Understanding these elements can ultimately lead to a more effective and enjoyable usage experience.

Key Components of the Ford 1900

Understanding the essential elements of a specific agricultural vehicle is crucial for maintaining its efficiency and longevity. Each unit is composed of various integral parts that work harmoniously to ensure optimal performance in various farming tasks. Familiarity with these components can aid operators in troubleshooting and enhancing functionality.

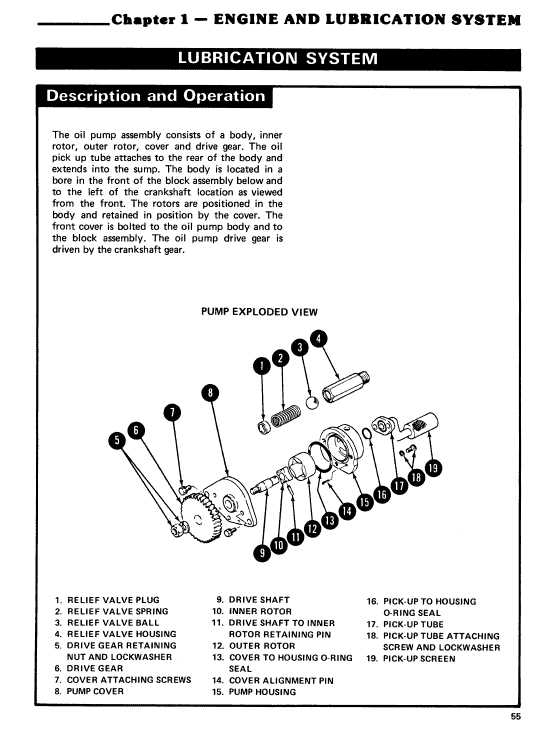

Engine and Power Transmission

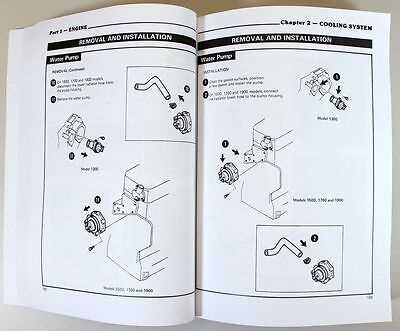

The heart of any machine lies in its engine, which converts fuel into mechanical energy. In this case, a robust engine provides the necessary power for various applications. Coupled with a reliable transmission system, it ensures smooth operation and effective power delivery to the wheels. Regular checks and maintenance of these components are vital to prevent unexpected breakdowns.

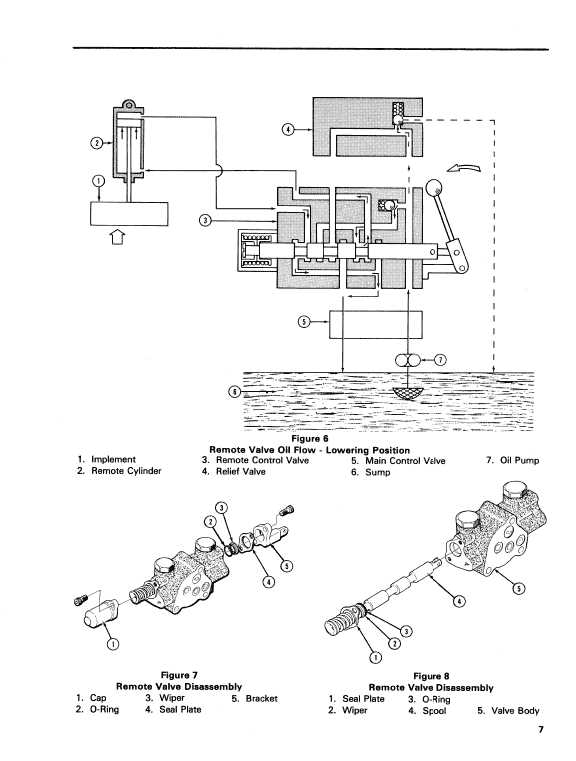

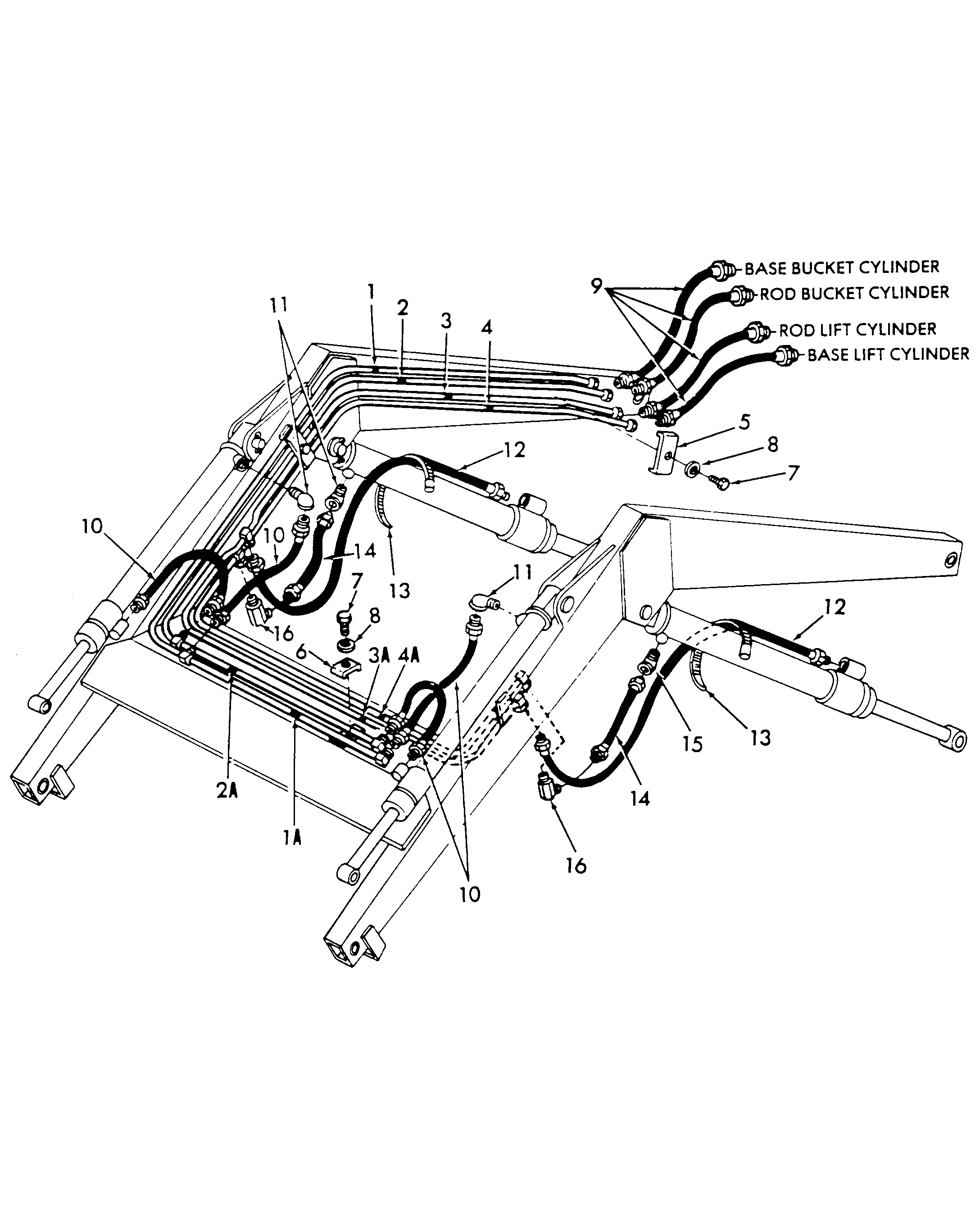

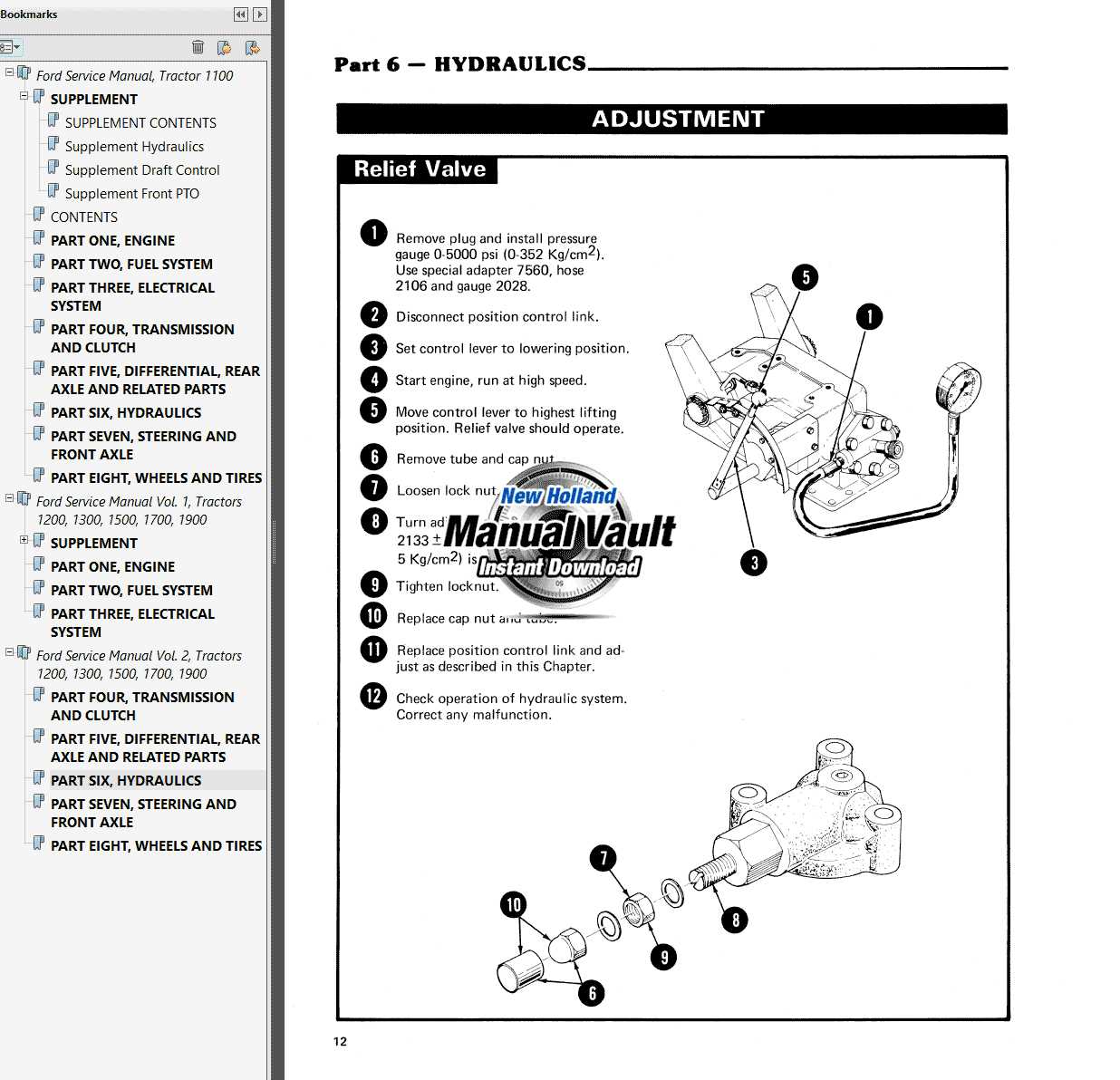

Hydraulic System

The hydraulic system is a key feature that enhances the versatility of the equipment. It allows for the operation of various implements and attachments, making the vehicle adaptable for multiple tasks. Regular maintenance of hydraulic components, such as pumps and cylinders, is essential for sustaining their performance. Understanding the workings of this system can lead to more efficient and productive use.

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components ensures optimal performance and reliability in machinery. These items are specifically designed to meet the exact specifications of the equipment, leading to enhanced functionality.

- Quality Assurance: Manufactured to stringent standards, ensuring durability.

- Perfect Fit: Engineered for seamless integration, reducing the risk of malfunction.

- Warranty Protection: Often covered by manufacturer warranties, providing peace of mind.

- Resale Value: Maintaining original components can enhance the resale potential of the machinery.

Choosing original components ultimately supports the longevity and efficiency of the equipment, making it a wise investment for users seeking reliability.

Common Issues with Ford 1900 Tractors

Many owners encounter a variety of challenges with their machinery, leading to performance issues and maintenance concerns. Understanding these common problems can help in troubleshooting and ensuring longevity.

Engine Performance

One prevalent issue is related to engine performance, where symptoms such as poor starting, misfiring, or stalling can occur. Regular checks on fuel quality and ignition systems can mitigate these problems.

Hydraulic System Failures

Another frequent concern involves hydraulic system failures, often manifested by slow or unresponsive lift mechanisms. Routine inspections of hydraulic fluid levels and seals can help maintain optimal functionality.

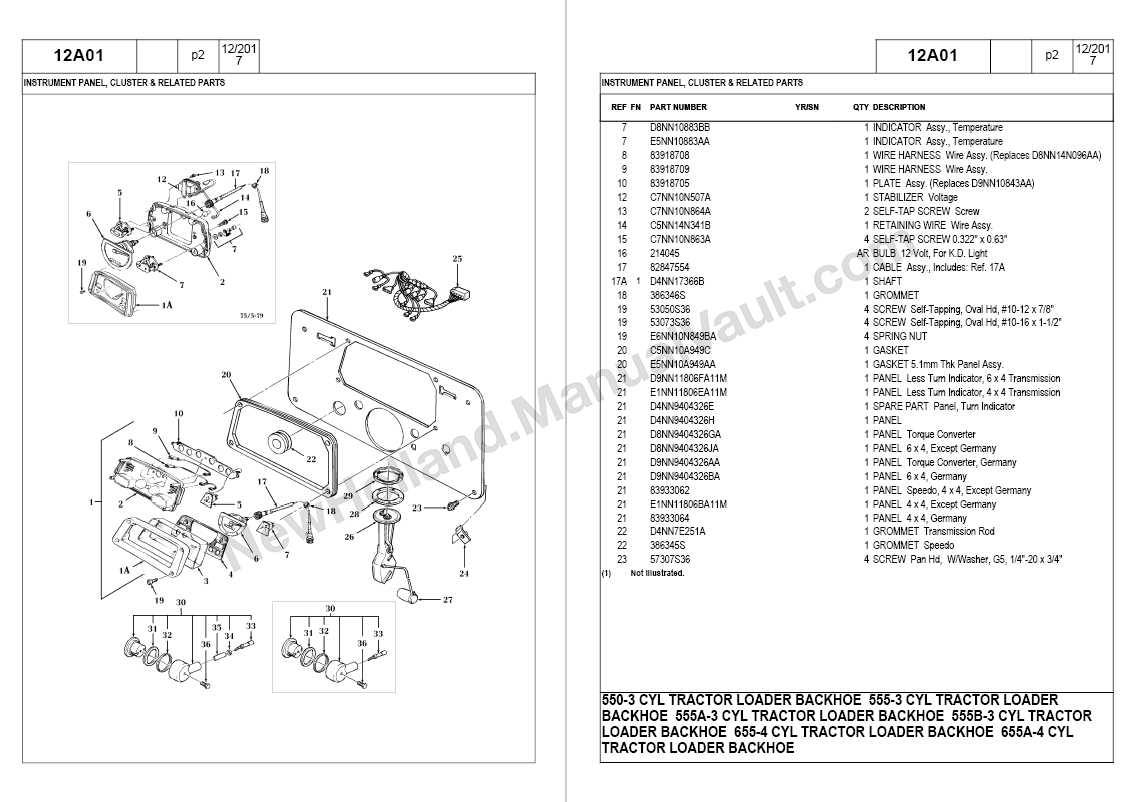

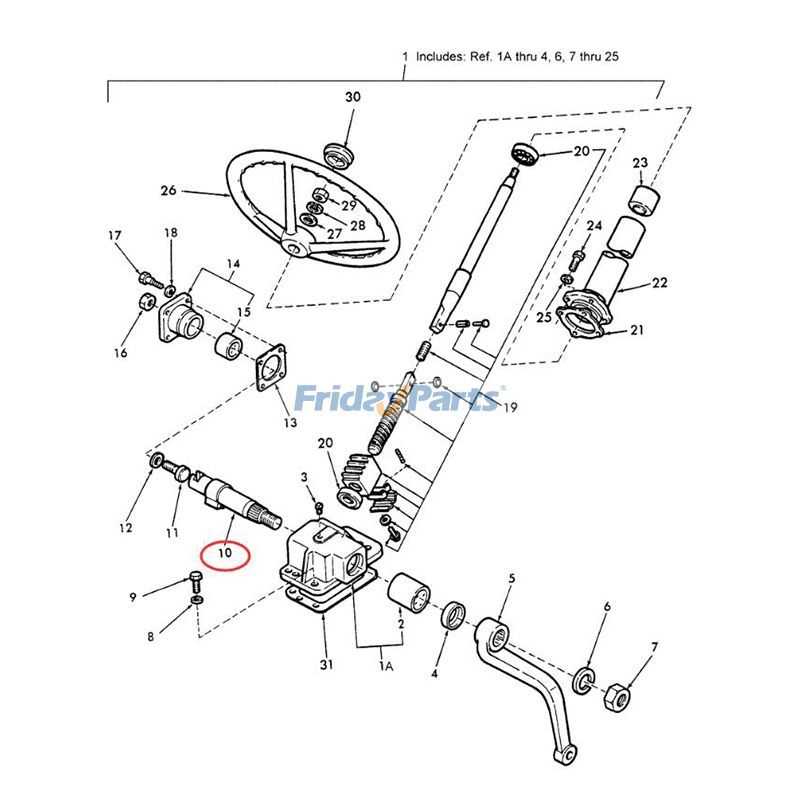

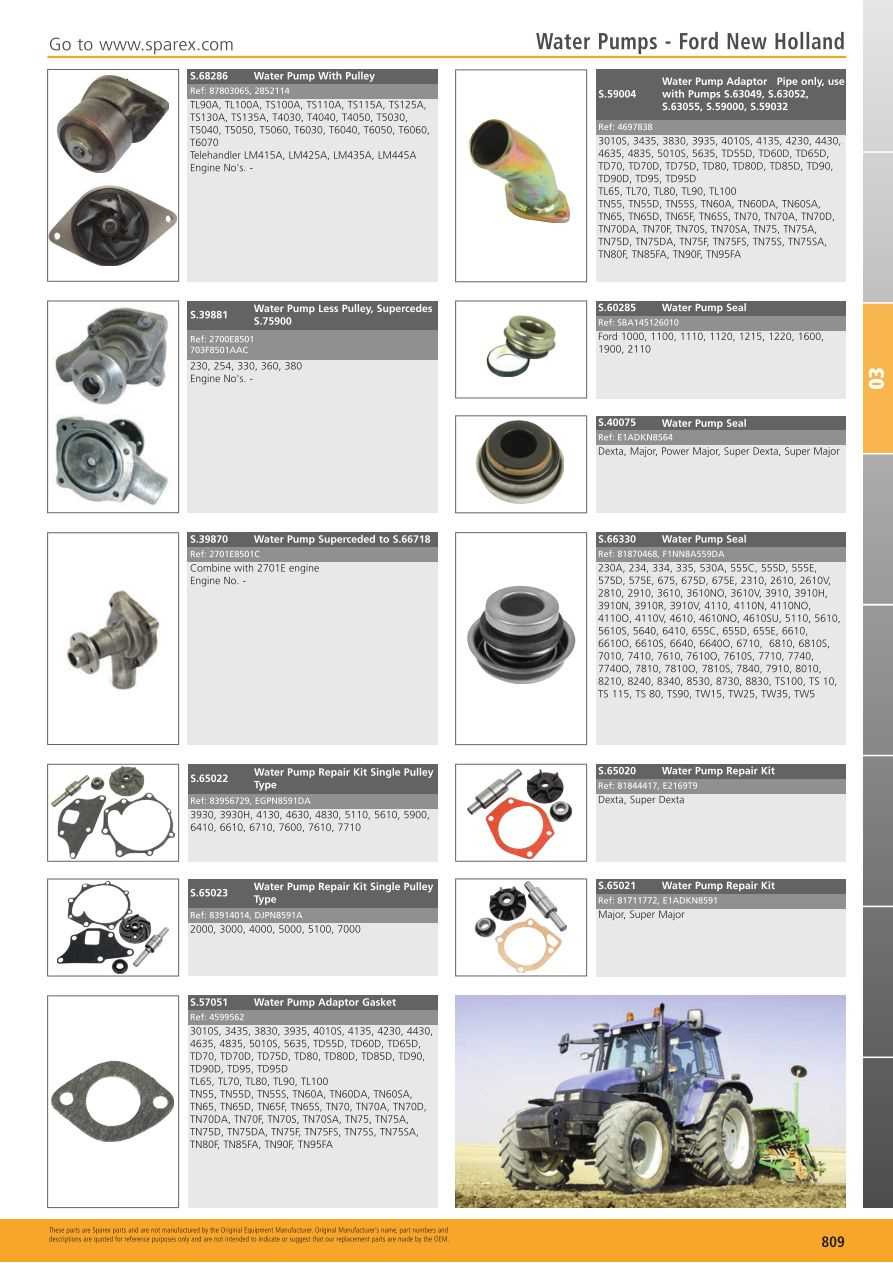

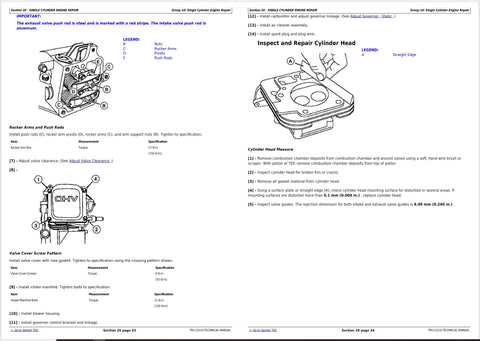

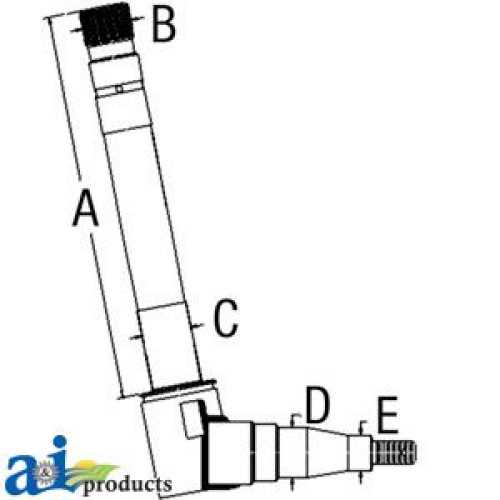

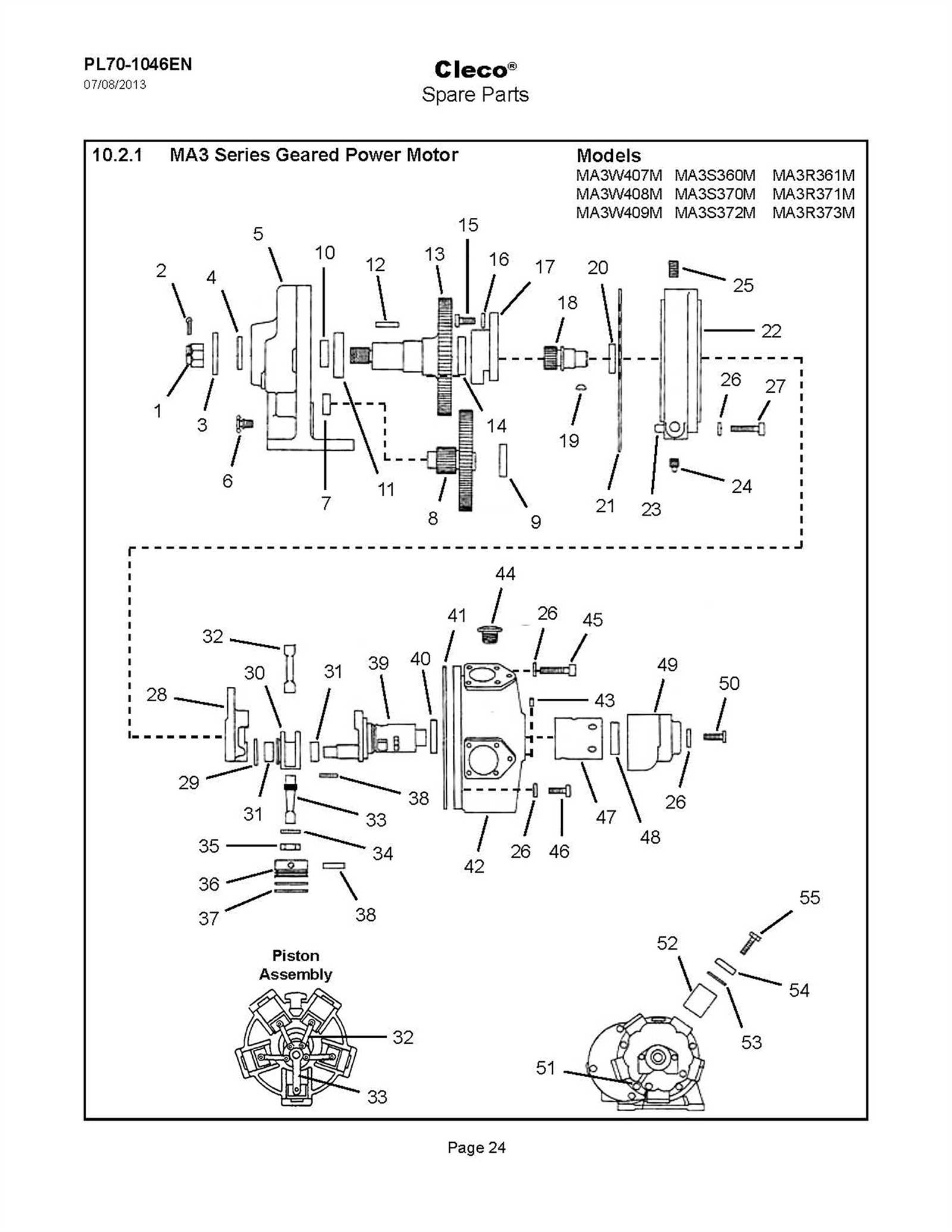

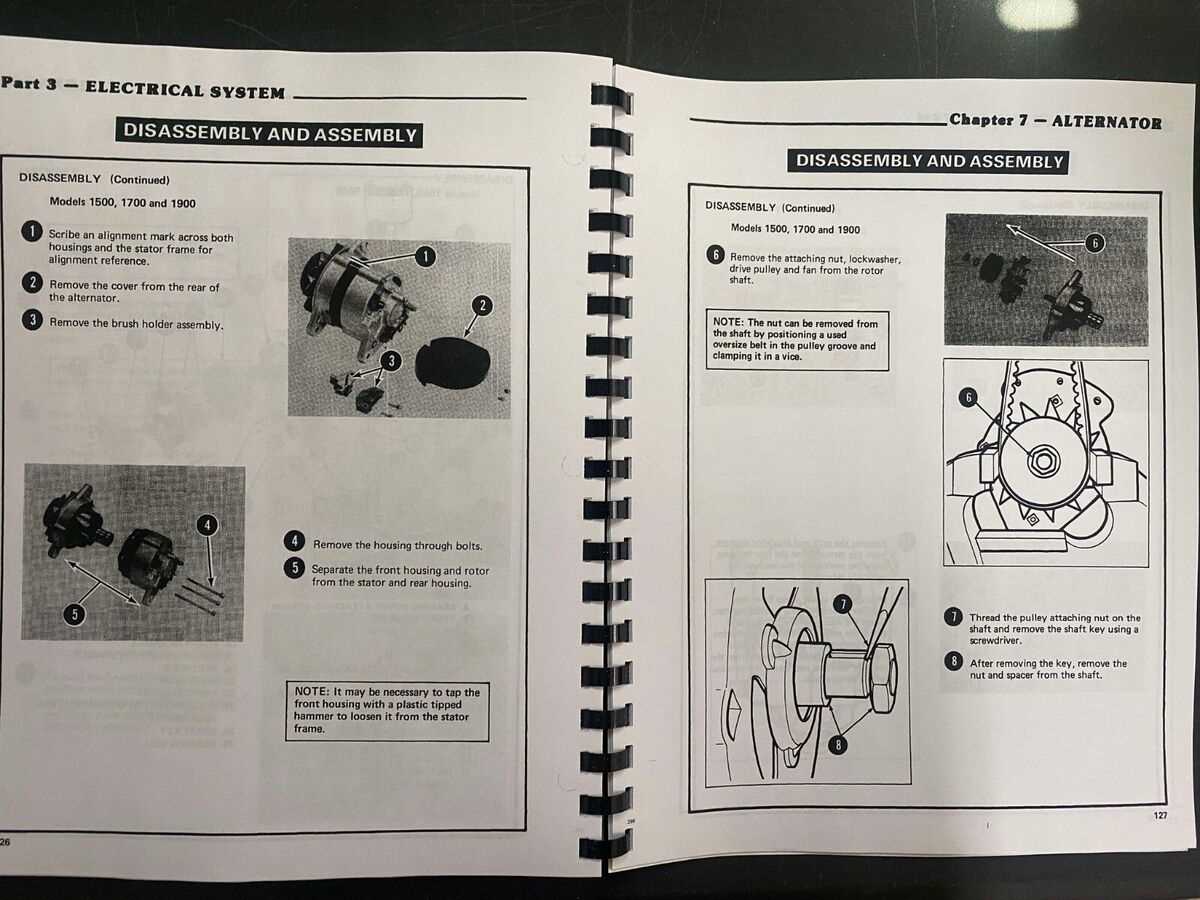

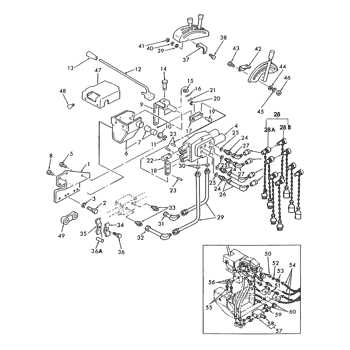

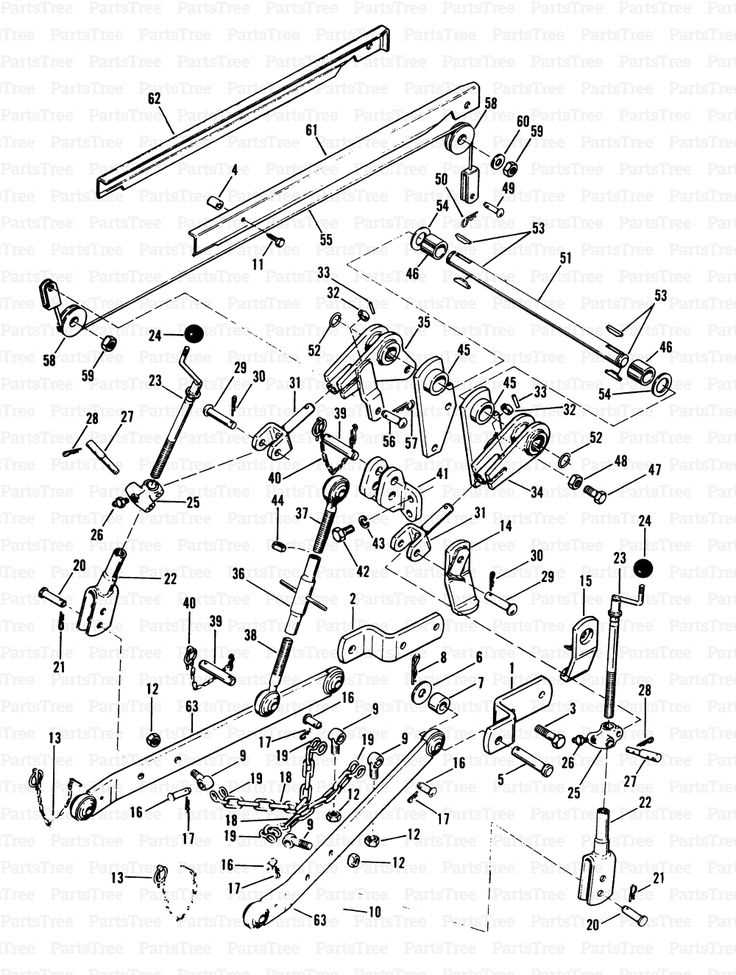

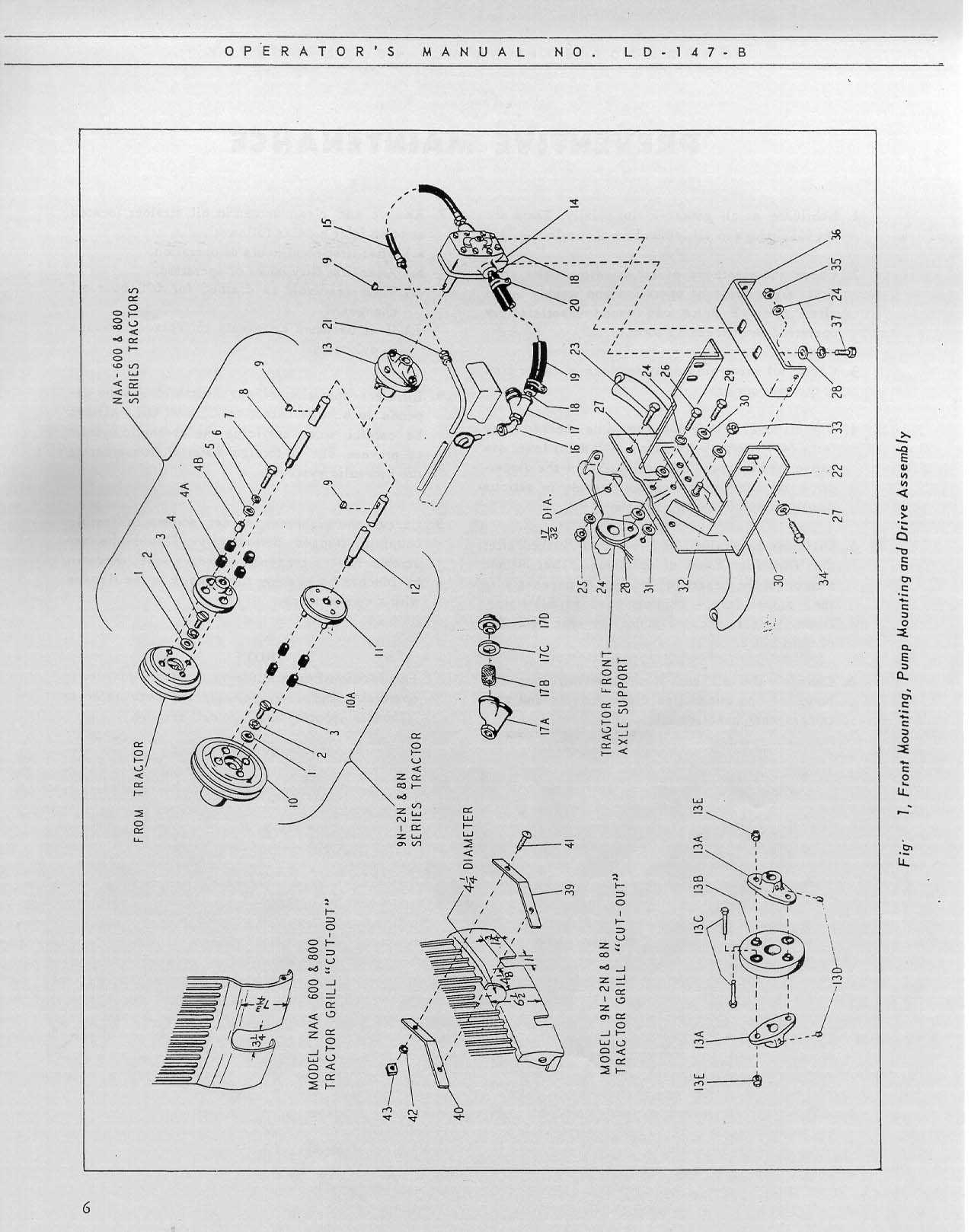

How to Read Parts Diagrams

Understanding visual representations of components is crucial for effective maintenance and repairs. These illustrations provide a clear overview of each element and its relationship to others, allowing for easier identification and ordering of necessary components. By familiarizing yourself with the layout and symbols used, you can streamline the repair process and ensure you have everything needed for a successful job.

Begin by examining the legend, which explains the various symbols and designations. Each item typically has a corresponding reference number that connects it to detailed information. Familiarize yourself with the different sections of the illustration, as they often categorize components by their function or location within the overall assembly.

Take note of any exploded views that show how parts fit together. These perspectives can provide valuable insight into assembly and disassembly procedures, making your work more efficient. By carefully analyzing these visuals, you can enhance your understanding and execution of repairs.

Finding Replacement Parts Online

Locating the necessary components for machinery maintenance can be a daunting task, especially when the items are no longer readily available in local stores. The internet has revolutionized this process, providing enthusiasts and professionals alike with a vast array of options. By leveraging online resources, one can access a wide selection of alternatives, ensuring that every piece required for optimal performance can be found.

Numerous websites specialize in offering components for various equipment, ranging from original manufacturers to aftermarket suppliers. Utilizing search engines effectively, coupled with specific keywords, can yield fruitful results. It is also beneficial to join online forums or communities dedicated to machinery, as members often share their insights and recommendations for trusted retailers.

When exploring options, it’s essential to verify the credibility of the seller. Reading customer reviews and checking ratings can provide valuable insights into the quality and reliability of the components. Additionally, ensure that the specifications match your requirements to avoid any compatibility issues. With careful research and a discerning eye, one can successfully find the necessary items to keep equipment running smoothly.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your machinery requires a consistent and informed approach to upkeep. By following key practices, you can significantly enhance performance and reliability over time. These essential guidelines not only promote functionality but also prevent costly repairs and downtime.

Regular Inspections: Conduct thorough checks at regular intervals to identify wear and tear. Look for signs of damage or corrosion, particularly in critical components, and address issues promptly to avoid more significant problems.

Proper Lubrication: Keep all moving parts well-lubricated to minimize friction and prevent overheating. Using the right type of lubricant is crucial; refer to the manufacturer’s recommendations for optimal results.

Cleanliness: Maintain a clean environment around the machinery. Dirt and debris can lead to malfunction and wear. Regularly clean surfaces and remove any buildup that could interfere with operations.

Timely Replacement: Replace worn or damaged components as soon as they are identified. Proactive replacement is key to maintaining efficiency and can save you from unexpected breakdowns.

Fuel Quality: Use high-quality fuel to ensure smooth operation. Poor fuel can lead to reduced performance and increased wear. Regularly check and replace fuel filters to maintain optimal flow and cleanliness.

Operator Training: Ensure that all users are well-trained in operating the equipment. Proper handling can prevent misuse and extend the life of the machinery significantly.

By implementing these maintenance strategies, you will not only enhance the performance of your equipment but also ensure its durability for years to come.

Upgrading Your Ford 1900 Model

Enhancing your agricultural vehicle can significantly improve its performance and efficiency. Whether you’re looking to increase power, enhance comfort, or boost overall functionality, there are numerous options to consider. A thoughtful approach to upgrades can transform your machine into a more effective tool for your farming needs.

Performance Enhancements

Focusing on performance can lead to notable improvements in your machine’s capabilities. Here are some popular upgrades to consider:

- Engine tuning: Adjusting fuel settings and optimizing air intake can provide more horsepower.

- Exhaust upgrades: Installing a high-flow exhaust system can enhance engine efficiency and reduce back pressure.

- Transmission modifications: Upgrading the transmission can improve power delivery and handling.

Comfort and Usability Improvements

Increasing the comfort of your machinery can lead to more productive workdays. Consider these enhancements:

- Cab insulation: Adding soundproofing materials can create a quieter working environment.

- Ergonomic seating: Upgrading to a more comfortable seat can reduce fatigue during long hours.

- Control upgrades: Installing modern controls can enhance usability and responsiveness.

By prioritizing both performance and comfort, you can create a more efficient and enjoyable experience while operating your agricultural vehicle.

Community Resources for Owners

Owners of agricultural machinery often seek valuable resources to enhance their experience and maintenance knowledge. Engaging with a community can provide insights, support, and access to essential tools and information.

- Online Forums: Join discussions on platforms dedicated to equipment enthusiasts.

- Local Clubs: Connect with nearby owners for hands-on tips and shared experiences.

- Social Media Groups: Participate in groups focused on machinery upkeep and modifications.

- Workshops: Attend local events that offer practical training and demonstrations.

- Resource Libraries: Access manuals and documentation through community libraries or digital archives.

Utilizing these community resources can significantly enhance your understanding and enjoyment of your equipment, leading to improved performance and longevity.