Understanding the internal makeup of various gardening machines can significantly enhance their operation and maintenance. When it comes to outdoor equipment designed for soil preparation, knowing how its essential mechanisms fit together ensures smoother functionality and more efficient use. This overview will delve into the arrangement of individual elements within a common gardening device, emphasizing key components responsible for optimal performance.

By familiarizing yourself with the specific layout and connections within this type of machine, you can not only troubleshoot potential issues but also make informed decisions about replacement or repair. Each element plays a crucial role in the overall efficiency, contributing to seamless operation during landscaping tasks. With the right knowledge, maintaining and optimizing this equipment becomes much more manageable, ensuring long-term reliability in outdoor projects.

Key Components of a Murray Tiller

The effective functioning of any garden tool relies on the integration of various essential elements, each contributing to its smooth operation. Understanding the main sections of this type of equipment helps ensure proper maintenance and long-term performance. These fundamental components are designed to work together, optimizing efficiency and ensuring durability in a range of conditions.

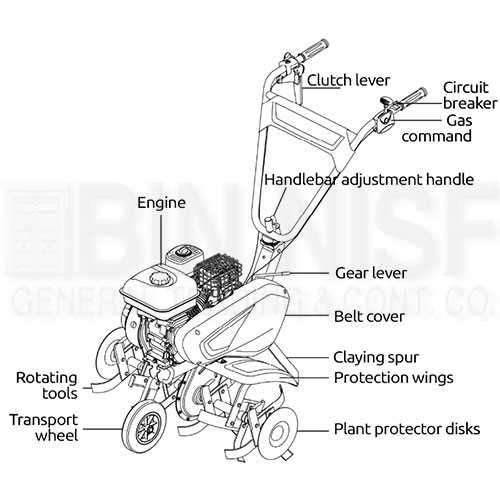

Engine plays a vital role by providing the necessary power to drive the device. It ensures the movement of all mechanical parts, allowing for seamless soil cultivation. Proper care of the motor is essential for consistent performance.

Blades are the key to cutting through soil and preparing it for planting. These sharp, rotating pieces break up hard ground, making it easier to manage. Regular inspection and sharpening are crucial to their effectiveness.

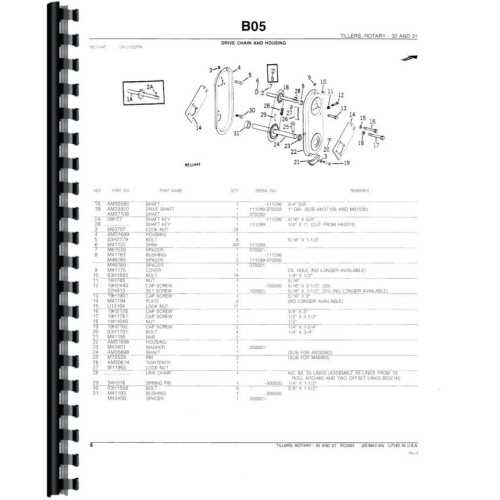

The transmission system links the motor to the blades, translating engine power into action. This system determines the speed and depth of ground penetration, impacting overall performance. Efficient gear mechanisms and proper lubrication are important for smooth operation.

Handles and controls allow the user to maneuver the machine with precision. These ergonomic features provide balance and ease of use, ensuring better control during operation, even in challenging terrain.

The frame serves as the structural backbone, providing stability and supporting all other

Understanding the Gear Mechanism

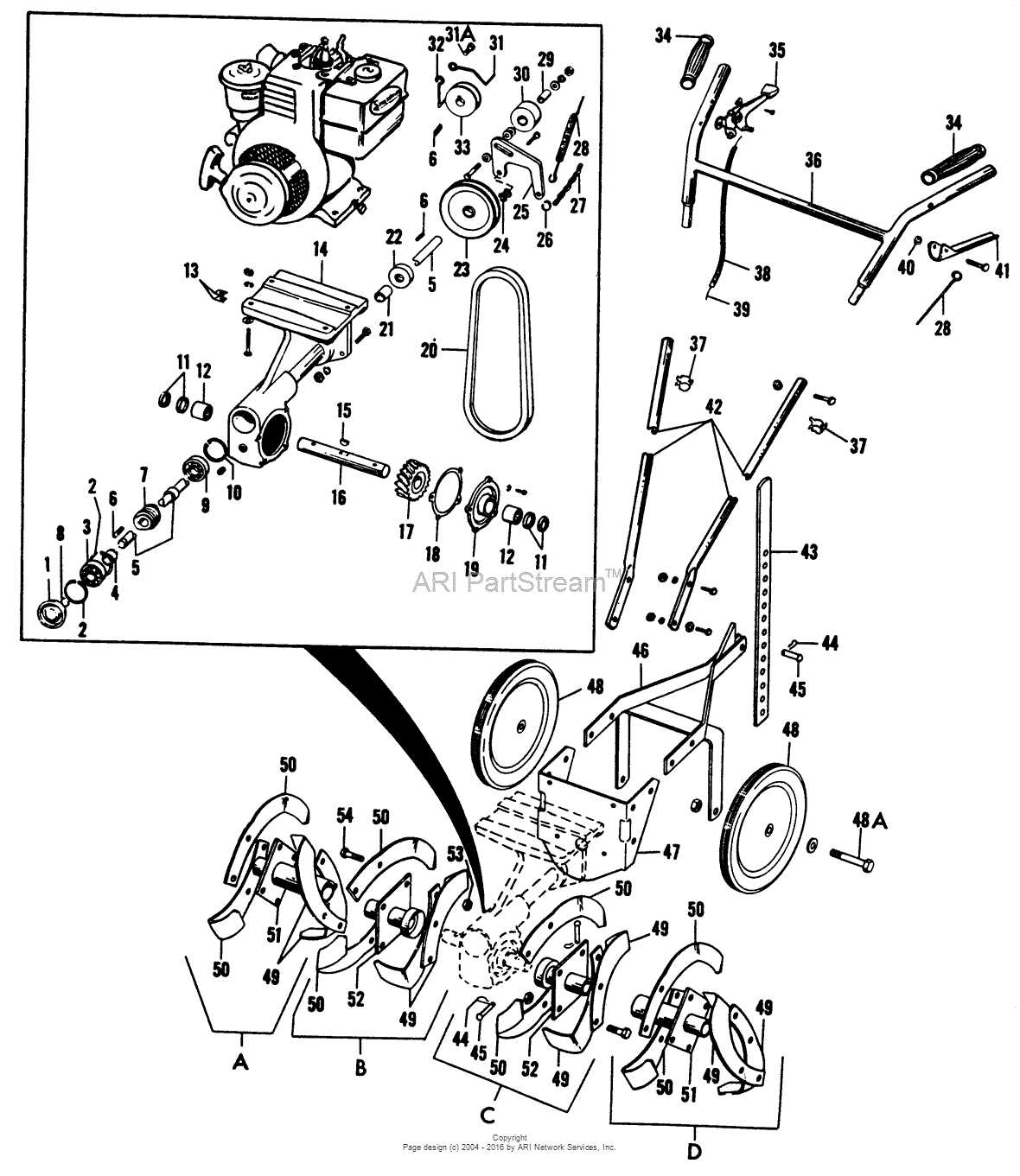

The gear mechanism plays a crucial role in converting motion and power, enabling the device to perform efficiently. Understanding its function is essential for maintaining smooth operation and addressing potential issues. This system relies on the precise interaction of various components, each contributing to the overall performance.

Key Components

At the core of this mechanism are several essential elements that work in unison. Gears transfer force by meshing together, creating the necessary movement to drive the machine forward or in reverse. Bearings ensure that these rotating parts operate smoothly, reducing friction and wear. The shaft serves as the primary connector, transmitting power from one component to another.

How it Works

When activated, the movement starts from the power source, typically an engine, which drives the shaft. The shaft, in turn, rotates the gears, which then engage with other moving parts. This synchronized action results in the desired motion, whether it’s forward propulsion or rotation in different directions. Proper lubrication and alignment are critical for minimizing resistance and ensuring longevity.

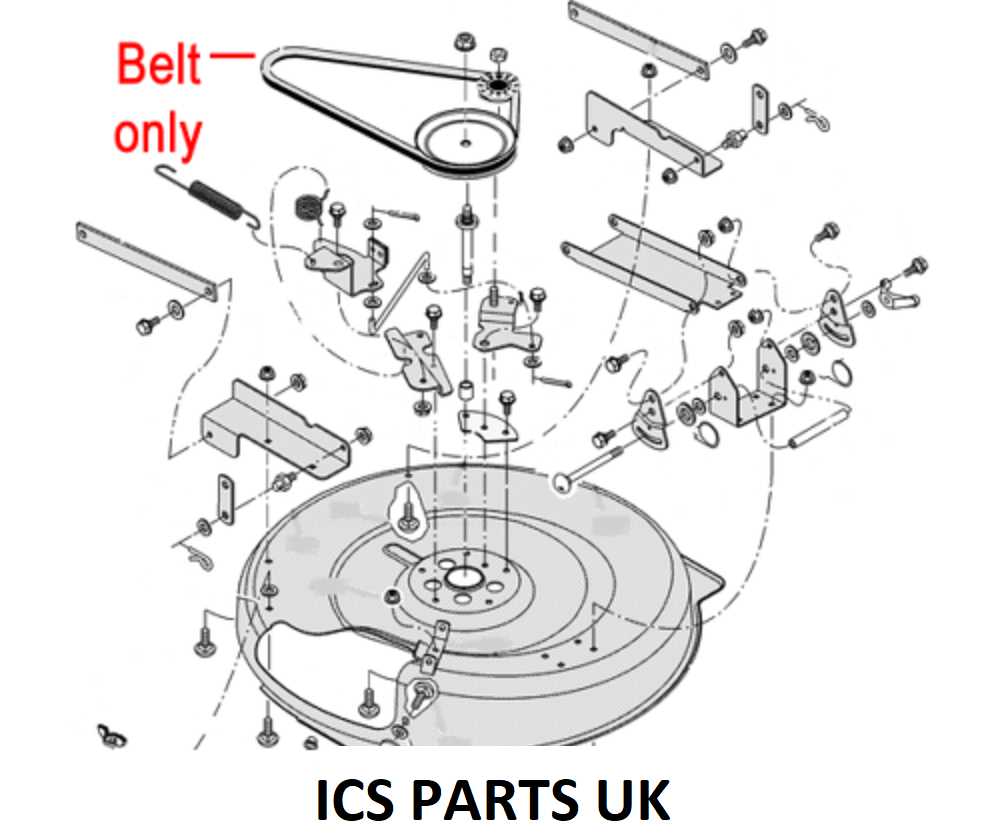

How to Identify Drive Belt Issues

The performance of your equipment can suffer due to wear or misalignment of the belt that connects essential components. Detecting problems early can prevent further damage and ensure optimal operation. Understanding how to spot signs of deterioration will help you maintain smooth functionality and avoid costly repairs.

Common Signs of Belt Problems

There are several warning signs that indicate the belt may be experiencing issues. These include noticeable squealing sounds, inconsistent performance, or visible cracks and fraying. Regular inspection of the belt condition is key to preventing these problems from escalating into more significant malfunctions.

Steps to Diagnose the Issue

| Issue | Cause | Solution |

|---|---|---|

| Slipping or poor performance | Loose or worn belt | Tighten or replace the belt |

| Squealing noise | Belt tension too high or low | Adjust the tension |

| Visible cracks or fraying | Excess

Exploring the Tiller Blade SystemThe mechanism responsible for ground engagement plays a crucial role in soil preparation and cultivation. This system comprises various components that work together to achieve effective tillage. Understanding its structure and function enhances the efficiency of land management tasks, allowing for optimal results in gardening and farming activities. Key Components of the Blade Mechanism

The assembly includes several vital elements, each contributing to the overall performance. Blades are typically made from durable materials to withstand the rigors of soil contact. The angle and design of these components can significantly impact how well they break up and aerate the ground. Additionally, attachments or extensions may be available to customize performance based on specific soil conditions or cultivation goals. Maintenance for Optimal PerformanceRegular upkeep is essential for sustaining the functionality of the blade assembly. Inspecting for wear and tear, tightening loose fittings, and ensuring sharp edges are critical steps in maintenance. Lubrication of moving parts further extends the lifespan and enhances operational efficiency. Keeping these components in excellent condition allows for smoother operation and better results in tillage tasks. Replacing the Control Handle PartsMaintaining the functionality of your gardening equipment often requires attention to various components, including the control handle. This section outlines the process of replacing the elements associated with the control handle, ensuring that your equipment operates smoothly and efficiently. Assessing the Condition Before starting the replacement, carefully examine the control handle for any signs of wear or damage. Look for cracks, bends, or loose connections that may affect performance. Identifying the specific issues will help determine the necessary replacements. Gathering Necessary Tools To facilitate the replacement process, collect the required tools, such as a screwdriver, pliers, and a wrench. Having these tools on hand will streamline the task and minimize downtime. Removing the Old Components Begin by disconnecting any cables or wires attached to the handle. Use a screwdriver to remove screws or bolts securing the components in place. Carefully take out the damaged parts, ensuring not to damage any surrounding areas. Installing New Components Once the old elements are removed, position the new ones in place. Align them properly and secure them with screws or bolts. Reconnect any cables or wires, ensuring they are firmly attached to maintain functionality. Final Checks After installation, conduct a thorough inspection to ensure everything is properly secured. Test the control handle’s movement to confirm that it operates smoothly. Regular maintenance checks will help prolong the lifespan of your equipment. Functionality of the Depth Adjuster

The depth adjuster plays a crucial role in optimizing the performance of gardening machinery, ensuring efficient soil cultivation. This component allows the user to modify the penetration depth of the working mechanism, which is vital for adapting to various soil conditions and achieving desired tillage results. Adjustment MechanismThe mechanism typically involves a lever or wheel that enables users to easily set the desired depth. By turning or moving this component, the user can raise or lower the working implements, providing flexibility for different tasks, such as aerating compacted soil or preparing seedbeds. The precision of this adjustment significantly impacts the overall effectiveness of the equipment. Impact on Soil HealthProperly managing the depth of operation not only improves the efficiency of the machine but also contributes positively to soil health. When the implement penetrates at the right level, it helps to break up compacted layers without disturbing beneficial microorganisms. This promotes better water infiltration and nutrient absorption, ultimately enhancing the growing conditions for crops. Maintaining the Engine and Its Parts

Proper upkeep of the motor and its components is crucial for optimal performance and longevity. Regular inspections and maintenance routines ensure that all elements function harmoniously, preventing potential breakdowns and costly repairs. Regular Checks: Consistent examination of essential components, such as the fuel system, ignition system, and air intake, is vital. Look for any signs of wear or damage, and replace worn parts promptly to maintain efficiency. Cleaning: Keeping the engine and its surroundings clean is essential. Remove any debris, dirt, or grass clippings that may obstruct airflow or cooling. A clean environment contributes to better performance and reduces overheating risks. Lubrication: Ensure that all moving parts are adequately lubricated to minimize friction and wear. Regularly check oil levels and replace the oil according to the manufacturer’s recommendations, as this will help maintain smooth operation. Fuel Quality: Using high-quality fuel can significantly impact the performance of the motor. Ensure that the fuel is fresh and free from impurities to avoid engine misfires and inefficient combustion. Seasonal Maintenance: Prepare the engine for seasonal changes by performing necessary maintenance tasks. This may include winterizing the motor or ensuring it’s ready for spring use. Address any issues promptly to avoid complications during peak operation times. Common Problems with the TransmissionThe mechanism responsible for transferring power in garden equipment can encounter various issues that affect performance and efficiency. Understanding these common challenges can help in diagnosing problems early and maintaining optimal functionality. Typical Symptoms of Transmission Issues

Common Causes of Transmission Failures

Choosing the Right Replacement PartsWhen it comes to maintaining and enhancing your gardening equipment, selecting appropriate components is crucial for ensuring optimal performance and longevity. Understanding the various options available can significantly impact the efficiency of your machinery and reduce the need for frequent repairs. Firstly, it is essential to consider the specifications of the equipment you are working with. Checking the manufacturer’s recommendations helps to identify compatible components that will seamlessly integrate with your machine. This step prevents issues related to fit and functionality. Additionally, opting for high-quality materials is vital. Components made from durable materials can withstand wear and tear, ensuring that your equipment operates smoothly over time. Investing in quality often results in better performance and reliability. Furthermore, consulting with experts or seeking advice from experienced users can provide valuable insights. They can offer recommendations on trusted brands and reliable suppliers, helping you make informed decisions. Finally, keeping a well-organized inventory of necessary components can streamline maintenance efforts. This practice ensures that you have access to essential items when needed, minimizing downtime and maximizing productivity in your gardening tasks. |