In the realm of outdoor machinery, the efficient functioning of a wood processing device is crucial for those who appreciate woodworking or landscaping. A well-structured system not only enhances performance but also extends the lifespan of the equipment. This article aims to provide insights into the components and their roles within these essential tools.

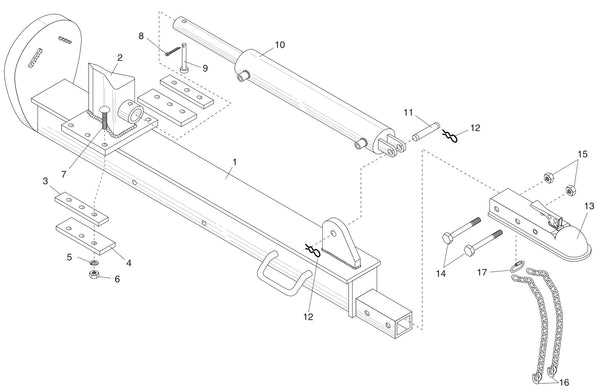

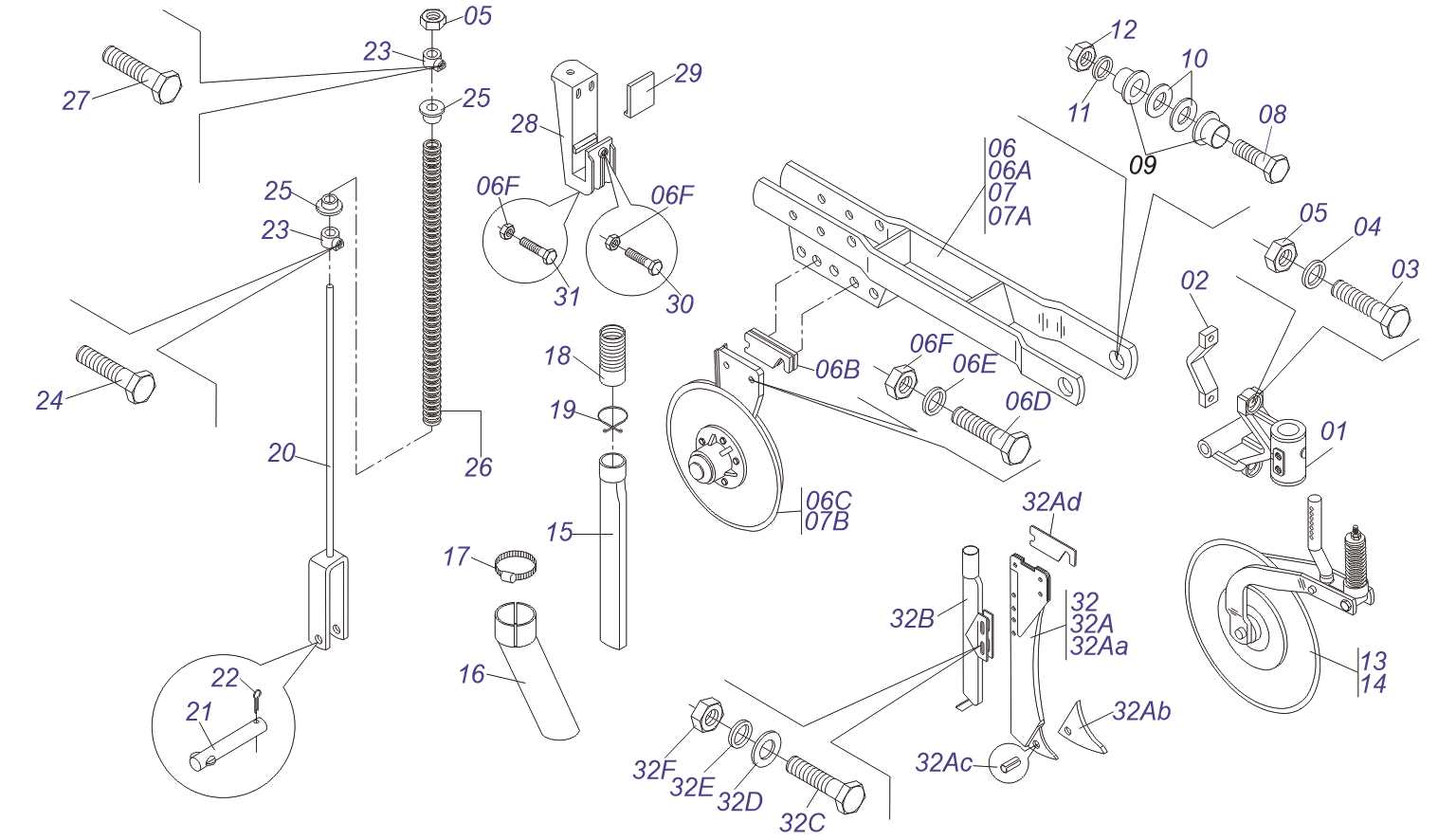

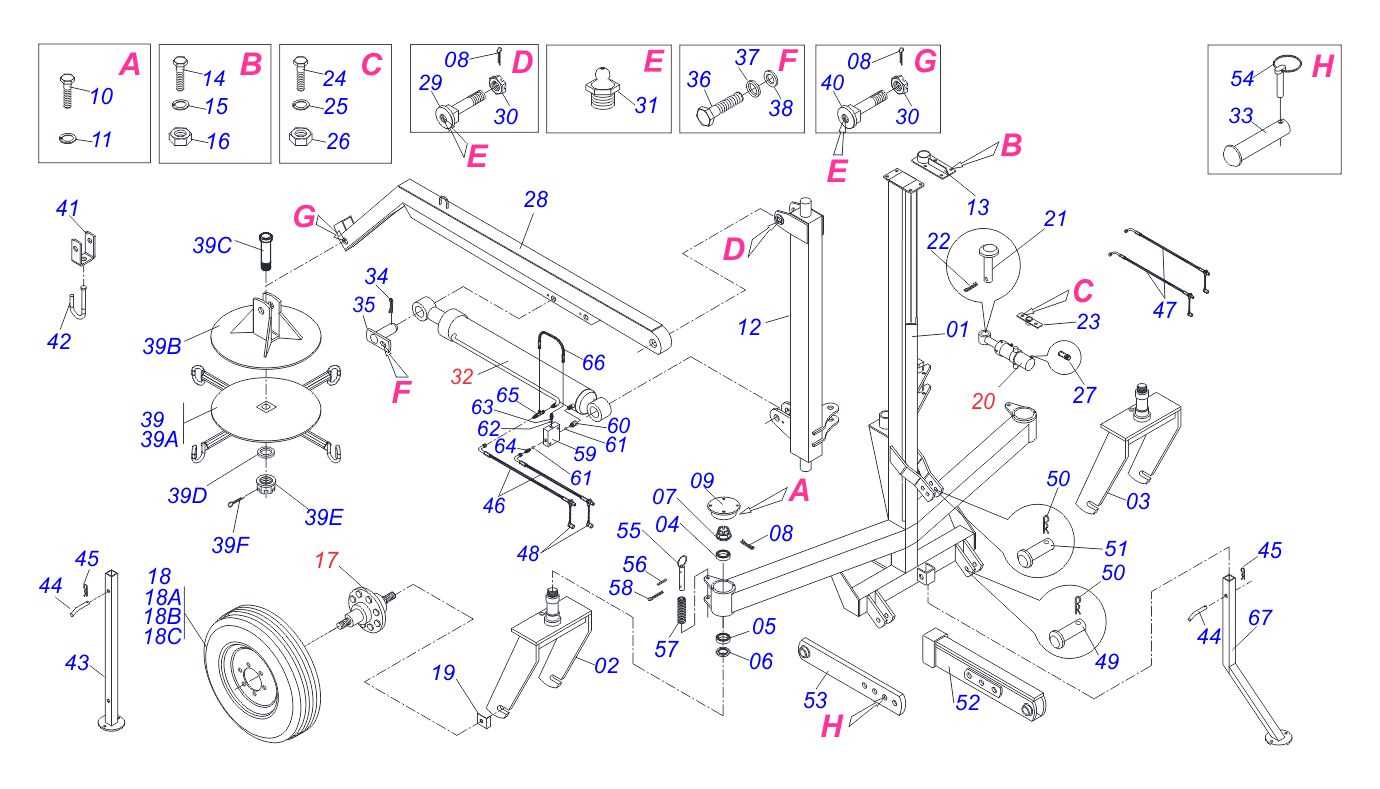

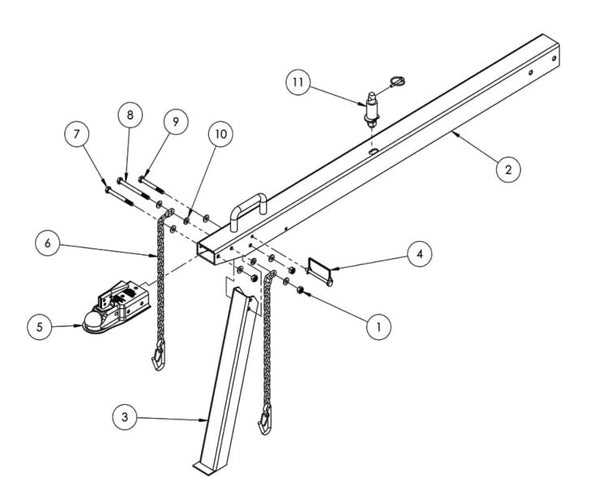

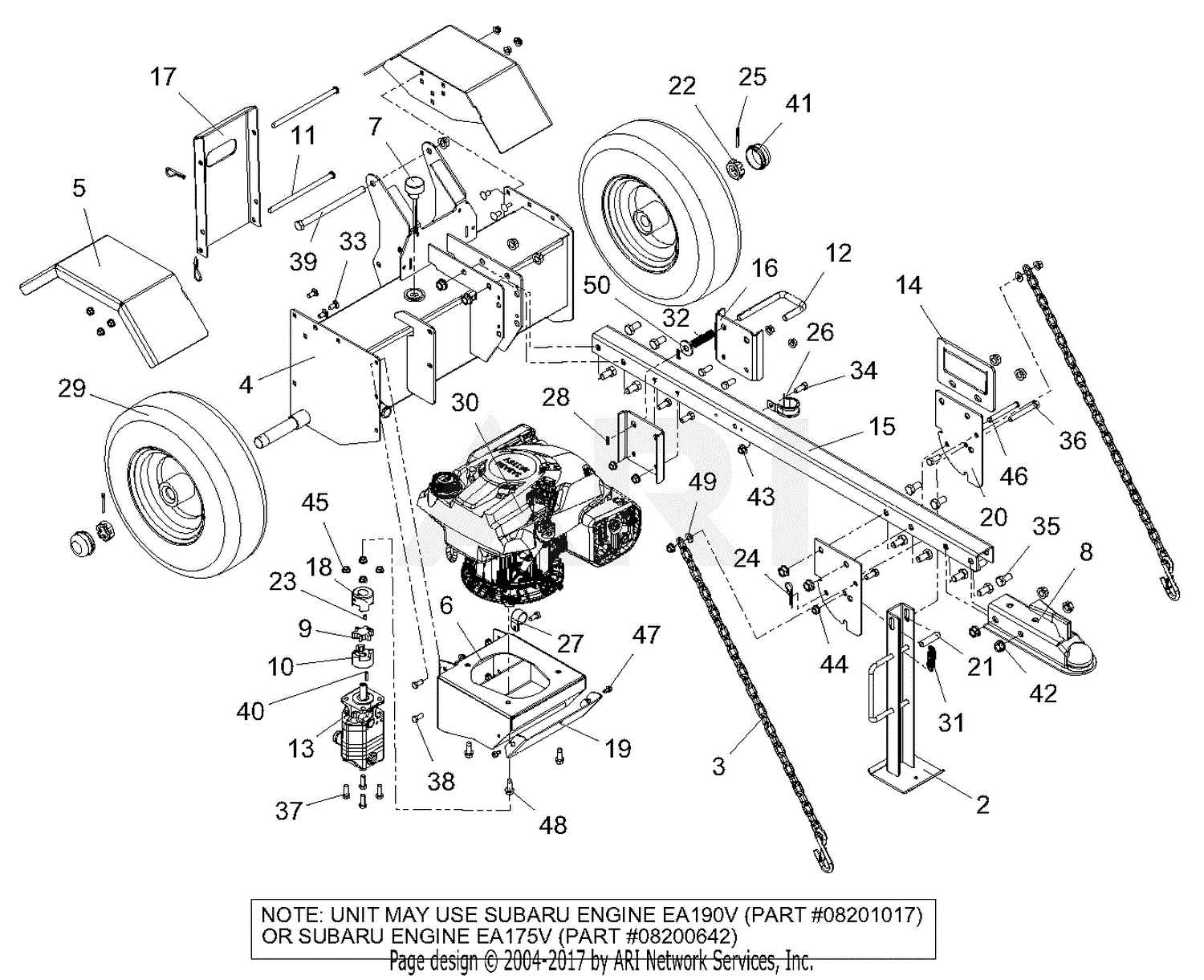

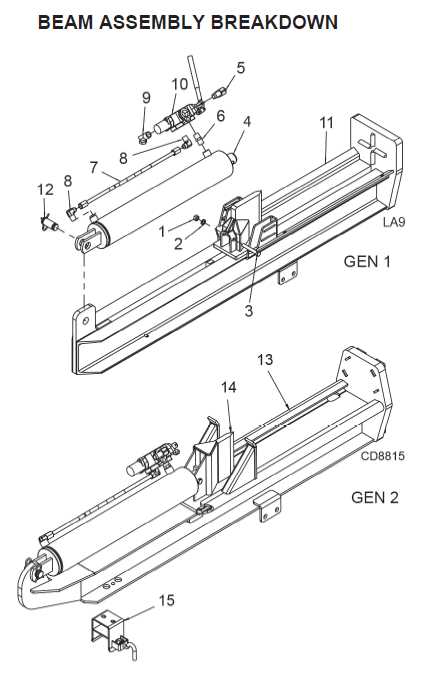

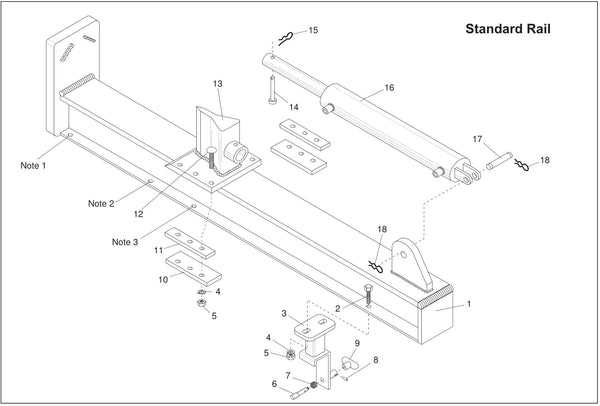

Visual aids can significantly enhance understanding, particularly when it comes to complex assemblies. By exploring the layout and relationships between various elements, users can gain a clearer perspective on how to maintain and optimize their machines. The intricacies of the components become evident as we delve deeper into their functions.

With the right knowledge at hand, operators can ensure their machines are in top condition, ready to tackle any task. This guide serves as a resource for anyone looking to maximize the effectiveness of their wood processing equipment and tackle any challenges that may arise.

Understanding Huskee Log Splitter Components

To effectively operate a wood processing machine, one must familiarize themselves with its various elements. Each component plays a crucial role in ensuring optimal performance and longevity of the device. A comprehensive understanding of these parts aids in maintenance, troubleshooting, and overall efficiency.

Key components typically include:

- Engine: The power source that drives the entire system.

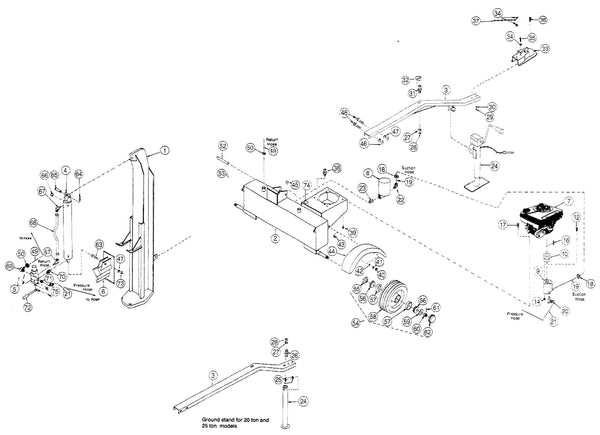

- Hydraulic System: Facilitates the movement and splitting mechanism through fluid pressure.

- Frame: The structural backbone that supports all other components.

- Wedge: The sharpened tool that penetrates the wood for splitting.

- Controls: The interface through which the operator manages the machine’s functions.

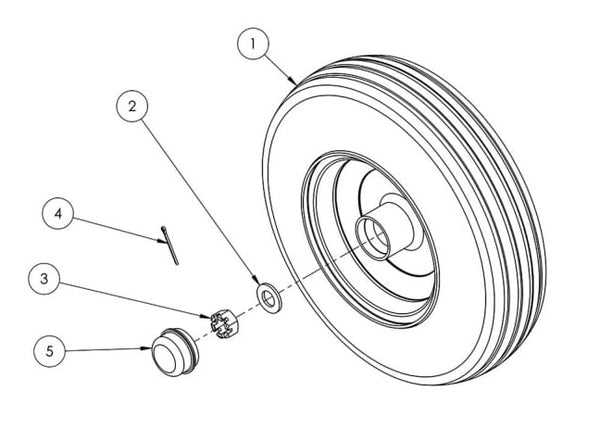

- Wheels: Provide mobility for easy transport of the equipment.

Regular inspection and understanding of each part can prevent potential issues and enhance the overall effectiveness of the machine. By recognizing how each component interacts, users can ensure smooth operation and reduce downtime.

Essential Parts of the Huskee 22 Ton

Understanding the key components of this powerful machine is crucial for effective operation and maintenance. Each element plays a vital role in ensuring optimal performance, making it essential to familiarize oneself with their functions and interrelations.

- Engine: The powerhouse that drives the entire system, providing the necessary force for operation.

- Hydraulic System: This includes the pump and cylinder, crucial for generating and controlling the pressure needed for efficient cutting.

- Frame: The robust structure that supports all other components, ensuring stability and durability during use.

- Wheels: Designed for easy maneuverability, allowing for transport across various terrains.

- Control Lever: This user interface allows the operator to manage the machine’s actions with precision and ease.

- Cutting Wedge: The sharp component that splits the material effectively, ensuring clean and efficient cuts.

- Safety Features: Includes guards and automatic shut-off mechanisms to protect the user during operation.

Familiarizing oneself with these components will not only enhance the user experience but also aid in troubleshooting and maintenance, ensuring longevity and efficiency of the equipment.

Common Issues with Log Splitter Parts

Understanding the typical challenges that arise with equipment components is essential for maintaining efficiency and longevity. Many users encounter specific problems that can hinder performance, leading to frustrating downtime. Identifying these issues early can save both time and resources, ensuring that your machinery operates smoothly.

Hydraulic System Failures

One of the most prevalent complications involves the hydraulic system. Leaks can occur in hoses or fittings, leading to diminished power and functionality. Regular inspections and timely replacements can mitigate these issues and enhance overall efficiency.

Worn-Out Cutting Blades

Another common concern is the degradation of cutting edges. Over time, blades may become dull or chipped, affecting their ability to perform effectively. Periodic sharpening or replacement is vital to maintain optimal cutting performance and reduce strain on the entire system.

Maintenance Tips for Huskee Equipment

Proper upkeep of your machinery is essential to ensure longevity and optimal performance. Regular maintenance not only enhances efficiency but also prevents unexpected breakdowns and costly repairs.

Routine Checks

- Inspect all components for wear and tear.

- Clean the equipment after each use to remove debris.

- Check fluid levels regularly and top up as necessary.

Storage Recommendations

- Store in a dry, sheltered area to prevent rust.

- Use protective covers when not in use.

- Ensure that all moving parts are lubricated before storage.

How to Identify Replacement Parts

Finding the right components for your equipment can greatly enhance its performance and longevity. This process involves recognizing specific features and dimensions to ensure compatibility with your machine. Here’s a guide to help you navigate through this task effectively.

Step-by-Step Identification

Begin by examining the existing components closely. Look for any brand markings, model numbers, or unique identifiers that can provide clues. Measuring dimensions such as length, width, and thickness can also assist in matching the right elements.

Utilizing Resources

Consulting manuals or online databases is invaluable. These resources often include detailed information on various components and their specifications, making it easier to locate exact replacements.

| Identifier Type | Details |

|---|---|

| Model Number | Usually found on the device; essential for accurate matching. |

| Dimensions | Measure length, width, and thickness for a proper fit. |

| Visual Inspection | Look for wear, cracks, or unique features that can guide you. |

Repairing the Huskee 22 Ton Splitter

Maintaining and fixing your outdoor equipment can significantly enhance its lifespan and performance. Proper understanding of its components and functionality is essential for effective repairs. This guide provides insight into common issues, troubleshooting methods, and maintenance tips to ensure your machine operates smoothly.

Common Issues and Troubleshooting

One of the frequent challenges faced is the inability to start the engine. This could stem from a drained battery or fuel line blockage. Inspecting the fuel system for leaks and ensuring the spark plug is clean can often resolve the issue. If you notice unusual noises during operation, it may indicate wear on moving parts. Regularly checking these components can prevent more serious damage.

Maintenance Tips

Routine upkeep is vital for longevity. Regularly changing the oil and checking hydraulic fluid levels can prevent breakdowns. Additionally, cleaning the exterior and ensuring all bolts and screws are tight can improve safety and efficiency. Keeping a maintenance log helps track what has been done and when further actions may be needed.

Upgrading Your Log Splitter Performance

Enhancing the efficiency and capability of your wood processing equipment can significantly improve your overall experience. By focusing on specific upgrades, you can maximize output, reduce effort, and ensure smoother operation. This section delves into various strategies to elevate the functionality of your machine.

Improving Power and Speed

One of the primary factors affecting performance is the power source. Upgrading to a more robust engine can deliver greater force, enabling you to tackle tougher materials with ease. Additionally, fine-tuning the hydraulic system can enhance cycle speed, allowing for quicker processing times. Regular maintenance of these components is crucial to sustain their efficiency over time.

Enhancing Mobility and Stability

Upgrading wheels and frames can significantly impact maneuverability. Larger, more durable wheels facilitate movement across rough terrain, while a sturdier frame enhances stability during operation. Furthermore, adding features like adjustable legs can help maintain a level working surface, improving safety and efficiency. Investing in quality upgrades will ultimately lead to a more reliable and effective wood processing experience.

Where to Purchase Replacement Parts

Finding the right components for your machinery can greatly enhance its performance and longevity. Whether you’re in need of new items due to wear and tear or simply looking to upgrade, it’s essential to know where to source these essentials efficiently.

Here are several options to consider when searching for quality replacements:

- Online Retailers: Numerous websites specialize in selling a wide variety of components. Major platforms often provide detailed descriptions and customer reviews.

- Local Hardware Stores: Visiting a nearby store can allow you to see the products in person. Staff members can often offer valuable advice based on your specific needs.

- Manufacturer Websites: Directly purchasing from the official site can ensure you receive authentic items that are specifically designed for your machinery.

- Specialty Suppliers: Look for businesses that focus on equipment and machinery. These suppliers typically have extensive inventories and knowledgeable staff.

Before making a purchase, consider checking for warranty options and return policies to safeguard your investment. Comparing prices and reading reviews can also help you make an informed decision.

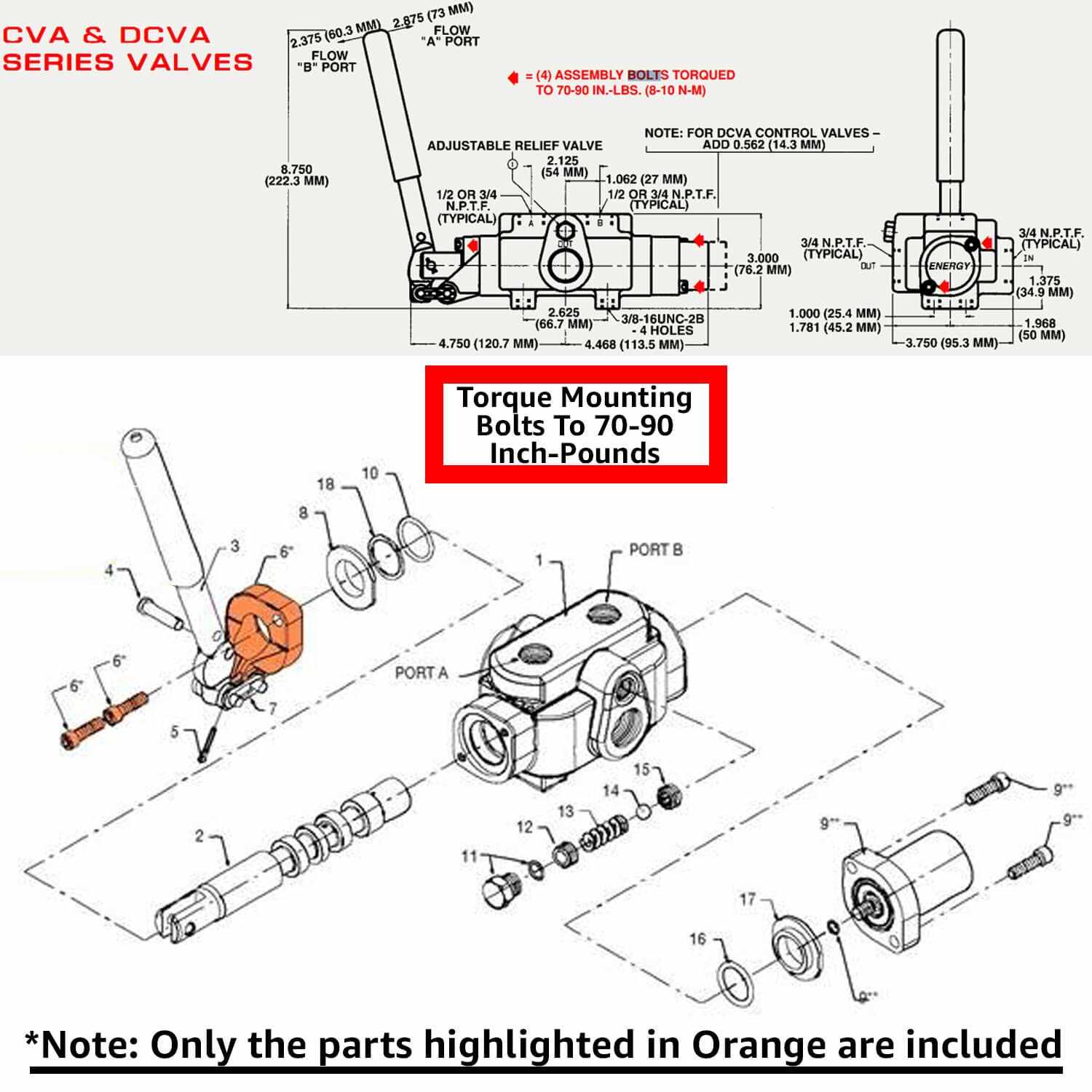

Visual Guide to Huskee Parts Diagram

This section provides an insightful overview of essential components for a specific machine, highlighting their functions and interconnections. Understanding these elements is crucial for maintenance and troubleshooting, ensuring optimal performance.

| Component | Description |

|---|---|

| Motor | The driving force behind the operation, powering the entire mechanism. |

| Hydraulic Pump | Responsible for generating the hydraulic pressure necessary for operation. |

| Control Valve | Regulates the flow and direction of hydraulic fluid throughout the system. |

| Frame | The structural base that supports all other components and ensures stability. |

| Wheels | Facilitates mobility, allowing for easy transport to various locations. |