The intricate design of a renowned cutting tool is a marvel of engineering, combining precision and functionality to deliver exceptional performance. For enthusiasts and professionals alike, comprehending the various elements that contribute to its operation is crucial. Each component plays a vital role in ensuring efficiency and longevity, making knowledge of these parts essential for maintenance and repair.

In this guide, we will explore the essential elements that comprise this classic machinery, highlighting their significance and interrelationships. Understanding how these pieces fit together not only enhances your ability to troubleshoot issues but also empowers you to perform routine upkeep with confidence.

Whether you’re a seasoned user or a newcomer eager to learn, familiarizing yourself with the anatomy of this powerful device will undoubtedly enhance your experience. Dive into the details and discover how each segment contributes to the overall functionality, ensuring optimal performance in any cutting task.

Understanding the Husqvarna 61 Chainsaw

The model in question is a well-regarded tool within the realm of forestry and landscaping, known for its reliability and performance. Designed to tackle various cutting tasks, this machine is favored by both professionals and enthusiasts. Its balance of power and ease of use makes it an ideal choice for diverse applications, from light trimming to heavy-duty felling.

Key Features

This chainsaw is equipped with a robust engine that delivers impressive torque and speed, enabling efficient cutting. Its lightweight design enhances maneuverability, allowing users to work for extended periods without excessive fatigue. Additionally, the ergonomic handle contributes to user comfort and control during operation.

Maintenance and Care

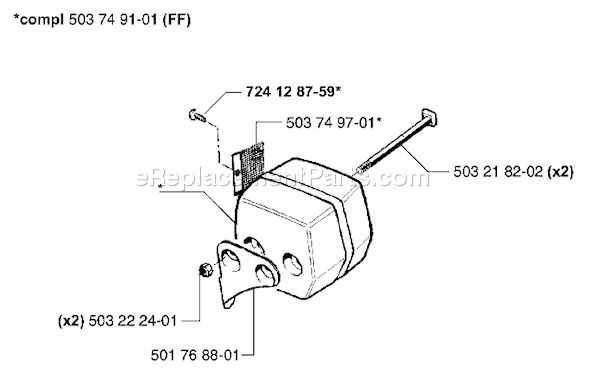

Regular maintenance is crucial for ensuring optimal performance. Keeping the chain sharp and the bar well-lubricated will significantly extend the lifespan of the equipment. Furthermore, routine checks of the air filter and spark plug are essential for maintaining engine efficiency. Proper care not only enhances functionality but also promotes safety during use.

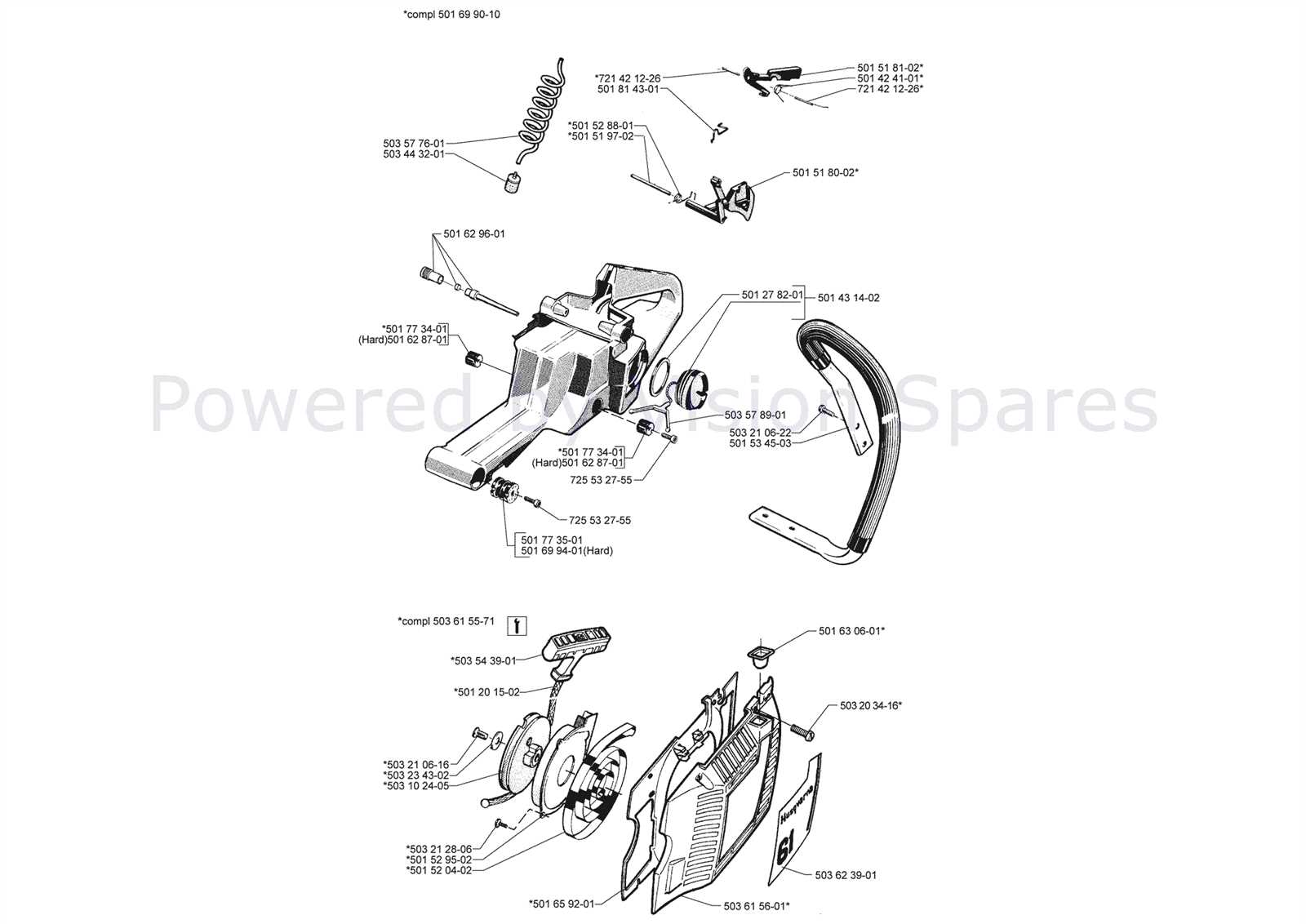

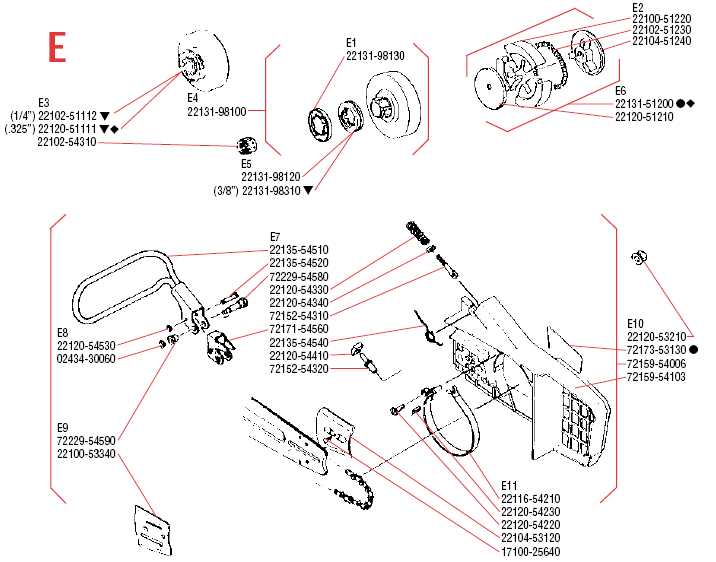

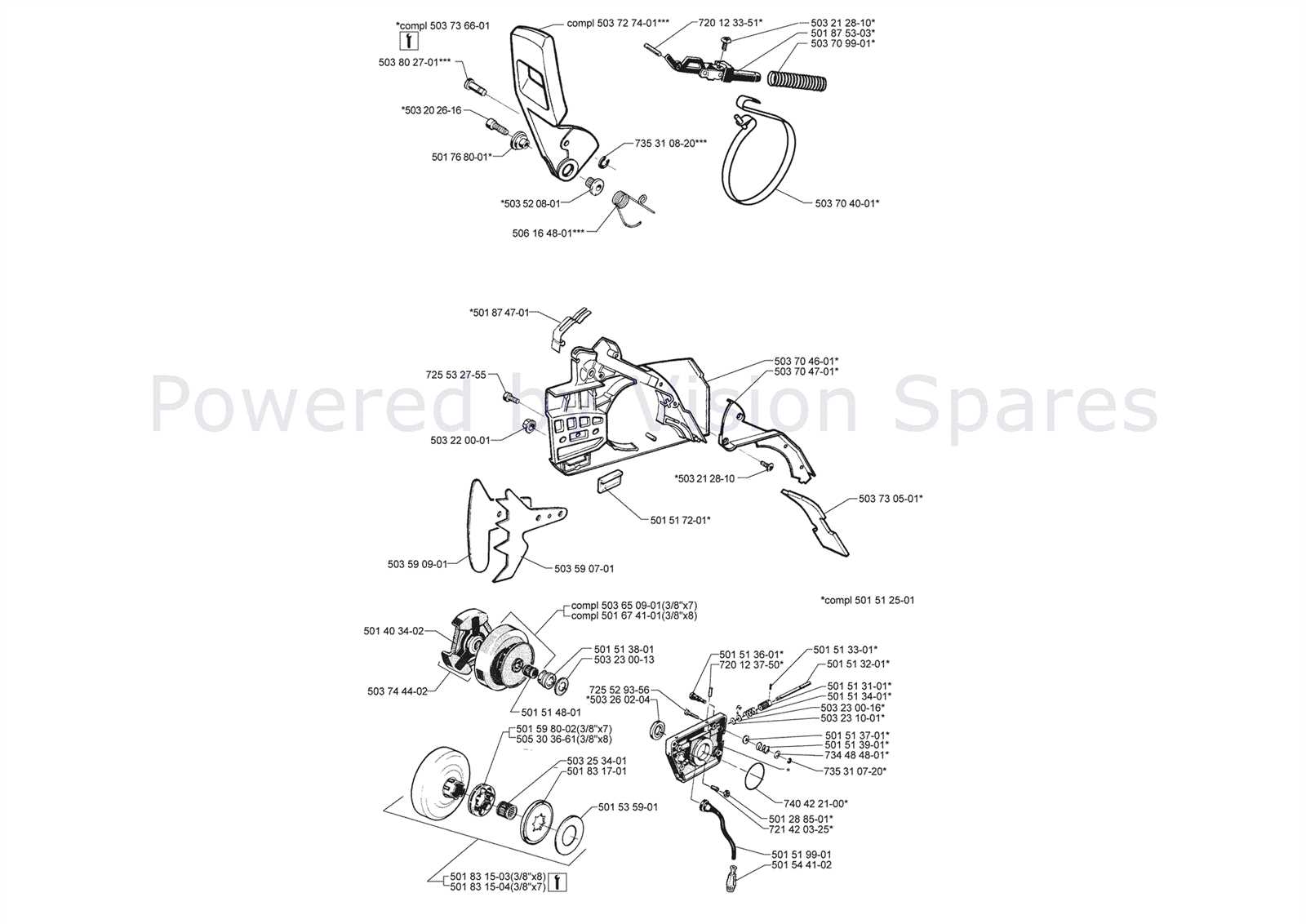

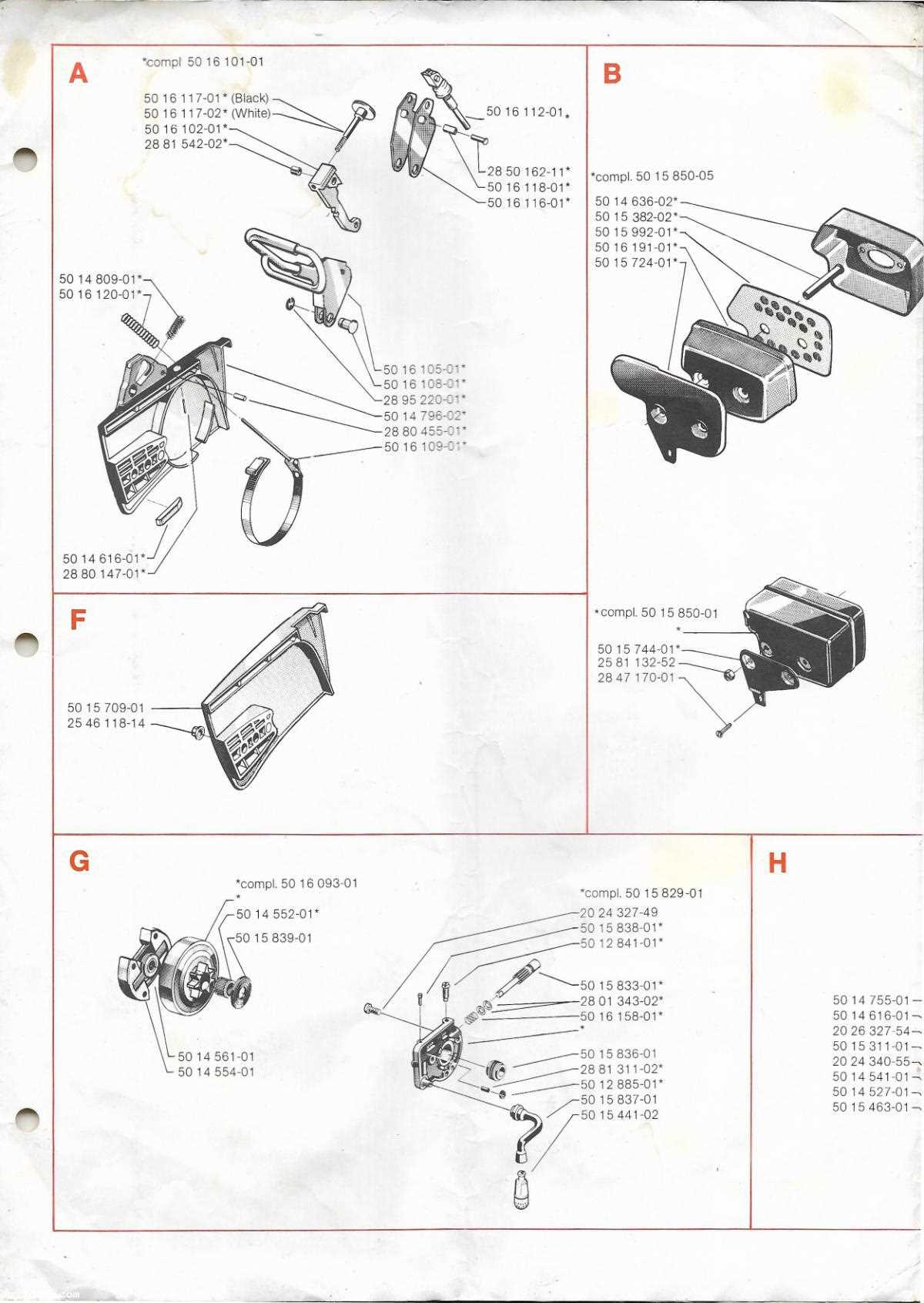

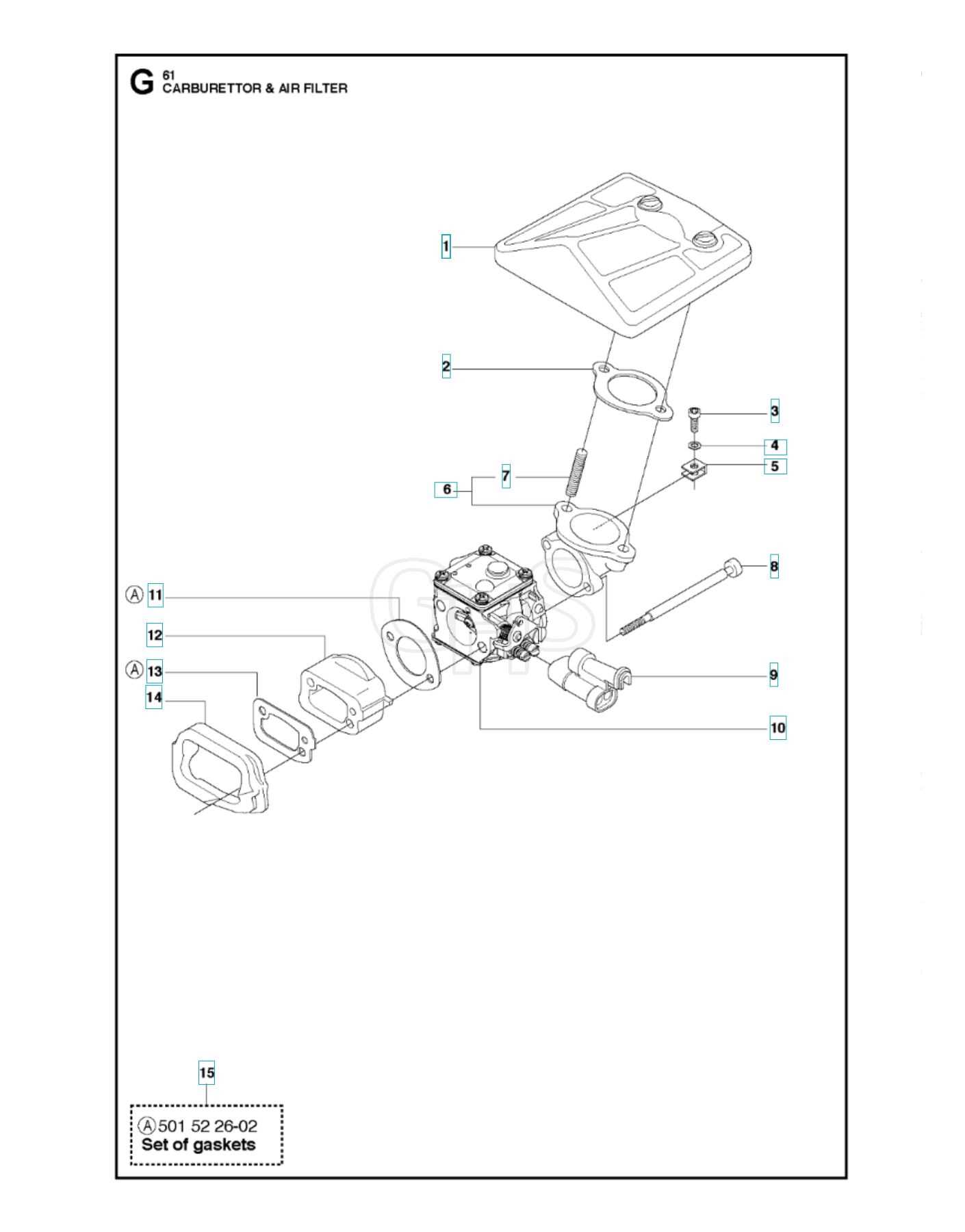

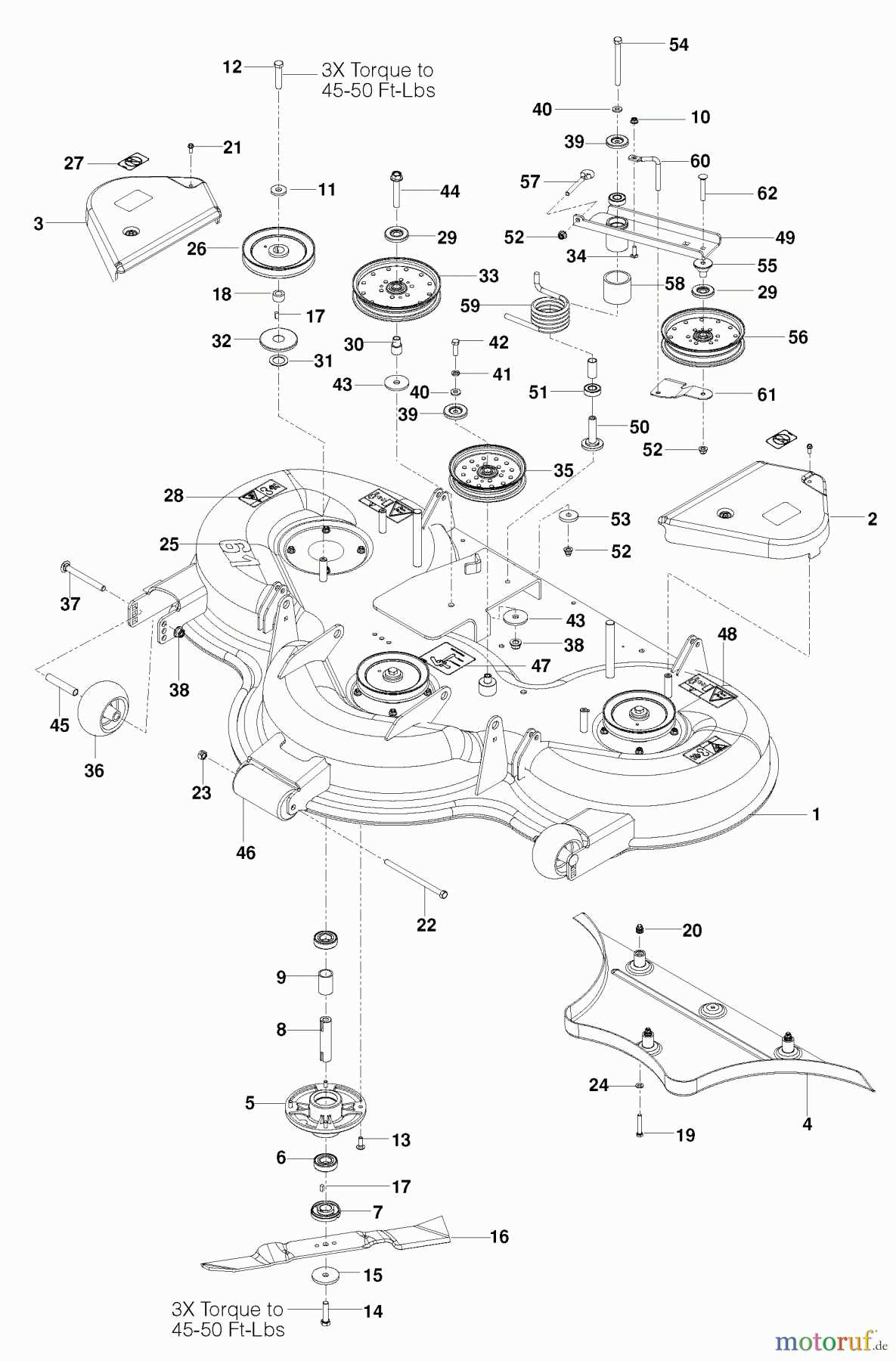

Essential Components of the Husqvarna 61

The effectiveness and reliability of any outdoor equipment hinge on its core elements. Each individual component plays a vital role in ensuring optimal performance and durability, making it essential to understand their functions and interrelationships. A well-maintained assembly not only enhances efficiency but also prolongs the life of the machine.

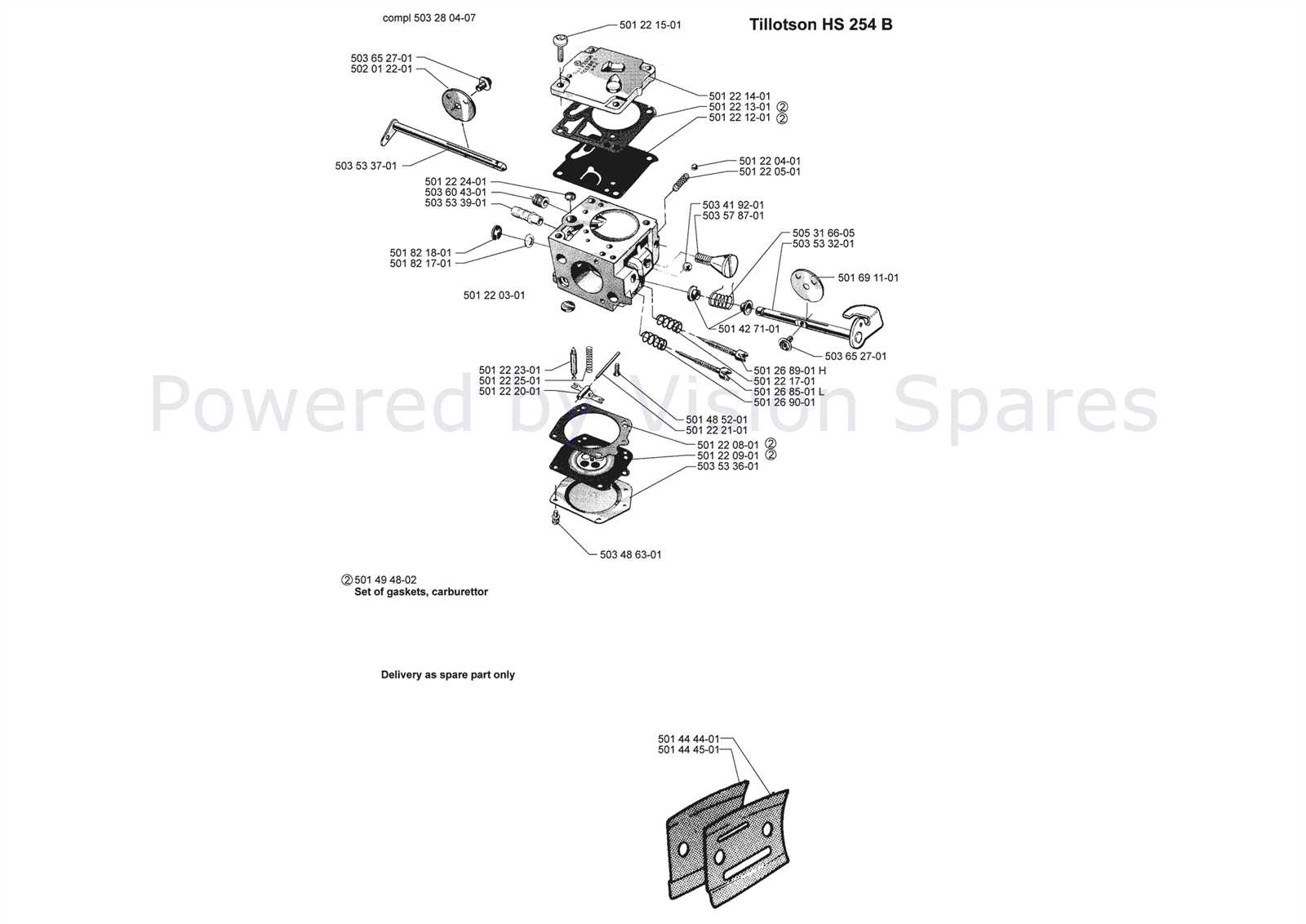

Among the crucial elements are the power unit, which drives the entire system, and the cutting mechanism that ensures precise operation. Fuel delivery components are equally important, as they regulate the flow of energy required for peak functionality. Additionally, the ignition system is pivotal for reliable starting and operation, while the housing protects internal mechanisms from external damage.

Understanding these integral parts allows for informed maintenance and troubleshooting, ensuring that the equipment remains in peak condition for any task at hand. Regular inspections and timely replacements of worn components can prevent significant issues, enhancing overall performance and safety.

How to Access the Parts Diagram

Understanding the assembly of your equipment is crucial for effective maintenance and repairs. To navigate through the visual representations of its components, follow these straightforward steps to obtain detailed illustrations that will aid in your tasks.

Utilizing Online Resources

Many manufacturers provide comprehensive online resources. Visit the official website, where you can find manuals and interactive guides. Enter the model number in the search bar to quickly locate the relevant materials.

Consulting Retailers and Repair Shops

Local dealers and repair specialists often have access to detailed breakdowns of the machinery. Engaging with them can provide not only the visual aids but also expert insights that enhance your understanding of the equipment.

Common Issues with Husqvarna 61 Parts

When it comes to maintenance and performance of outdoor power equipment, certain challenges often arise. Understanding these common problems can aid in ensuring longevity and efficiency of the machine.

Frequent Malfunctions

Some users experience recurring malfunctions that can hinder functionality. These issues often stem from wear and tear or improper usage.

| Issue | Description |

|---|---|

| Fuel System Blockage | Clogs can prevent proper fuel flow, affecting engine performance. |

| Starting Difficulties | Problems with ignition components can make starting challenging. |

| Chain Tension Problems | Incorrect tension can lead to inefficient cutting and safety hazards. |

Preventative Measures

Regular inspections and timely replacements of worn components are essential. Staying proactive can help mitigate these common challenges.

Finding Replacement Parts Easily

Locating suitable components for your equipment can be a straightforward process with the right approach. Whether you’re dealing with a malfunction or simply performing routine maintenance, understanding how to source the necessary items efficiently is essential for keeping your machinery in optimal condition.

Start by identifying the specific components you need. Make a detailed list, including model numbers and any other relevant information. This will streamline your search and ensure you find the exact items required for repair or upkeep.

Utilize online resources and communities dedicated to equipment enthusiasts. Many websites offer comprehensive catalogs, where you can search by model or part type. Additionally, user forums and social media groups can be invaluable for recommendations on where to find reliable suppliers.

Consider contacting authorized dealers or service centers. These professionals often have access to original items and can provide guidance on compatibility with your specific model. They can also offer insights into any upgrades or alternatives that may enhance performance.

Local hardware stores and specialty shops may carry a selection of common components as well. Building a relationship with these retailers can help you get quicker access to what you need and advice on installation or maintenance tips.

By combining these strategies, you can simplify the process of obtaining the necessary components, ensuring that your equipment remains functional and efficient.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring that your equipment functions smoothly and efficiently. By following specific care practices, you can enhance longevity and maintain peak performance, allowing for a more productive experience.

Regular Cleaning

- Remove debris after each use to prevent buildup.

- Use appropriate cleaners to avoid damaging components.

- Inspect filters regularly and clean or replace as needed.

Routine Checks

- Examine the lubrication levels frequently.

- Check for any signs of wear on essential components.

- Ensure all screws and fasteners are secure.

Comparing Husqvarna 61 to Other Models

When evaluating a specific chainsaw model, it is essential to understand how it stacks up against its competitors. By analyzing various aspects such as performance, weight, and durability, users can make informed decisions based on their specific needs and preferences. This comparison aims to highlight the key differences and similarities with other popular models in the market.

Performance and Efficiency

In terms of performance, different chainsaw models vary widely in power output and cutting efficiency. The focus here is on engine capacity and cutting speed, which play crucial roles in determining how effectively the equipment can handle various tasks.

| Model | Engine Power (cc) | Bar Length (inches) | Weight (lbs) |

|---|---|---|---|

| Model A | 50 | 16 | 10 |

| Model B | 60 | 18 | 12 |

| Model C | 55 | 20 | 11 |

| Model D | 61 | 18 | 11 |

Durability and Build Quality

Another critical factor is the construction quality of the chainsaw, which affects its longevity and resistance to wear and tear. Different models incorporate varying materials and designs that contribute to their overall robustness and usability in challenging environments.

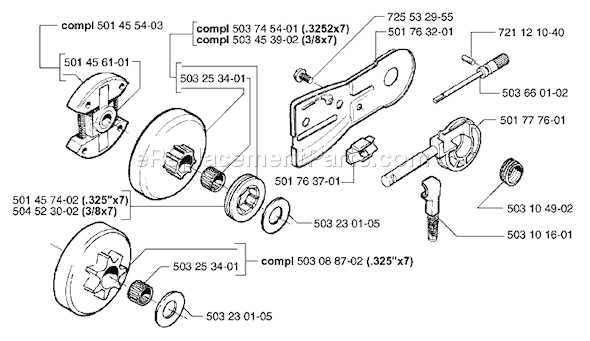

Upgrades and Accessories for the Chainsaw

Enhancing the functionality and performance of your cutting tool can greatly improve your overall experience and efficiency. Upgrades and additional components not only boost performance but also increase safety and convenience during operation.

Here are some popular upgrades and accessories to consider:

- Chain Upgrades: Opt for a higher-quality chain that offers better cutting efficiency and durability.

- Bar Length Variations: Choosing a different bar length can help you tackle various cutting tasks more effectively.

- Performance Filters: Installing advanced air and fuel filters can enhance engine performance and longevity.

- Anti-Vibration Handles: Upgrading to ergonomic handles reduces fatigue during prolonged use.

In addition to performance enhancements, accessories can improve safety and convenience:

- Protective Gear: Always use chainsaw chaps, gloves, and helmets to ensure your safety while operating.

- Carrying Cases: A sturdy case protects your tool during transport and storage.

- Maintenance Kits: Regular maintenance is crucial; consider kits that include essential tools and supplies.

- Fuel Mixers: A precise fuel mixer ensures optimal performance and reduces engine wear.

Investing in these enhancements and accessories not only maximizes the potential of your cutting tool but also ensures a safer and more enjoyable cutting experience.

User Experiences and Testimonials

This section delves into the insights and feedback from individuals who have interacted with their equipment, sharing valuable perspectives on performance, reliability, and overall satisfaction. Real-world accounts help potential users make informed decisions based on firsthand experiences.

Many users highlight the following aspects:

- Ease of maintenance and availability of accessories

- Durability and longevity under various conditions

- User-friendly design that enhances operational efficiency

Here are some testimonials that encapsulate diverse user experiences:

- “I’ve been using my equipment for years, and it has never let me down. The performance remains top-notch!”

- “Finding replacement components was a breeze, which kept my machine running smoothly without any long downtimes.”

- “I appreciate how lightweight and manageable it is, making my tasks much less strenuous.”

Overall, these experiences underscore the importance of reliable tools in achieving successful outcomes, with users feeling confident in their choices and the performance of their machines.