Maintaining the efficiency of a lawn mowing machine is essential for optimal performance and longevity. A comprehensive overview of its individual elements can provide valuable insights into how to keep your equipment running smoothly. This section delves into the intricacies of each component, shedding light on their functions and interrelations.

Identifying the various sections of your machine is crucial for troubleshooting and maintenance. Familiarity with the assembly allows users to tackle repairs with confidence and ensures that every part is functioning as intended. This exploration will assist in recognizing common issues and addressing them effectively.

For both seasoned users and newcomers, understanding these mechanical details can significantly enhance the overall experience of lawn care. A well-informed approach to machinery not only saves time but also minimizes the risk of unexpected breakdowns, ensuring that your outdoor tasks are accomplished efficiently.

Understanding Husqvarna YTH24K48 Overview

The model in question is a remarkable piece of outdoor equipment designed for efficiency and durability. It is engineered to meet the needs of homeowners seeking a reliable solution for lawn care. This machine combines power with advanced technology, making it suitable for various tasks in maintaining a pristine yard.

Features of this model include a robust engine, a user-friendly control panel, and a cutting system that ensures even results. The design emphasizes comfort, with adjustable seating and intuitive steering that make operation effortless. Additionally, its compact structure allows for easy maneuverability around obstacles in the garden.

Maintenance is simplified through accessible components, enabling users to perform routine checks and repairs without professional assistance. This enhances longevity and performance, ensuring the machine remains a valuable asset over time. Understanding these aspects helps users maximize the potential of their equipment while ensuring optimal care and performance.

Key Components of the Mower

Understanding the essential elements of a lawn care machine is crucial for effective maintenance and operation. Each part plays a specific role, contributing to the overall performance and efficiency of the equipment.

Core Elements

- Engine: The power source, crucial for driving the mower.

- Deck: The housing that contains the cutting blades, influencing the cutting width.

- Blades: Sharp tools responsible for trimming grass, essential for a clean cut.

- Wheels: Facilitate movement across various terrains, affecting maneuverability.

Additional Features

- Transmission: Transfers power from the engine to the wheels, impacting speed.

- Fuel System: Stores and supplies fuel, crucial for engine operation.

- Control Panel: Interface for managing settings and operations, enhancing user experience.

- Grass Catcher: Collects clippings, promoting a tidy lawn and reducing cleanup time.

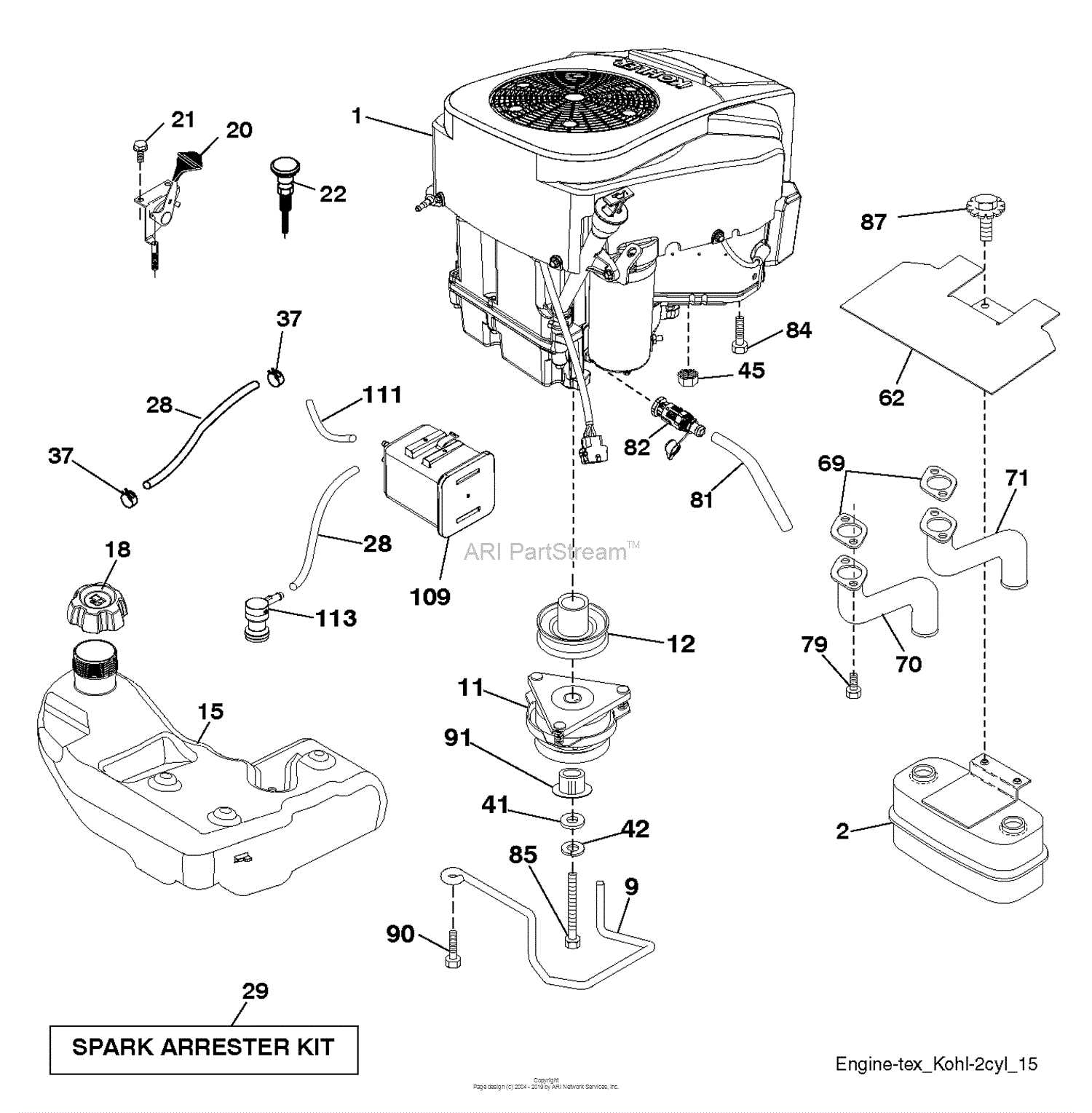

Importance of a Parts Diagram

Understanding the components of any machinery is crucial for effective maintenance and repairs. A visual representation that details each element and its relationship to others serves as an invaluable tool for both professionals and enthusiasts. This not only streamlines the identification of specific sections but also enhances overall comprehension of how the entire system operates.

Utilizing such visual aids can significantly reduce the likelihood of errors during disassembly or reassembly. When users can clearly see where each piece fits, they are less likely to misplace items or overlook critical parts. This clarity fosters a more efficient workflow and minimizes downtime, making it easier to keep equipment in optimal condition.

Moreover, having access to this kind of illustration can simplify troubleshooting processes. When problems arise, knowing the exact configuration and function of each part allows for quicker diagnosis and resolution. It empowers individuals to approach issues methodically, leading to more effective solutions and enhancing the longevity of the equipment.

In summary, a comprehensive visual guide is not just a luxury; it is a necessity for anyone involved in the upkeep or repair of machinery. It serves to educate, simplify, and improve the overall experience of managing complex systems.

Common Repairs and Maintenance Tasks

Regular upkeep and timely repairs are essential for ensuring the longevity and efficient performance of outdoor power equipment. Understanding basic maintenance procedures can help you avoid costly repairs and extend the life of your machinery. This section highlights some of the most common tasks that can be performed to keep your equipment running smoothly.

1. Blade Sharpening and Replacement: Maintaining sharp blades is crucial for optimal cutting performance. Dull blades can tear grass instead of cutting it cleanly, leading to a less healthy lawn. Regularly inspect the blades and sharpen or replace them as necessary.

2. Oil Changes: Just like any engine, regular oil changes are vital for maintaining performance and preventing wear. Check the manufacturer’s recommendations for oil type and change intervals to keep the engine running smoothly.

3. Air Filter Cleaning: A clean air filter ensures that the engine receives adequate airflow, which is essential for efficient combustion. Regularly inspect and clean or replace the air filter to improve engine performance and fuel efficiency.

4. Battery Maintenance: For electric start models, keeping the battery in good condition is important. Check the battery terminals for corrosion and ensure it is charged adequately. If the battery is old or weak, consider replacing it to avoid starting issues.

5. Tire Inspection and Inflation: Properly inflated tires not only enhance maneuverability but also improve safety. Regularly check tire pressure and inspect for any signs of wear or damage.

By regularly performing these maintenance tasks, you can ensure that your equipment remains in peak condition, providing reliable service for years to come.

Identifying Compatible Replacement Parts

Finding the right components for your equipment can significantly enhance its performance and longevity. Ensuring compatibility is essential for maintaining optimal function and avoiding unnecessary issues. Below are key strategies for identifying suitable replacements.

- Model Number: Always check the model number of your machine. This will help narrow down the search to specific components designed for that model.

- OEM vs. Aftermarket: Understand the difference between original equipment manufacturer parts and aftermarket options. Each has its advantages, depending on your needs and budget.

- Specifications: Review the technical specifications such as size, material, and compatibility with existing components. This ensures the new piece will fit and function as intended.

- Consult Manufacturer Resources: Utilize available manuals and official resources. These documents often provide detailed information on compatible components.

By following these steps, you can confidently select the right replacements to ensure your equipment operates smoothly and efficiently.

Tools Required for Repair Work

Effective repair tasks demand a well-rounded set of equipment to ensure precision and efficiency. Having the right tools not only facilitates the process but also enhances safety and accuracy. A well-organized toolkit can make all the difference when tackling maintenance or restoration projects.

Basic Hand Tools: Essential hand tools include screwdrivers, wrenches, and pliers. These instruments are fundamental for loosening or tightening components and addressing minor adjustments.

Power Tools: For more intensive repair work, power tools such as drills, saws, and impact drivers can expedite tasks significantly. They are invaluable for cutting, shaping, or assembling materials quickly and efficiently.

Measurement Instruments: Accurate measurements are critical. Tools like tape measures, calipers, and levels ensure that every part is fitted correctly and aligned properly, which is vital for optimal performance.

Safety Equipment: Protecting oneself is paramount. Safety goggles, gloves, and ear protection should always be on hand to safeguard against potential hazards during repair operations.

Specialized Tools: Depending on the specific task at hand, specialized tools may be required. These can range from torque wrenches to diagnostic instruments that assist in identifying issues more effectively.

Equipping yourself with the appropriate tools can transform the repair experience, leading to better results and increased satisfaction upon completion.

Where to Find Official Diagrams

Accessing reliable visual guides is essential for anyone looking to maintain or repair their machinery. These resources provide clarity on components and assembly, making the process much easier. Understanding where to locate these official illustrations can save time and ensure accuracy in your projects.

One of the most effective sources is the manufacturer’s website, where users can often find a dedicated section for manuals and technical resources. Additionally, authorized dealers and service centers frequently have printed materials available for customers. Online forums and community groups dedicated to similar equipment can also be invaluable, as they often share links and resources for accessing these vital documents.

Lastly, consider visiting reputable online retailers that specialize in machinery parts. Many of them provide digital manuals alongside their inventory, allowing users to easily reference the necessary guides while shopping for replacements.

Tips for Efficient Parts Management

Effective management of components is crucial for maintaining operational efficiency and minimizing downtime. By implementing systematic strategies, one can streamline processes, enhance productivity, and ensure timely access to necessary elements.

Organize and Categorize

Establish a clear organizational system that categorizes items based on type, usage frequency, or compatibility. This structure not only simplifies retrieval but also helps in monitoring inventory levels, ultimately reducing the risk of shortages or excess.

Regular Inventory Audits

Conducting routine checks ensures that stock levels are accurate and that worn or outdated items are identified and replaced promptly. This practice not only maintains operational integrity but also aids in forecasting future needs effectively.

Customer Support and Resources Available

Access to reliable customer assistance and comprehensive resources is essential for ensuring optimal performance and longevity of outdoor equipment. Whether you require technical guidance, product information, or maintenance tips, numerous avenues exist to support users in effectively managing their machines.

Contacting Customer Service

For personalized support, reaching out to the dedicated customer service team is recommended. They are equipped to answer inquiries, provide troubleshooting steps, and assist with warranty issues. Contact options often include phone, email, and live chat, ensuring that help is readily accessible.

Online Resources and Community Forums

In addition to direct support, a wealth of online materials is available. Official websites typically feature detailed guides, FAQs, and instructional videos. Community forums also serve as a valuable platform for users to share experiences, seek advice, and exchange tips with fellow enthusiasts, fostering a collaborative environment for problem-solving.