In the world of construction and heavy machinery, having a clear visual reference for various systems and assemblies is crucial for ensuring smooth operation and maintenance. This section delves into the intricate configuration of essential mechanisms that power these machines, focusing on how various elements come together to deliver functionality. By analyzing these connections, operators and technicians can achieve a deeper understanding of the machinery’s overall structure.

Every piece of equipment is made up of several interconnected units that need to function in harmony. Identifying the correct placement and alignment of these units is key to troubleshooting and optimizing performance. This guide provides a comprehensive overview, offering a clear perspective on how to effectively approach maintenance, repair, or replacement tasks. Whether you’re preparing for routine upkeep or addressing specific issues, understanding the structure is the first step.

Regular upkeep of your equipment ensures optimal performance and a longer lifespan. Proper care minimizes the risk of unexpected breakdowns and costly repairs. By following a few simple guidelines, you can keep your machinery running smoothly and avoid potential issues.

- Inspect the components regularly for signs of wear and tear. Early detection can prevent more significant damage down the line.

- Ensure that all moving parts are lubricated adequately. Proper lubrication reduces friction and helps extend the lifespan of mechanical elements.

- Check fluid levels frequently, especially oil and hydraulic fluids, to maintain smooth operation and prevent overheating.

- Keep the air filter clean and replace it when necessary to avoid blockages and ensure efficient airflow.

- Tighten any loose bolts and fasteners to prevent vibrations from causing further damage to the structure.

- Follow the manufacturer’s maintenance schedule and replace any worn

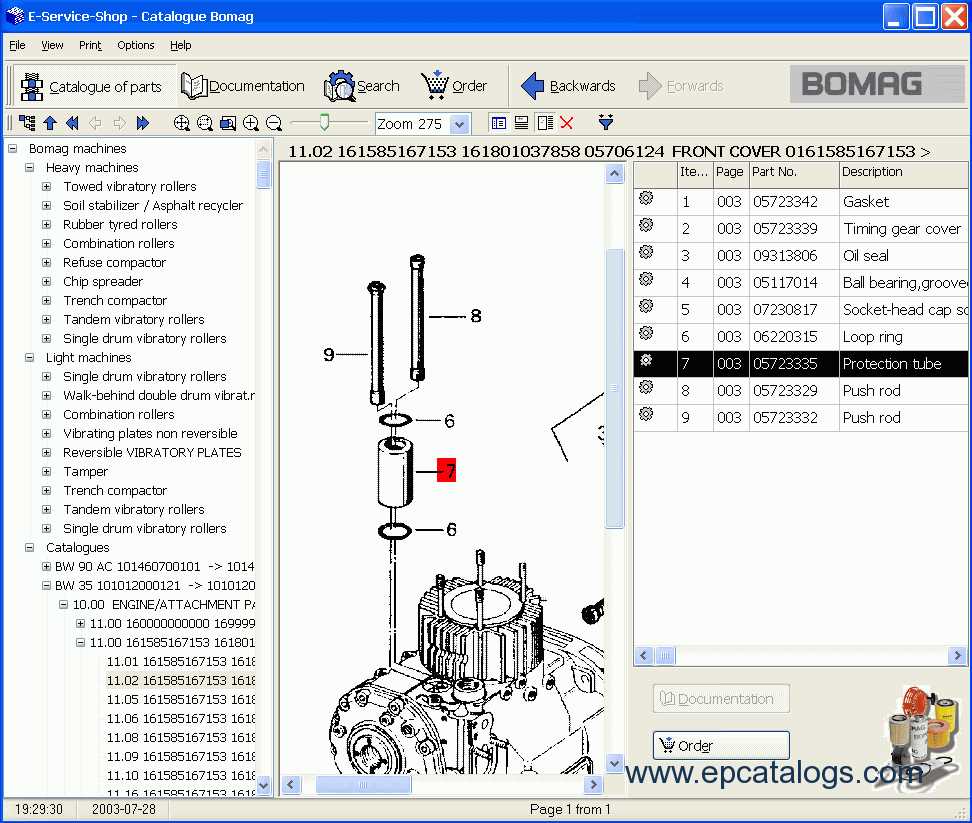

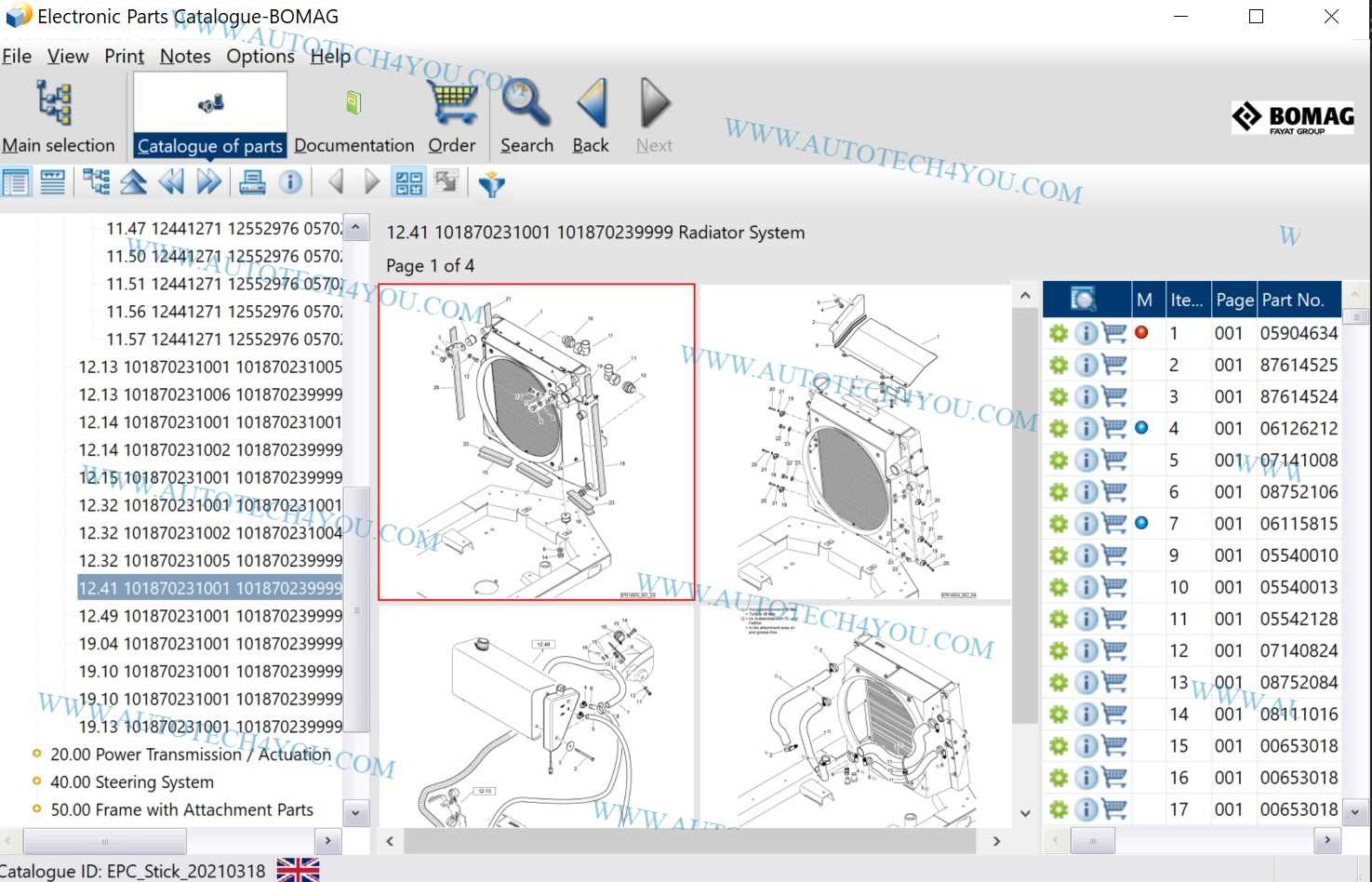

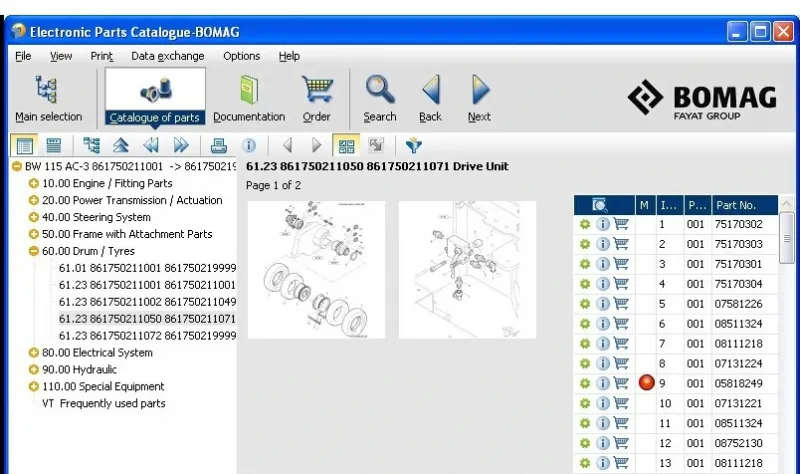

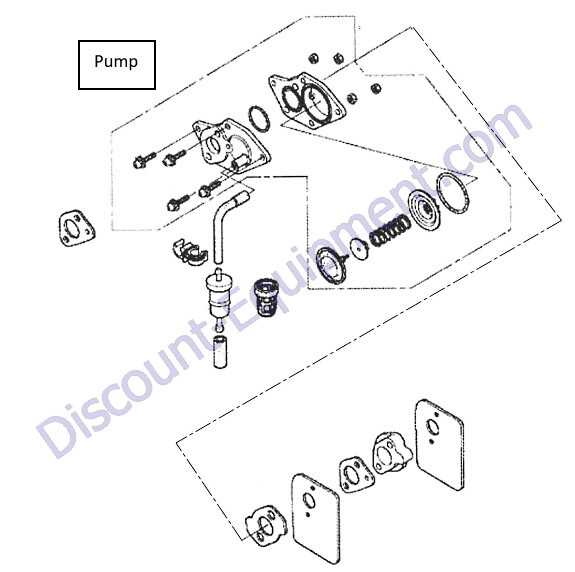

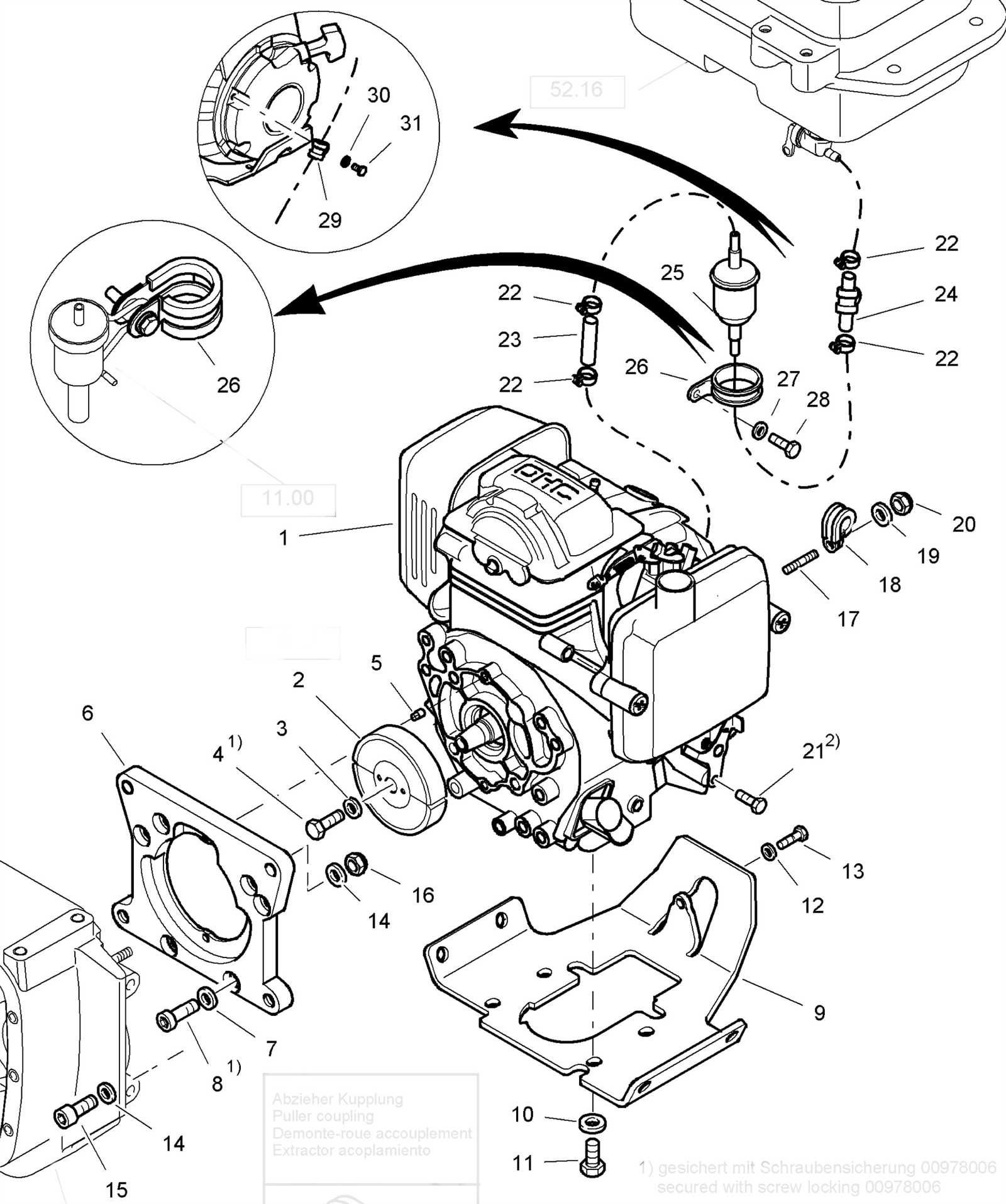

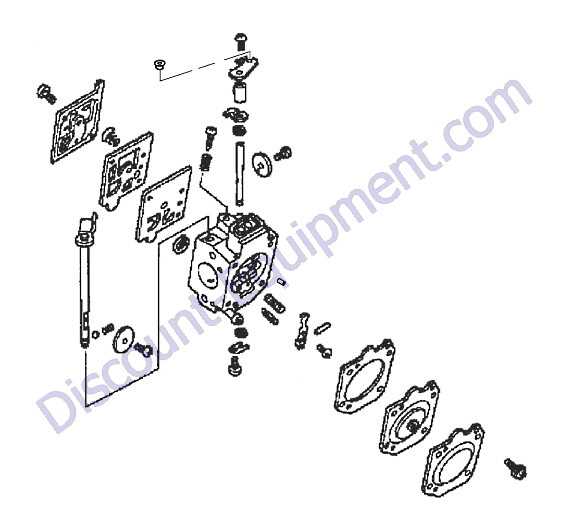

Identifying Parts Through Visual References

Recognizing components by utilizing graphical illustrations can simplify the process of maintenance or repairs. Visual aids serve as an efficient way to quickly locate and differentiate individual elements within a complex assembly. By comparing real-world objects with images or sketches, users can gain a deeper understanding of their structure and function.

- Focus on detailed comparisons between visual references and physical objects.

- Utilize images to clarify how components fit within larger systems.

- Highlight key characteristics that set similar elements apart from one another.

Visual guides also help identify any potential replacements or upgrades needed. When working with machinery or technical systems, such visual tools are invaluable for ensuring accuracy in assembly and troubleshooting.

Tools Needed for Parts Replacement

Replacing components in mechanical systems requires careful selection of the right tools to ensure a smooth and efficient process. Each task can vary in complexity, so having the appropriate equipment on hand is crucial to minimize downtime and avoid potential damage to the machine during the repair process.

Essential Hand Tools

Basic hand tools, such as wrenches, screwdrivers, and pliers, are fundamental for disassembly and reassembly. These tools allow precise manipulation of fasteners and other small elements that must be removed or adjusted during the procedure.

Specialized Equipment

In addition to standard tools, specialized instruments, like torque wrenches and bearing pullers, may be required to handle more specific tasks. These tools ensure components are tightened or removed according to precise specifications, which is

Common Issues and Troubleshooting Techniques

Understanding the common malfunctions and ways to resolve them is essential for maintaining the performance and longevity of any construction equipment. Problems can arise due to wear, improper usage, or environmental factors. Addressing these issues promptly ensures smooth operation and avoids more extensive damage.

Issue Possible Cause Solution Engine won’t start Low fuel or faulty ignition system Check fuel levels, inspect spark plugs, and test the ignition system. Irregular vibration Where to Find Genuine Replacement Parts

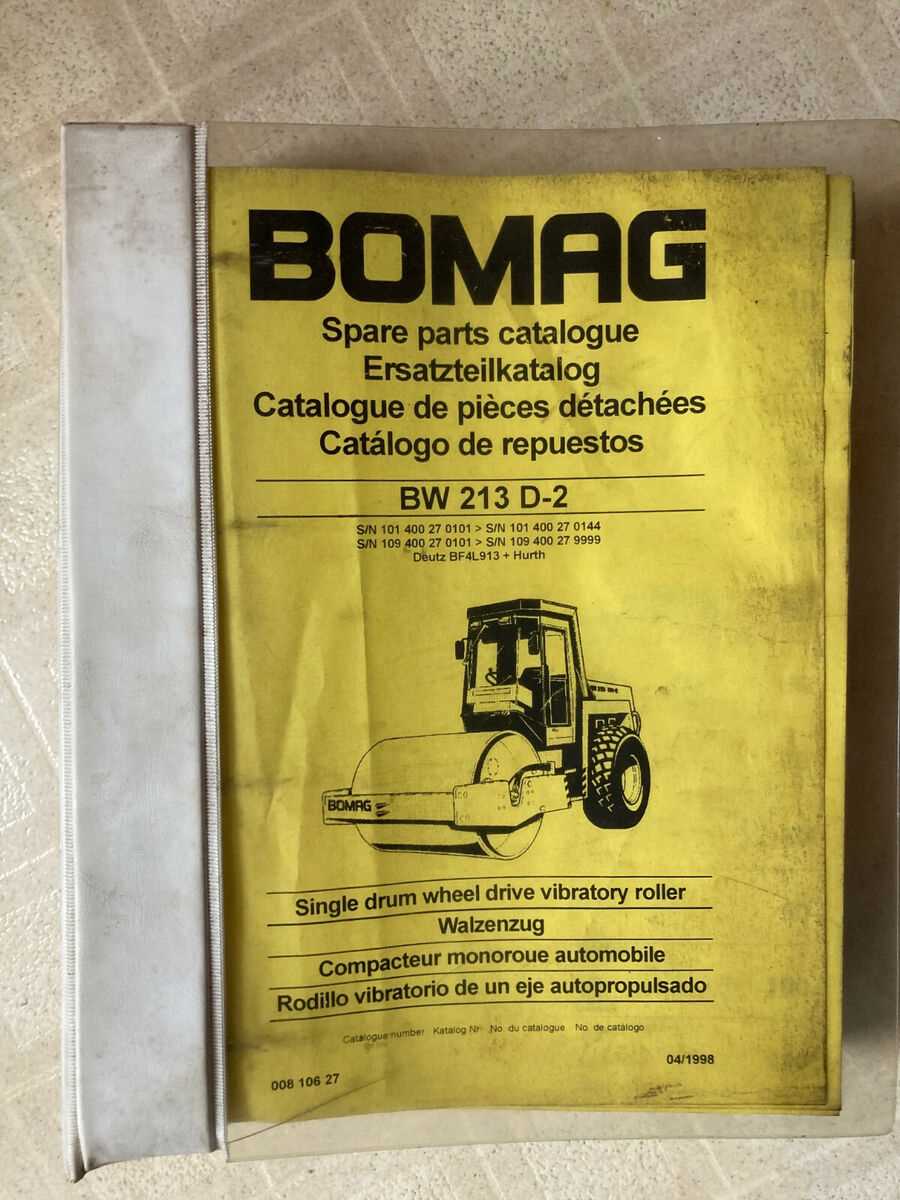

Maintaining your equipment in top condition requires sourcing high-quality components from trusted suppliers. Ensuring that your device runs smoothly means selecting original replacements that are specifically designed to meet manufacturer standards. This guarantees longevity and optimal performance for your machine.

Authorized Dealers and Official Websites

One of the most reliable sources for authentic spare components is through authorized distributors and official manufacturer websites. These outlets ensure you receive verified replacements that are compatible with your specific model, along with comprehensive support and warranty services.

Specialized Stores and Online Platforms

Specialized retailers, both physical and online, offer a wide variety of genuine replacements. Online platforms often feature detailed listings and customer reviews, making it easier to identify the exact component you need. Be sure to verify the authenticity of sellers and confirm product specifications to avoid counterfeit goods.

Advantages of Using Original Components

Choosing authentic components for your equipment can significantly improve performance and extend the lifespan of the machinery. These parts are designed to fit perfectly and function in harmony with the system, ensuring reliable and consistent operation. By opting for genuine elements, you reduce the risk of malfunction and unnecessary repairs.

Enhanced Durability: Original components are manufactured to meet the highest standards, providing superior durability. They are built to withstand the stresses and demands of daily use, minimizing the need for frequent replacements.

Optimal Performance: Genuine parts are specifically engineered for the exact specifications of your equipment, ensuring optimal performance. This precision fit leads to better efficiency, reducing wear and tear over time.

Safety Assurance: Using certified components guarantees that all safety measures are adhered to, lowering the chances of operational hazards. High-quality materials and rigorous testing ensure that