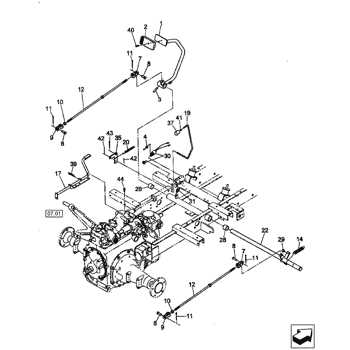

Maintaining a well-functioning machine requires a clear understanding of its internal structure. Each individual component plays a vital role in ensuring smooth operation and longevity. Familiarizing yourself with the layout and organization of these essential elements can significantly improve troubleshooting and repair efficiency.

Identifying specific mechanical elements and how they interconnect allows users to navigate repairs with confidence. From the engine components to the smaller connecting parts, having a detailed map of the system can simplify maintenance tasks and help pinpoint issues more effectively. This overview will guide you through the core components and offer insights into how they function together.

Whether you’re dealing with routine checks or addressing a specific issue, understanding the intricate layout of machinery is crucial. With the right information, even complex repairs can become more manageable, leading to better performance and durability over time.

Equipment Component Layout Overview

Understanding the structure and arrangement of various elements within this machine model is essential for both maintenance and repairs. A detailed visual representation can greatly assist in identifying individual elements and how they fit into the overall system, ensuring efficient troubleshooting and part replacement.

Main Structural Components

The primary elements consist of the outer framework, engine mounts, and transmission assembly. These crucial pieces form the foundation, holding together all other parts. Proper maintenance of these areas ensures durability and longevity of the equipment.

Engine and Drive Mechanism

The heart of the system lies in its power source and propulsion. Key aspects include the engine, drive belt, and wheels. Understanding the placement of these components allows for easier identification and replacement, especially when dealing with wear and tear.

| Component | Function | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine Block | Provides power to drive the machinery. | |||||||||||

| Transmission | Facilitates gear shifts and movement control. | |||||||||||

| Drive Belt | Connects the engine to the wheels for motion. | |||||||||||

| Wheels | Ensure smooth movement across surfaces.

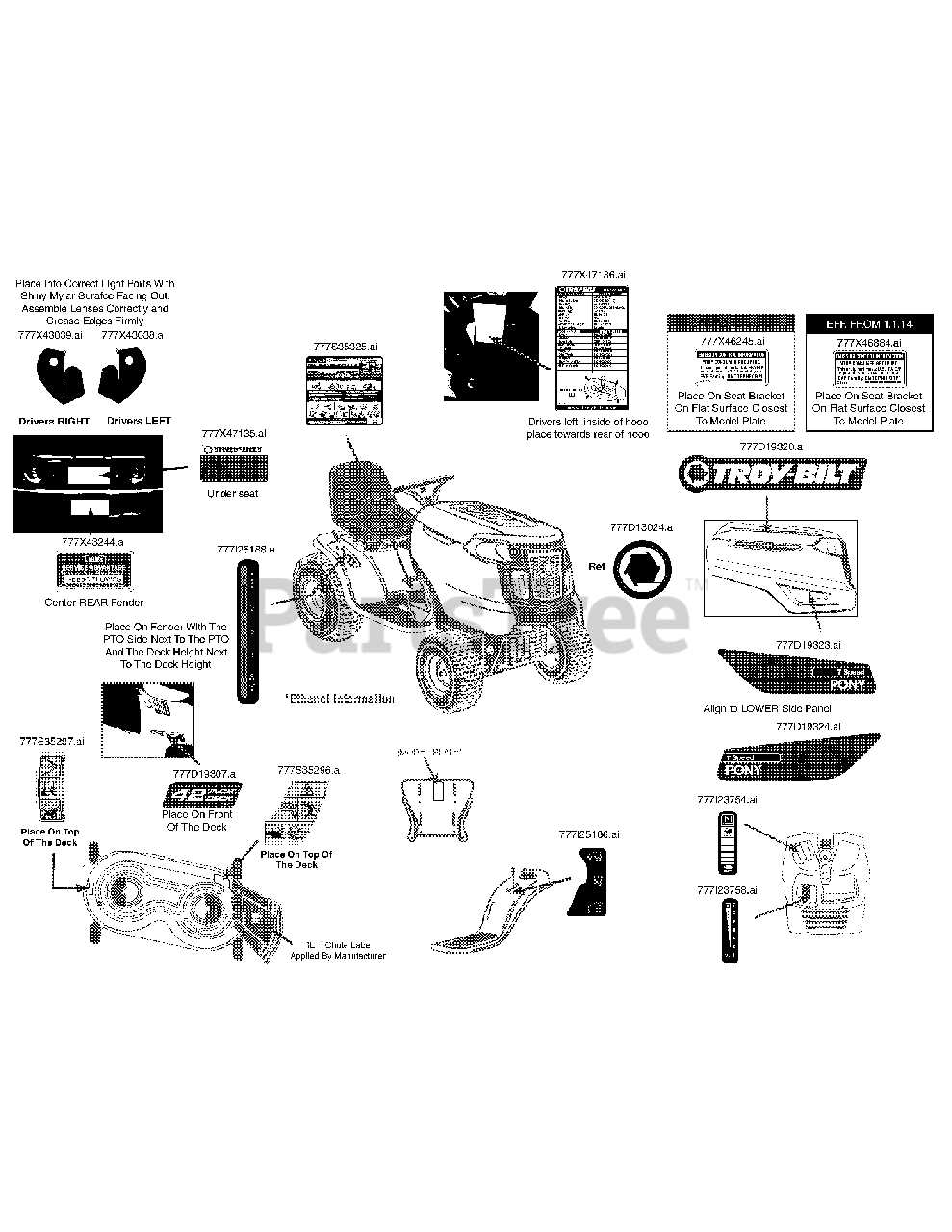

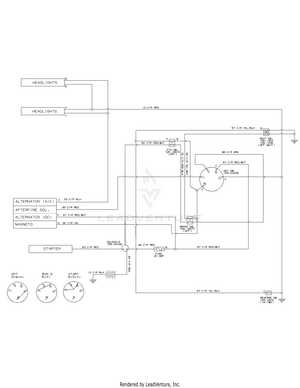

Key Components of the Lawn TractorThe lawn tractor is a complex machine designed to handle a variety of tasks related to lawn care. Understanding its essential elements can help ensure proper maintenance and efficient operation. This section provides an overview of the critical components that work together to deliver smooth performance and durability. One of the primary features is the engine, which powers the machine and drives its functionality. The transmission system allows the tractor to move forward and backward, controlling speed and direction. Another key component is the cutting deck, responsible for mowing the grass evenly. Additional essential parts include the steering system, which provides control over navigation, and the wheels, which give stability and traction on different surfaces. Safety mechanisms, such as brakes and emergency shut-off switches, are also vital for ensuring a safe operating experience. Each element plays a crucial role in the overall performance and lifespan of the machine. How to Identify Engine PartsUnderstanding the key components of an engine is essential for both maintenance and troubleshooting. By familiarizing yourself with the various elements, you can easily spot issues and keep the machine in top condition. Identifying these components requires attention to details like their shape, location, and connections within the engine system. Key Components of an Engine

|