In the realm of culinary preparation, efficiency and precision are paramount. An essential tool that aids in transforming various ingredients into desirable forms plays a significant role in many kitchens. To maximize its potential, one must grasp the intricate elements that contribute to its functionality.

Every unit consists of a collection of interconnected components, each designed for a specific purpose. By comprehending how these elements work together, users can not only enhance their culinary skills but also ensure the longevity of their equipment. This knowledge serves as a foundation for troubleshooting and maintenance, ultimately leading to better results in food preparation.

In this exploration, we will delve into the various sections that constitute this invaluable appliance. By familiarizing yourself with the terminology and function of each part, you can gain a deeper appreciation for the craftsmanship involved in creating a seamless cooking experience.

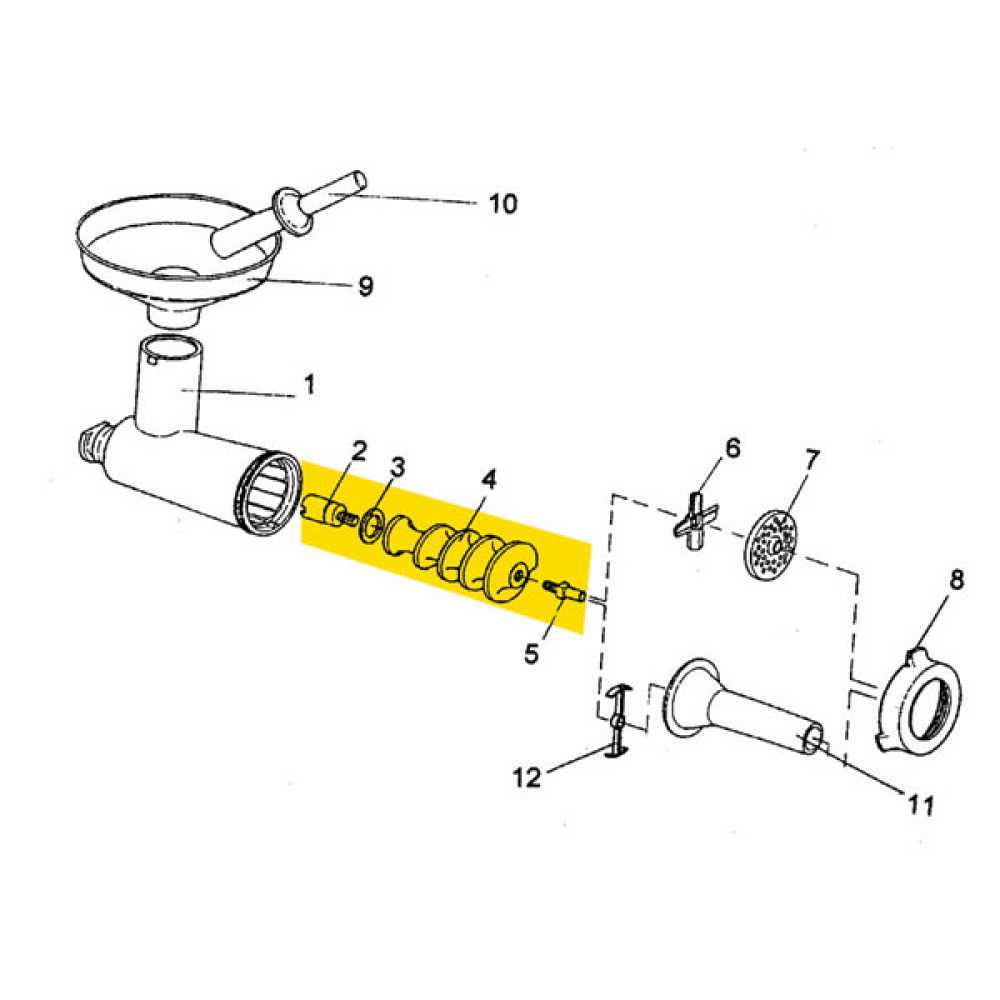

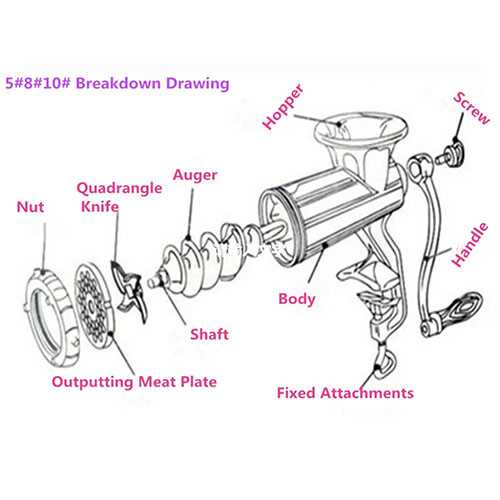

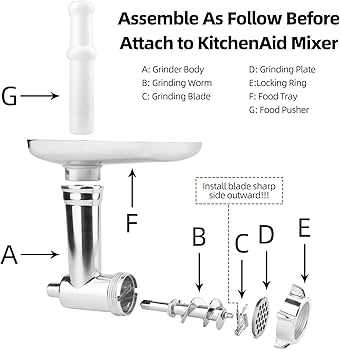

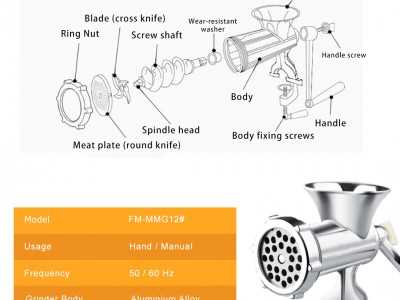

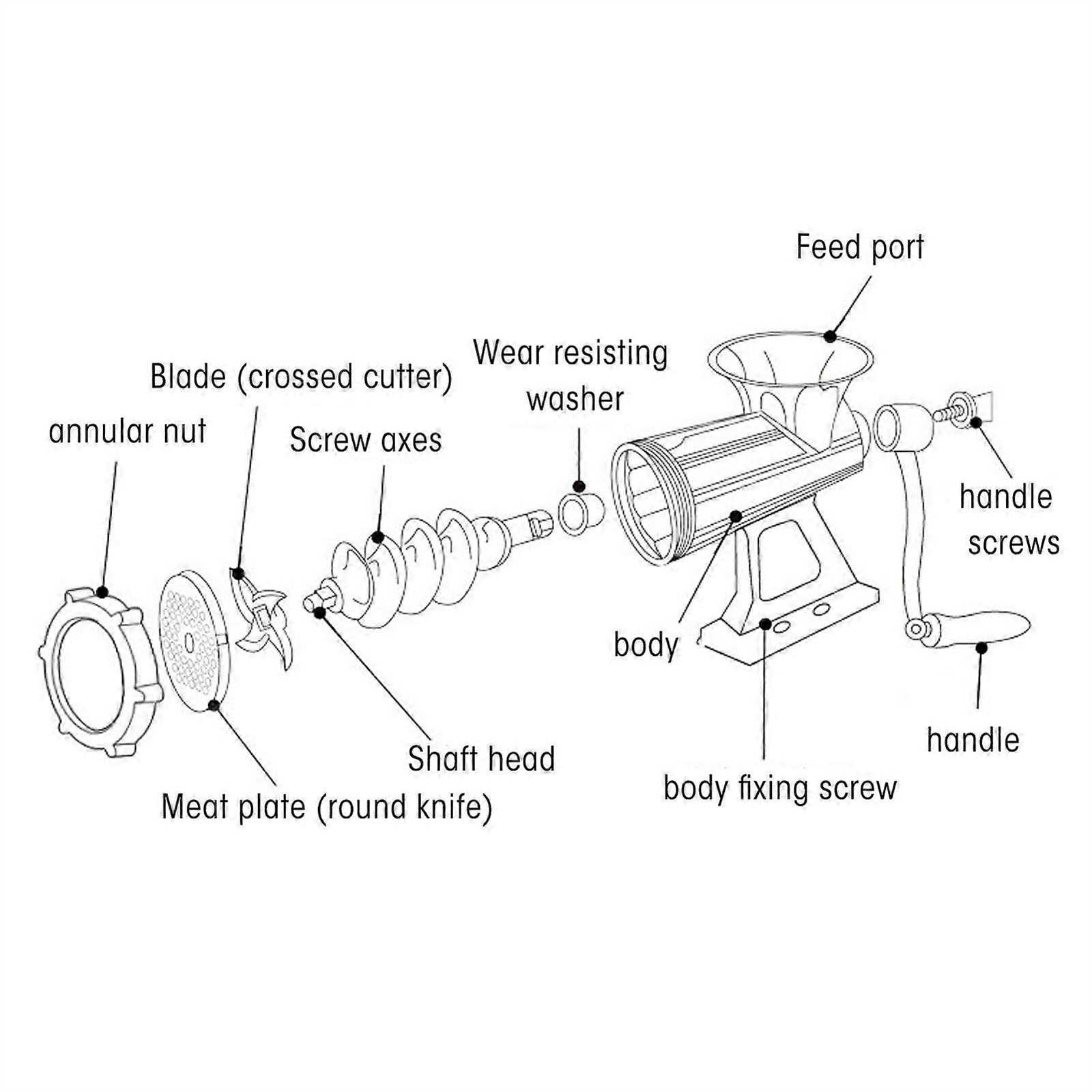

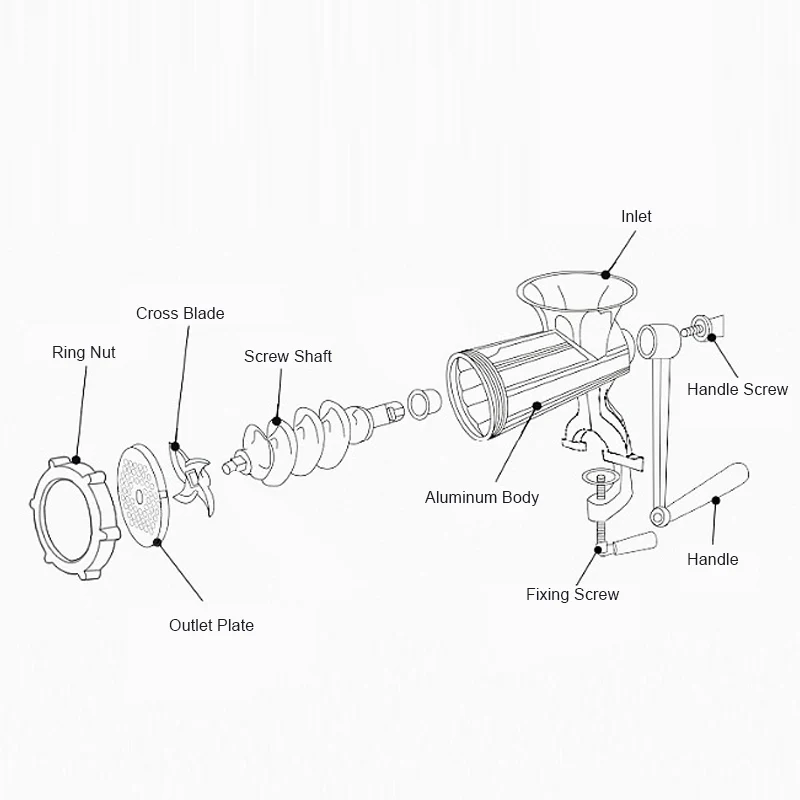

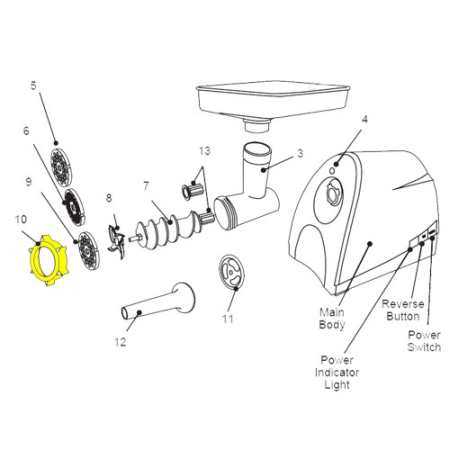

This section aims to provide a comprehensive overview of the essential components involved in the process of transforming raw ingredients into finely processed products. By breaking down each element, readers can gain insights into the functionality and significance of every piece within the apparatus.

| Component | Description |

|---|---|

| Feed Tube | The entry point for the raw materials, allowing for efficient loading into the machine. |

| Cutter Blade | Sharp element responsible for slicing and dicing the ingredients, ensuring uniformity. |

| Grating Disc | A perforated disc that determines the final texture of the processed materials based on hole size. |

| Auger | The spiral component that moves the ingredients towards the blade for processing. |

| Housing | The outer shell that encases all internal components, providing stability and safety. |

| Power Source | The mechanism that provides the necessary energy to operate the equipment effectively. |

Understanding these components enhances one’s ability to maintain and operate the device, ensuring optimal performance and longevity.

Main Components Explained

This section will explore the essential elements that contribute to the functionality of a popular culinary tool. Each component plays a significant role in achieving optimal performance, ensuring that the process is both efficient and effective.

Core Elements

At the heart of this appliance lies the motor, which provides the necessary power to facilitate operation. Coupled with the motor are various attachments that determine the texture and consistency of the output. These elements work in harmony to deliver the desired results.

Supporting Mechanisms

Additional features such as the feed tube and the discharge chute are vital for the seamless transfer of ingredients. Moreover, components like the blade and the screen are critical for achieving the ultimate grind quality, enhancing both the versatility and functionality of the tool.

Importance of Knowing Each Part

Understanding the components of a food processing device is essential for ensuring its optimal functionality and longevity. Each element plays a specific role, and awareness of their functions can significantly enhance the overall experience and efficiency of use.

Benefits of Familiarity

- Maintenance: Recognizing how each component operates helps in performing regular upkeep, preventing wear and tear.

- Troubleshooting: Knowing the function of each piece enables quick identification of issues, allowing for faster resolutions.

- Efficiency: Awareness of how different elements work together can improve operational speed and output.

Enhancing Safety

- Understanding the layout minimizes the risk of accidents during usage.

- Familiarity with assembly and disassembly can prevent injuries when cleaning or repairing.

- Knowledge of safety features ensures proper handling and reduces hazards.

Common Maintenance Tips

Regular upkeep is essential for ensuring the longevity and optimal performance of your equipment. By following a few straightforward guidelines, you can prevent wear and tear, reduce the risk of malfunction, and maintain high efficiency during use.

First, always clean the device thoroughly after each use. Residue can accumulate and lead to clogs or deterioration over time. Use warm, soapy water and a soft cloth to remove any remaining debris.

Next, lubricate moving components periodically. This reduces friction and helps prevent breakdowns. Make sure to use the appropriate lubricant recommended by the manufacturer for best results.

Inspect all elements regularly for signs of damage or wear. Look for cracks, rust, or loose fittings. Addressing these issues early can save you from more extensive repairs down the line.

Finally, store the apparatus in a cool, dry place when not in use. This will help protect it from environmental factors that could cause corrosion or other forms of deterioration.

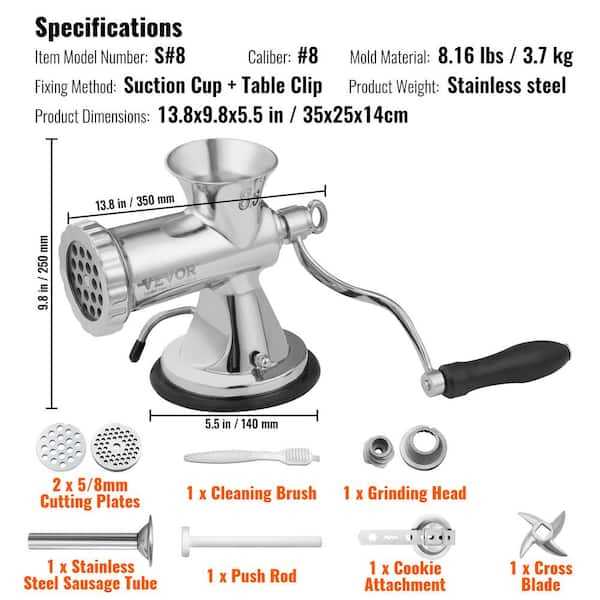

Choosing the Right Grinder for Your Needs

Selecting the appropriate device for your culinary tasks can greatly enhance your cooking experience. Understanding your requirements and preferences is essential in making an informed choice. Various options are available, each designed to cater to specific tasks and user expectations.

Consider your frequency of use. If you plan to use the equipment regularly, investing in a high-quality model that offers durability and efficiency is wise. For occasional use, a more compact and cost-effective version may suffice.

Think about the types of ingredients you intend to process. Different devices excel in handling various materials, from soft vegetables to denser products. Ensure that the selected model is versatile enough to accommodate your culinary needs.

Assess the size and capacity of the equipment. A larger model may be necessary for bigger households or meal prep, while a smaller unit is ideal for limited spaces or single servings. Always choose one that fits well within your kitchen layout.

Ease of cleaning is another crucial factor. Look for options with removable components that are dishwasher-safe, simplifying maintenance and ensuring hygiene.

Finally, consider additional features such as attachments and settings that can enhance functionality. Some models offer various cutting plates and speeds, allowing for greater flexibility in food preparation.

By taking these factors into account, you can confidently choose the right appliance that will meet your culinary demands and make your cooking endeavors more enjoyable.

Safety Measures When Handling Parts

Ensuring safety during the manipulation of machinery components is crucial to prevent accidents and injuries. Adhering to proper protocols not only protects the user but also enhances the overall efficiency of operations.

- Always wear appropriate personal protective equipment, such as gloves and safety goggles.

- Disconnect power sources before performing any maintenance or adjustments.

- Keep the workspace clean and free of obstacles to minimize risks of tripping or falling.

Additionally, it is essential to follow specific guidelines:

- Read the manufacturer’s instructions thoroughly before attempting any handling.

- Inspect components for any signs of damage before use.

- Maintain a clear understanding of the machinery’s operation to avoid mishaps.

Comparison of Manual vs Electric Grinders

When it comes to processing food, choosing between a hand-operated model and an electric version can significantly affect efficiency and convenience. Each option offers distinct advantages and drawbacks that cater to different needs and preferences.

Advantages of Manual Models

- Greater control over the texture and consistency of the product.

- Quieter operation, making it suitable for peaceful environments.

- Portability, allowing for use in various locations without the need for power sources.

- Lower cost, appealing to budget-conscious consumers.

Benefits of Electric Models

- Speed and efficiency, ideal for large volumes of food.

- Less physical effort required, making it user-friendly for all ages.

- Consistent results with minimal variability.

- Additional features, such as multiple speed settings and attachments for versatility.

Troubleshooting Typical Issues

Understanding and resolving common problems in equipment can significantly enhance performance and longevity. This section addresses frequent challenges users may encounter, providing insights into effective solutions and preventative measures.

Identifying Common Problems

Issues may arise from improper assembly, wear and tear, or insufficient maintenance. Recognizing symptoms like unusual noises or inconsistent output is crucial. Inspecting components regularly can help pinpoint the root cause before it escalates.

Effective Solutions

To address malfunctions, start by ensuring all components are securely fitted. Cleaning and lubricating parts can often resolve friction-related issues. If problems persist, consider replacing worn elements to restore optimal function.

Future Innovations in Grinder Technology

The landscape of food preparation technology is evolving rapidly, with cutting-edge advancements poised to enhance efficiency, safety, and user experience. As we delve into the future, several innovations promise to revolutionize the way we process ingredients, ultimately changing culinary practices.

Smart Features and Automation

Integrating smart technology into processing equipment will streamline operations. Features may include:

- Touchscreen controls for user-friendly navigation.

- Automated settings for precise consistency.

- Smart sensors that adjust speed based on the texture of ingredients.

Enhanced Materials and Design

The development of advanced materials will significantly impact durability and hygiene. Potential improvements might involve:

- Non-stick coatings for easier cleaning.

- Lightweight composites that reduce energy consumption.

- Modular designs allowing for easy upgrades and repairs.