The intricate design of a vintage rifle offers enthusiasts and hobbyists alike the opportunity to explore the inner workings of a piece of history. Familiarity with its individual elements and their assembly is crucial for both maintenance and restoration. A clear understanding of how each part interacts within the whole mechanism ensures longevity and functionality, making it a valuable pursuit for anyone dedicated to preserving these remarkable weapons.

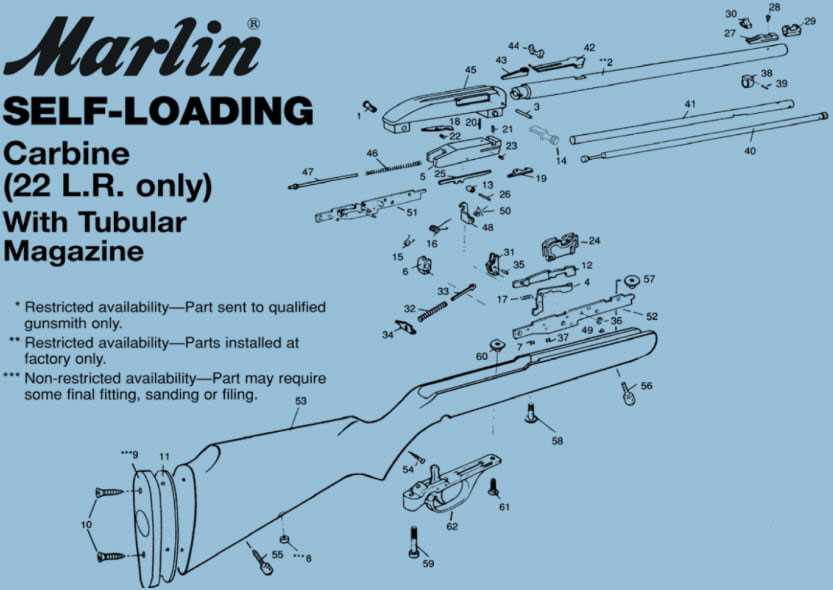

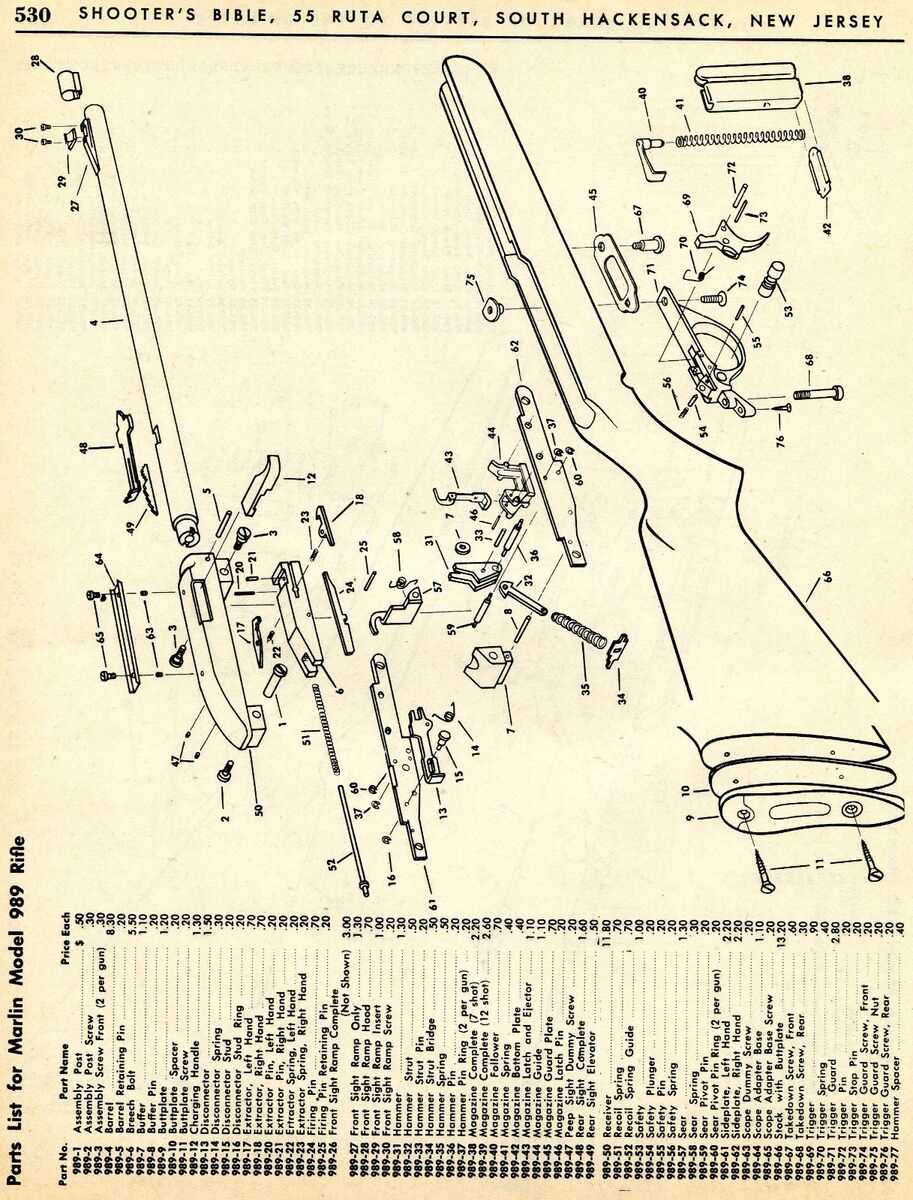

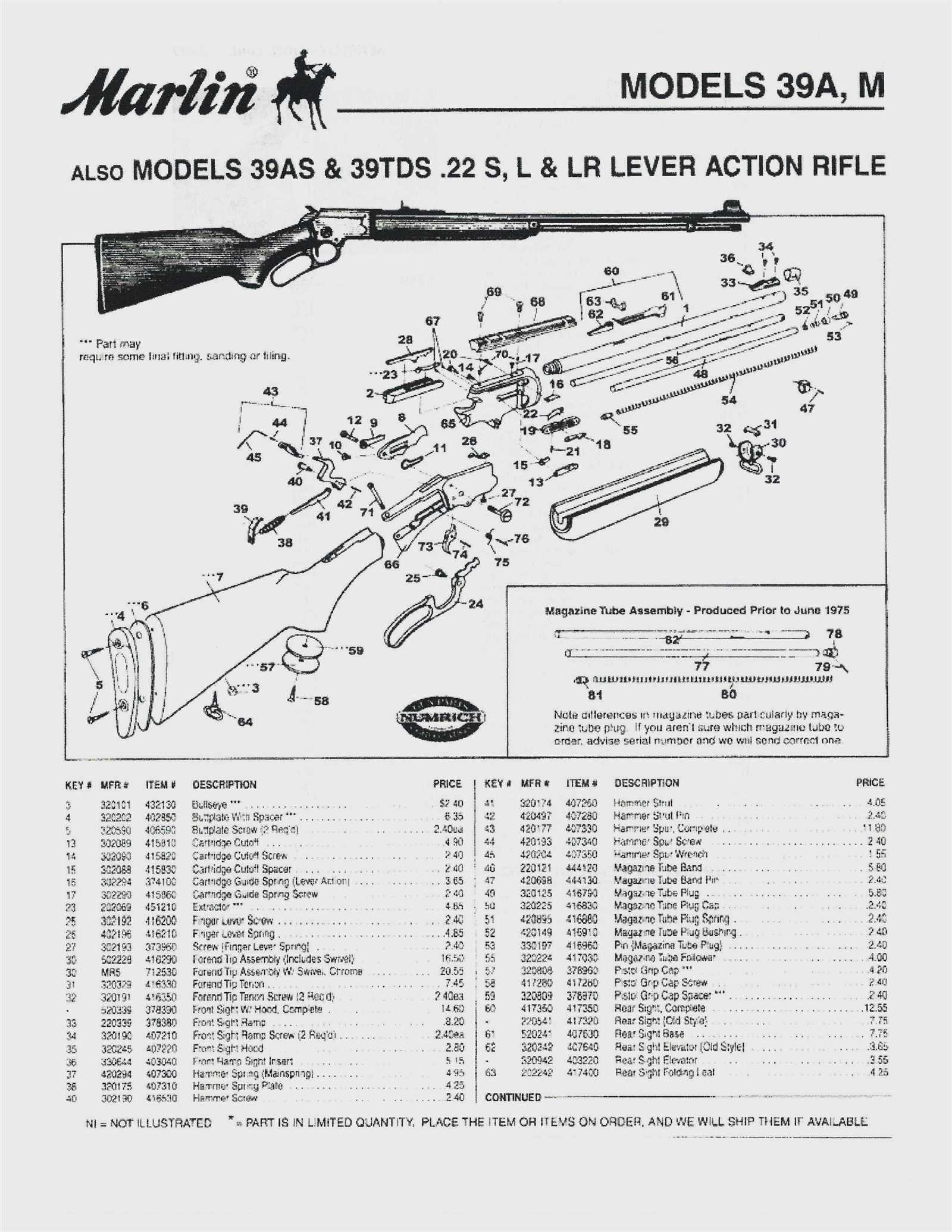

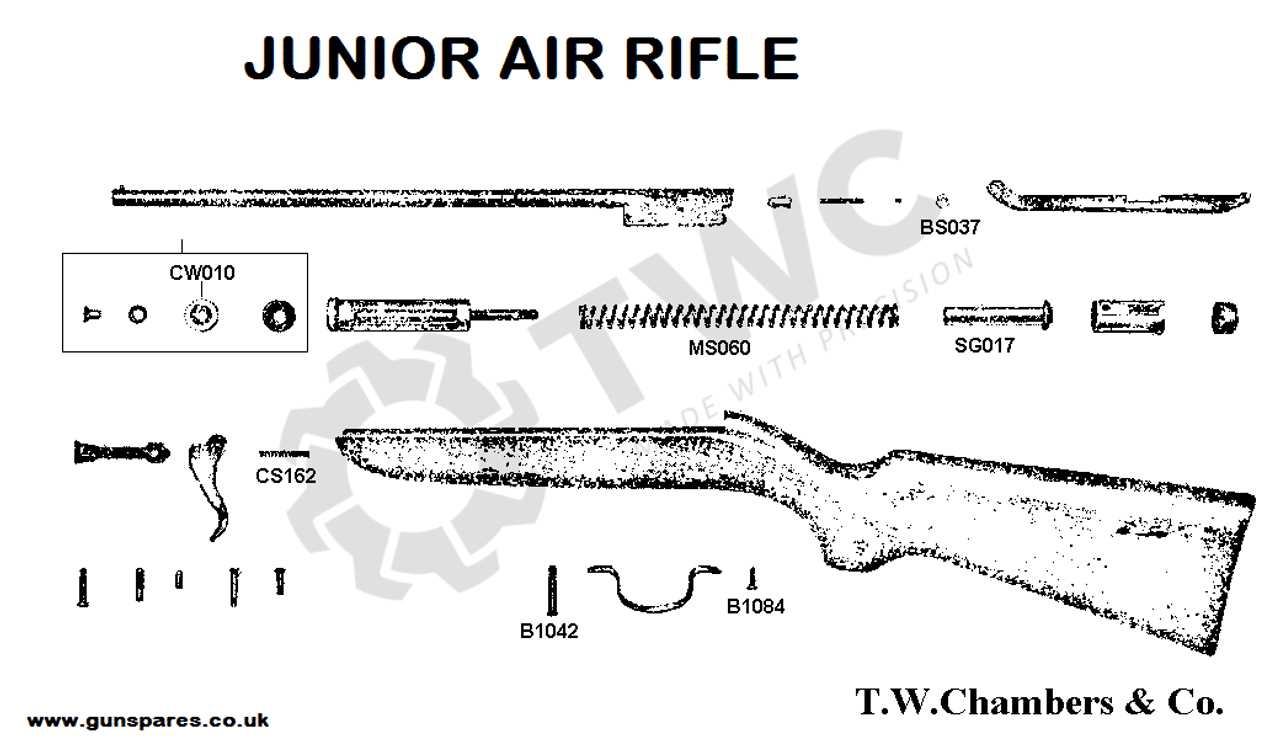

When working with such firearms, being able to identify each component and its role in the firing sequence is essential. A detailed breakdown of the entire assembly provides clarity and helps in troubleshooting or upgrading specific sections. Whether you’re aiming for efficient repairs or simply looking to deepen your appreciation of the craftsmanship, having access to a visual reference can significantly simplify the process.

For those new to firearm disassembly or reassembly, visual aids become indispensable. These guides not only help in identifying individual sections but also illustrate how each piece fits into the larger structure. By following these reference materials, one can enhance their understanding of the firearm, making repairs more precise and enjoyable.

Understanding the Marlin Model 60

For enthusiasts and collectors of firearms, understanding the components and inner workings of a specific rifle is crucial. The firearm in question offers a reliable and smooth experience, thanks to its innovative design and durability. Knowing its various features, how they interact, and how to properly maintain them ensures longevity and optimal performance over time.

The construction of this rifle incorporates a variety of key elements that work together to create a well-balanced shooting experience. Each individual section serves a distinct purpose, whether it’s enhancing accuracy, improving loading efficiency, or contributing to overall safety. Familiarity with these components allows users to perform necessary repairs or upgrades when needed.

For anyone looking to dive deeper into the mechanics of this rifle, it’s essential to have a clear understanding of how each part functions. With the right knowledge, users can identify potential issues, perform regular maintenance, and make informed decisions when it comes to customization or repairs.

Mastering the internal design is vital for proper care and handling. When broken down, each segment offers specific functionality that enhances the user experience, from the loading system to the trigger mechanism, ensuring smooth and safe operation.

Exploring the assembly in detail helps shooters appreciate the engineering behind their rifle. Whether you’re an experienced user or a first-time owner, grasping the full scope of its design will empower you to make the most of your firearm.

Key Components of the Model 60

Understanding the critical elements that make up a firearm is essential for both maintenance and performance. Each individual component contributes to the overall functionality and reliability. In this section, we will explore the primary features that form the core of this classic rifle, focusing on their purpose and how they interact with each other to ensure smooth operation.

Essential Operating Parts

The efficient operation of this rifle depends on several key parts working in unison. These components are designed to provide durability and precision, enabling users to achieve optimal performance under various conditions. Below are the most important features:

- Receiver: The central hub where many other parts come together, housing the action and trigger mechanism.

- Barrel: One of the most critical elements, it controls the accuracy and power of each shot, directly influencing shooting precision.

- Trigger Assembly: A mechanism that releases the hammer or firing pin when engaged, allowing for the ignition of the round.

- Magazine: Stores ammunition and feeds it into the chamber, ensuring continuous firing with minimal interruption.

Supportive Mechanisms

In addition to the core operational parts, several supportive mechanisms enhance usability and safety. These parts ensure smooth loading, safety, and overall user experience:

- Safety Lever: A crucial safety feature that prevents accidental firing by locking the trigger mechanism.

- Sights: Aiming devices that guide the shooter in accurately aligning the target with the barrel.

- Stock: The handle of the firearm, providing a stable platform for gripping and steadying the rifle during use.

How to Identify Parts in the Diagram

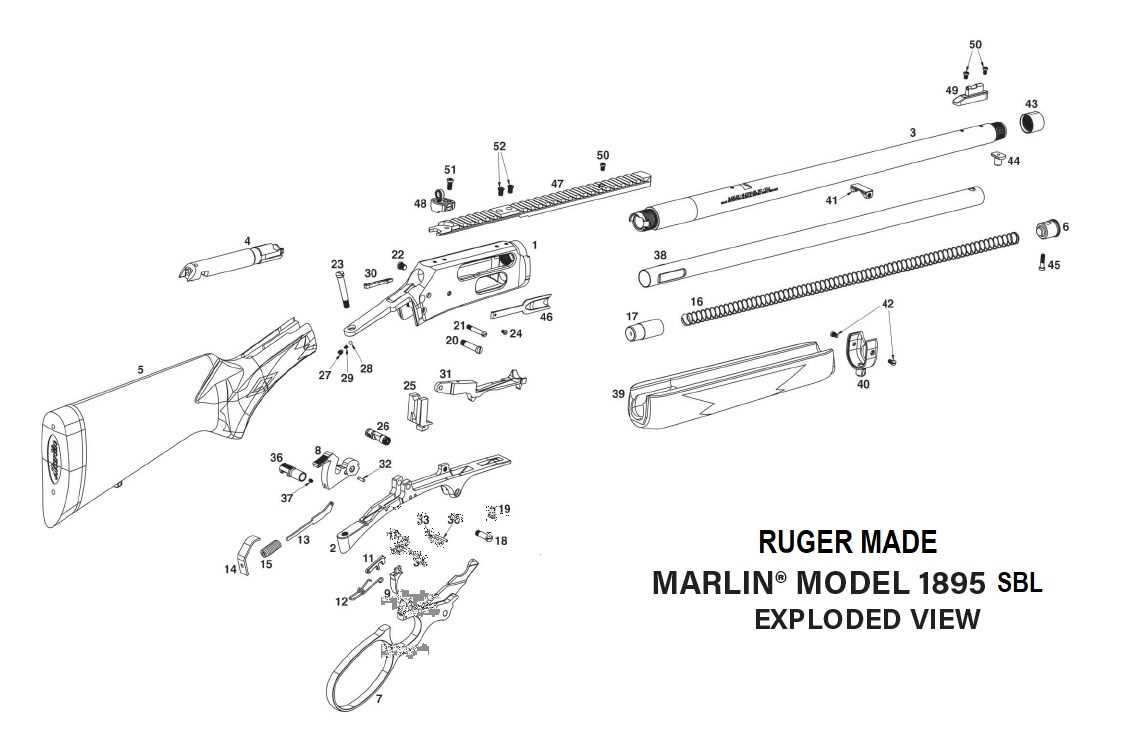

Understanding the components shown in a technical illustration requires familiarity with both the visual and textual information presented. A clear recognition of each element plays a crucial role in maintenance and repair, ensuring accurate assembly or troubleshooting. This section will guide you through the process of identifying these components effectively.

Step-by-Step Approach

Start by carefully examining the overall layout. Each component is usually numbered or labeled for easy reference. By following a systematic method, you can match these numbers with descriptions in the corresponding guide or manual.

- Examine the image carefully from left to right, top to bottom.

- Look for any labels or identifiers next to the illustrations of the components.

- Cross-reference the visual with the written guide, which often includes a parts list or description corresponding to each numbered part.

- Identify major and minor components separately. Larger parts are usually easier to spot, while smaller elements may require a more detailed inspection.

Tips for Efficient Identification

- Ensure proper lighting and zoom in for a clearer view of smaller parts.

- Use a magnifying tool if necessary to distinguish fine details in intricate parts.

- Cross-check the same parts across multiple diagrams, if available, to reinforce recognition.

By following these steps, you’ll enhance your ability to quickly and accurately identify the elements you need for repairs or upgrades. A thorough understanding of the visual language used in these illustrations can save time and reduce errors in any assembly process.

Common Issues with Model 60 Parts

When maintaining a popular rifle, it’s essential to be aware of common issues that can arise with its components. Over time, certain parts can wear out or become misaligned, leading to performance problems. Identifying and addressing these issues early can help extend the life of the firearm and maintain its reliability. Below are some of the most frequently encountered problems with individual elements of the firearm.

Feeding and Cycling Problems

One of the most common issues faced by users is related to the feeding and cycling of ammunition. This can occur for a variety of reasons:

- Faulty Magazine: A worn or damaged magazine can cause rounds to misfeed or fail to load properly into the chamber.

- Extractor Issues: The extractor may become worn or clogged, leading to failed ejections of spent casings.

- Weak Springs: Springs that are too weak or worn out can affect the cycling process, preventing the firearm from fully cycling after each shot.

Accuracy and Alignment Problems

Another issue that can degrade performance is related to the alignment and condition of the barrel and other key components. Over time, these parts can shift or degrade:

- Barrel Wear: Prolonged use can cause the barrel to wear down, which may lead to decreased accuracy and inconsistent shot placement.

- Loose Screws: Components such as the stock, trigger assembly, and sights may loosen over time, affecting the overall alignment and causing a decline in accuracy.

Regular cleaning, inspection, and timely replacement of worn-out parts can prevent many of these issues and help maintain optimal performance of the rifle.

Maintaining Your Marlin Rifle

Proper care and upkeep of your firearm are essential for ensuring long-lasting performance and safety. Regular maintenance helps preserve its functionality, accuracy, and overall reliability. By following a consistent cleaning routine and performing basic checks, you can significantly extend the life of your rifle while ensuring it’s always ready for use.

Cleaning and Lubrication

The most fundamental aspect of rifle maintenance is thorough cleaning. After each use, it’s important to remove any residue or debris left in the barrel and internal components. Using the correct cleaning tools, such as a cleaning rod, brushes, and solvent, will prevent rust and buildup that can negatively affect accuracy. Once cleaned, applying a light layer of lubricant to moving parts will ensure smooth operation and prevent wear.

Routine Inspections

Beyond cleaning, regular inspection of your firearm’s key components is crucial. Check the receiver, trigger mechanism, and stock for any signs of wear, cracks, or loose screws. Make sure the action cycles smoothly, and that the sights or scope are properly aligned. Tightening any loose parts and replacing worn-out springs or components will keep the rifle functioning at its best.

Remember, safety should always be a priority when performing any maintenance. Always ensure the firearm is unloaded before starting any work, and wear protective gloves if necessary to avoid injury from sharp edges or solvents.

Where to Find Replacement Parts

When your firearm requires repairs or upkeep, finding the correct components is crucial for maintaining performance and safety. Whether you’re restoring an older model or upgrading your gear, locating reliable sources for the necessary pieces can sometimes be challenging. Fortunately, there are several trusted places where enthusiasts and professionals alike can find what they need to keep their weapons in optimal condition.

Authorized Dealers are one of the most reliable sources for original components. These establishments typically carry genuine replacements that ensure proper fit and function, preserving the integrity of your firearm. They are often backed by the manufacturer’s warranty and support services, which adds an extra layer of trust when making a purchase.

Another excellent option is online retailers. Many websites specialize in firearm components, offering detailed catalogs and easy search options to help you find specific pieces. These platforms can be particularly helpful as they provide access to a broad range of products and sometimes even discontinued or hard-to-find items.

If you’re looking for something more specialized, local gun shops may offer both new and used items. These stores often have experienced staff who can guide you in the right direction, making them a valuable resource for both amateur and seasoned gun owners.

Lastly, gun shows are another venue where firearm parts can be found. These events bring together vendors, collectors, and experts who may have exactly what you’re looking for, sometimes at competitive prices. However, it’s important to verify the condition and authenticity of the components before making a purchase at these venues.

Disassembly and Reassembly Guide

Disassembling and reassembling a firearm requires careful attention and precision. The process involves systematically removing components, cleaning or replacing parts, and then reassembling the firearm to its original working condition. Proper handling and organization of each part during these stages is crucial to ensure smooth operation and safety when the firearm is put back together.

Step 1: Safety First

Before beginning, ensure the firearm is unloaded and that no ammunition is in the vicinity. Always handle the firearm with caution, following safety protocols to prevent accidents.

Step 2: Disassembly

Start by removing the magazine and clearing the chamber. Use appropriate tools to carefully detach the stock, barrel, and receiver. It is essential to keep track of screws, pins, and springs as you go along. A small container or parts tray can help organize these small pieces, preventing loss or damage.

Step 3: Cleaning and Inspection

Once disassembled, each component should be thoroughly cleaned. Look for signs of wear, rust, or damage on the metal parts. Ensure that all springs, pins, and moving parts are in good condition and replace any damaged components.

Step 4: Reassembly

Begin the reassembly process by reversing the disassembly steps. Carefully align and fit each part back into its original position. Pay close attention to the correct placement of springs and pins, ensuring everything is securely fastened. Double-check that all parts are properly seated before moving on to the next step.

Step 5: Final Inspection and Testing

After reassembling, inspect the firearm for any misalignments or loose components. Perform a function check to ensure everything operates correctly. Verify the safety mechanisms and ensure the firearm is safe to handle and use.

Upgrading Your Model 60 Parts

Improving the components of your firearm can significantly enhance its performance, reliability, and longevity. Whether you’re aiming for smoother operation, better accuracy, or increased durability, upgrading certain elements can make a noticeable difference. With the right modifications, you can tailor your weapon to meet your specific needs and preferences, making each shot count more effectively.

When considering enhancements, it’s important to evaluate the key areas where improvements will yield the most benefit. Upgrades may involve replacing older or worn-out pieces with more robust alternatives or adding specialized features that optimize functionality. The right adjustments can elevate your shooting experience, whether it’s for competitive sports, hunting, or personal defense.

Many enthusiasts choose to replace trigger mechanisms, enhance the feed system, or add aftermarket sights to achieve quicker target acquisition and greater precision. Additionally, refining the barrel or recoil spring may contribute to more consistent performance. The possibilities for upgrades are vast, depending on your intended use and the level of enhancement you’re seeking.

Before embarking on any modifications, always ensure that the new components are compatible with your specific model and that they are installed correctly. Proper installation is crucial for maintaining safety, as improper upgrades may compromise the firearm’s operation and overall integrity. By carefully selecting and installing high-quality upgrades, you can unlock a new level of performance and enjoyment from your equipment.

Tips for Troubleshooting Marlin 60

When dealing with a malfunctioning firearm, it’s essential to carefully diagnose and resolve the issue methodically. Identifying the root cause of a problem can prevent unnecessary repairs and improve the longevity of the weapon. Below are some practical tips that can help you troubleshoot common issues and get your equipment back in working order quickly.

Check the Ammunition

One of the simplest yet often overlooked causes of malfunction is the ammunition itself. Make sure you are using the correct type and caliber of cartridges. Also, check for any visible signs of wear or damage on the rounds. Damaged ammunition can cause feeding or firing failures. Additionally, consider trying a different brand or batch to rule out any inconsistency in performance.

Inspect the Feeding Mechanism

If you’re experiencing failures to feed or eject, the feeding mechanism might be at fault. Ensure that all components involved in the cycle are clean and lubricated. Pay particular attention to any buildup of dirt or debris, which can impede movement. If the issue persists, inspect the magazine and loading tube for any bends or damage that may be affecting the flow of rounds.

Tip: Regularly clean and maintain the internal mechanisms to avoid malfunctions. Proper lubrication can help ensure smooth operation and prevent wear over time.

Examine the Trigger and Action

If your weapon fails to fire despite pulling the trigger, check for any mechanical issues in the trigger assembly. Look for worn-out springs, misalignments, or obstructions in the trigger mechanism. A malfunction in this area can result in a failure to discharge the round even if the rest of the system appears intact.

Key Point: Ensure that all internal springs and pins are correctly positioned and not showing signs of excessive wear. If the problem seems persistent, a professional inspection may be necessary.