The world of agricultural machinery is a complex web of various elements working in harmony to ensure efficiency and productivity. Each individual component plays a crucial role in the overall functionality of these powerful machines. Understanding these essentials is vital for anyone involved in the maintenance or operation of farming equipment.

Within this intricate system, specific elements contribute to the seamless operation, enhancing performance and durability. From the driving mechanisms to the control units, every segment is engineered for optimal interaction, ensuring that tasks are completed effectively and with minimal downtime. This knowledge empowers operators to make informed decisions regarding care and troubleshooting.

Exploring the structure and function of these essential units not only enhances operational expertise but also fosters a deeper appreciation for the engineering that supports modern agriculture. By delving into the intricacies of these components, individuals can gain valuable insights that translate into better management practices and improved productivity on the field.

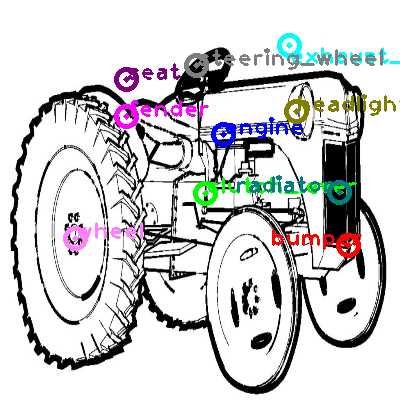

Understanding Tractor Components

The efficiency of agricultural machinery relies heavily on the intricate assembly of its various elements. Each component plays a critical role in ensuring optimal performance, contributing to the overall functionality and effectiveness of the equipment. By examining these elements, one gains insight into how they interact to facilitate seamless operation in the field.

Main Elements

At the core of any agricultural machine are the essential elements that enable mobility, power transmission, and operational control. Understanding the significance of each part allows operators to appreciate their contributions and maintain the machinery effectively.

| Component | Function |

|---|---|

| Engine | Generates power to drive the machine. |

| Chassis | Provides structural support and stability. |

| Transmission | Transfers power from the engine to the wheels. |

| Hydraulic System | Facilitates movement and control of implements. |

Importance of Maintenance

Regular upkeep of each individual element is crucial for the longevity and reliability of the machine. Neglecting maintenance can lead to decreased efficiency, increased downtime, and costly repairs. Familiarity with these components not only aids in proactive management but also enhances overall operational success.

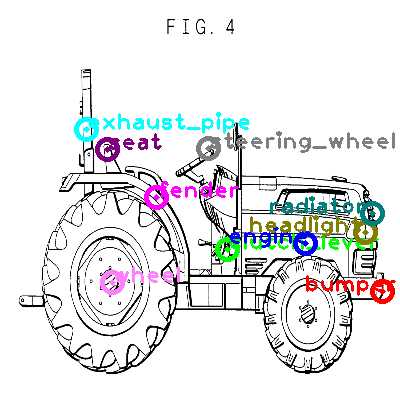

Essential Parts of a Tractor

Understanding the key components of agricultural machinery is crucial for efficient operation and maintenance. Each element plays a vital role in enhancing performance and ensuring reliability during farming tasks.

Core Components

- Engine: The powerhouse that provides the necessary energy for movement and operation.

- Transmission: Facilitates the transfer of power from the engine to the wheels, enabling various speed settings.

- Chassis: The structural framework that supports all other components and ensures stability.

- Hydraulic System: Essential for powering attachments and implements, allowing for various tasks such as lifting and digging.

- Wheels: Provide traction and stability, critical for maneuverability across diverse terrains.

Auxiliary Features

- Cab: The operator’s space, designed for comfort and control during operation.

- Cooling System: Prevents overheating by regulating the engine temperature.

- Fuel System: Stores and delivers the necessary energy to the engine for operation.

- Electrical System: Powers lights, ignition, and other electronic components essential for modern machinery.

- Implement Mounts: Facilitate the attachment of various tools and accessories, enhancing functionality.

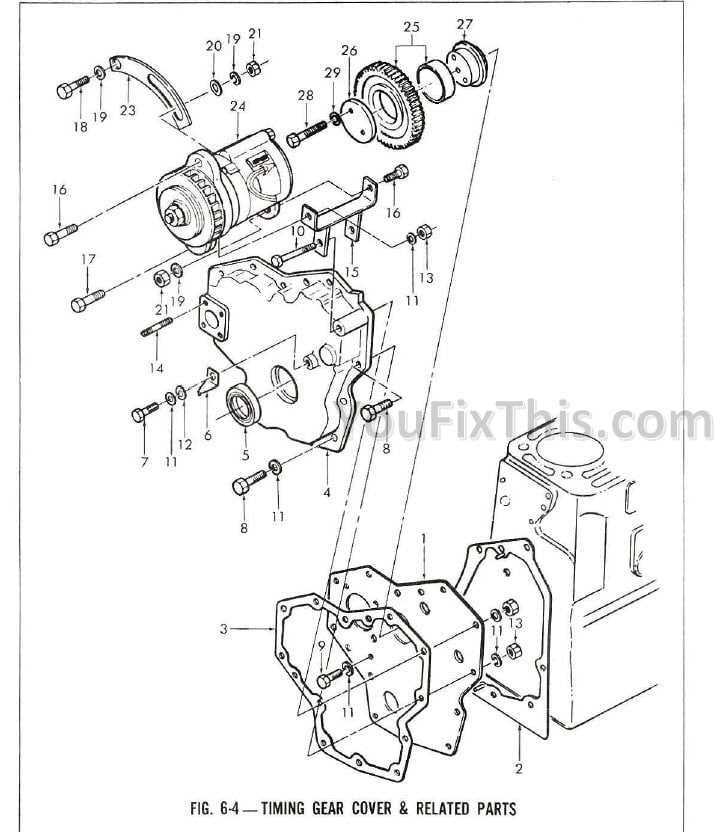

Functions of the Engine System

The engine system serves as the heart of heavy machinery, transforming fuel into mechanical energy to power various operations. This complex assembly is crucial for driving movement and ensuring efficient performance across diverse tasks. Its effective functionality directly impacts productivity and operational reliability.

| Function | Description |

|---|---|

| Energy Conversion | Transforms fuel into kinetic energy to initiate movement. |

| Power Generation | Supplies the necessary power to operate attachments and perform tasks. |

| Cooling | Maintains optimal operating temperature to prevent overheating. |

| Lubrication | Reduces friction between moving components to ensure smooth operation. |

| Emission Control | Minimizes harmful emissions through advanced exhaust management systems. |

Role of the Transmission Mechanism

The transmission mechanism serves as a vital link between the power source and the driving wheels, facilitating the transfer of energy efficiently. Its function is to adapt the engine’s output to the needs of the vehicle, ensuring optimal performance across various operating conditions. This adaptability is crucial for achieving desired speed and torque while maintaining fuel efficiency.

In essence, the transmission mechanism is responsible for converting the rotational power generated by the engine into a form that can effectively propel the vehicle. This involves not only transferring power but also modifying it to suit different driving scenarios, such as starting from a standstill or climbing steep inclines.

| Function | Description |

|---|---|

| Power Transfer | Transmits energy from the engine to the wheels. |

| Speed Adjustment | Modifies engine output to match vehicle speed requirements. |

| Torque Control | Regulates torque to enhance performance in various conditions. |

| Efficiency Optimization | Improves fuel efficiency by adapting power delivery. |

Understanding the significance of this mechanism is essential for anyone involved in the design, maintenance, or operation of these vehicles. Its role is integral to ensuring reliability and performance, making it a cornerstone of efficient machinery.

Importance of the Hydraulics System

The hydraulic system plays a crucial role in the functionality and efficiency of various machinery. By utilizing fluid power, it enables the transfer of force, facilitating smooth and powerful movements necessary for different operations. This system enhances the overall performance, allowing for precise control and responsiveness in challenging environments.

One of the key advantages of hydraulics is its ability to generate significant force with minimal physical effort. This characteristic makes it essential for tasks that require heavy lifting or complex maneuvering. Moreover, the system’s adaptability allows it to be integrated into a wide range of applications, from construction to agriculture, maximizing productivity and efficiency.

Regular maintenance and monitoring of the hydraulic system are vital for ensuring its longevity and optimal performance. Issues such as leaks or pressure drops can lead to decreased effectiveness and increased operational costs. By prioritizing the health of this system, operators can achieve reliable results and prolong the lifespan of their machinery.

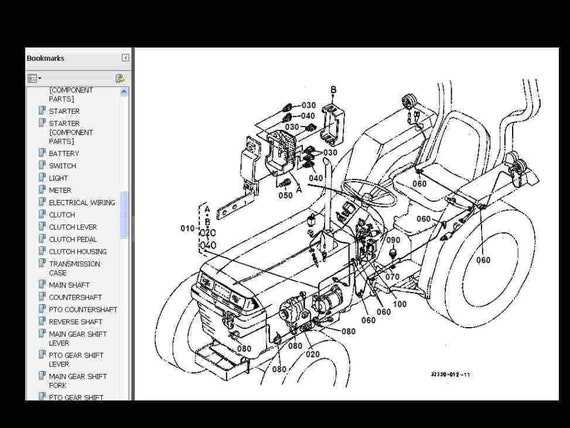

Overview of the Electrical System

The electrical system plays a crucial role in the functionality and efficiency of heavy machinery. It encompasses a network of components designed to manage power distribution, control systems, and operational features, ensuring that various mechanisms work harmoniously. This interconnected setup not only powers the engine but also supports auxiliary systems, enhancing overall performance.

Main Components

A well-designed electrical system ensures reliable starting, efficient operation of implements, and the effectiveness of safety features. It plays a vital role in monitoring performance metrics and providing diagnostic information, which is essential for maintenance and troubleshooting. Understanding these functions helps operators maximize the utility of their equipment. The structural foundation of any agricultural vehicle is crucial for its performance and durability. This section delves into the key components that provide stability and support, ensuring efficient operation in various environments. Understanding these elements is essential for anyone involved in maintenance or design. Wheels play a crucial role in the performance and efficiency of various agricultural and industrial vehicles. Their design and characteristics directly influence traction, stability, and the overall handling of the machine in different terrains. Understanding the various wheel types and their specific functions can significantly enhance operational effectiveness and vehicle adaptability. Standard rubber wheels are commonly used for paved and hard surfaces, providing excellent grip and comfort during operation. They are designed to absorb shocks and vibrations, making them suitable for high-speed tasks. On the other hand, wider wheels are often employed in softer, muddy conditions, as they distribute weight more evenly, reducing ground pressure and preventing the vehicle from sinking. Metal wheels or tracks are ideal for extreme terrains, such as rocky or heavily saturated grounds. Their robust construction allows for improved traction and durability, making them perfect for heavy-duty applications. Additionally, these wheels can navigate rough surfaces more effectively than traditional designs. Specialized designs, such as turf-friendly wheels, are created for sensitive environments, ensuring minimal damage to grass or soil. These wheels often feature a unique tread pattern that balances grip and surface protection, making them suitable for maintenance tasks in parks and sports fields. In conclusion, selecting the appropriate wheel type is essential for optimizing performance across various environments. Each design serves a distinct purpose, and understanding these functionalities can lead to improved efficiency and effectiveness in operational tasks. Ensuring the longevity and efficiency of agricultural machinery requires regular upkeep and attention to specific components. Proper maintenance not only enhances performance but also prevents unexpected breakdowns, saving time and resources in the long run. Here are some essential guidelines to keep in mind for effective maintenance. Conducting routine examinations of the machinery’s essential elements is crucial. Look for signs of wear and tear, such as cracks, leaks, or unusual noises. Regular checks help identify potential issues before they escalate, ensuring smooth operation. Pay attention to filters, belts, and fluids, as these areas often require more frequent monitoring. Keeping machinery clean and well-lubricated is vital for optimal performance. Dirt and debris can accumulate and lead to corrosion or mechanical failures. Make it a habit to clean various surfaces regularly and apply appropriate lubricants to moving parts. This practice reduces friction, enhances efficiency, and prolongs the life of the equipment.Tractor Chassis and Frame Details

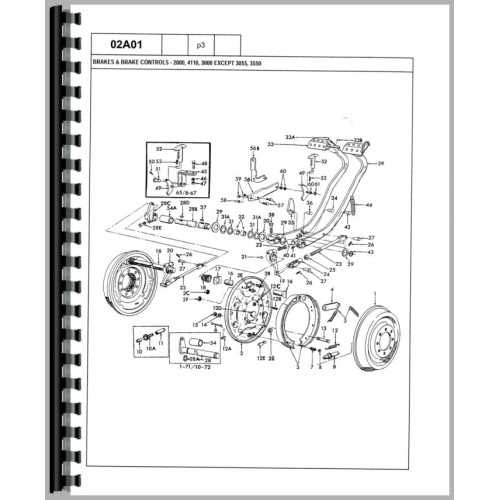

Key Components

Considerations for Maintenance

Wheel Types and Their Functions

Maintenance Tips for Tractor Parts

Regular Inspections

Lubrication and Cleaning