In the realm of farming equipment, the intricate design and functionality of machinery play a crucial role in enhancing productivity and efficiency. Proper comprehension of each element within these machines allows operators to maintain optimal performance and minimize downtime. An insightful exploration of these components reveals their interrelationships and the impact they have on the overall operation.

Every piece of equipment is composed of various essential elements, each contributing to the machine’s capabilities. Familiarity with these individual parts enables users to identify potential issues, ensuring timely repairs and replacements. By dissecting the assembly, users can appreciate the engineering ingenuity that goes into creating robust and reliable machinery tailored for agricultural tasks.

Understanding the layout of these components not only aids in maintenance but also empowers users to make informed decisions regarding upgrades and modifications. Knowledge of the specific roles and functions of each part enhances the operator’s ability to troubleshoot effectively, leading to improved operational efficiency. As we delve deeper into this subject, the significance of comprehending each aspect of the machinery becomes increasingly apparent.

Understanding the Ford 1920 Tractor Parts Layout

In order to fully appreciate the intricacies of this agricultural machine, it is essential to explore its structural arrangement. The configuration reveals how each component interacts with the others, contributing to the overall functionality and efficiency of the equipment.

The layout comprises various systems, including the engine, transmission, and hydraulic components, each serving a distinct purpose. Analyzing these sections helps users identify potential areas for maintenance and upgrades, ensuring optimal performance over time.

Each assembly is designed with precision, showcasing the importance of engineering in agricultural machinery. Familiarity with the layout allows operators to troubleshoot issues effectively and make informed decisions regarding repairs or enhancements.

Ultimately, understanding the arrangement of the various elements empowers users to maintain their equipment better, ensuring reliability and longevity in the field. This knowledge also enhances the ability to recognize and address common challenges that may arise during operation.

Key Components of the Ford 1920 Tractor

Understanding the essential elements of a specific agricultural machine is crucial for effective maintenance and operation. Each component plays a vital role in ensuring that the machine functions smoothly and efficiently. This section will explore the critical features that contribute to the overall performance of this versatile agricultural implement.

Engine and Powertrain

The heart of the implement lies in its robust engine, which provides the necessary power for various tasks. The powertrain system, including the transmission and drive components, ensures that the power generated is efficiently transferred to the wheels. This synergy allows for optimal maneuverability and productivity in the field.

Hydraulic System

A reliable hydraulic system is fundamental for operating implements and attachments. This system controls various functions, including lifting and lowering tools, making it indispensable for enhancing the machine’s versatility. The hydraulic components must be well-maintained to prevent leaks and ensure smooth operation.

By recognizing these essential elements, operators can appreciate the intricate design and functionality of this agricultural machine, leading to better maintenance practices and improved performance in the field.

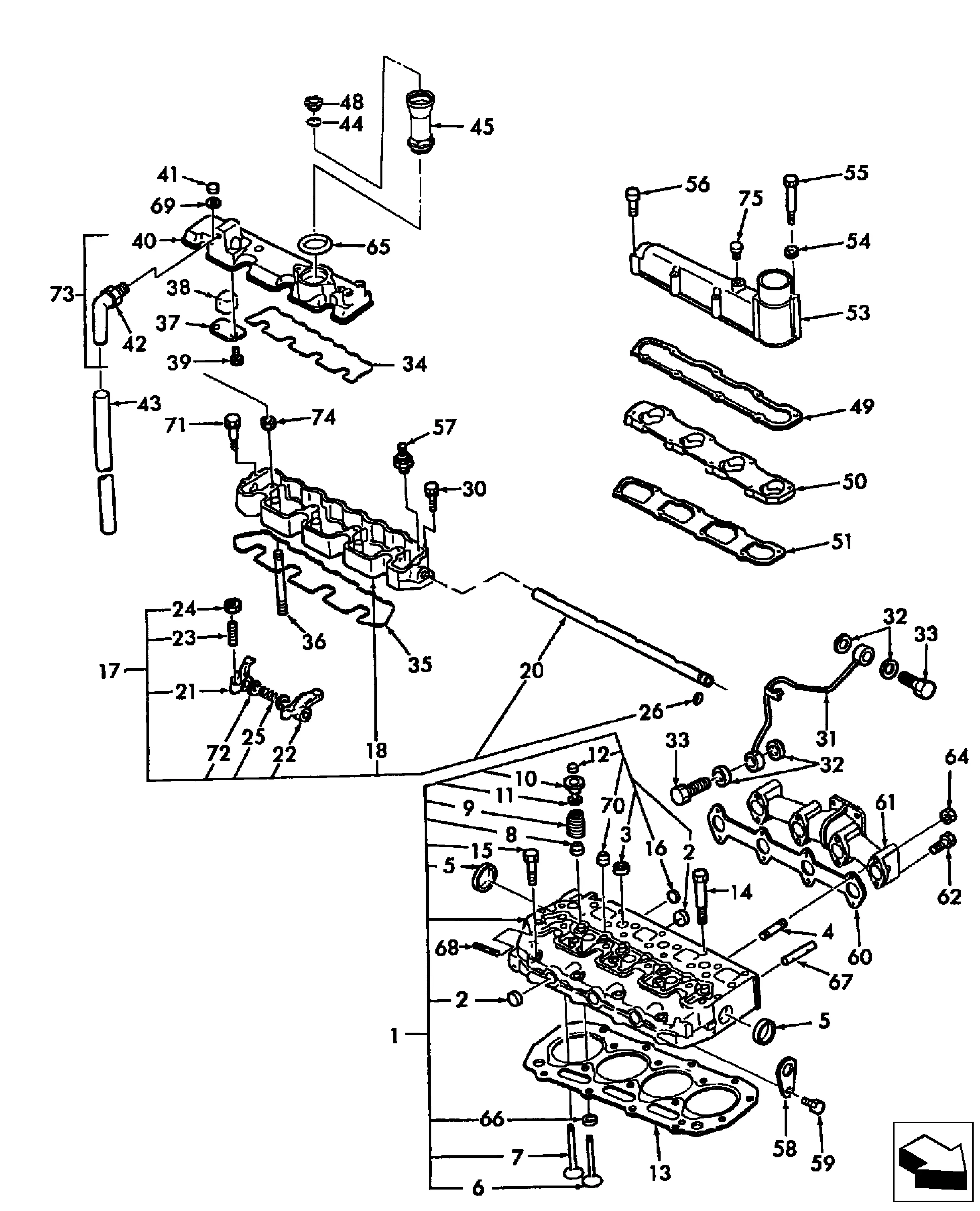

How to Identify Ford 1920 Engine Parts

Recognizing components of an engine is essential for effective maintenance and repair. Understanding the different elements and their functions allows for efficient troubleshooting and ensures optimal performance. This guide provides insights into identifying various engine elements, facilitating informed decisions when it comes to service and replacement.

Understanding Component Functions

Each element within the engine serves a specific purpose, contributing to the overall functionality. Familiarize yourself with the main components, such as the crankshaft, pistons, and camshaft. Knowledge of their roles will help you diagnose issues more effectively. For instance, if you notice unusual noises, you might suspect a problem with the crankshaft or associated bearings.

Using Reference Resources

Utilizing reference materials can greatly assist in identifying the correct components. Service manuals, online databases, and specialized forums provide detailed information, including images and specifications. Cross-referencing with these resources will enhance your ability to recognize components accurately and ensure you procure the right replacements when needed.

Ford 1920 Tractor Transmission System Overview

The transmission system plays a crucial role in any agricultural machinery, ensuring that power generated by the engine is effectively transmitted to the wheels for optimal performance. This component is responsible for controlling the speed and torque, allowing operators to adjust their work according to various field conditions. Understanding its structure and function can enhance the efficiency of the machine and prolong its lifespan.

Key Components of the Transmission System

At the heart of the transmission system lies a series of gears that work in unison to provide the desired speed and torque output. These gears are housed within a robust casing, designed to withstand the rigors of agricultural use. The system typically includes a clutch mechanism that allows for smooth engagement and disengagement of power, providing greater control over the operation. Additionally, hydraulic components may be integrated to enhance performance, facilitating easier shifts between gears and improving overall functionality.

Operating Principles

The operation of the transmission system is based on the principle of mechanical advantage, allowing the engine’s rotational energy to be transformed into the necessary force to move the machine. By selecting different gear ratios, operators can optimize performance for various tasks, such as plowing, tilling, or transporting goods. Proper maintenance and timely adjustments to this system are essential for ensuring reliable operation and avoiding costly repairs, thereby maximizing productivity during farming activities.

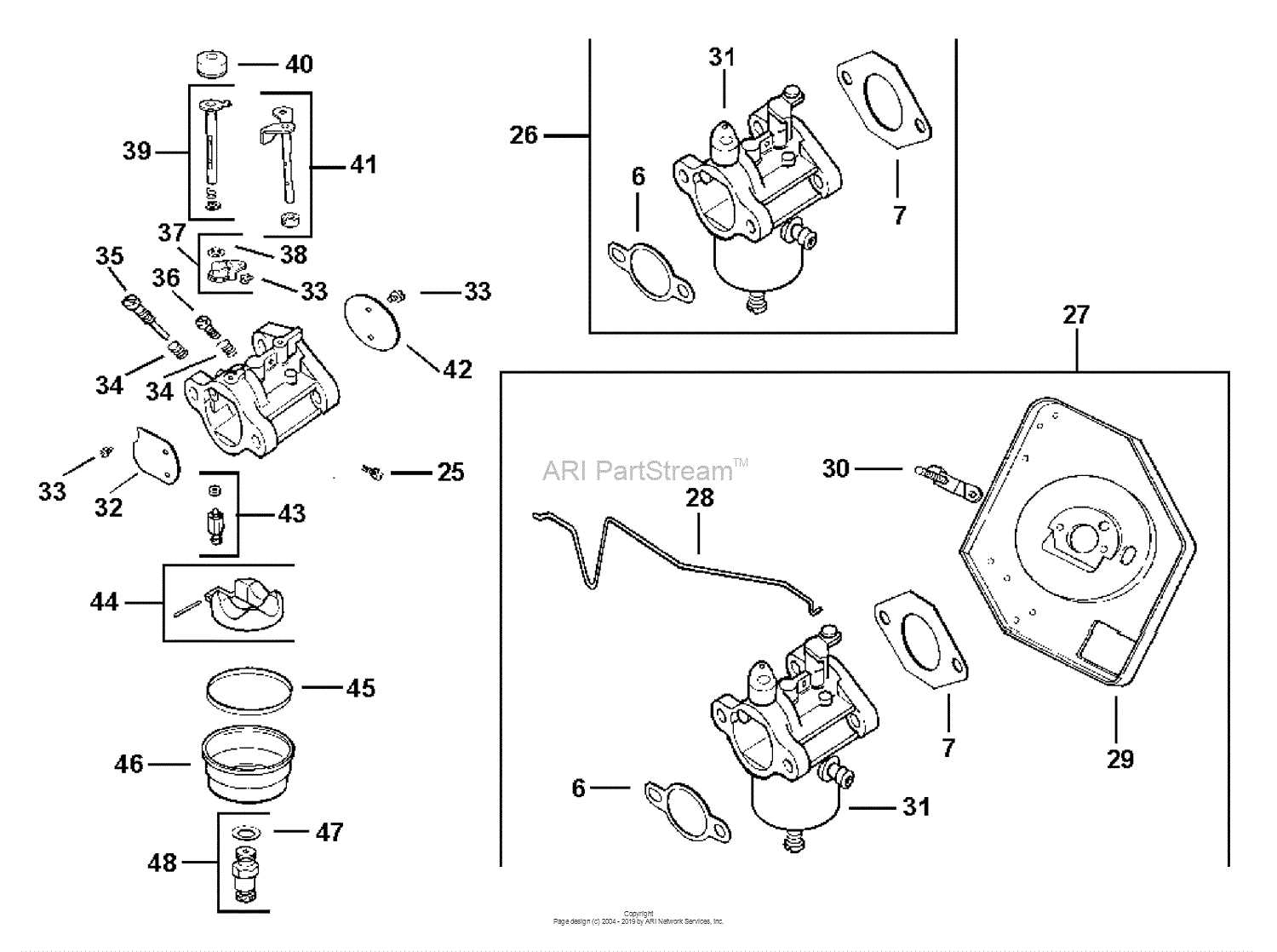

Examining the Ford 1920 Hydraulic System

The hydraulic mechanism in agricultural machinery plays a crucial role in enhancing functionality and efficiency. This system is designed to facilitate various operations, providing the necessary force to lift and move heavy implements with ease. Understanding its components and operation can significantly improve maintenance practices and operational effectiveness.

At the core of the hydraulic system lies a pump that generates pressure, enabling the fluid to move through the system. This fluid is crucial for transmitting power to the hydraulic cylinders, which in turn perform lifting and lowering actions. The system comprises several key components that work in unison to ensure optimal performance.

| Component | Description |

|---|---|

| Hydraulic Pump | Generates pressure to move hydraulic fluid through the system. |

| Hydraulic Reservoir | Stores hydraulic fluid and maintains a consistent supply for the system. |

| Control Valve | Regulates the flow and direction of hydraulic fluid to various components. |

| Hydraulic Cylinders | Convert hydraulic energy into mechanical force to lift and lower implements. |

| Hydraulic Lines | Transport hydraulic fluid between the components, ensuring efficient operation. |

Regular inspection and maintenance of the hydraulic system are essential to prevent failures and ensure smooth operation. Common issues may include fluid leaks, pressure drops, and inefficient lifting capabilities. By addressing these problems promptly, operators can extend the lifespan of the machinery and enhance productivity in the field.

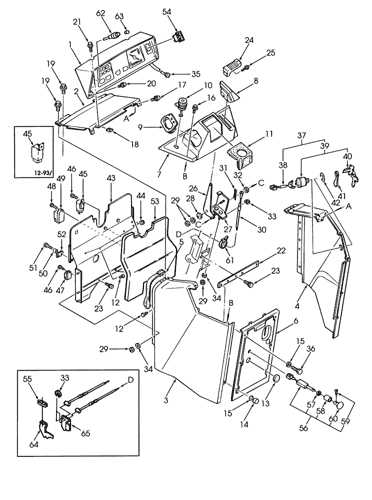

Brake and Steering Mechanisms of the Ford 1920

The braking and steering systems play a crucial role in ensuring the safety and maneuverability of any heavy machinery. In this segment, we will explore the essential components that contribute to the effective operation of these systems, emphasizing their functionality and interconnection. A thorough understanding of these mechanisms is vital for proper maintenance and operation, enhancing the overall performance and longevity of the equipment.

The braking system is designed to provide reliable stopping power, which is achieved through a combination of hydraulic and mechanical components. This system allows operators to exert control over the machine’s speed and movement, ensuring safe navigation on various terrains.

| Component | Description |

|---|---|

| Brake Pedal | Actuated by the operator’s foot, it engages the braking system to slow down or stop the machine. |

| Master Cylinder | Converts the force from the brake pedal into hydraulic pressure, facilitating brake engagement. |

| Brake Lines | Transmits hydraulic fluid from the master cylinder to the brake assemblies. |

| Brake Shoes | Press against the brake drum to create friction and slow down the machine. |

| Brake Drums | Part of the wheel assembly, they work in conjunction with brake shoes to halt movement. |

The steering mechanism allows for precise direction control, which is essential for navigating tight spaces and making sharp turns. Understanding the components involved in steering is equally important for effective operation.

| Component | Description |

|---|---|

| Steering Wheel | The primary interface for the operator to control the direction of the machine. |

| Steering Column | Connects the steering wheel to the gear mechanism, transmitting the operator’s inputs. |

| Steering Gearbox | Converts the rotational motion of the steering wheel into lateral movement. |

| Linkage Rods | Transfer motion from the gearbox to the front wheels, enabling directional changes. |

| Front Axle | Supports the weight of the machine and houses the wheels, allowing them to pivot during turns. |

In conclusion, understanding the intricacies of the braking and steering systems is essential for the safe and efficient operation of heavy machinery. Regular maintenance and checks are crucial

Common Ford 1920 Electrical Parts Explained

This section focuses on the essential electrical components that play a crucial role in the operation of heavy machinery. Understanding these elements is vital for maintaining efficiency and ensuring smooth functionality.

Here are some of the key electrical components found in these machines:

- Starter Motor: Responsible for initiating the engine’s operation, this component converts electrical energy into mechanical energy, allowing the engine to crank.

- Alternator: This device generates electrical power to recharge the battery and supply energy to the machine’s electrical systems while the engine is running.

- Battery: A vital source of energy, it stores electrical power necessary for starting the engine and powering accessories when the engine is not running.

- Ignition Switch: This component controls the electrical flow to the starter motor, allowing the operator to start and stop the engine.

- Wiring Harness: A collection of wires that connect various electrical components, ensuring that signals and power are transmitted efficiently throughout the machine.

- Fuses: These safety devices protect electrical circuits from overloads by breaking the circuit when excessive current flows, preventing potential damage.

Maintaining and understanding these electrical components is essential for reliable operation and longevity of the machinery. Regular checks and timely replacements can prevent failures and ensure optimal performance.

Ford 1920 Tractor Maintenance and Replacement Tips

Proper upkeep and timely substitutions are essential for the longevity and efficiency of any machinery. Regular attention not only enhances performance but also reduces the likelihood of unexpected failures. This section outlines crucial maintenance strategies and replacement advice for ensuring optimal functioning of your equipment.

Routine Maintenance Practices

Implementing a consistent maintenance schedule is vital. Begin with regular oil changes to ensure smooth engine operation. Additionally, inspect air filters periodically and replace them as needed to maintain optimal airflow. Regularly check fluid levels, including coolant and hydraulic fluids, to prevent overheating and system failures. Furthermore, ensure that the battery terminals are clean and connections secure to avoid electrical issues.

Replacement Recommendations

When it comes to replacements, always opt for high-quality components. Monitor tire wear and replace them promptly to maintain traction and stability. Keep an eye on belts and hoses, as they are prone to wear over time. Replace any that show signs of cracking or fraying. Finally, consider maintaining a stock of essential components to minimize downtime during critical repairs.

Where to Find Ford 1920 Tractor Diagrams

For those seeking detailed visuals and schematics for their machinery, various resources are available that can provide essential information. Whether you are a seasoned mechanic or a novice enthusiast, accessing accurate illustrations can significantly aid in maintenance and repairs. This section will guide you on where to locate these invaluable references.

One reliable source is the manufacturer’s official website, where you can often find comprehensive guides and technical documents. Additionally, online forums dedicated to agricultural machinery are excellent platforms for sharing resources, as fellow users frequently post links and images of relevant schematics. For those who prefer a more hands-on approach, local libraries or bookstores may have technical manuals that include the necessary visuals.

Specialized parts retailers and distributors also provide catalogs featuring detailed illustrations. These resources not only showcase component locations but often include installation instructions, making them perfect for DIY repairs. Lastly, video platforms can be a great help, with many mechanics sharing tutorials that visually guide you through the specific workings of the equipment.