For any gardening enthusiast or professional landscaper, maintaining the efficiency of your equipment is crucial. The intricacies of these machines can often be daunting, yet comprehending their various elements can significantly enhance their performance. This section delves into the essential components that make up these vital tools, offering insights that will empower users to troubleshoot and optimize their machinery.

Familiarity with the inner workings of your device not only ensures smoother operation but also aids in prolonging its lifespan. Each piece plays a specific role, contributing to the overall functionality and effectiveness of the equipment. By exploring these individual elements, you can better appreciate how they interact and support the tool’s capabilities.

Whether you’re a seasoned user or a novice, understanding these crucial aspects can elevate your gardening experience. This knowledge is instrumental in addressing issues as they arise and making informed decisions about maintenance and repairs. Engaging with the anatomy of your equipment opens up a world of possibilities for enhanced performance and productivity.

Understanding Swisher Trimmer Components

Grasping the various elements that make up these landscaping machines is essential for effective maintenance and operation. Each component plays a significant role in ensuring optimal performance and longevity.

| Component | Description |

|---|---|

| Engine | The powerhouse that drives the entire system, providing necessary energy. |

| Cutting Blade | Designed for precision, it is crucial for achieving clean and efficient cutting. |

| Handle | Facilitates user control and maneuverability during operation. |

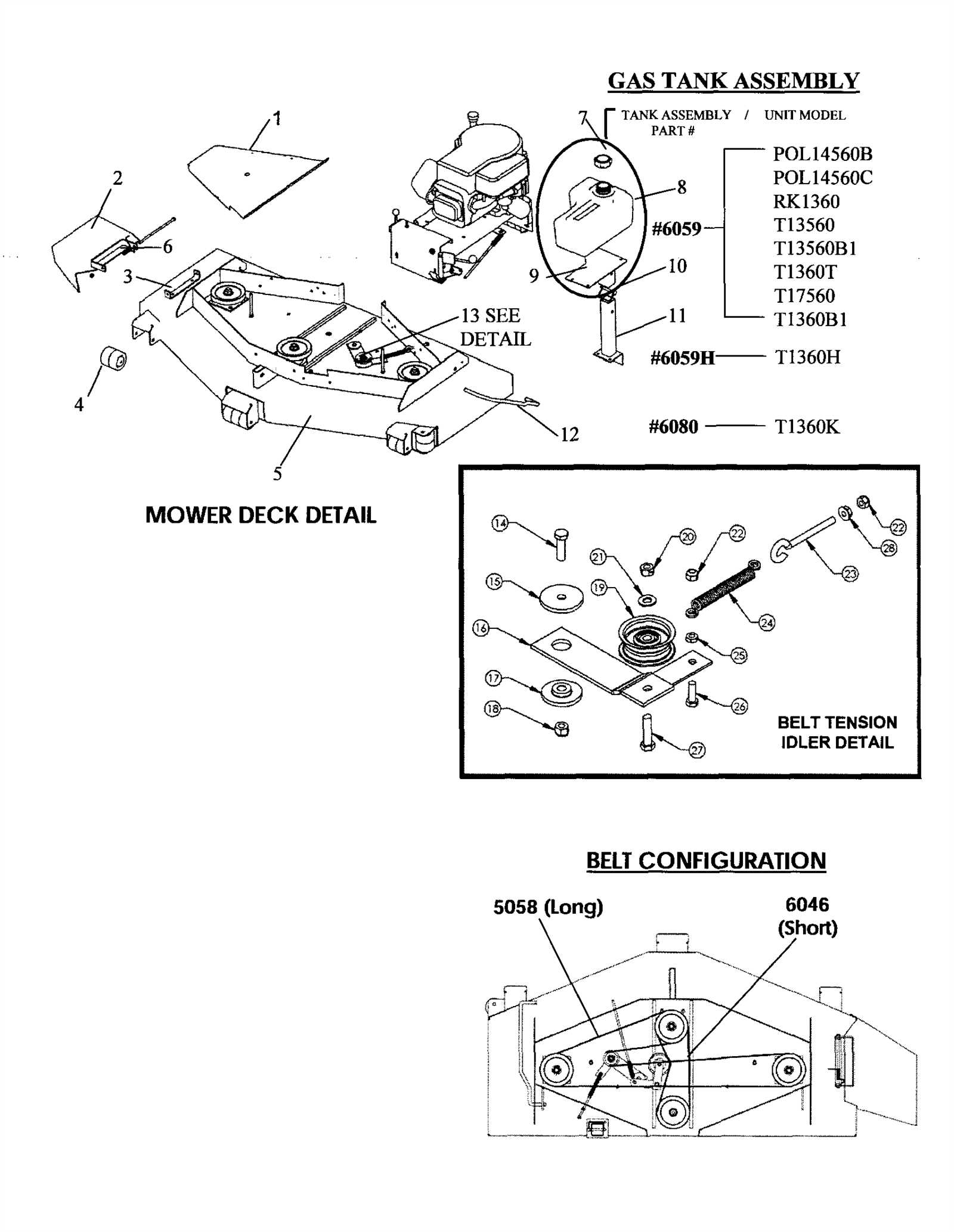

| Fuel Tank | Stores the energy source required for the engine to function. |

| Chassis | The framework that houses and supports all other components. |

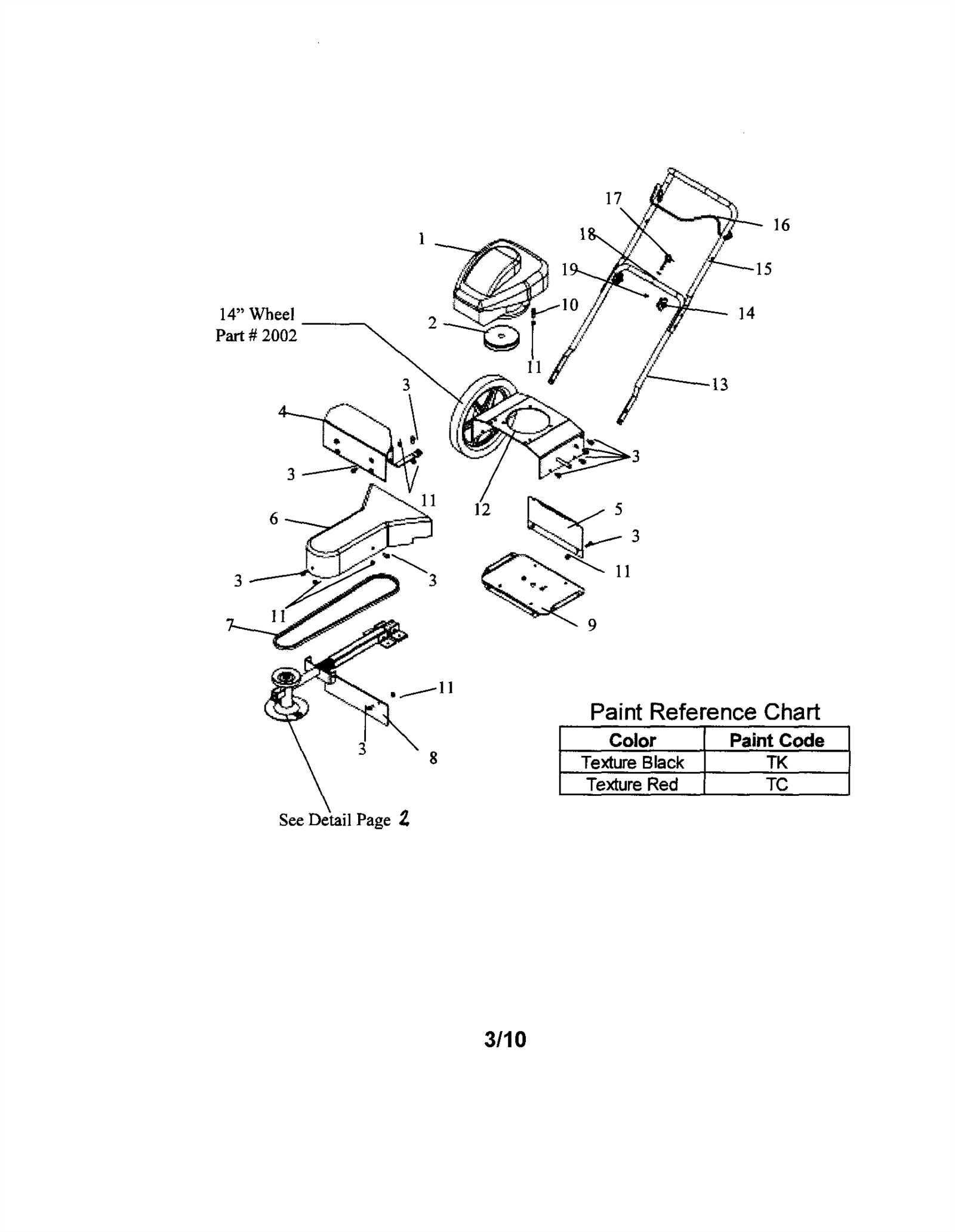

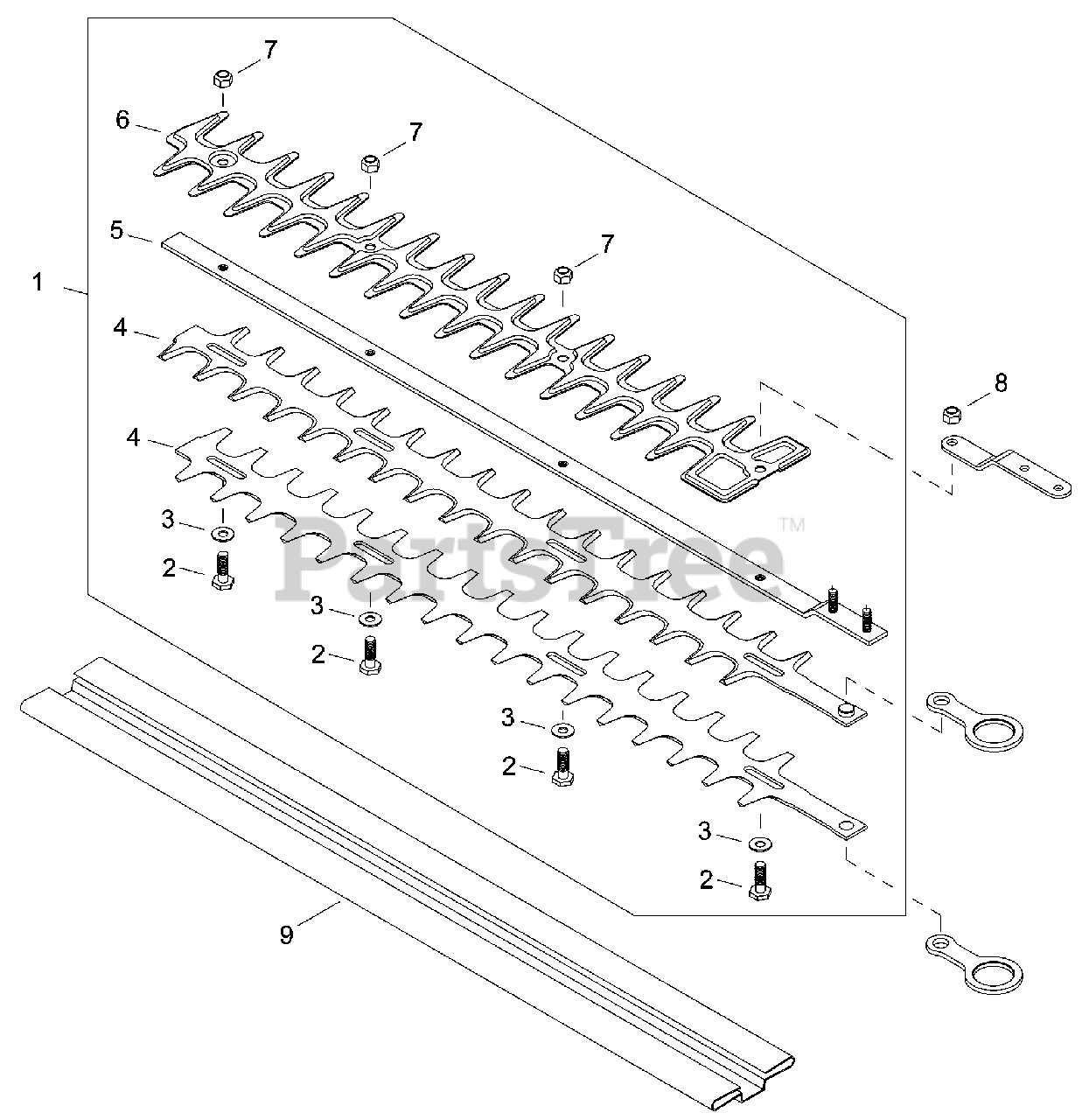

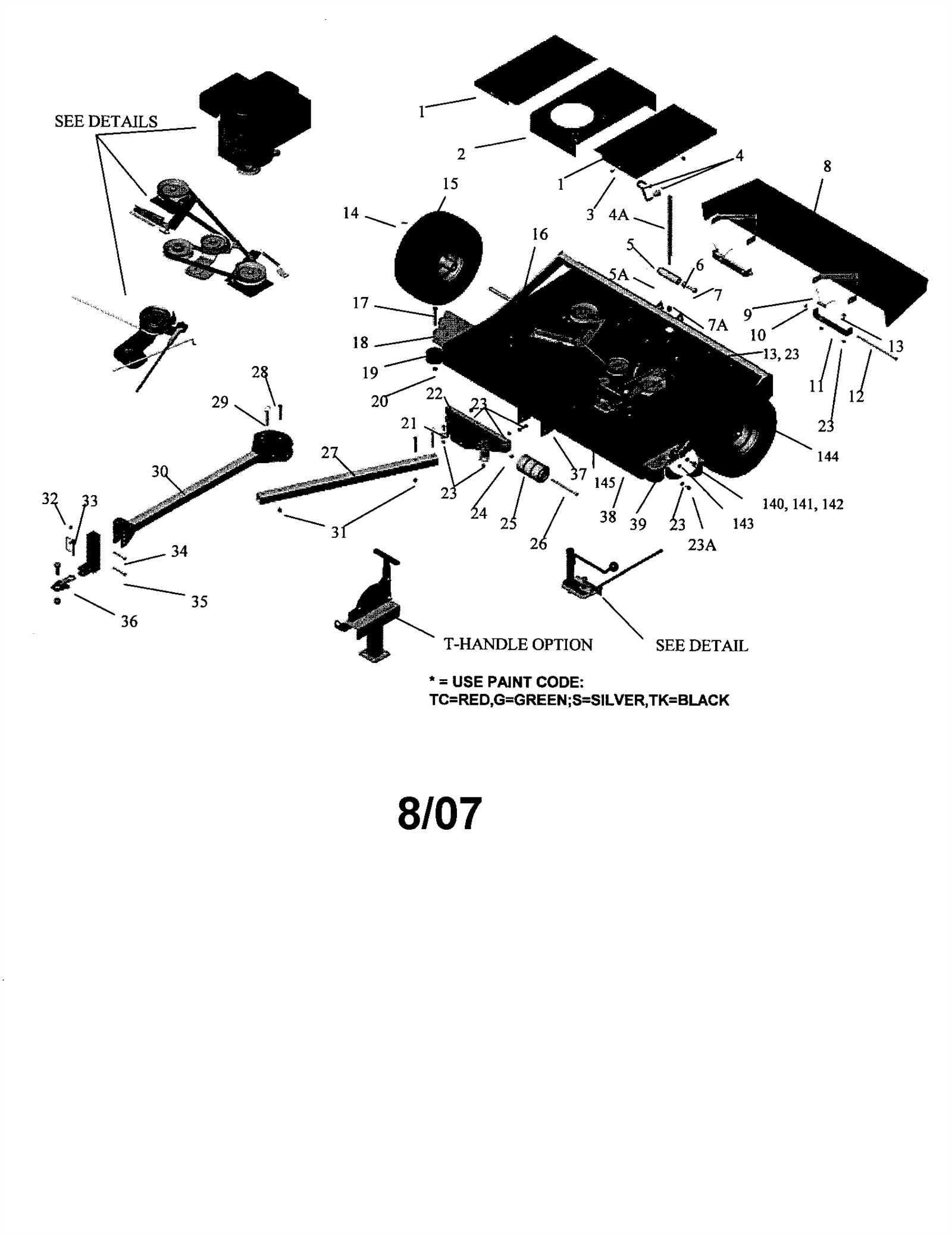

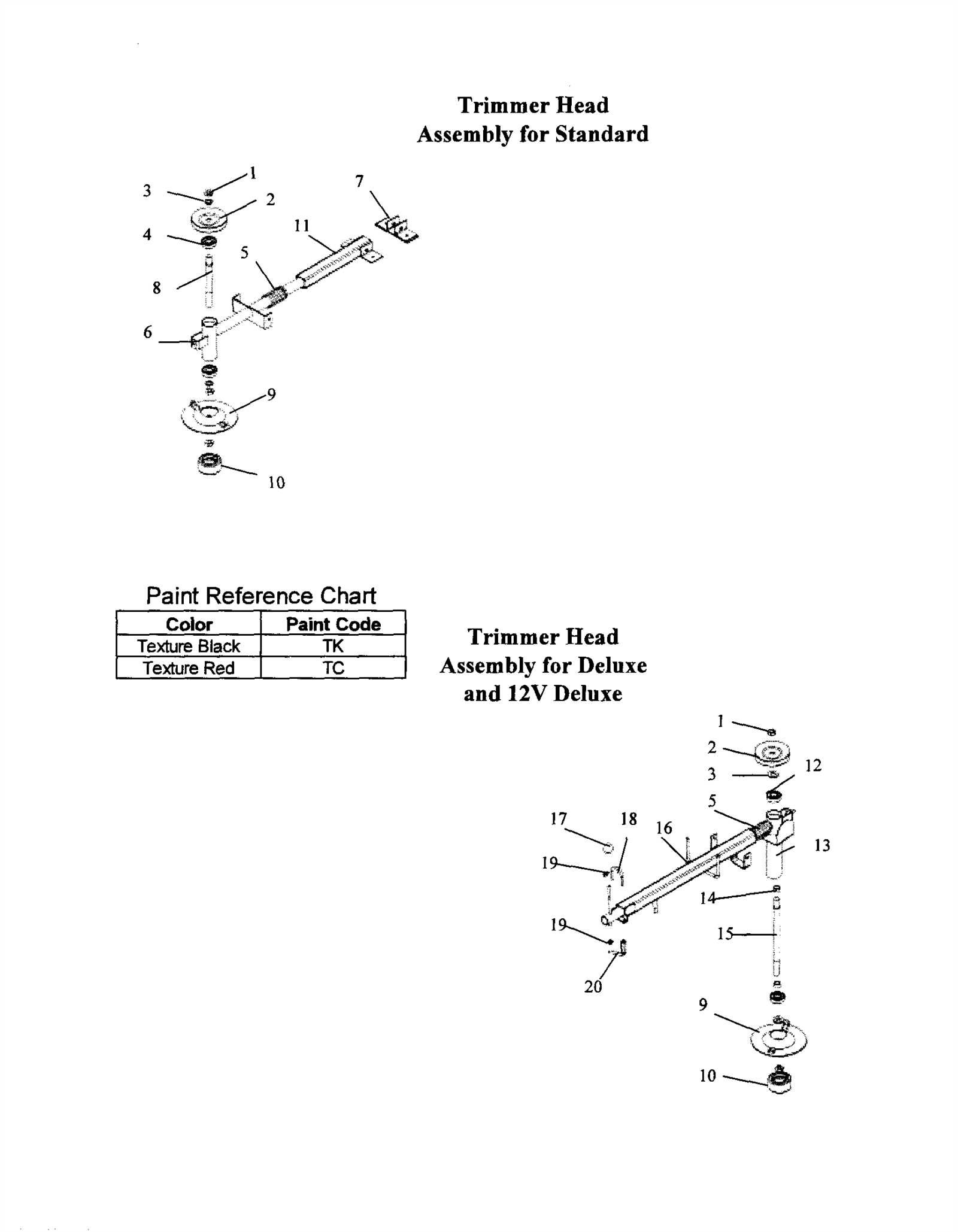

Importance of a Parts Diagram

A visual representation of components plays a crucial role in the maintenance and repair of machinery. It not only aids in identifying individual elements but also enhances understanding of their interactions within the system. Such an illustration simplifies troubleshooting processes, allowing users to quickly locate issues and implement necessary corrections.

Moreover, having a clear visual reference promotes efficiency. Technicians can easily reference the layout when ordering replacements or reassembling equipment, reducing downtime and ensuring that the machinery operates at peak performance. A well-structured illustration can also serve as a valuable educational tool, helping new users familiarize themselves with the machine’s configuration.

In addition, it fosters safety by clearly marking various parts and their functions, thereby minimizing the risk of mishandling during repairs. By providing a comprehensive overview, a visual guide becomes an indispensable resource for anyone involved in the upkeep of equipment.

Key Features of Swisher Trimmers

When it comes to maintaining a pristine outdoor environment, certain equipment stands out for its exceptional design and functionality. These machines are engineered to provide efficiency and reliability, making them indispensable for both professional landscapers and home gardeners alike.

Robust Construction: Built to withstand rigorous use, these machines feature durable materials that ensure longevity. The heavy-duty frame is designed to handle tough conditions, providing a solid foundation for consistent performance.

Versatile Cutting Options: With various attachments and adjustable settings, users can easily switch between different tasks. This adaptability allows for precision cutting in various environments, from gardens to larger fields.

User-Friendly Controls: Ergonomically designed handles and intuitive controls make operation straightforward, even for those new to outdoor maintenance. This accessibility enhances user experience, reducing fatigue during extended use.

Powerful Engine: Equipped with high-performance motors, these machines deliver robust power that ensures effective trimming. The efficient engines are designed to optimize fuel consumption, balancing performance with environmental considerations.

Safety Features: Safety is paramount, and these units come with built-in safety mechanisms to protect users during operation. Features such as automatic shut-off and reinforced shields provide peace of mind while working.

Overall, the combination of strength, versatility, ease of use, and safety makes these tools essential for achieving a well-manicured landscape efficiently and effectively.

Common Issues with Trimmer Parts

When maintaining outdoor equipment, users often encounter a range of challenges related to various components. Understanding these common issues can significantly enhance performance and longevity. By addressing these problems proactively, operators can ensure their machinery runs smoothly and efficiently.

Wear and Tear

One of the most frequent concerns is the natural degradation of components over time. Factors such as exposure to elements, frequent use, and improper maintenance contribute to wear and tear. This can result in decreased efficiency and performance, making it essential to regularly inspect and replace affected items to avoid further complications.

Clogging and Blockages

Another common issue arises from the accumulation of debris and residue. This can hinder the functionality of the equipment, leading to inefficient operation. Regular cleaning and maintenance are crucial to prevent clogs, ensuring that everything runs seamlessly and effectively. Staying vigilant about these factors can save time and resources in the long run.

How to Read Parts Diagrams

Understanding technical illustrations is crucial for efficient equipment maintenance and repairs. These visuals provide a detailed representation of various components, allowing users to identify and locate essential elements quickly. Mastering this skill can significantly enhance your ability to manage and troubleshoot machinery.

1. Familiarize Yourself with Symbols: Each illustration often employs specific icons and notations to signify different items. Take time to learn what these symbols represent, as they form the foundation of your comprehension.

2. Reference the Legend: Most technical visuals include a legend or key that explains the symbols and colors used. Refer to this section to clarify any uncertainties, ensuring accurate identification of the components.

3. Follow the Flow: Observe how the components are arranged and connected. Many illustrations depict the assembly in a logical sequence, which can help you understand how parts interact and function together.

4. Look for Annotations: Pay attention to any notes or labels accompanying the visual. These annotations often provide additional context, such as specifications or installation tips, which can be invaluable during repairs.

5. Cross-Reference with Manuals: For deeper understanding, compare the illustration with the equipment’s user manual. This cross-referencing can clarify any discrepancies and reinforce your knowledge of the system.

By mastering these techniques, you’ll improve your ability to interpret technical visuals, leading to more effective maintenance and repair practices.

Essential Maintenance Tips for Longevity

To ensure the extended lifespan and optimal performance of your outdoor equipment, regular upkeep is crucial. Implementing a routine maintenance schedule not only enhances efficiency but also prevents costly repairs down the line. By following these essential tips, you can keep your machinery in peak condition.

1. Regular Cleaning: After each use, it is important to remove debris and dirt from the machine. This prevents buildup that can affect performance and cause wear over time. Use a soft brush or cloth to wipe down all surfaces, ensuring that air vents and blades are clear.

2. Blade Maintenance: Keeping blades sharp is essential for effective cutting. Dull blades not only reduce efficiency but can also strain the engine. Regularly inspect and sharpen or replace blades as necessary. Additionally, ensure that blades are securely fastened before operation.

3. Lubrication: Moving parts require proper lubrication to function smoothly. Use the recommended oil type for your equipment and apply it to joints and pivot points as specified in the user manual. This reduces friction and helps prevent premature wear.

4. Fuel Care: Always use fresh fuel to avoid engine issues. Old or contaminated fuel can lead to poor performance and starting difficulties. If the equipment will not be used for an extended period, consider draining the fuel or adding a stabilizer to prevent degradation.

5. Storage Solutions: When not in use, store your equipment in a dry, sheltered area to protect it from the elements. Using a cover can further shield it from dust and moisture, which can lead to rust and corrosion.

By adhering to these maintenance guidelines, you can significantly extend the life of your outdoor machinery and ensure it operates efficiently for years to come.

Where to Find Replacement Parts

Locating suitable components for your equipment is essential for maintaining its performance and longevity. Various sources offer a range of options, ensuring you can find exactly what you need to keep your machinery in top condition.

- Manufacturer’s Website: The first place to check is often the official website of the manufacturer. They typically have a dedicated section for accessories and components, complete with diagrams and specifications.

- Authorized Dealers: Many manufacturers partner with authorized retailers. Visiting these dealers can provide access to genuine components, often with knowledgeable staff who can assist with your search.

- Online Marketplaces: Websites such as eBay, Amazon, and specialized online retailers often stock a variety of components. User reviews can help assess the quality of the items.

- Local Repair Shops: Many local shops that specialize in equipment repair may have the parts you need or can order them for you. This option also supports local businesses.

- Salvage Yards: For older models, checking salvage yards can yield valuable finds. You may discover functional components at a fraction of the original cost.

- Forums and Community Groups: Online forums and social media groups dedicated to machinery can be invaluable. Members often share resources and may have leads on where to find components.

lessCopy code

Using a combination of these resources will help ensure you find the right items to keep your equipment running smoothly.

Upgrading Your Trimmer: What to Consider

When enhancing your gardening equipment, several key factors come into play to ensure optimal performance and longevity. It’s essential to evaluate your current model’s capabilities and identify areas for improvement. Consideration of various aspects can lead to a more efficient and satisfying experience in your outdoor maintenance tasks.

| Factor | Description |

|---|---|

| Power Source | Evaluate whether electric, battery-operated, or gas options better suit your needs. |

| Cutting Width | A wider cutting area can increase efficiency but may be harder to maneuver. |

| Weight | Consider the balance between sturdiness and ease of handling for your specific tasks. |

| Durability | Look for materials that can withstand wear and environmental conditions. |

| Accessories | Explore available attachments that can enhance functionality for various jobs. |

Safety Precautions When Repairing Equipment

Ensuring safety during maintenance tasks is essential to prevent accidents and injuries. Proper precautions must be taken to create a secure working environment, allowing for efficient and safe handling of tools and machinery. Awareness of potential hazards and adherence to safety guidelines can significantly reduce risks associated with repairs.

Essential Safety Measures

Before starting any maintenance work, it’s crucial to implement the following safety measures:

| Measure | Description |

|---|---|

| Personal Protective Equipment (PPE) | Always wear appropriate gear, including gloves, goggles, and masks, to shield against debris and harmful substances. |

| Power Source Disconnection | Ensure all power sources are disconnected to prevent accidental startups during repairs. |

| Workspace Organization | Keep the work area tidy and free from clutter to minimize trip hazards and improve focus. |

| Tool Inspection | Regularly check tools for damage or wear, and use the correct tools for specific tasks to avoid mishaps. |

| Emergency Preparedness | Have a first aid kit and emergency contacts readily available in case of an accident. |

Additional Considerations

Stay informed about the equipment being repaired and follow manufacturer guidelines. Training in safe operation and maintenance practices can further enhance safety. Always seek assistance when uncertain about any procedure to avoid making mistakes that could lead to injury or equipment damage.