In the realm of heavy machinery, compact track loaders play a crucial role in various applications, from construction to landscaping. Their efficiency and versatility stem from a well-engineered system of interconnected elements that work harmoniously to perform a multitude of tasks. Grasping the intricacies of these components is essential for optimal operation and maintenance.

Whether you are a seasoned operator or a newcomer to the field, having a clear visual representation of the different sections and their functions can enhance your understanding of how this equipment functions. Each section is designed to fulfill specific roles, contributing to the loader’s overall performance and reliability. This insight can empower you to make informed decisions regarding repairs and upgrades, ensuring that your machinery remains in peak condition.

Additionally, familiarizing yourself with the layout and relationships between various parts can aid in troubleshooting issues that may arise during operation. By delving into the design and arrangement of these crucial elements, you can cultivate a deeper appreciation for the engineering prowess behind compact track loaders, ultimately leading to improved efficiency and productivity on the job site.

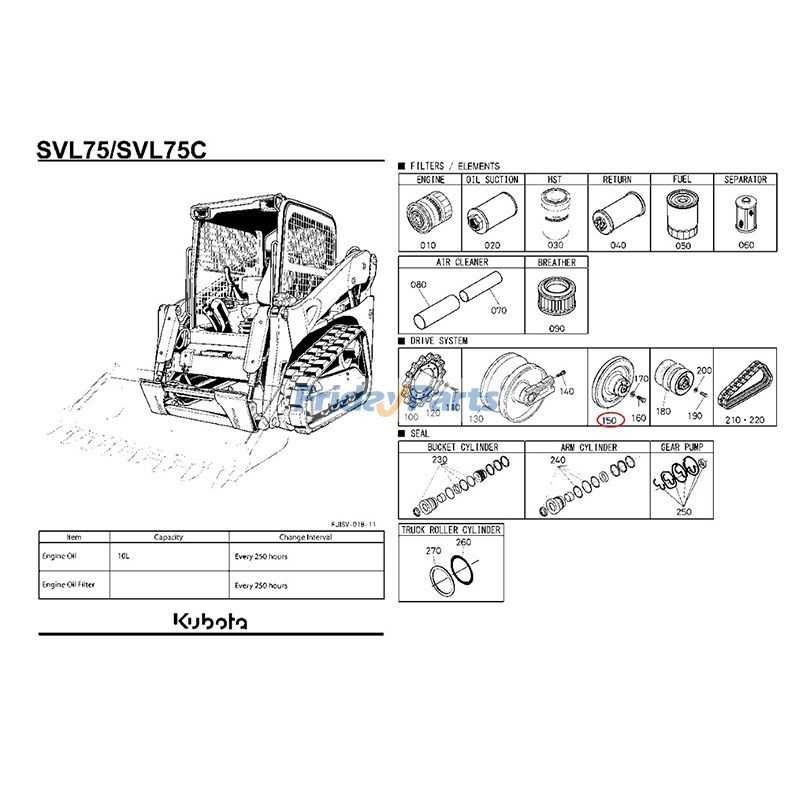

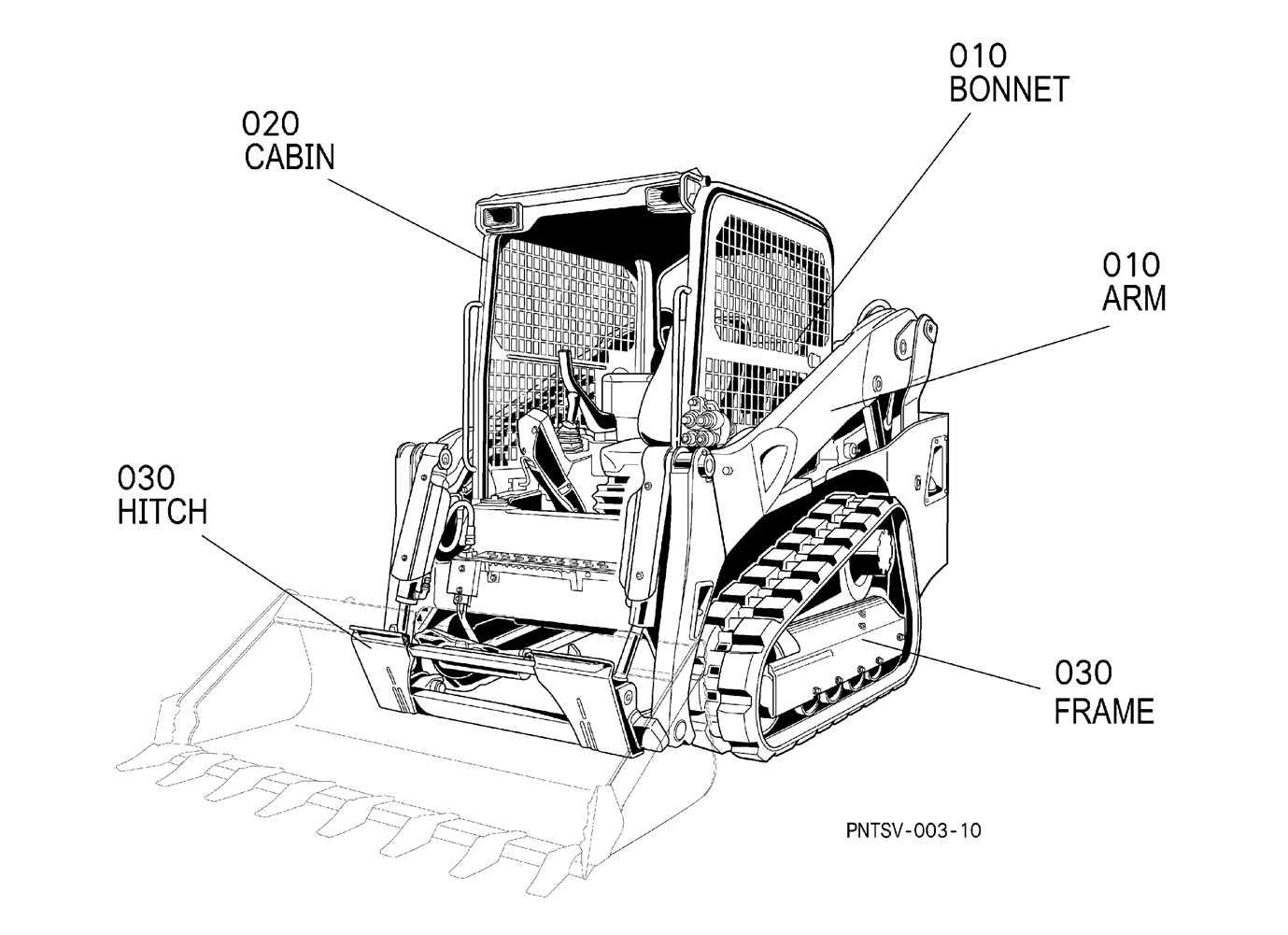

This section aims to provide a comprehensive understanding of a powerful machinery model designed for various tasks. By examining its components, users can gain insights into the structure and functionality of this robust equipment. Understanding the intricate elements of this model is essential for maintenance and optimal performance.

Key Features and Benefits

The machinery is renowned for its durability and efficiency, making it suitable for a wide range of applications. Its advanced engineering ensures reliability, while ergonomic design enhances user comfort. Regular maintenance and awareness of component functionality can significantly extend the lifespan of this heavy-duty vehicle.

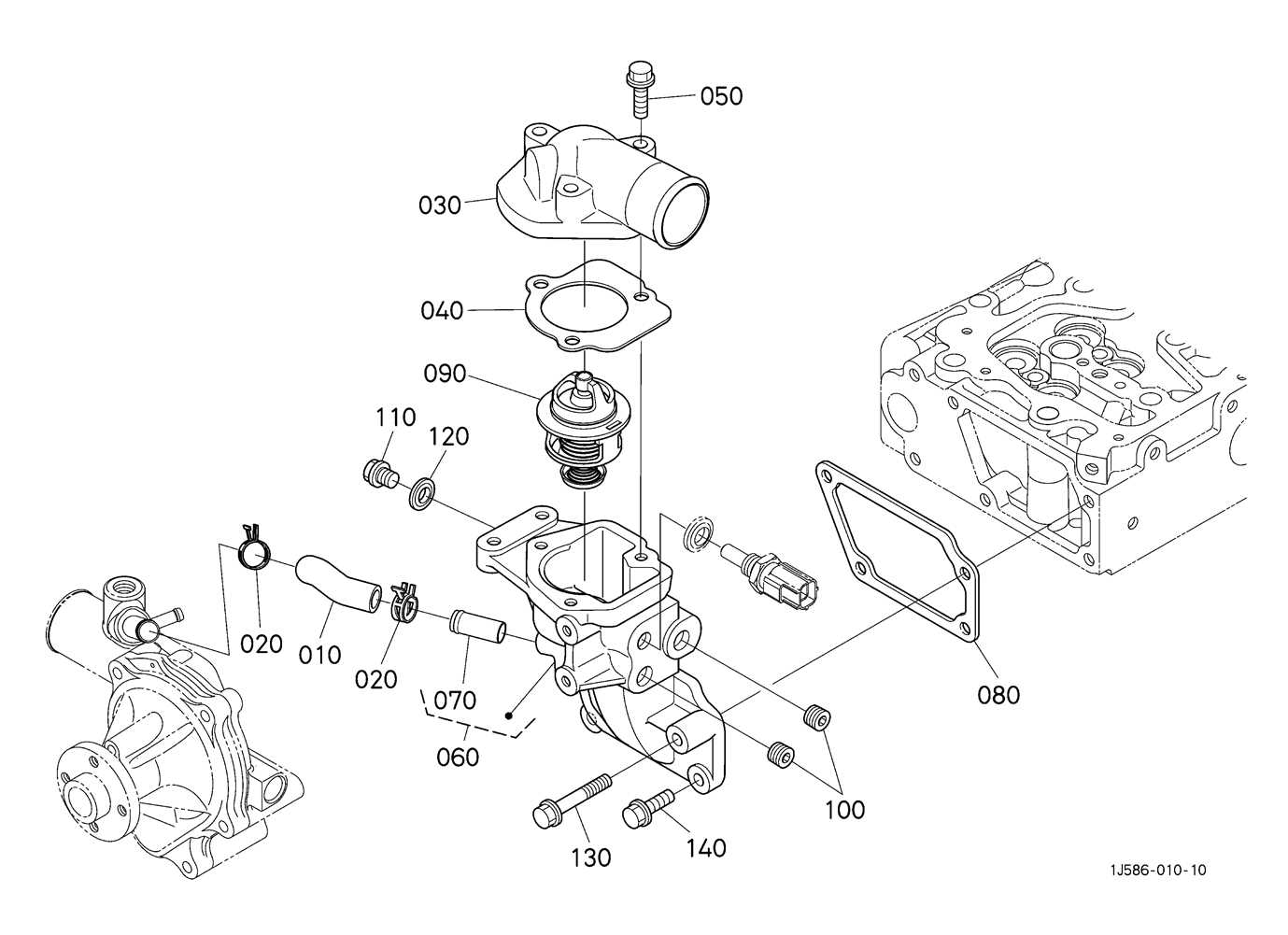

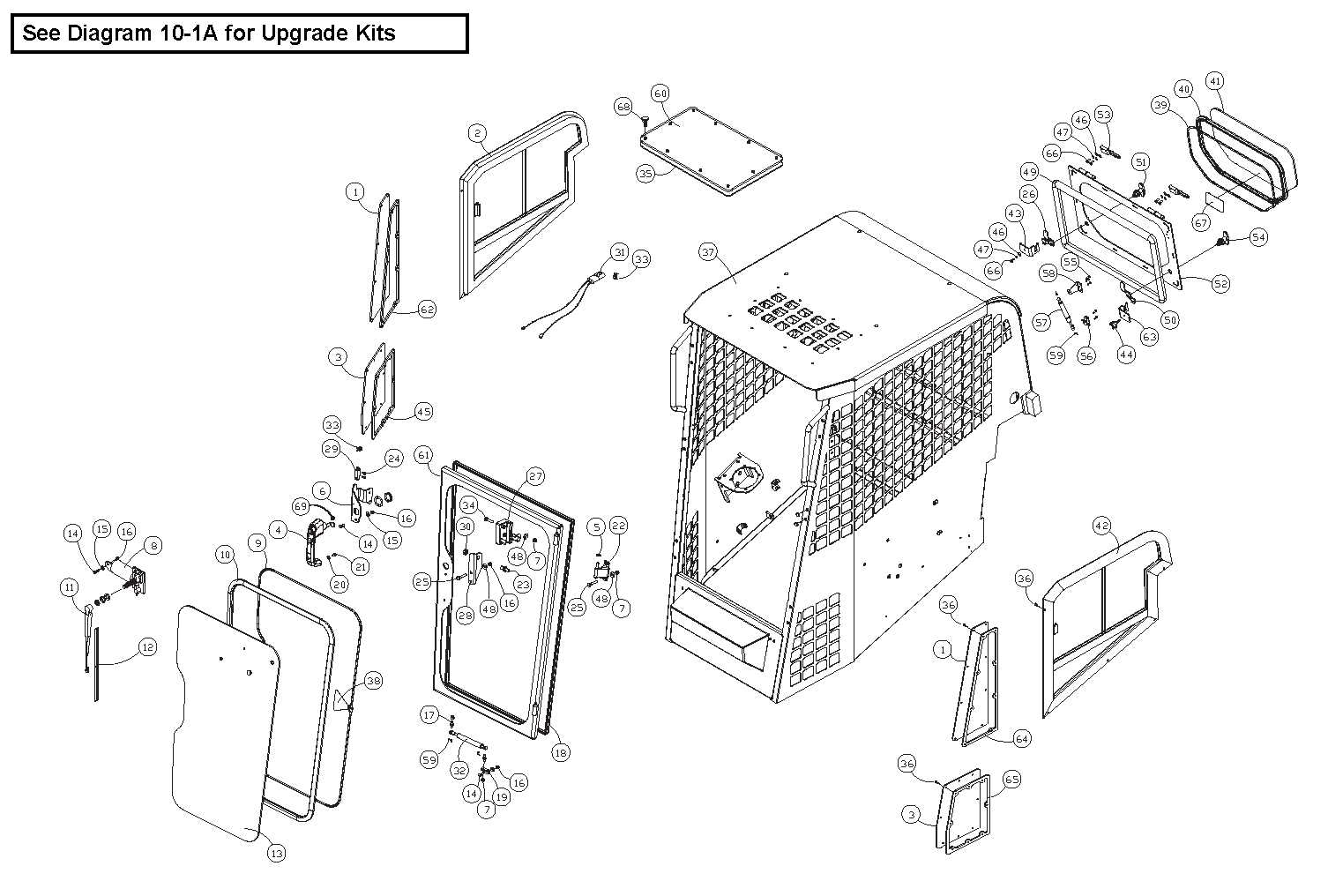

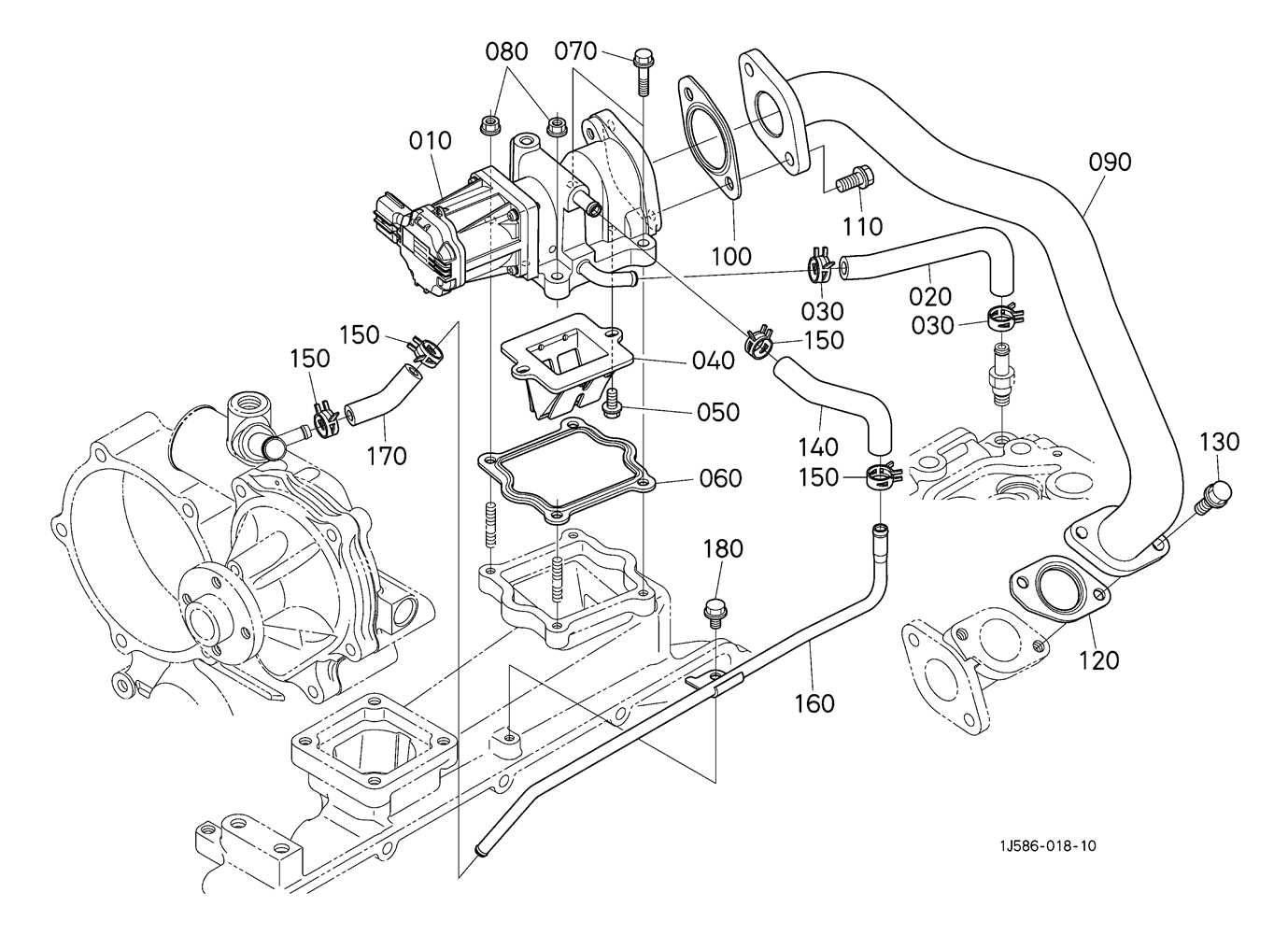

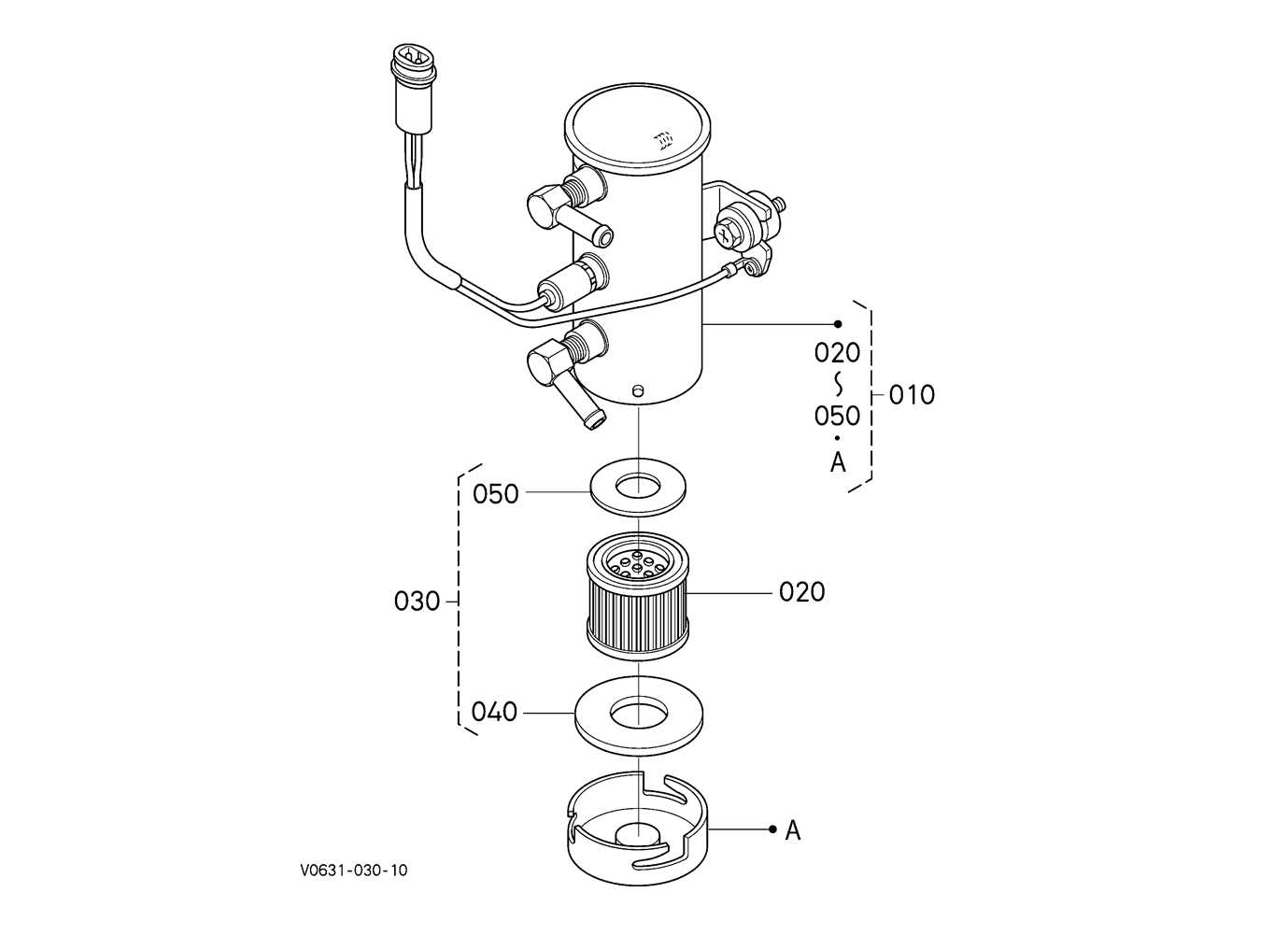

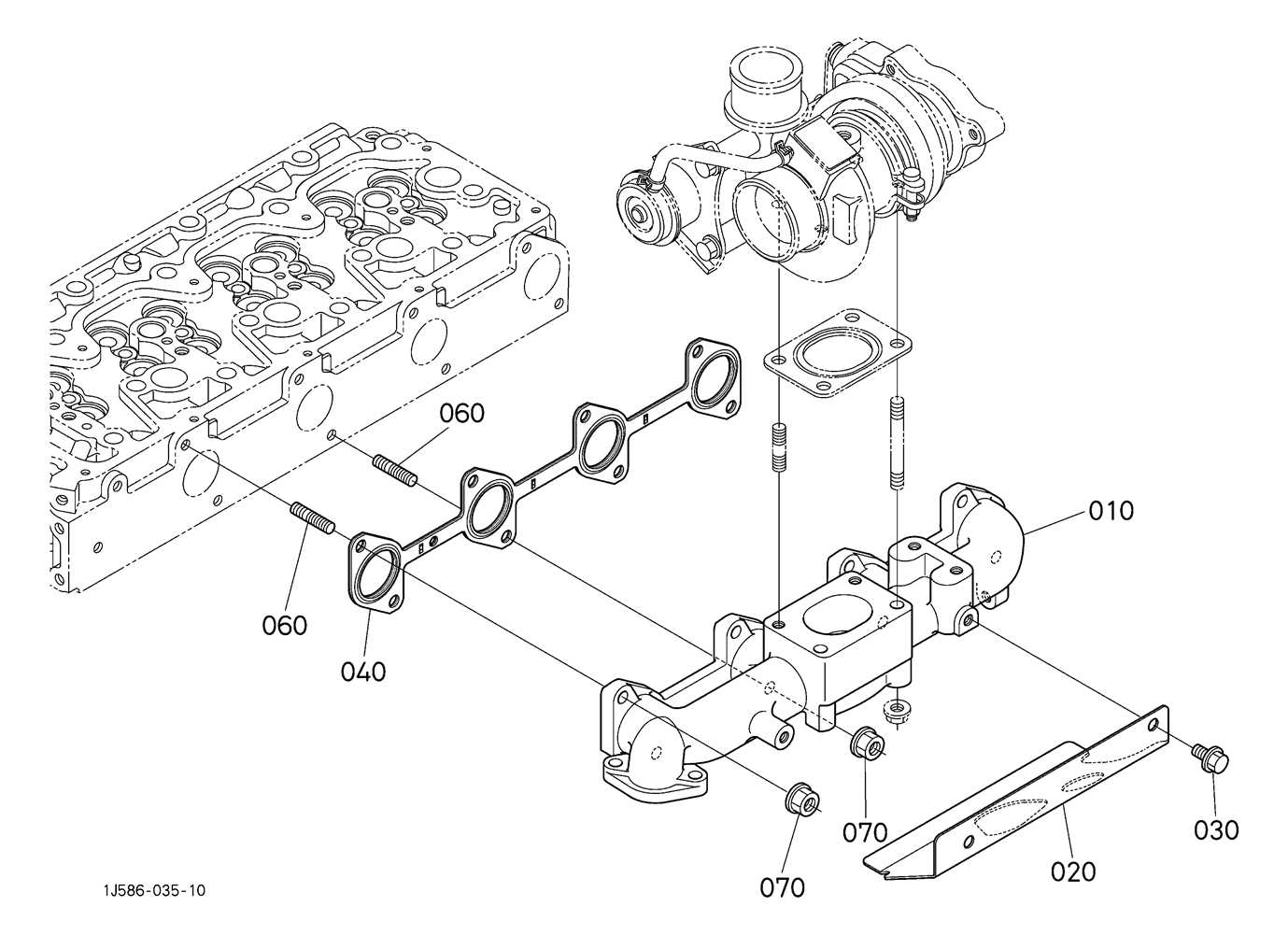

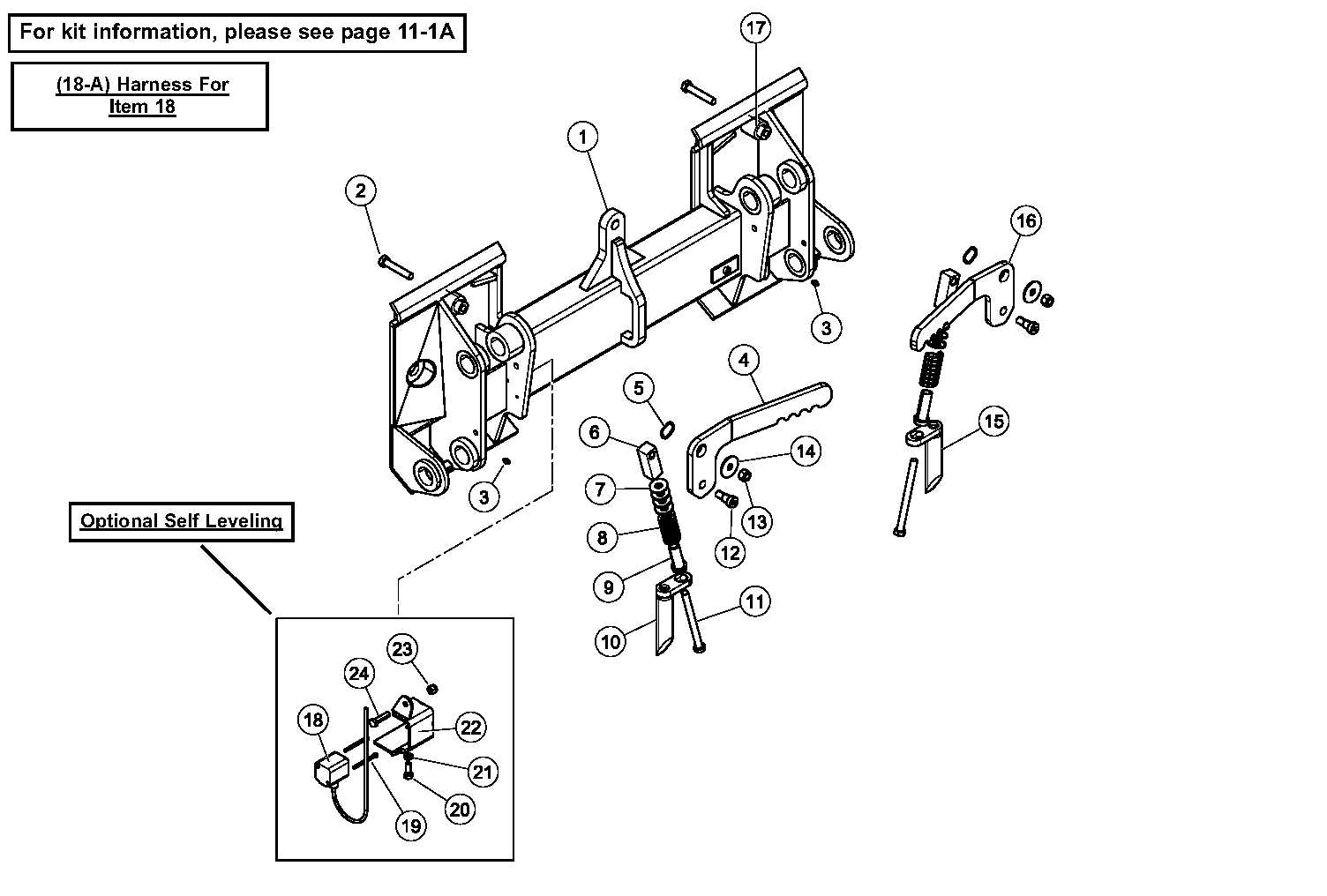

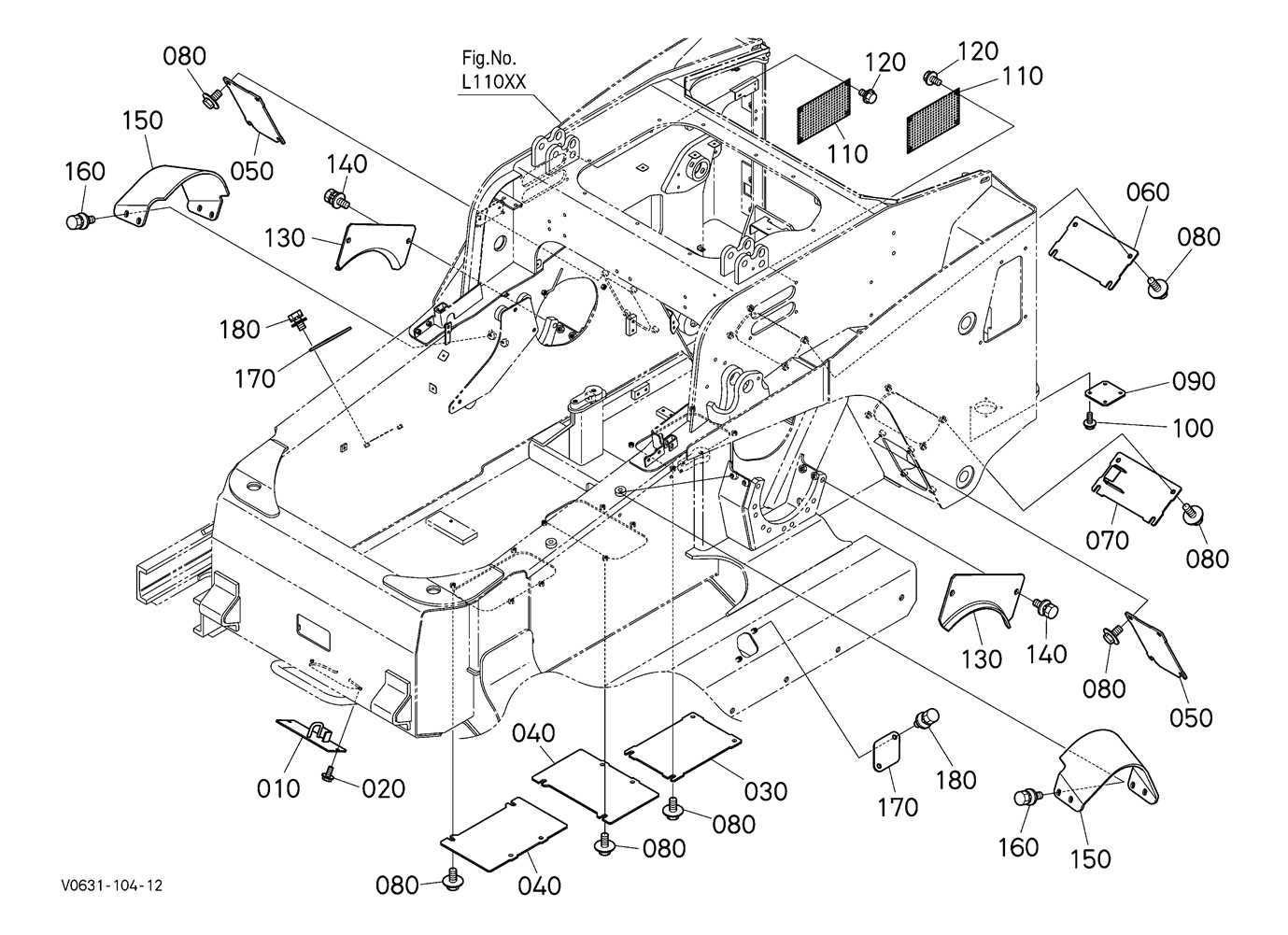

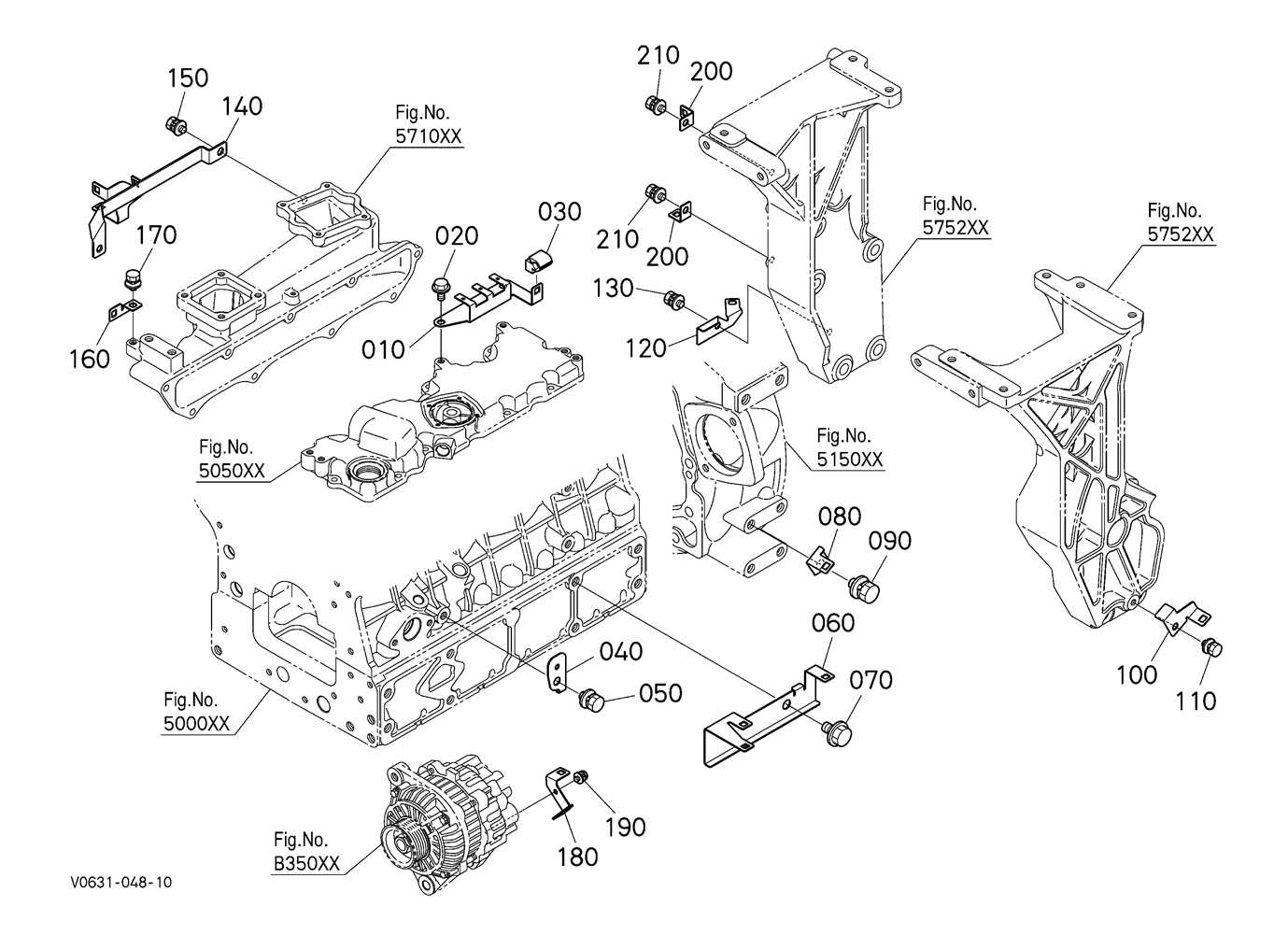

Understanding Component Layout

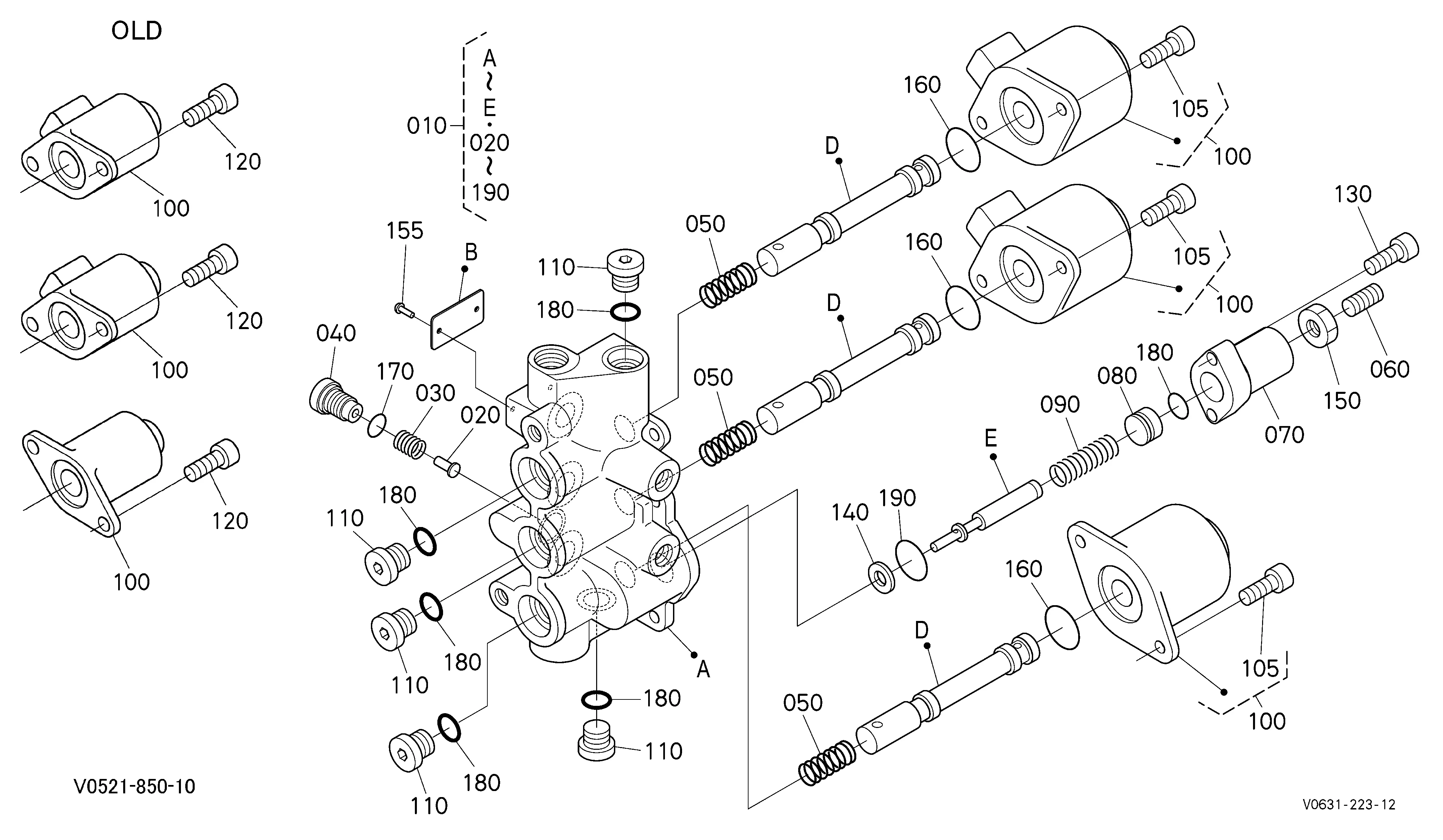

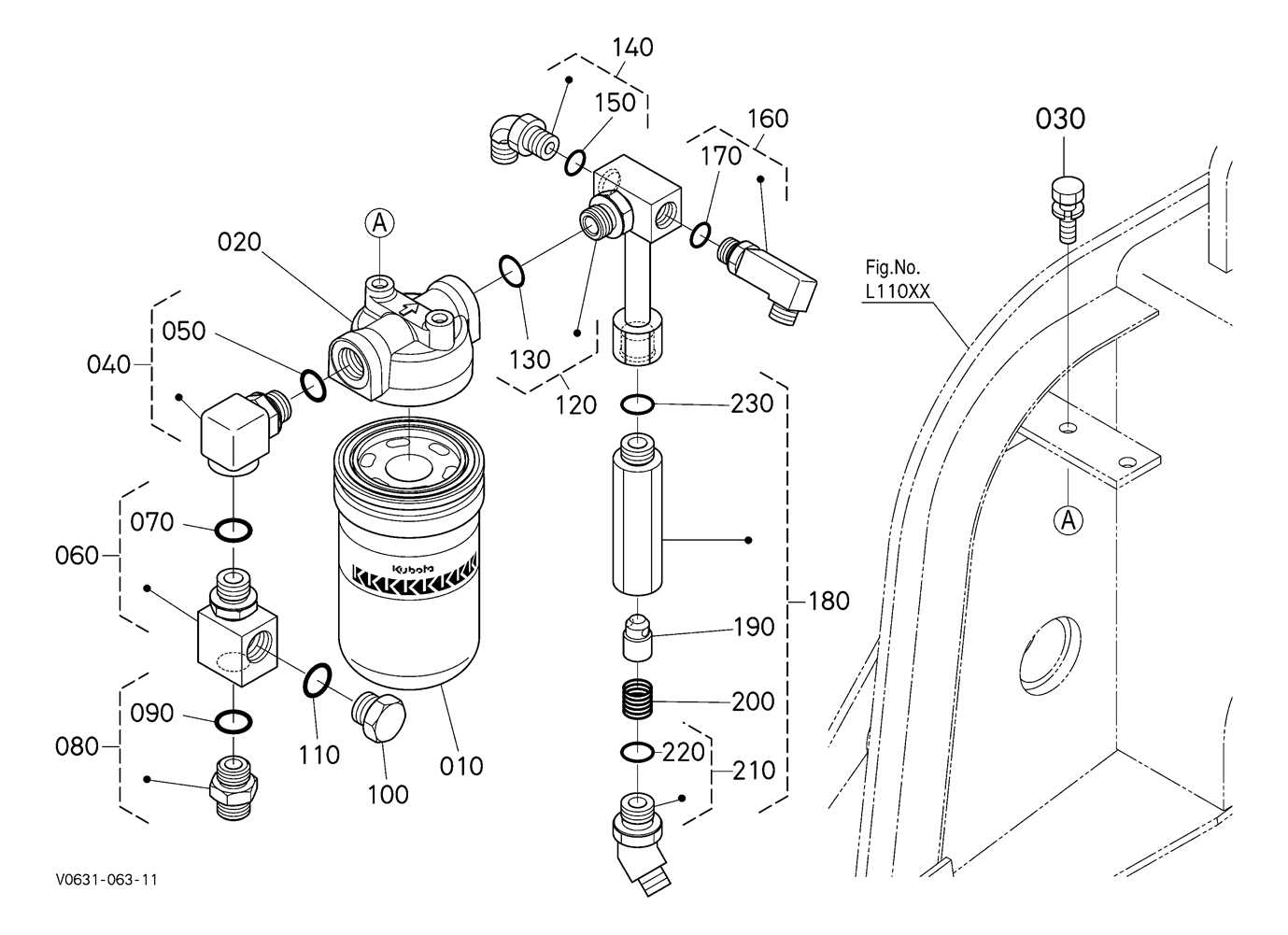

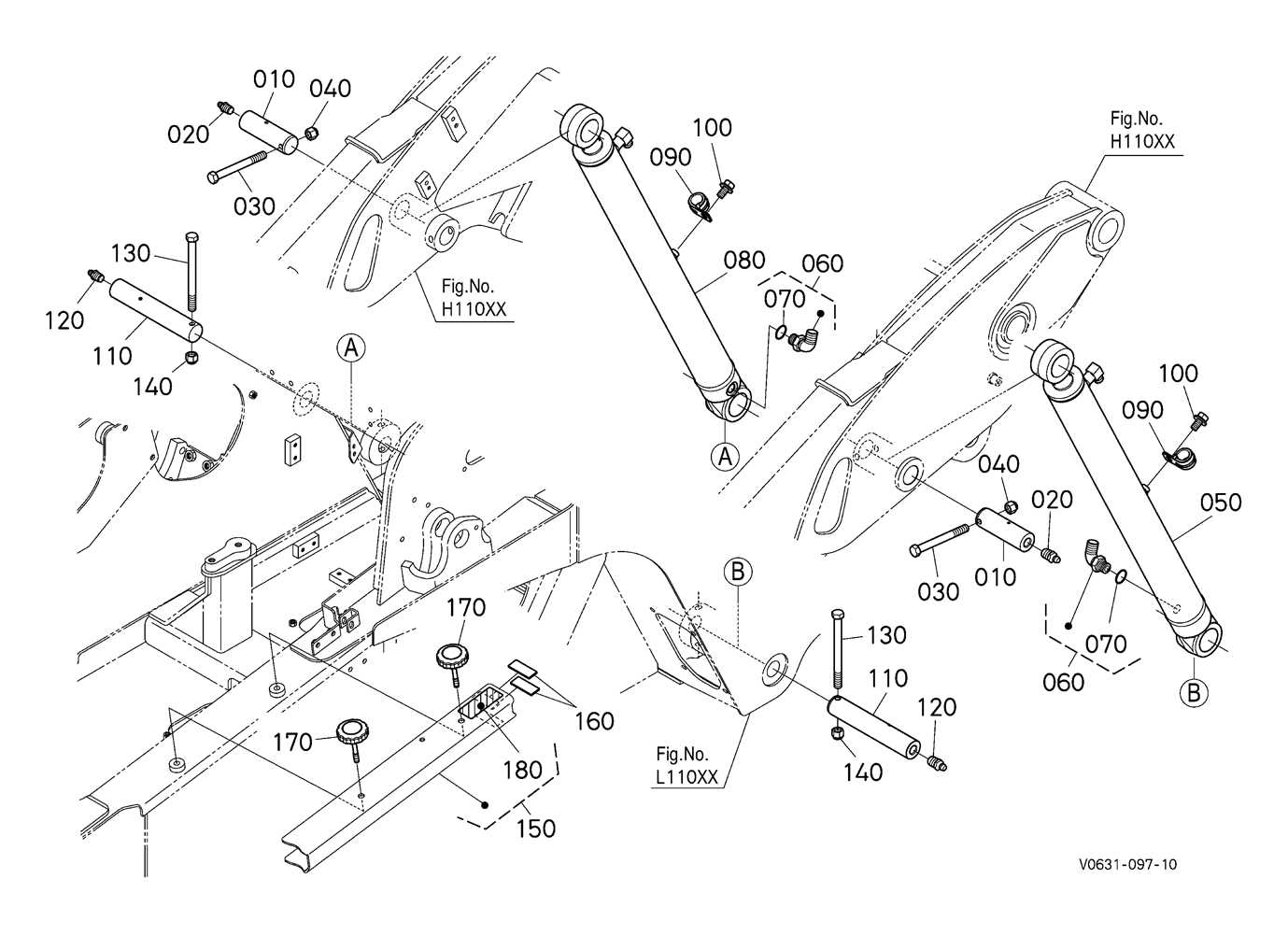

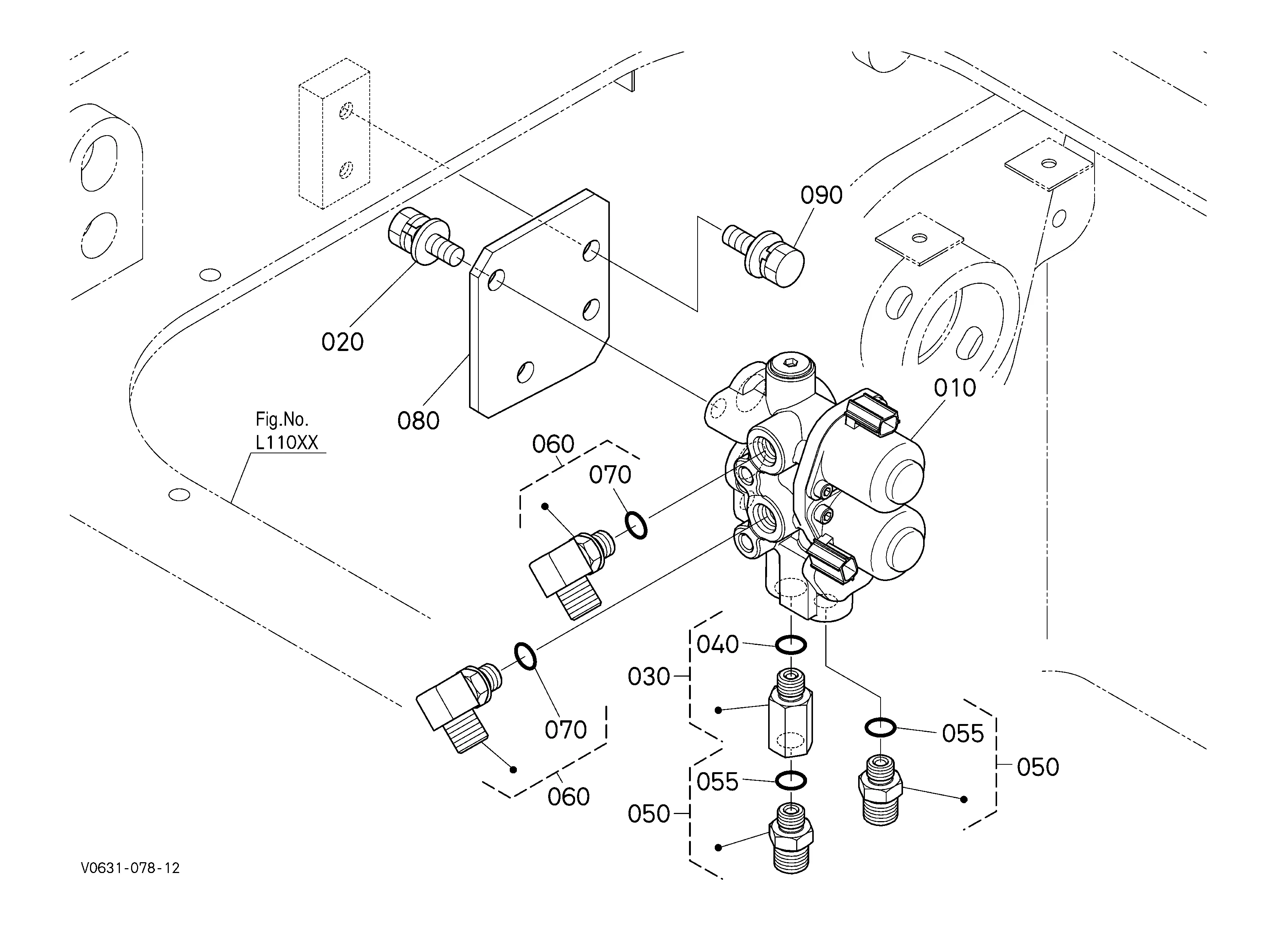

A clear illustration of the different elements helps users identify each part and its role within the machinery. Recognizing how these components work together contributes to effective troubleshooting and repairs. Below is a simplified representation of key components.

| Component | Description |

|---|---|

| Engine | Powers the entire machine, ensuring optimal performance. |

| Hydraulic System | Facilitates movement and operation of attachments. |

| Transmission | Controls power delivery from the engine to the wheels. |

| Chassis | Provides structural support and stability. |

| Control Panel | Enables the operator to monitor and control various functions. |

Key Components of the SVL95-2S

The effectiveness of this compact machine relies heavily on its essential elements, which work together to enhance performance and reliability. Understanding these critical components can aid in maintenance, repair, and overall operational efficiency.

Primary Features

- Engine: The powerhouse responsible for providing the necessary energy for various tasks.

- Hydraulic System: This system enables smooth movement and operation of attachments, ensuring precise control.

- Transmission: The mechanism that facilitates gear changes, allowing for effective power delivery to the wheels.

Operational Tools

- Loader Arms: Designed for lifting and carrying materials with ease.

- Bucket: Essential for digging, scooping, and transporting materials.

- Cabs: Provides operator comfort and protection from the elements while maintaining visibility.

By familiarizing oneself with these vital components, users can ensure optimal performance and longevity of their machine.

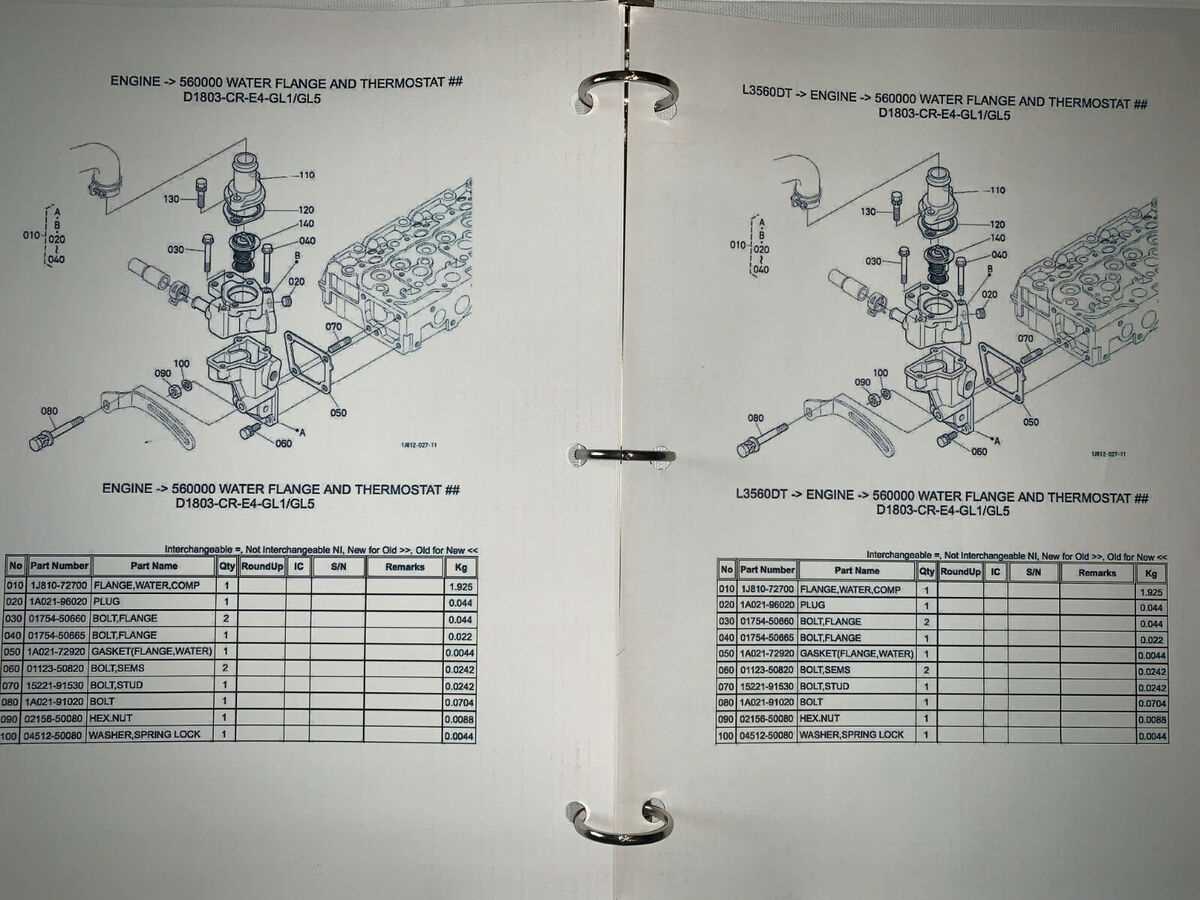

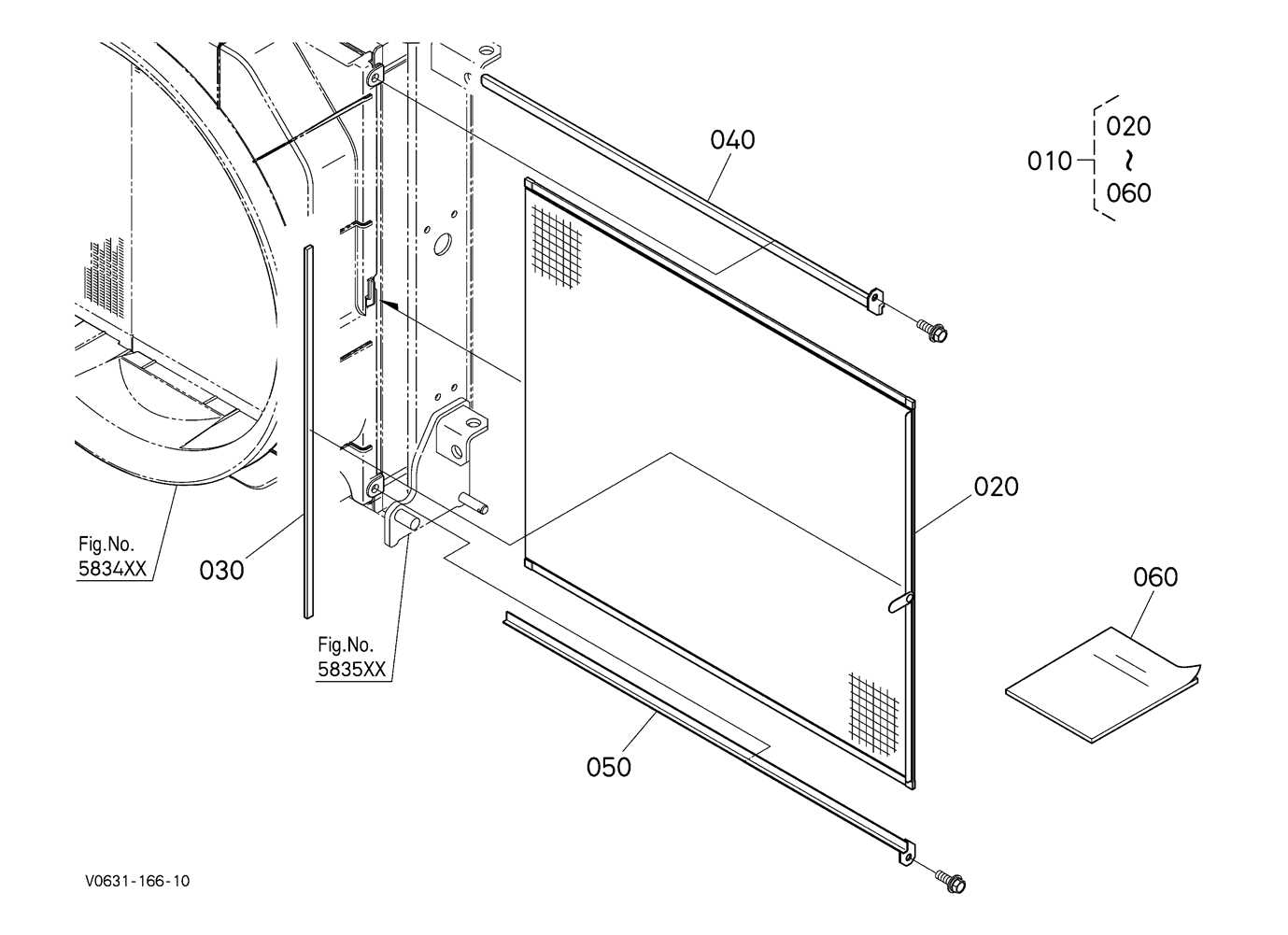

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the assembly and maintenance of machinery. These illustrations serve as essential tools for technicians and engineers, allowing them to identify various elements, their functions, and their interrelationships within a system. By providing clear guidance, these resources facilitate efficient troubleshooting and repair processes, ensuring that equipment operates smoothly.

Enhanced Understanding

Comprehending complex systems becomes significantly easier with well-structured visual aids. Here are some key benefits:

- Clarity: Visual guides eliminate ambiguity, showcasing how each element fits into the whole.

- Efficiency: Technicians can quickly locate necessary components, streamlining repair tasks.

- Training Aid: New employees can learn faster by referencing visual materials, gaining insight into operational structures.

Streamlined Maintenance

Proper upkeep is vital for the longevity of machinery. Utilizing visual resources offers several advantages:

- Accurate Identification: Quickly recognize worn or damaged components that require replacement.

- Effective Planning: Understand which elements need attention, helping to prioritize maintenance tasks.

- Reduced Downtime: Swiftly addressing issues minimizes disruptions in operations, enhancing productivity.

Understanding the Layout and Functionality

Grasping the arrangement and operational aspects of a heavy machinery model is crucial for optimal performance and maintenance. An effective configuration allows operators to easily identify components and comprehend their roles, enhancing efficiency during operation and repair. This section delves into the structural organization and functional significance of various elements within the machinery.

Key Components and Their Roles

- Engine: Acts as the powerhouse, converting fuel into mechanical energy.

- Hydraulic System: Responsible for powering attachments and facilitating movement.

- Operator Cabin: Designed for comfort and control, housing essential controls and displays.

- Chassis: Provides structural integrity and supports other components.

- Transmission: Transfers power from the engine to the wheels or tracks.

Arrangement for Accessibility

The strategic positioning of parts plays a vital role in ease of access for repairs and maintenance. Understanding this layout helps in:

- Quickly locating parts that require attention.

- Efficiently planning maintenance tasks.

- Reducing downtime through swift identification of issues.

Common Repairs and Maintenance Tips

Proper upkeep and timely repairs are essential for the longevity and efficiency of heavy machinery. Regular attention to various components can prevent larger issues down the line and ensure optimal performance. This section provides insights into typical maintenance tasks and troubleshooting strategies that can be beneficial for operators and technicians alike.

Routine Inspection and Cleaning

Frequent inspections are vital for identifying wear and tear. Focus on key areas such as hydraulic systems, filters, and engine components. Keeping these parts clean and free of debris helps maintain operational efficiency.

Fluid Levels and Replacements

Regularly check and maintain fluid levels in the engine, hydraulics, and transmission. Changing fluids as per the manufacturer’s recommendations prevents contamination and promotes smooth operation. Keeping an eye on fluid quality can help avoid costly repairs.

| Task | Frequency | Notes |

|---|---|---|

| Inspect hydraulic hoses | Monthly | Look for leaks or signs of wear |

| Change engine oil | Every 250 hours | Use recommended oil type |

| Clean air filter | Every 100 hours | Replace if necessary |

| Check tire pressure | Weekly | Maintain proper inflation |

Where to Find Replacement Parts

Locating suitable components for your machinery can significantly enhance its performance and longevity. Whether you are performing routine maintenance or undertaking a repair, having access to reliable resources is essential. Numerous avenues exist to source these essential items, each offering unique benefits and a variety of options.

Consider the following avenues for acquiring the necessary components:

| Source | Description |

|---|---|

| Authorized Dealers | Official distributors often provide high-quality items that meet the original specifications, ensuring compatibility and reliability. |

| Online Retailers | Websites dedicated to machinery components offer a vast selection and often include customer reviews, which can aid in making informed choices. |

| Local Repair Shops | These establishments frequently carry a selection of items or can order specific components directly from manufacturers, providing personalized service. |

| Salvage Yards | These locations can be treasure troves for hard-to-find items, allowing you to purchase used components at a fraction of the cost. |

Utilizing these resources can streamline the process of finding the right components, ensuring your machinery remains in optimal working condition.

Utilizing the Parts Diagram Effectively

Understanding the visual representation of components is crucial for efficient maintenance and repairs. Such illustrations serve as valuable resources, providing detailed views of each element and its placement within the overall assembly. By leveraging these resources, users can streamline their workflow, ensuring that they accurately identify and procure the necessary components.

To make the most of these visual guides, it is important to familiarize yourself with the layout and symbols used within the illustration. Recognizing each section and its respective parts will significantly enhance your ability to troubleshoot issues and carry out replacements efficiently. The following table highlights key aspects to consider when working with these resources:

| Aspect | Description |

|---|---|

| Identification | Learn the labels and numbers associated with each item for easier reference. |

| Layout | Understand how components are arranged to facilitate effective navigation. |

| Compatibility | Check for variations in parts that may exist across different models. |

| Maintenance Tips | Note any recommendations for upkeep and best practices for installation. |

In conclusion, utilizing these visual resources effectively can significantly reduce downtime and enhance the overall efficiency of maintenance tasks. Mastering the information presented will empower users to tackle repairs with confidence and precision.

Comparing Models: SVL95-2S vs. Others

When assessing the capabilities of various compact track loaders, it becomes essential to explore the nuances that differentiate them. Each model offers a unique blend of specifications and features, catering to specific needs and preferences in the field. Understanding these distinctions aids operators in selecting the most suitable equipment for their tasks.

This discussion focuses on how one model stands in relation to its competitors, examining attributes such as performance, efficiency, and versatility. The table below summarizes key specifications of the featured model alongside a few comparable alternatives, facilitating an informed decision-making process.

| Model | Engine Power (HP) | Operating Weight (lbs) | Rated Capacity (lbs) |

|---|---|---|---|

| Model A | 95 | 10,000 | 3,500 |

| Model B | 85 | 9,500 | 3,200 |

| Model C | 100 | 11,000 | 4,000 |

| Featured Model | 95 | 10,500 | 3,600 |

This comparison highlights the importance of understanding the specific needs of a project. Operators can select equipment that aligns best with their operational demands by evaluating power, weight, and capacity across different models.