The intricate assembly of machinery that provides essential energy solutions is vital for both residential and industrial applications. A comprehensive grasp of these systems allows users to optimize performance and troubleshoot effectively. Recognizing how each element interacts can significantly enhance efficiency and reliability.

Within the realm of energy solutions, various components play crucial roles in ensuring smooth operation. Familiarity with these elements can empower users to make informed decisions regarding maintenance and upgrades. This understanding ultimately leads to improved functionality and longevity of the entire setup.

By exploring detailed schematics and the relationships between different sections, individuals can delve deeper into the mechanisms at play. Mastering this knowledge serves as a powerful tool for anyone looking to maximize the potential of their energy systems.

Kohler Generator Overview

This section provides a comprehensive look at the renowned brand known for its reliable power solutions. With a strong reputation in the market, the company has established itself as a leader in the field, offering a variety of systems designed for both residential and commercial use. These solutions are engineered to deliver dependable energy, ensuring that users remain connected and operational during outages.

Key Features

- Robust performance across various applications

- Advanced technology for enhanced efficiency

- Easy maintenance and support options

- Wide range of power outputs to suit different needs

Applications

- Home backup power systems

- Commercial power supply solutions

- Industrial applications requiring consistent energy

- Portable power for outdoor activities

Understanding the core attributes and potential uses of these energy systems can help users make informed decisions about their power needs. The commitment to quality and innovation ensures that these solutions are not only effective but also designed to last.

Understanding Generator Components

To grasp the functioning of an electric power source, it is essential to explore the various elements that contribute to its operation. Each component plays a vital role in ensuring efficiency and reliability, forming a cohesive unit that generates energy effectively. Familiarity with these parts not only aids in troubleshooting but also enhances overall comprehension of the system’s mechanics.

One of the key elements is the engine, which serves as the primary driving force. This internal combustion mechanism converts fuel into mechanical energy, enabling the system to produce electricity. Next, the alternator is crucial, as it transforms mechanical energy into electrical energy through electromagnetic induction, highlighting the interplay between motion and electricity.

The control panel is another important feature, acting as the interface for monitoring performance and managing operation. It includes various indicators and switches that allow users to manage power output and monitor vital statistics. Additionally, fuel systems ensure a steady supply of energy, maintaining optimal performance levels and preventing downtime.

Moreover, exhaust and cooling systems play a significant role in maintaining operational integrity. The exhaust system directs harmful gases away from the unit, while the cooling system prevents overheating, ensuring longevity and efficiency. Understanding these components is essential for anyone looking to operate or maintain a reliable power source.

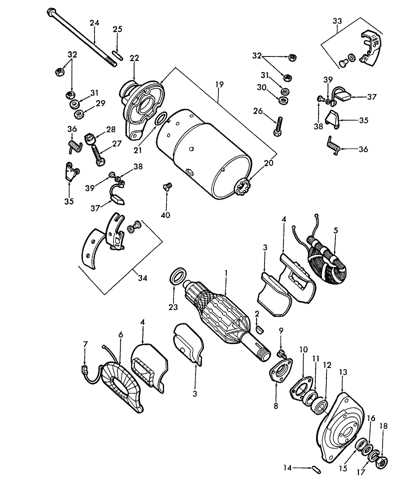

Parts Identification Guide

This section aims to assist users in understanding and recognizing the various components essential for the optimal performance of their equipment. Knowing each element’s role and appearance can significantly enhance maintenance efforts and troubleshooting processes.

Understanding Components

Familiarity with individual elements can lead to more effective care and prompt identification of any issues. Each component serves a unique function, contributing to the overall efficiency of the machine. Users should familiarize themselves with key attributes such as size, shape, and location to ensure accurate identification.

Tips for Identification

To streamline the identification process, consider the following:

- Refer to user manuals for detailed descriptions.

- Utilize labeled diagrams where available to cross-reference.

- Inspect components regularly to recognize wear and tear.

- Take note of any unique identifiers, such as serial numbers.

By applying these strategies, users can maintain their equipment more effectively and ensure optimal performance throughout its lifespan.

Importance of Regular Maintenance

Consistent upkeep is essential for the longevity and efficiency of any machinery. Neglecting routine care can lead to unexpected breakdowns, decreased performance, and costly repairs. Establishing a regular maintenance schedule helps ensure optimal functionality and reliability.

Benefits of Regular Upkeep

- Enhances Performance: Regular checks improve operational efficiency.

- Extends Lifespan: Routine servicing can significantly prolong the life of equipment.

- Reduces Downtime: Preventative measures minimize the chances of unexpected failures.

- Cost Savings: Addressing minor issues early can prevent larger, more expensive repairs.

Key Maintenance Practices

- Regular Inspections: Schedule periodic assessments to identify potential issues.

- Fluid Checks: Monitor and replace fluids to maintain optimal function.

- Clean Components: Keep parts clean to prevent buildup and ensure efficient operation.

- Replace Worn Parts: Timely replacement of components is crucial for reliability.

Troubleshooting Common Issues

When dealing with power equipment, various complications may arise that can disrupt functionality. Understanding how to identify and resolve these challenges is essential for maintaining optimal performance. This section provides insights into some frequent problems and practical solutions to help restore efficiency.

1. Starting Difficulties: If the unit fails to start, check the fuel supply and ensure it is clean and adequate. Additionally, inspect the battery connections for any corrosion or loose wires, as these can hinder the ignition process.

2. Unusual Noises: Hearing strange sounds during operation often indicates underlying issues. Investigate for loose components or wear in mechanical parts. Regular maintenance can prevent such problems from escalating.

3. Overheating: An overheating unit can signal blockages in airflow or low coolant levels. Make sure the vents are free from debris, and regularly check the fluid levels to ensure proper circulation.

4. Inconsistent Power Output: Fluctuations in energy production can stem from faulty connections or damaged wiring. Inspect all electrical components thoroughly, looking for signs of wear or damage that may affect performance.

5. Error Codes: Many systems display error codes to indicate specific faults. Refer to the manual for a list of these codes and their meanings to assist in diagnosing the issue effectively.

By systematically addressing these common challenges, users can enhance the reliability and longevity of their equipment. Regular inspections and maintenance are key to preventing issues before they arise.

Replacement Parts and Compatibility

When it comes to maintaining and enhancing the functionality of your equipment, understanding the various components available and their compatibility is essential. Ensuring that each element fits seamlessly can significantly impact performance and longevity.

Finding the right replacements requires attention to detail. Here are some key considerations:

- Specifications: Always check the specifications of the original unit. Dimensions, power ratings, and design features are crucial for proper integration.

- Manufacturer Guidelines: Refer to the manufacturer’s recommendations for compatible options. They often provide a list of approved alternatives to ensure optimal performance.

- Quality Assurance: Opt for high-quality alternatives that match or exceed the original standards. This can prevent future issues and improve reliability.

To assist in the selection process, consider the following steps:

- Identify the specific component you need to replace.

- Research compatibility with your existing model.

- Consult product reviews and ratings for additional insights.

- Purchase from reputable suppliers to guarantee quality.

By following these guidelines, you can ensure that your equipment remains in top condition and continues to perform efficiently over time.

Wiring Diagrams Explained

Understanding the layout of electrical connections is essential for anyone working with power systems. These illustrations serve as a visual guide, outlining the interrelationships between various components and providing clarity on how to establish connections safely and efficiently.

Importance of Electrical Layouts

Clear wiring schematics are crucial for several reasons:

- Facilitate troubleshooting by identifying potential issues quickly.

- Provide a reference for maintenance and upgrades.

- Help ensure compliance with safety standards.

- Enhance understanding for both professionals and enthusiasts.

Key Elements in Electrical Schematics

Familiarizing yourself with the essential elements of these layouts can greatly improve your ability to interpret them:

- Symbols: Each component is represented by a unique symbol, allowing for easy identification.

- Lines: The connections between components are depicted by lines, indicating the flow of electricity.

- Labels: Annotations provide critical information about each part, including specifications and ratings.

- Color Coding: Different colors can signify various functions or voltages, aiding in quick recognition.

By grasping these fundamental aspects, individuals can navigate electrical layouts with greater confidence and accuracy.

Safety Considerations for Users

Ensuring safety during operation and maintenance of machinery is crucial to prevent accidents and injuries. Users must be aware of potential hazards and implement practices that promote a secure working environment. This section highlights essential safety tips that should be followed diligently.

| Safety Tip | Description |

|---|---|

| Read the Manual | Familiarize yourself with the equipment’s instructions to understand proper operation and safety measures. |

| Use Protective Gear | Always wear appropriate personal protective equipment, such as gloves, goggles, and ear protection. |

| Regular Inspections | Conduct routine checks to identify any wear or damage that may pose risks during operation. |

| Avoid Overloading | Do not exceed the recommended capacity to prevent malfunctions and hazards. |

| Maintain Ventilation | Ensure proper airflow to avoid buildup of harmful gases, especially in enclosed spaces. |