When examining the construction and functionality of machinery used in agricultural settings, it’s essential to understand how various components are interconnected. Each element serves a vital role in ensuring efficient performance, contributing to the overall reliability and durability of the equipment.

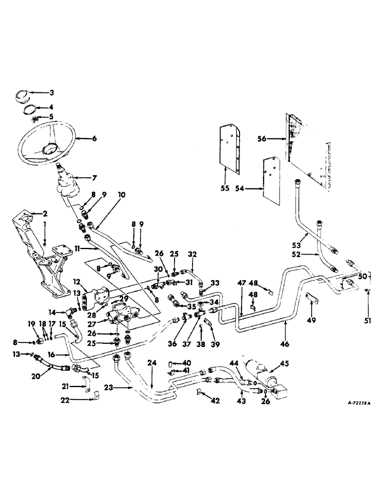

The operational stability of these machines depends heavily on a precise arrangement of various sections. Whether it involves power transmission, control mechanisms, or hydraulic systems, all components are strategically positioned to work together seamlessly. Knowing how these elements interact with each other ensures smooth maintenance and helps prevent potential breakdowns.

Understanding the complete setup allows users to perform repairs more effectively, replacing specific sections when needed. A detailed breakdown of the assembly offers valuable insights into the proper handling of the machinery, improving both performance and longevity.

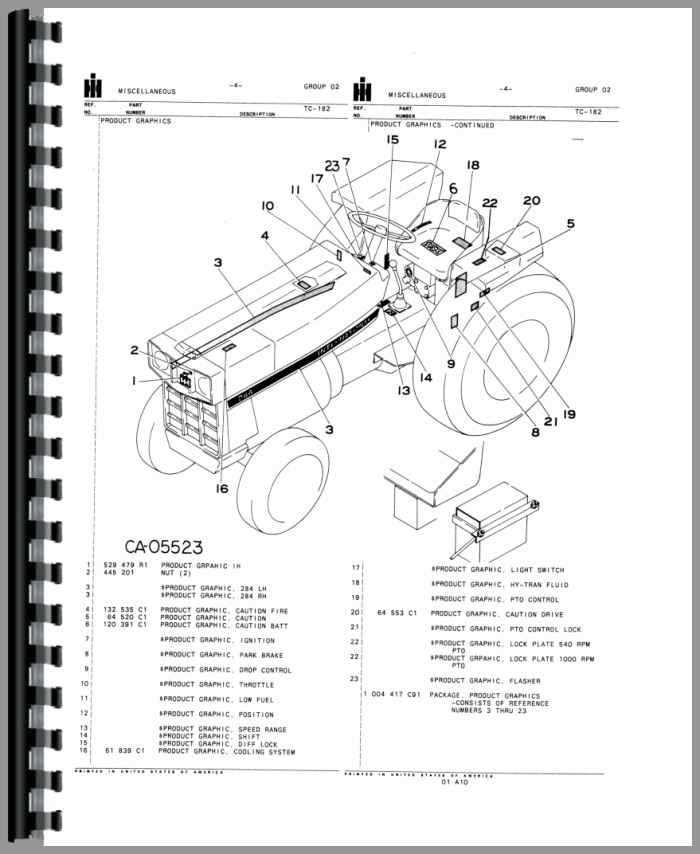

Understanding Component Layouts for Farm Equipment

Farm machinery consists of numerous interconnected systems that work together to achieve specific tasks in agricultural operations. Each piece of equipment has a distinct arrangement of mechanical and electrical elements, making it essential for operators to be familiar with these configurations for effective use and maintenance.

Key Elements and Their Roles

The structure of agricultural machines typically revolves around several essential components. These include systems responsible for power distribution, fluid movement, and control mechanisms. Understanding how these systems interact helps in diagnosing issues and optimizing performance.

- Powertrain – Transmits energy from the engine to various operational parts.

- Hydraulic System – Manages the flow of fluids to control implements and movement.

- Control Panels – Provide the interface for adjusting settings and managing different operations.

Efficient Maintenance and Troubleshooting

Recognizing the layout of critical systems allows for more efficient upkeep and troubleshooting. Proper understanding of the positioning of key modules ensures quicker identification of potential faults and reduces downtime.

- Identify key system locations such as the engine, transmission, and control hubs.

- Understand the flow of power and fluids across different sections of the equipment.

- Regularly inspect connections and moving parts to prevent wear and tear.

Mastering the arrangement of components in farming machinery is vital for improving operational efficiency, minimizing repair times, and ensuring longer equipment lifespan.

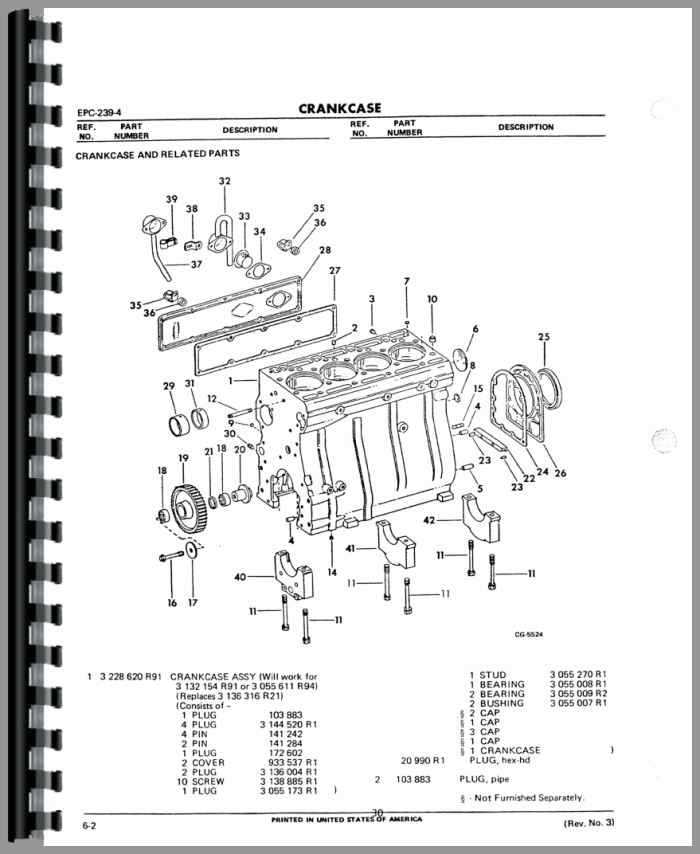

Engine Systems and Their Key Components

Mechanical power systems in heavy machinery rely on a combination of interconnected elements that work together to ensure efficiency and longevity. Understanding the core elements that make up these systems is crucial for maintaining performance and ensuring that everything operates smoothly.

Main Power Generation Units

The central driving force of any power system is responsible for converting fuel into motion. This process involves several critical elements, including mechanisms that manage air and fuel intake, combustion, and exhaust. Each unit plays a vital role in transforming raw energy into usable power, keeping the machinery running under different conditions.

Cooling and Lubrication Systems

Cooling and lubrication are essential to maintaining optimal temperatures and reducing friction between moving parts. These support mechanisms ensure that the machinery can function continuously without overheating or suffering wear from metal-on-metal contact.

| Component | Function | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Air Intake System | Controls the amount of air that enters the system, critical for fuel combustion. | ||||||||||||

| Fuel Injection Unit | Regulates fuel delivery, ensuring the correct mix for

Hydraulic System Breakdown and Repair Insights

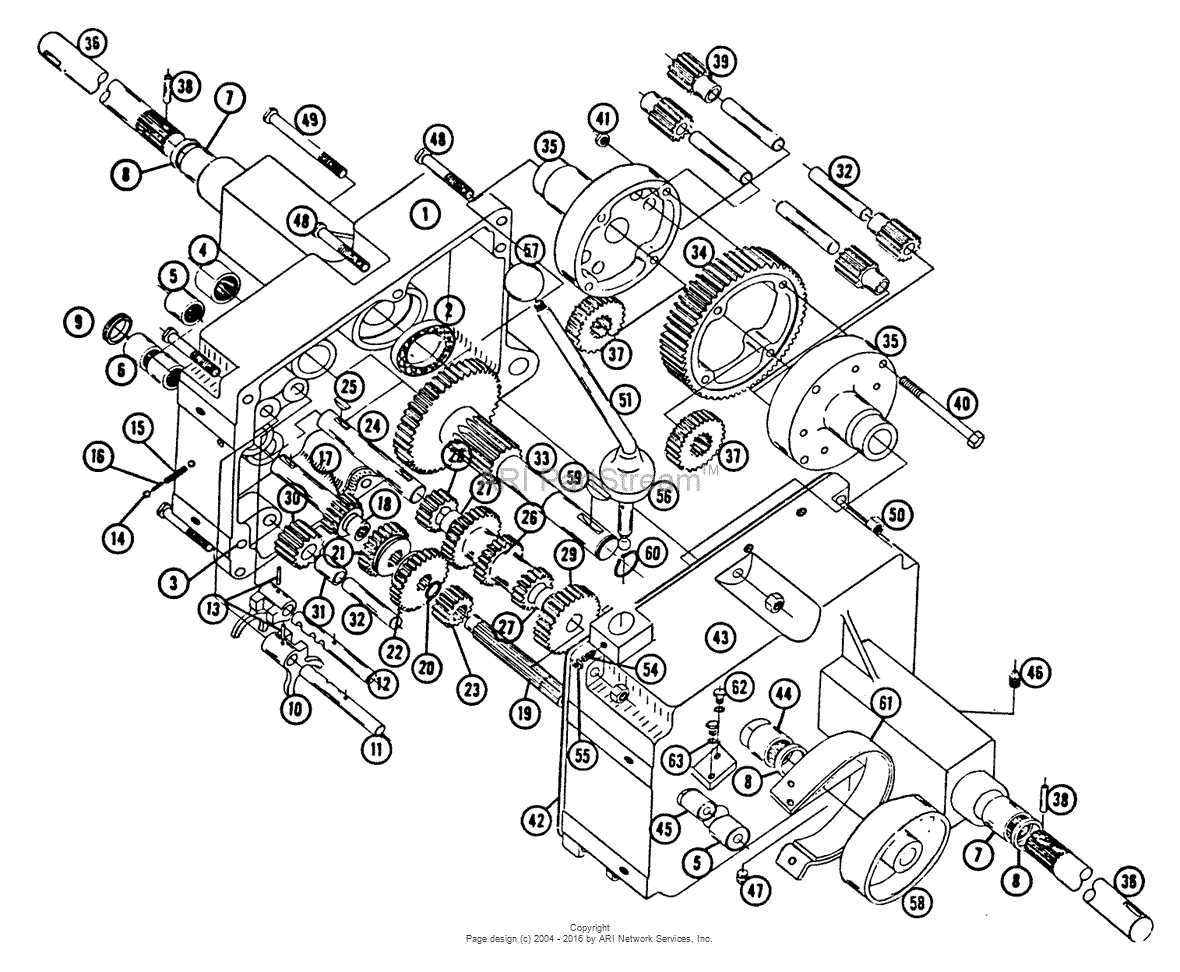

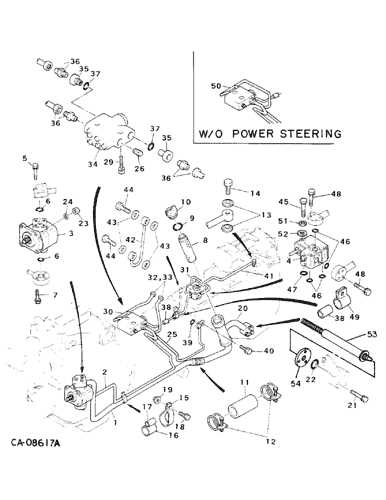

Understanding the hydraulic system is essential for maintaining optimal performance and ensuring smooth operation. This section provides insights into how key components interact within the system, highlighting common areas prone to wear and malfunction. By recognizing the symptoms of potential issues early, you can prevent more serious damage and extend the longevity of the machinery. Common Issues: Over time, components such as seals, valves, and hoses may degrade, leading to fluid leaks or pressure loss. Identifying these issues promptly is crucial for preventing further complications. Pay close attention to changes in the responsiveness of the system, as well as unusual noises during operation. Repair Tips: Regular inspection and timely replacement of worn-out parts can significantly reduce downtime. Ensuring the correct fluid levels and using quality lubricants are also key factors in maintaining the system’s efficiency. Always follow proper disassembly procedures when addressing issues with pumps or cylinders to avoid accidental damage. Transmission Parts and Their FunctionsThe system responsible for transferring power from the engine to the wheels consists of multiple key components. Each element plays a crucial role in ensuring smooth power delivery and maintaining the vehicle’s performance. Understanding these components and their roles can help maintain optimal functionality and prolong the machine’s lifespan. Main Components of the Transmission System

Additional Components and Their Roles

Each of these elements plays a pivotal role in the overall performance of the transmission system, ensuring that power is delivered efficiently and safely under various operating conditions. Electrical System Overview for Efficient MaintenanceThe electrical setup in machinery plays a crucial role in ensuring smooth operation and minimizing downtime. A clear understanding of its structure allows for better management of regular upkeep, preventing potential malfunctions. Familiarity with the key elements of this system can help identify issues early and avoid costly repairs. Main Components and Their FunctionsCore elements in the electrical configuration include the power source, control modules, and various connectors. The power source provides the necessary energy to operate other systems, while control units regulate and distribute this energy efficiently. Properly maintained connections ensure the flow remains uninterrupted, safeguarding other components from damage. Regular Inspection and Preventative MeasuresConsistent inspections are vital for maintaining peak performance. Look for signs of wear on cables and ensure that all connections remain secure. It is also important to regularly test key components, such as the battery and fuses, to verify they are functioning correctly. Addressing these small issues early can greatly extend the lifespan of the entire system. Steering and Control Mechanism DetailsThe steering and control assembly plays a crucial role in the operation and maneuverability of heavy machinery. Understanding its components and functions can enhance maintenance and troubleshooting efforts, ensuring smooth and efficient handling in various conditions. Key Components

Functionality Overview

Fuel System Parts Identification and UsesThe fuel delivery system plays a crucial role in the performance and efficiency of any machinery that relies on combustion for operation. Understanding the various components within this system is essential for maintenance and troubleshooting. Each element has a specific function that contributes to the overall effectiveness of fuel utilization.

Recognizing these components and their roles ensures that the machinery operates smoothly and efficiently. Regular inspection and maintenance can prevent fuel-related issues that may lead to decreased performance or even failure. Understanding this system is vital for anyone involved in the upkeep and operation of combustion-engine machinery. Cooling System Components and Replacement TipsThe effectiveness of a vehicle’s temperature regulation system is crucial for maintaining optimal performance. This system comprises various elements that work in tandem to dissipate heat generated by the engine, ensuring smooth operation and preventing overheating. Understanding the components involved and knowing when and how to replace them can enhance the longevity and reliability of the machinery. Key Elements of the Cooling SystemAmong the essential components of this system are the radiator, water pump, thermostat, and hoses. The radiator plays a vital role in transferring heat away from the engine coolant, while the water pump circulates the coolant through the system. The thermostat regulates the temperature, opening and closing as needed to maintain the optimal operating range. Hoses connect these parts, allowing coolant to flow seamlessly. Regular inspection of these elements is necessary to prevent malfunctions. Replacement Tips

When it comes to replacing any component, ensure that the engine is cool and that you follow the manufacturer’s guidelines for specific procedures. Use high-quality replacement parts to guarantee compatibility and performance. Additionally, flushing the cooling system regularly can help prevent blockages and corrosion, prolonging the lifespan of the entire system. Pay attention to any signs of leaks or unusual noises, as these may indicate the need for immediate replacement of faulty components. Brake and Suspension Assemblies Explained

The brake and suspension systems are crucial components that ensure safe and efficient operation of heavy machinery. These assemblies work in tandem to provide stability, control, and stopping power, contributing to the overall performance and safety of the equipment. Understanding their functions and structure is essential for maintenance and troubleshooting. Brake System Overview

The braking mechanism consists of several elements that work together to reduce speed or bring the vehicle to a complete stop. This system typically includes components such as calipers, discs, and pads, which interact to create the necessary friction. When pressure is applied, the brake pads clamp onto the discs, generating heat and slowing the machine down. Regular inspection of these components is vital to ensure optimal performance and prevent potential failures. Suspension System FunctionalityThe suspension assembly is designed to absorb shocks and maintain vehicle stability during operation. It includes parts such as suspension arms, shocks, and springs, which work together to provide a smooth ride over uneven terrain. This system is crucial for enhancing traction and ensuring that the wheels remain in contact with the ground, which directly impacts handling and safety. Proper maintenance of the suspension components is essential for extending the lifespan of the equipment and improving operational efficiency. |