In the world of agricultural machinery, a deep comprehension of essential elements is crucial for effective maintenance and operation. This section delves into the intricate network of components that contribute to the overall functionality of these

Overview of Kubota Tractor Front Axle

This section delves into the crucial components responsible for the vehicle’s stability and maneuverability. Understanding the elements that contribute to the steering and support mechanisms is essential for effective operation and maintenance.

Essential Functions and Features

The primary role of these components involves ensuring proper weight distribution and enhancing traction. They play a significant part in enabling smooth navigation across diverse terrains, which is vital for optimal performance during agricultural tasks.

Maintenance and Care Considerations

Regular inspection of these critical elements is imperative for preventing wear and tear. Timely maintenance helps to extend the lifespan of the system, ensuring reliable performance and reducing the risk of operational failures. Proper care can significantly enhance the efficiency and durability of the machinery.

Key Components of Front Axle

The structure that supports the vehicle’s weight while providing stability during operation is crucial for optimal performance. Understanding the essential elements of this assembly aids in proper maintenance and enhances overall functionality.

One of the primary elements is the housing, which encases the vital components, ensuring protection from external elements. Attached to the housing, you will find bearings that facilitate smooth rotation and movement, minimizing friction.

Additionally, the assembly includes spindles that connect to the wheels, allowing for responsive steering and maneuverability. The suspension system plays a critical role, absorbing shocks and providing comfort while driving over various terrains.

Another significant component is the steering linkage, which transmits driver input to the wheels, ensuring precise handling. Regular inspection and maintenance of these key elements are essential for the longevity and reliability of the entire system.

Understanding Axle Functionality

The role of a supporting structure in vehicles is crucial for their overall performance and stability. This component not only connects the wheels but also facilitates effective power distribution, enabling smooth movement across various terrains. Understanding its mechanics can significantly enhance maintenance and operational efficiency.

Key functions of this structural element include:

- Load distribution: It bears the weight of the vehicle, ensuring even pressure on the wheels.

- Torque transfer: This structure transmits engine power to the wheels, enabling acceleration and movement.

- Stability: It provides a stable platform, enhancing vehicle control during turns and rough conditions.

Moreover, the design and construction of this element can vary, impacting its functionality and durability. Here are some common types:

- Rigid designs, which offer robustness for heavy-duty applications.

- Independent systems that allow for better handling and comfort.

- Live structures, which incorporate differential mechanisms for improved traction.

Understanding these elements will aid in recognizing the importance of regular inspections and timely repairs, ensuring the longevity and reliability of the entire vehicle system.

Maintenance Tips for Front Axle

Ensuring the longevity and optimal performance of your vehicle’s steering and suspension system requires regular attention. By following a set of best practices, you can prevent premature wear and enhance the reliability of this essential assembly.

Regular inspections are crucial for identifying potential issues before they escalate. Check for signs of wear, such as unusual noises or vibrations while in operation. It’s important to keep all components clean, as dirt and debris can contribute to accelerated wear and tear.

Lubrication plays a vital role in maintaining smooth functionality. Apply high-quality grease to joints and moving parts as recommended in the maintenance schedule. Over time, seals can degrade, so inspecting them for leaks and replacing them when necessary will help keep the assembly functioning correctly.

Aligning the wheels correctly can prevent uneven tire wear and enhance handling. Regularly check the alignment and make adjustments as needed. Additionally, monitoring the tire pressure will contribute to better traction and overall performance.

Lastly, consider professional servicing at regular intervals. Experienced technicians can provide comprehensive assessments and address issues that may not be easily visible during routine checks. Proactive maintenance will ultimately save you time and money while ensuring a smooth driving experience.

Common Issues with Front Axle

When dealing with agricultural machinery, certain components can experience wear and tear, leading to various complications. Understanding these frequent challenges is essential for maintenance and ensuring optimal performance. Common problems often arise from mechanical stress, environmental factors, and inadequate lubrication, resulting in decreased efficiency and increased operational risks.

Typical Mechanical Problems

One of the most common mechanical issues involves misalignment, which can lead to uneven tire wear and difficulties in steering. Additionally, damage to critical components such as bearings and bushings may occur due to excessive load or poor maintenance practices.

Environmental Factors

Exposure to harsh conditions can exacerbate wear on machinery. Moisture, dirt, and debris can accumulate, leading to corrosion and hindering functionality. Regular cleaning and inspections are crucial to mitigate these environmental impacts.

| Issue | Symptoms | Solutions |

|---|---|---|

| Misalignment | Uneven tire wear, steering difficulties | Regular alignment checks, adjustment |

| Bearing wear | Noise, vibrations | Frequent lubrication, timely replacement |

| Corrosion | Visible rust, mechanical failure | Protective coatings, regular cleaning |

Replacing Front Axle Parts

Maintenance and replacement of crucial components are essential for ensuring optimal performance and longevity of agricultural machinery. This section discusses the necessary steps and considerations for effectively updating these vital elements.

Identifying Worn Components

Before initiating the replacement process, it is important to thoroughly examine the essential elements for signs of wear or damage. Look for any irregularities such as cracks, excessive play, or unusual noises during operation. Early identification of compromised components can prevent more extensive damage and costly repairs.

Step-by-Step Replacement Process

Once the worn elements have been identified, follow these general steps for successful replacement:

- Gather Necessary Tools: Ensure you have the appropriate tools and replacement components at hand.

- Safety First: Engage safety measures, including disconnecting the power source and securing the machinery.

- Remove the Damaged Component: Carefully detach the affected piece, taking care not to damage surrounding areas.

- Install the New Element: Position the new component accurately and secure it in place.

- Conduct a Final Check: Inspect the installation for proper alignment and functionality before resuming operation.

Regular maintenance and timely replacement of crucial components are vital for the seamless operation of your agricultural machinery.

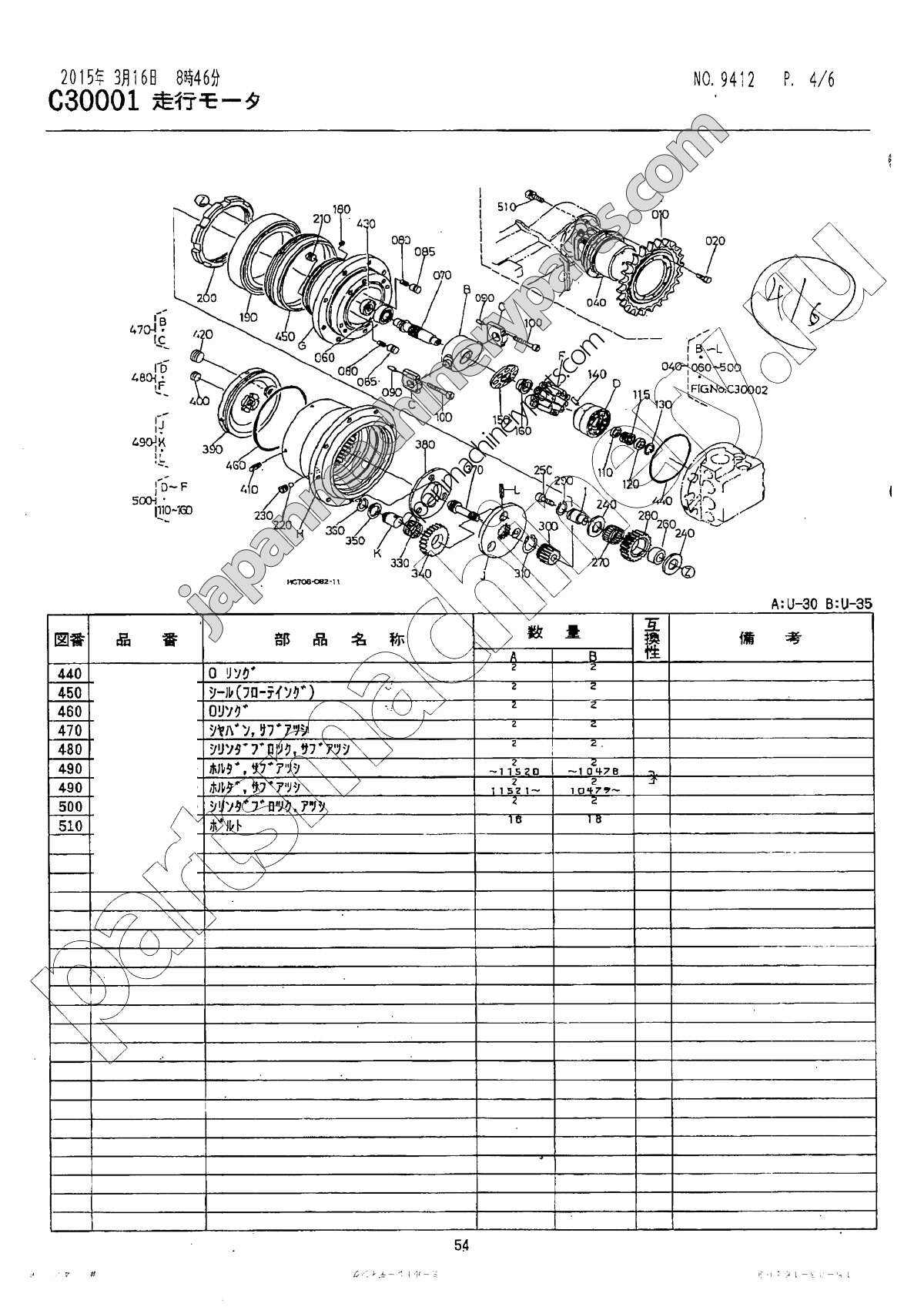

Diagram Interpretation for Repairs

Understanding the layout of components is crucial for effective maintenance and repair tasks. A well-structured visual representation can simplify the identification of various elements and their interconnections, facilitating a more efficient troubleshooting process.

When analyzing such visual aids, consider the following steps:

- Identify Key Elements: Start by pinpointing major components and their functions within the overall assembly.

- Note Interconnections: Observe how parts interact and connect, as this can reveal potential areas of wear or failure.

- Consult Additional Resources: Use manuals or online databases for reference, ensuring accurate comprehension of each element’s role.

By following these guidelines, you can enhance your ability to effectively manage repairs and maintenance. Familiarity with the layout and function of components not only speeds up the process but also minimizes the risk of errors during repairs.

Resources for Kubota Parts

When it comes to maintaining machinery, having access to quality components is essential. Various resources are available to help individuals locate the necessary replacements for their equipment, ensuring optimal performance and longevity.

Here are some valuable avenues to explore:

- Manufacturer Websites: Most manufacturers provide online catalogs and user guides that detail their offerings. This is a reliable starting point for finding authentic components.

- Authorized Dealers: Visiting or contacting authorized dealers can yield personalized assistance. They often have specialized knowledge about specific requirements.

- Online Marketplaces: Websites like eBay or Amazon can have a wide selection of components at competitive prices. Always check the seller’s ratings before making a purchase.

- Forums and Online Communities: Joining discussion boards or social media groups dedicated to machinery can provide insights and recommendations from fellow users.

- Local Repair Shops: Many local mechanics have established relationships with suppliers and can assist in sourcing parts quickly.

Utilizing these resources can facilitate the acquisition of necessary components, allowing users to maintain their equipment efficiently and effectively.