In the realm of agricultural machinery, a comprehensive understanding of the various elements that make up these powerful machines is essential for efficient operation and maintenance. Each component plays a crucial role in ensuring optimal performance, allowing operators to tackle their tasks with confidence.

Exploring the intricate relationships between these elements reveals the ultimate synergy required for seamless functionality. By delving into the layout and interactions of each section, users can better appreciate the design and engineering that go into these remarkable machines.

Whether you are a seasoned professional or a novice, grasping the organization of these essential components not only enhances your knowledge but also empowers you to make informed decisions regarding repairs and upgrades. This guide serves as a valuable resource for those seeking to deepen their understanding of agricultural machinery.

Understanding Ford 600 Tractor Mechanics

The inner workings of agricultural machinery are a marvel of engineering, combining various components that work in harmony to achieve optimal performance. A comprehensive understanding of these mechanisms is essential for effective maintenance and troubleshooting. By delving into the operational principles and structural arrangements of such equipment, operators can enhance efficiency and prolong the lifespan of their machinery.

Core Components and Their Functions

Every piece of heavy equipment is composed of several key elements that perform specific functions. Knowledge of these parts and their interactions can greatly assist in the effective operation and repair of the machine. The table below outlines some of the primary components, their descriptions, and functions:

| Component | Description | Function |

|---|---|---|

| Engine | The power source of the machine. | Converts fuel into mechanical energy to drive the system. |

| Transmission | System that transfers power from the engine to the wheels. | Adjusts speed and torque for various tasks. |

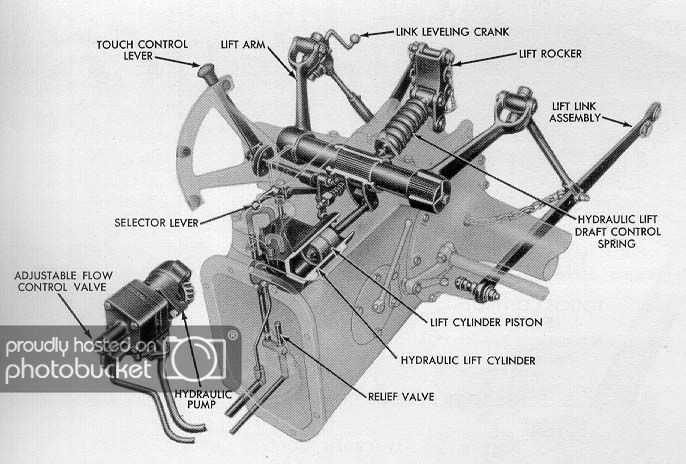

| Hydraulic System | Uses fluid power to operate implements. | Facilitates lifting and lowering attachments. |

| Chassis | The frame that supports all other components. | Provides stability and structure for the entire machine. |

| Cooling System | Maintains optimal operating temperature. | Prevents overheating of the engine. |

Maintenance Best Practices

Regular upkeep is vital for ensuring the longevity and efficiency of machinery. Adopting best practices can prevent major breakdowns and enhance performance. Key maintenance tasks include regular fluid checks, timely oil changes, and inspecting belts and hoses for wear. Operators should also maintain cleanliness in critical areas to avoid debris buildup, which can lead to operational issues.

Importance of Parts Diagrams

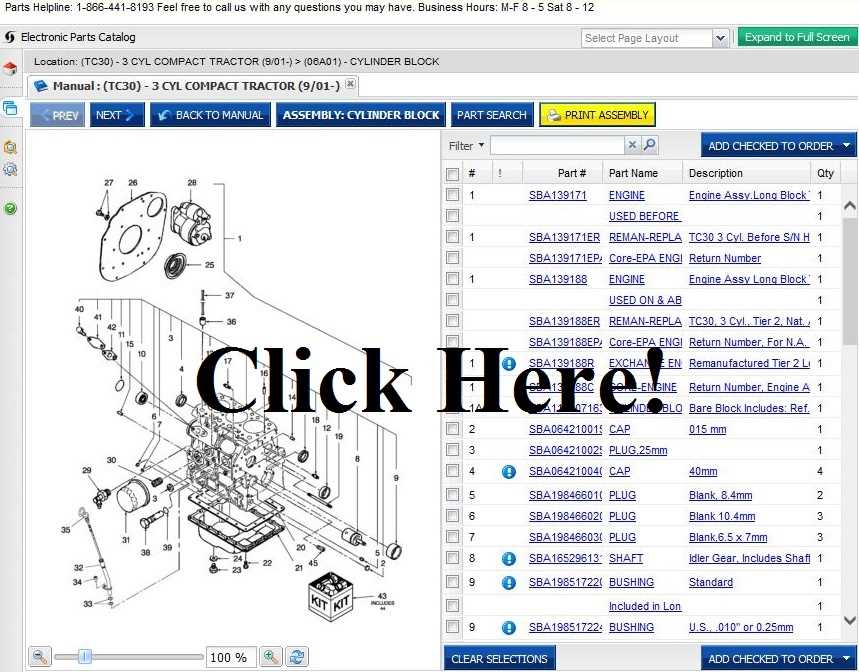

Understanding the intricate assembly of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools that facilitate the identification and organization of components, ultimately enhancing the efficiency of servicing processes. When users can clearly see how each element fits into the larger system, they are better equipped to tackle repairs and upgrades.

Enhancing Communication

Illustrative guides improve communication among technicians and engineers, allowing for a shared understanding of mechanical configurations. This clarity can reduce errors during maintenance, ensuring that all involved parties are aligned on procedures and expectations.

Streamlining Repairs

Having access to detailed visual references significantly accelerates the repair process. Technicians can quickly locate the necessary components, reducing downtime and optimizing workflow, which is vital for any operational setting.

Key Components of the Ford 600

This section explores the essential elements that contribute to the functionality and efficiency of a classic agricultural machine. Understanding these components can enhance maintenance practices and ensure optimal performance over time.

Engine System

The heart of any agricultural machine is its power unit. This assembly is crucial for generating the necessary energy to perform various tasks. Key features include:

- Fuel Delivery: Responsible for supplying the combustion chamber with the necessary fuel.

- Cooling Mechanism: Ensures the engine operates within safe temperature limits, preventing overheating.

- Lubrication System: Reduces friction among moving parts, thereby enhancing longevity and efficiency.

Transmission and Drive

The mechanism that transmits power from the engine to the wheels is vital for movement and control. Important aspects include:

- Gearbox: Allows the operator to select different speeds and torque levels for various tasks.

- Clutch: Facilitates smooth engagement and disengagement of the power flow.

- Axles: Supports the vehicle’s weight and transmits power to the wheels for traction.

By familiarizing oneself with these crucial components, operators can better understand their machine and ensure its effective operation.

Finding Reliable Replacement Parts

When it comes to maintaining machinery, sourcing trustworthy components is essential for optimal performance. Ensuring that you obtain high-quality items can significantly impact the longevity and efficiency of your equipment.

Where to Look for Quality Components

- Authorized Dealers: Visiting authorized distributors ensures you receive genuine items that meet the manufacturer’s specifications.

- Online Marketplaces: Reputable websites often provide customer reviews and ratings, helping you gauge the reliability of sellers.

- Local Shops: Establishing relationships with local suppliers can lead to personalized service and expert advice.

Evaluating Potential Suppliers

- Check for warranties or guarantees that indicate confidence in their products.

- Read customer testimonials to understand others’ experiences with the supplier.

- Verify the supplier’s reputation within the industry through forums and community discussions.

By taking the time to research and select reputable sources, you can ensure that your machinery remains in excellent working condition, minimizing downtime and enhancing productivity.

Common Issues and Solutions

Maintaining machinery involves understanding potential problems that may arise over time. Identifying these issues early can help in implementing effective solutions, minimizing downtime, and ensuring optimal performance. This section outlines some frequent challenges encountered with equipment and offers practical remedies to address them.

Engine Performance Problems

One of the most common issues is related to engine performance, which may manifest as difficulty starting, unusual noises, or a decrease in power output. These symptoms can be attributed to various factors, such as fuel quality, air intake restrictions, or electrical system failures. Regular inspections and maintenance of fuel filters, air filters, and battery connections can significantly enhance engine reliability.

Hydraulic System Failures

Hydraulic malfunctions can lead to decreased efficiency and functionality. Common signs include slow or unresponsive hydraulic movements and fluid leaks. Checking hydraulic fluid levels and ensuring all connections are secure can often resolve these issues. If problems persist, it may be necessary to inspect hydraulic hoses and cylinders for wear or damage.

Maintaining Your Ford 600 Tractor

Proper upkeep of your machinery is essential for optimal performance and longevity. Regular maintenance routines ensure that all components function smoothly, preventing costly repairs and downtime. By staying proactive, you can enhance efficiency and reliability.

Regular Inspections

Conducting frequent checks on various systems is crucial. Look for signs of wear or damage, paying special attention to the engine, hydraulic systems, and belts. Identifying issues early can save you time and money.

Lubrication and Fluids

Ensuring all moving parts are adequately lubricated is vital for smooth operation. Regularly check and change fluids, including oil and coolant, to maintain proper function. Keeping everything well-lubricated reduces friction and enhances the lifespan of your equipment.

Upgrading Parts for Better Performance

Enhancing machinery functionality often involves the careful selection and installation of superior components. By investing in upgraded elements, operators can significantly improve efficiency, reliability, and overall output. This process not only maximizes the equipment’s potential but also extends its lifespan, resulting in long-term benefits for users.

When considering enhancements, it’s essential to identify areas where performance can be optimized. For instance, upgrading the engine’s internal components can lead to increased power and fuel efficiency. Choosing high-quality materials for these upgrades can make a substantial difference in durability and performance.

Another critical aspect to consider is the hydraulic system. Upgrading hoses, fittings, and pumps can enhance lifting capacity and responsiveness, making operations smoother and more effective. Improved hydraulic functionality can dramatically affect the overall productivity of the equipment.

Additionally, replacing worn-out elements such as bearings and seals with advanced versions can reduce friction and wear, ensuring a more efficient operation. Investing in modern technology not only enhances performance but also contributes to safer working conditions.

Ultimately, focusing on strategic upgrades fosters a proactive approach to maintenance, ensuring that equipment remains competitive and effective in various applications. By prioritizing quality and performance, operators can achieve exceptional results while minimizing downtime and repair costs.

Visual Aids for Assembly and Repair

Effective visual resources play a crucial role in facilitating the assembly and maintenance processes. They not only enhance comprehension but also streamline tasks by providing clear and concise information. Whether through illustrations, charts, or photographs, these aids assist individuals in understanding complex mechanisms and executing repairs with confidence.

When engaging in assembly or repair tasks, consider the following types of visual aids:

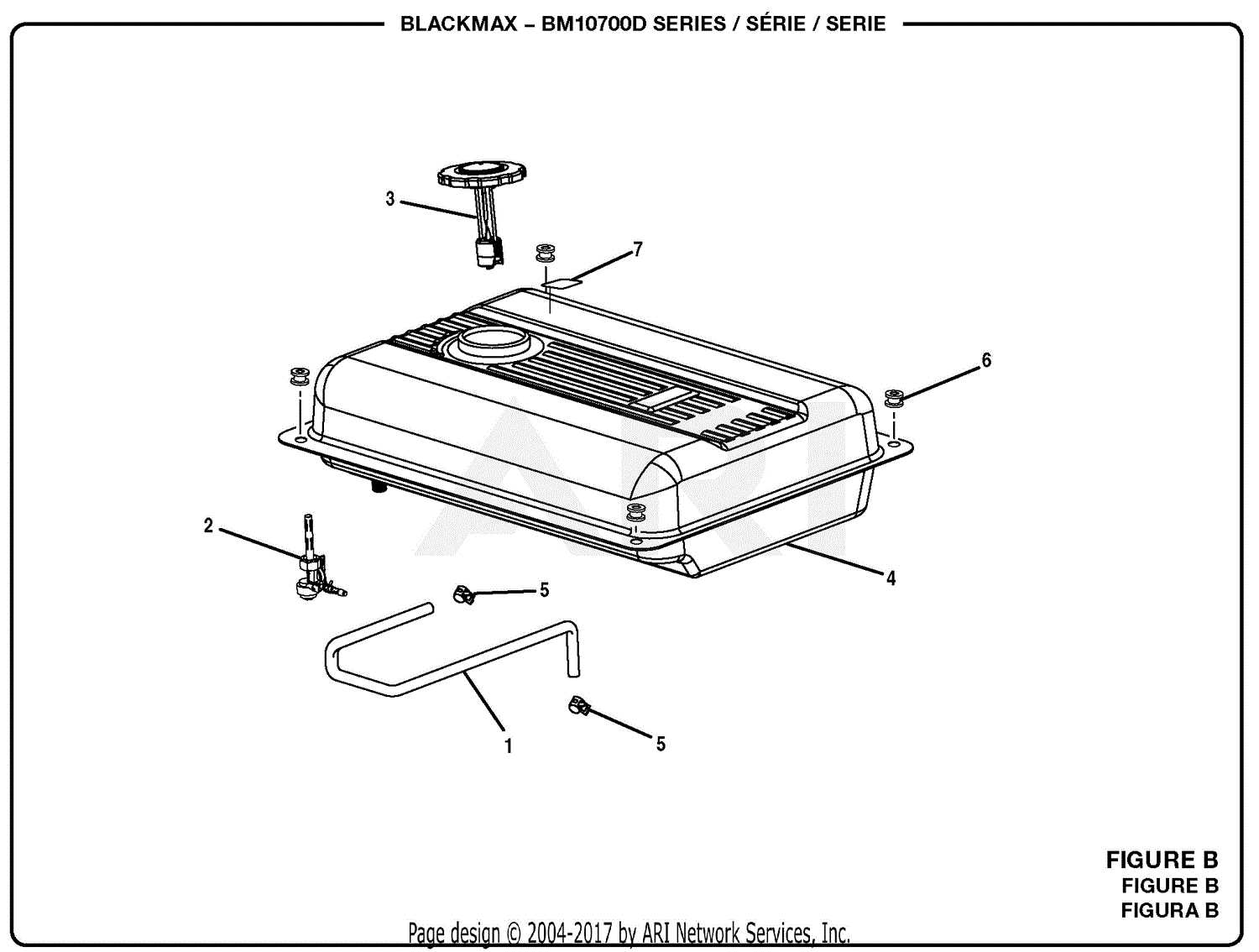

- Illustrations: Detailed drawings that depict specific components and their relationships. These can be invaluable for identifying parts and understanding how they fit together.

- Flowcharts: Diagrams that outline processes or sequences of actions. They help in visualizing the steps required for assembly or troubleshooting.

- Photographs: Real-life images that showcase parts in situ. These can assist in recognizing components and understanding assembly orientation.

- Exploded Views: Visual representations that display components separated from each other. This type of aid clarifies how different pieces interact and can simplify reassembly.

Utilizing these resources can significantly improve accuracy and efficiency during assembly and repair tasks. By providing a visual context, they help individuals quickly locate components, understand procedures, and avoid common pitfalls.

For optimal results, it is essential to reference these aids throughout the entire process. Keeping them accessible can reduce frustration and increase the likelihood of successful outcomes.