Understanding the inner workings of modern farming equipment is essential for ensuring optimal performance and maintenance. Various mechanical systems operate together, forming a complex network that powers heavy-duty machines used in agricultural tasks. Familiarizing yourself with these systems allows for a deeper comprehension of how each section contributes to the overall operation.

In this section, we will dive into the detailed structure of key mechanical assemblies, exploring how they interconnect and function. This knowledge can help in identifying specific mechanisms, assisting in proper upkeep and adjustments, ensuring smooth operation in the field.

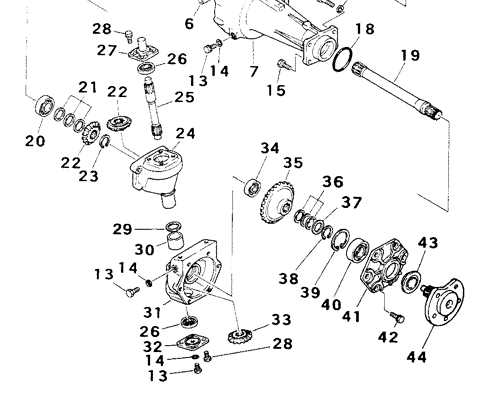

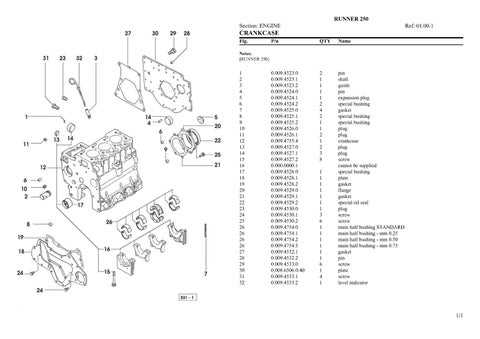

Comprehensive diagrams can be a valuable resource for visualizing each individual component, providing clear insight into the machine’s construction. Such clarity is crucial for technicians and users alike, making repairs and routine servicing more efficient and precise.

Mitsubishi Tractor Parts Overview

When it comes to maintaining reliable equipment, it’s crucial to understand the individual elements that keep the machinery running smoothly. This section offers an overview of the essential components used in agricultural vehicles, focusing on their importance in daily operations. Regular inspection and upkeep of these elements can significantly extend the service life of your machinery.

Key Components and Their Functions

Each element of agricultural equipment plays a specific role in ensuring overall functionality. Below is a list of the most vital elements and how they contribute to performance.

- Engine system: Powers the machine and ensures efficient operation across various terrains.

- Transmission: Transfers power from the engine to the wheels, allowing for movement and control.

- Hydraulics: Provides lifting and other essential functions that improve versatility.

- Electrical system: Manages the lighting and control systems, ensuring optimal working conditions.

Importance of Regular Maintenance

Proper care of each element is essential for long-term use. Routine checks help identify wear

Engine Components and Their Functions

Understanding the various elements within an engine is crucial for efficient maintenance and performance optimization. Each component plays a specific role, contributing to the overall operation and reliability of the machine. Below, we explore key engine elements and their respective tasks.

Cylinder and Piston

The cylinder and piston form the heart of the engine, where combustion occurs. The piston moves within the cylinder, compressing fuel and air mixtures to generate power. This process is fundamental to the creation of mechanical energy from combustion.

Crankshaft and Camshaft

The crankshaft converts the piston’s linear motion into rotational energy, driving other parts of the system. The camshaft, on the other hand, controls the opening and closing of the valves, ensuring proper timing for air intake and exhaust, which is essential for smooth operation

Transmission System Explained

The transmission system plays a crucial role in transferring power from the engine to the wheels, allowing smooth movement and control. Its primary function is to regulate the amount of power sent to the wheels depending on the speed and load. This system ensures efficient performance and optimal fuel consumption by adjusting power output as needed.

Key Components of the Transmission System

The transmission system consists of several key elements working together to provide seamless operation. These include gears, a clutch, and a differential. Each part plays a specific role in controlling speed and torque, ensuring that the machine operates effectively under various conditions.

Types of Transmission Systems

There are different types of transmission systems, including manual, automatic, and hydrostatic. Manual transmission systems require the operator to shift gears manually, while automatic systems handle gear changes automatically, providing ease of use. Hydrostatic transmissions use fluid pressure for smoother and more precise control of movement.

Understanding the Hydraulic Mechanism

The hydraulic system is a crucial element in modern machinery, enabling smooth and efficient operation. It relies on fluid dynamics to generate movement, allowing various components to perform their tasks seamlessly. This section explores how the hydraulic mechanism functions, detailing its core principles and how different parts work together to achieve optimal performance.

Key Components of the Hydraulic System

- Pump: Responsible for generating fluid flow, powering the entire system.

- Valves: Control the direction and pressure of the fluid, ensuring proper function.

- Cylinders: Convert the fluid power into mechanical force, enabling motion.

- Filters: Keep the fluid clean by removing debris and contaminants.

How the Hydraulic Process Works

- The pump moves the fluid through the system, pressurizing it.

- Valves control the flow and pressure of the fluid, guiding it to specific areas.

- Cylinders

Electrical System and Key Parts

The electrical system is a crucial component in ensuring smooth operation, providing power to essential functions. Without this system, various important operations would be impossible, affecting overall performance and reliability. Understanding the core elements of this system helps in maintaining efficiency and troubleshooting potential issues.

Component Function Battery Supplies power to start the engine and operates electrical accessories. Alternator Recharges the battery and powers the electrical system when the engine is running. Starter Motor Initiates engine operation by cranking it at startup. Ignition Switch Controls the flow of electricity to start the Steering and Suspension Elements

The components responsible for guiding and stabilizing a vehicle play a crucial role in ensuring smooth operation and comfort during movement. Understanding these elements is essential for maintaining optimal performance and handling characteristics. This section delves into the various components that contribute to the overall functionality of the steering and suspension systems.

Key Components of Steering

The steering mechanism comprises several vital components that work together to facilitate precise direction control. Rods, linkages, and steering gears form the backbone of this system, allowing the driver to maneuver effectively. Each component must function seamlessly to provide responsive handling and maintain vehicle stability.

Suspension System Overview

The suspension system is engineered to absorb shocks and support the vehicle’s weight, ensuring a smooth ride over uneven terrain. Key elements include shocks, struts, and springs, which work in tandem to enhance comfort and maintain tire contact with the ground. Regular inspection and maintenance of these components are essential for prolonging their lifespan and ensuring optimal performance.

Brake System and Maintenance Tips

The braking mechanism is crucial for ensuring safety and efficiency in various machinery. Understanding its components and how they function together can greatly enhance performance and longevity. Regular maintenance practices are essential to prevent potential issues and ensure optimal operation.

Key Components of the Braking Mechanism

The braking assembly typically includes several key elements such as discs, pads, and hydraulic systems. Each of these components plays a significant role in the overall functionality. Discs provide the surface for friction, while pads press against them to create the necessary stopping power. The hydraulic system ensures that the pressure is evenly distributed, allowing for smooth and effective braking.

Maintenance Recommendations

To keep the braking system in top condition, routine inspections are necessary. Check for wear and tear on the pads and discs, as excessive damage can lead to decreased effectiveness. Replacing worn-out components promptly will help maintain safety. Additionally, regularly inspect the hydraulic fluid levels and look for any leaks that could compromise the braking performance. Keeping the system clean from dirt and debris will also enhance its longevity and reliability.

Cooling System Parts and Diagram

The cooling system plays a vital role in maintaining the optimal operating temperature of an engine. It prevents overheating and ensures the efficiency of the machine by regulating the temperature of various components. Understanding the components and their arrangement can aid in proper maintenance and troubleshooting.

Essential Components

This system comprises several critical components, each serving a specific function to ensure efficient cooling. Key elements include the radiator, water pump, thermostat, and cooling fans. Each part collaborates to circulate coolant and dissipate heat effectively.

Arrangement Overview

The configuration of these components is designed for optimal performance. The coolant flows through the engine, absorbing heat, and is then routed to the radiator, where it is cooled before being recirculated. This continuous process helps maintain the engine at a stable temperature.

Component Function Radiator Dissipates heat from the coolant to the air. Water Pump Circulates coolant throughout the system. Thermostat Regulates coolant flow based on temperature. Cooling Fans Enhance airflow over the radiator for better cooling. Common Wear and Tear Parts

Every machine experiences degradation over time, especially components subjected to frequent use. Identifying these crucial elements is essential for maintaining functionality and preventing operational disruptions. Understanding which components are most likely to wear out can help in planning for timely replacements and ensuring continued efficiency.

Some of the frequently affected items include belts, bearings, and hydraulic seals. These elements endure significant stress during operation, making them susceptible to wear. Regular inspection and replacement of these items can extend the overall lifespan of the machinery.

Additionally, filters and fluids play a vital role in the proper functioning of equipment. Clogged filters can lead to decreased performance, while degraded fluids may compromise the integrity of various systems. It is important to adhere to maintenance schedules to replace these consumable components promptly.

Overall, proactive management of wear and tear items can greatly enhance performance, reduce downtime, and save costs in the long run. By staying informed about the typical lifecycle of these crucial elements, operators can ensure their equipment remains in optimal working condition.