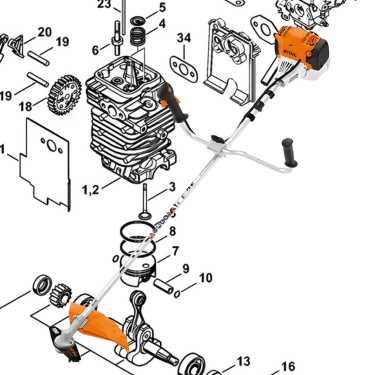

The maintenance of any grass trimmer requires a thorough understanding of its internal elements and structure. This knowledge ensures smooth performance, long-lasting durability, and proper upkeep. Being aware of each essential piece helps users manage repairs efficiently, even when challenges arise.

Every machine, regardless of its complexity, is made up of a variety of interconnected elements that serve different roles. Identifying these key components can aid in troubleshooting and optimizing usage, especially when some elements show signs of wear. Learning the functions of different mechanisms is a crucial step toward reliable operation.

Overview of Key Components

The equipment relies on several essential elements that ensure its functionality and efficiency. These components are designed to work in harmony, contributing to the overall performance and longevity of the tool.

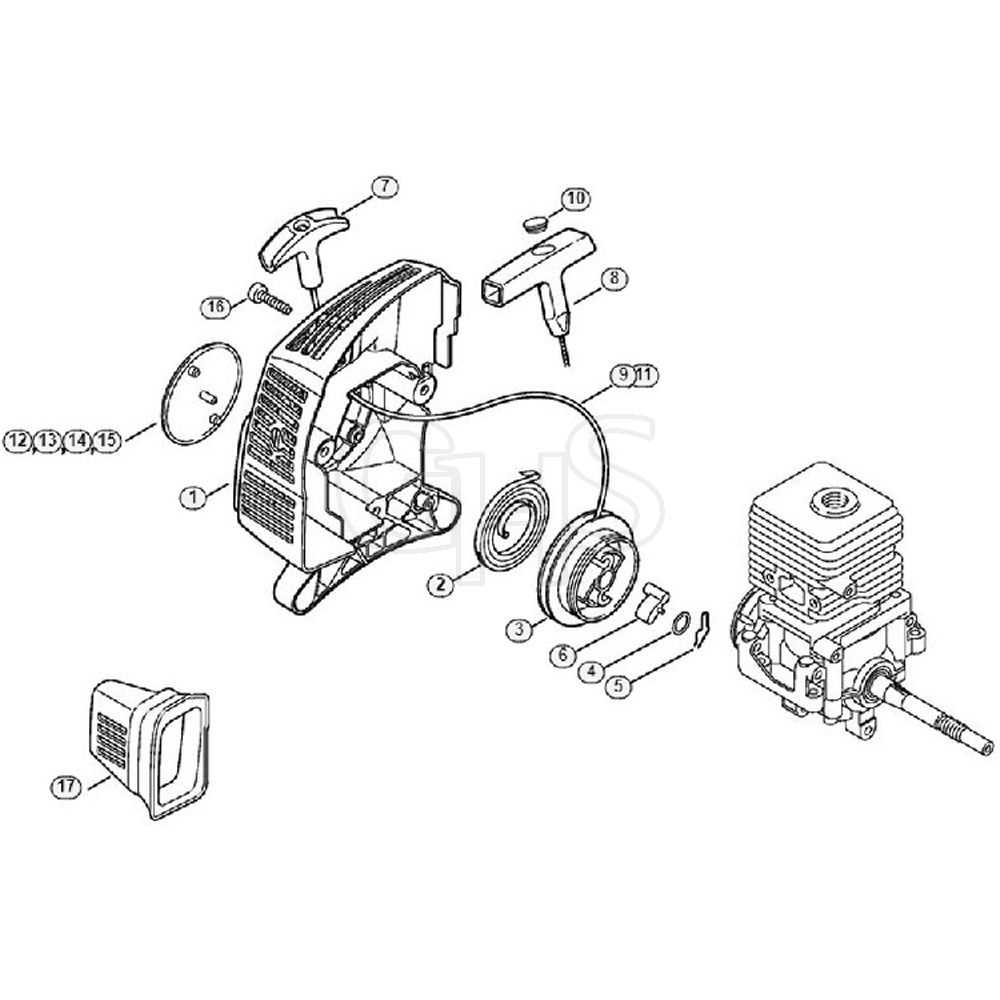

- Engine: The motor provides the power needed for the machine to operate, delivering consistent energy output during use.

- Fuel System: This system manages the flow of fuel, ensuring proper combustion and optimal energy transfer.

- Handle: Designed for comfort and control, the handle allows for precise movements and easy handling.

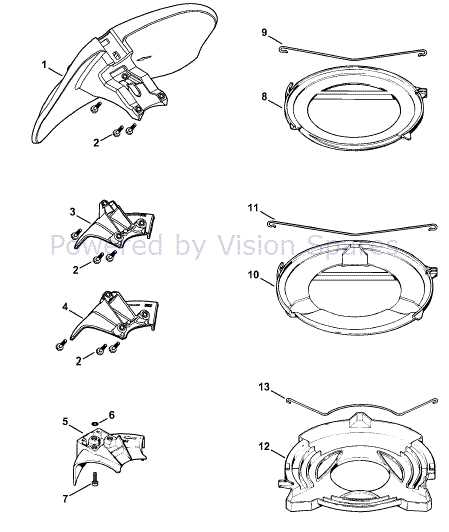

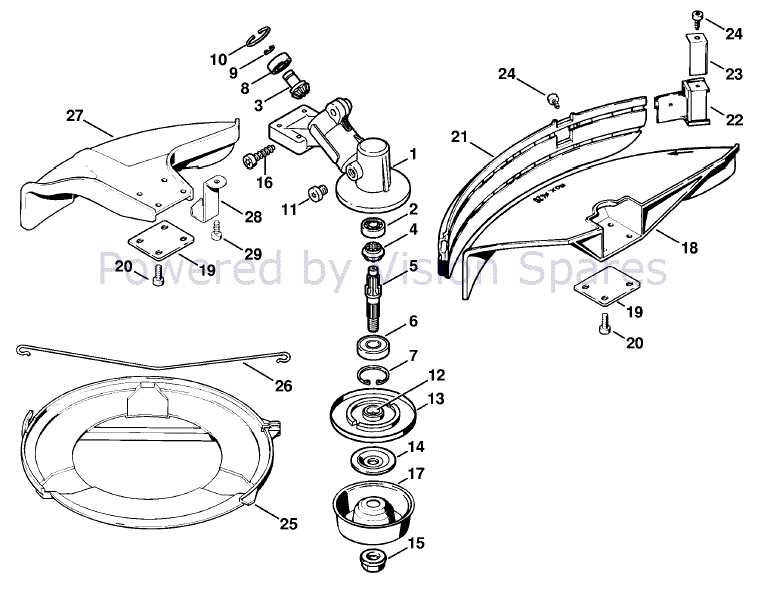

- Cutting Mechanism: The cutting component plays a crucial role in performing the primary task, with different designs available depending on the type of work.

- Protective Guard: A shield that prevents debris from causing harm during operation, ensuring user safety.

- Adjustable height for personalized comfort

- Curved shape to enhance grip and control

- Vibration-dampening materials to minimize strain

- Integrated controls for ease of use

- Check the handlebar height and adjust it according to your stature.

- Ensure that the angle of the handlebar aligns with your preferred working position.

- Secure all fasteners to maintain stability during operation.

- Test the adjustments by performing a brief operation to ensure comfort.

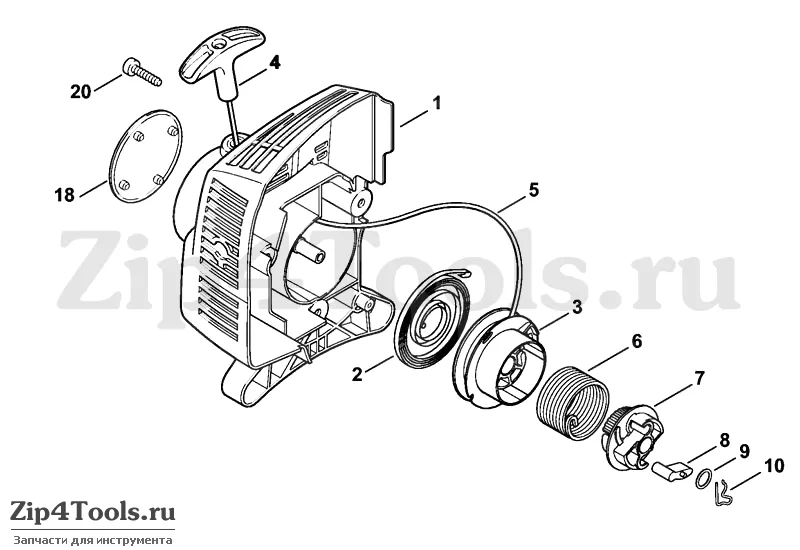

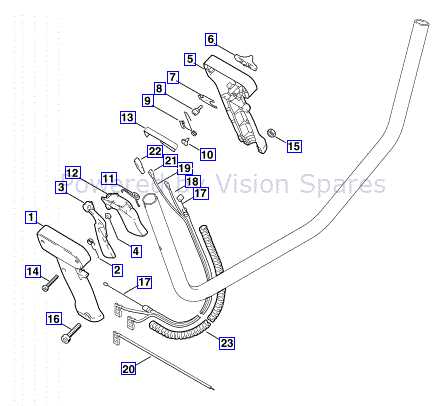

Throttle Assembly and Control Details

The throttle mechanism plays a crucial role in managing the engine’s speed and overall performance. Proper control of this system ensures smooth operation and safe handling during use. In this section, we will explore the key components involved in throttle control and their respective functions, ensuring optimal machine responsiveness.

Main Components of the Throttle System

The throttle assembly includes several interconnected elements that work together to regulate power delivery. These components must function in harmony to ensure the engine responds accurately to user input. Understanding how each part contributes to the overall control system is vital for maintaining proper functionality.

Throttle Cable and Handle Functions

The throttle cable connects the control handle to the engine, transmitting signals from the user to adjust power levels. The handle itself offers intuitive control, allowing easy adjustments during operation. A well-maintained cable ensures quick and precise throttle response, enhancing the equipment’s efficiency.

| Component | Function | |||

|---|---|---|---|---|

| Throttle Cable |

| Blade Type | Ideal Use |

|---|---|

| Metal Blades | Thicker brush and small shrubs |