In various restroom systems, a complex network of elements ensures smooth and efficient water flow. These components play a crucial role in maintaining a consistent performance, adapting to diverse needs and settings. Their design aims to balance efficiency and functionality, ensuring optimal operation over time.

Each mechanism within this setup is tailored for specific roles, contributing to the overall functionality. From controlling water flow to ensuring proper operation, these elements are designed for durability and adaptability. The right combination of these parts is essential for achieving a seamless and reliable experience.

Whether in public facilities or private establishments, understanding the intricacies of such systems can help with maintenance and troubleshooting. It allows for a deeper appreciation of how individual elements work together, ensuring the system remains in peak condition throughout its use.

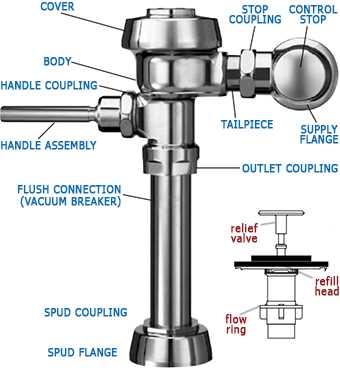

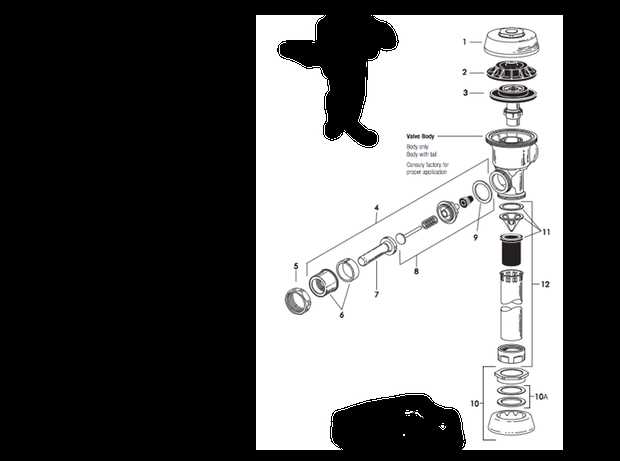

Sloan Flushometer Parts Diagram

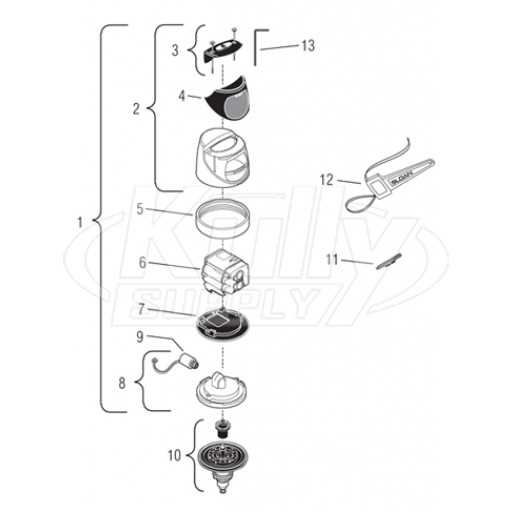

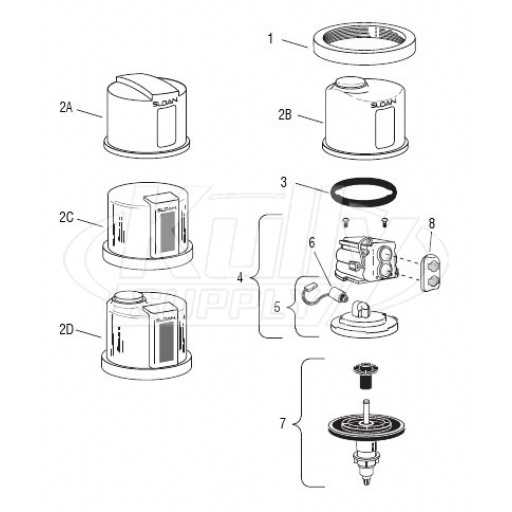

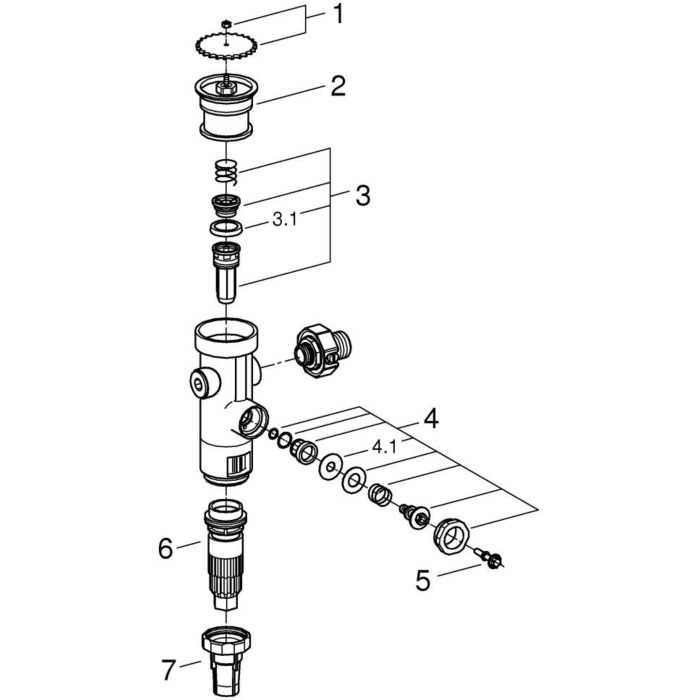

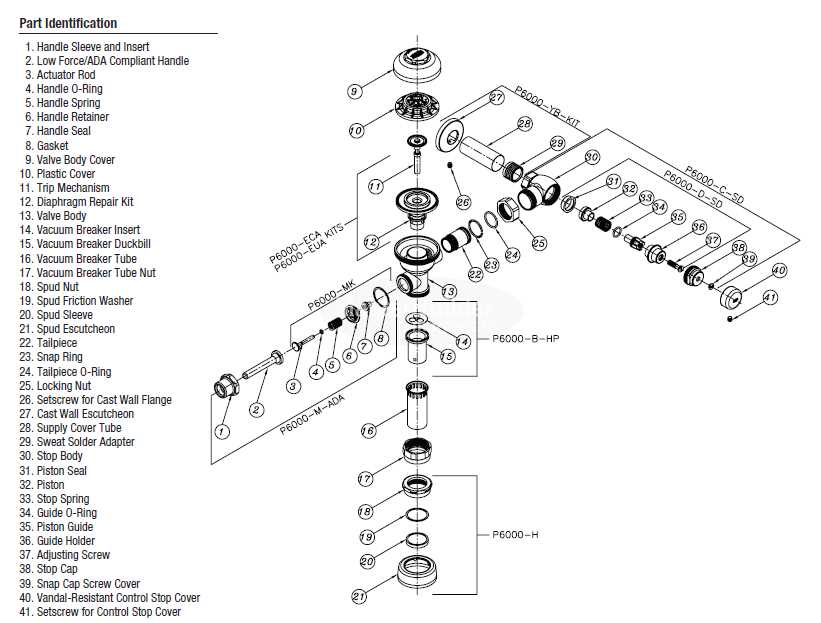

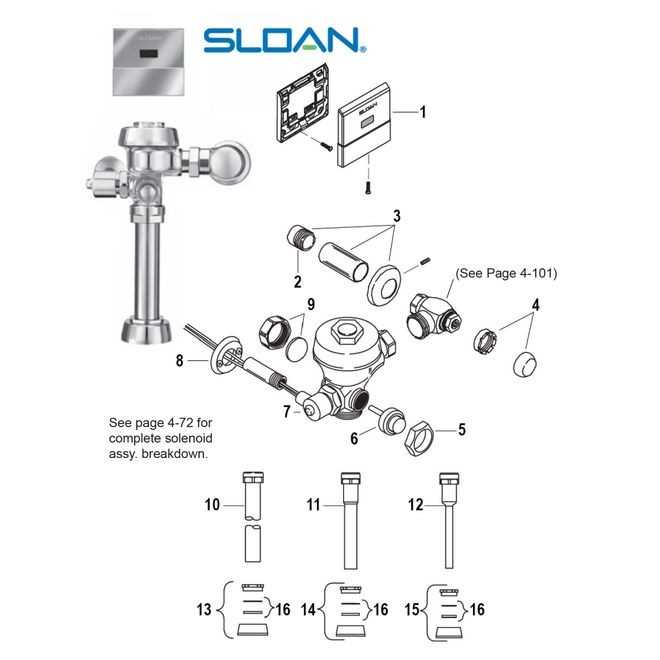

Understanding the components of a commercial-grade water control device is crucial for maintenance and repairs. Each element of this mechanism plays a role in managing the flow and pressure of water, ensuring efficient operation and reducing wastage. A detailed overview of these elements can assist in identifying the source of issues and ensuring smooth functioning.

Key Elements of the Mechanism

The system is comprised of various intricate components, each designed to control water flow precisely. The main control unit is responsible for regulating the opening and closing mechanisms, ensuring a steady discharge. Supporting elements include seals and valves, which help maintain consistent pressure and prevent leakage. Proper understanding of these elements ensures effective troubleshooting and maintenance.

Common Issues and Solutions

Over time, wear and tear can affect the device’s efficiency. Leaks, inconsistent flow, or pressure imbalances may occur. Regular inspection of seals and cleaning of control units can prevent such issues. Replacing worn-out elements and ensuring tight connections can extend the lifespan of the device and maintain optimal performance. Addressing these common challenges promptly keeps the system functioning as intended.

Understanding the Sloan Flush Mechanism

The operation of a water-efficient flushing system relies on a combination of valves and controls to manage the flow of water. This system is designed to deliver a precise amount of water for each activation, ensuring efficient and thorough rinsing while minimizing waste. Its components work together to maintain pressure and control the release of water, allowing for smooth and consistent operation.

Key elements of this mechanism include pressure regulation and flow control. These aspects ensure that the system delivers the appropriate volume of water with each use. The balance between these functions is crucial for maintaining optimal performance, preventing leaks, and ensuring a proper seal after each use.

Maintenance and adjustments of this mechanism often involve fine-tuning certain elements to keep the flow steady and effective. Understanding how these adjustments impact the overall performance can help users maintain the system in peak condition, extending its operational life and ensuring reliable performance in various settings.

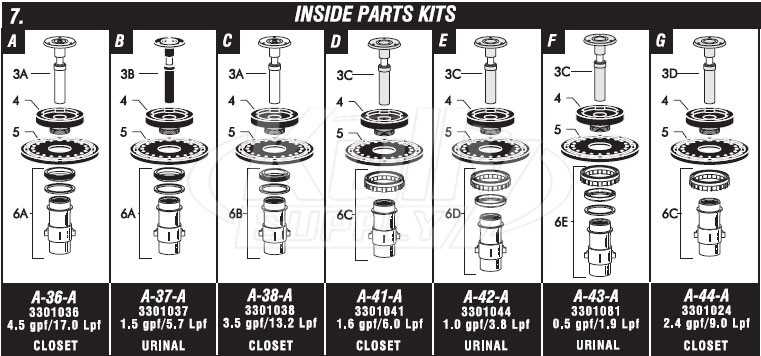

Key Components of Flushometer Systems

Understanding the essential elements of these water control systems allows for a deeper insight into how they manage the efficient flow of liquids. Each component plays a crucial role in ensuring smooth functionality and optimal performance, contributing to the effective regulation of water usage in various settings.

| Component | Description |

|---|---|

| Control Valve | Regulates the release and shut-off of water, ensuring precise flow control and preventing leaks. |

| Flow Regulator | Balances the water stream to maintain consistent pressure, providing efficient operation under varying conditions. |

| Sealing Mechanism | Ensures tight closure after use, preventing water from escaping and maintaining system integrity. |

| Actuation Device | Engages the system’s mechanism, allowing for the controlled release of water when activated. |

| Pressure Chamber | Utilizes air or water pressure to manage the timing and intensity of the flow, contributing to efficient operation. |

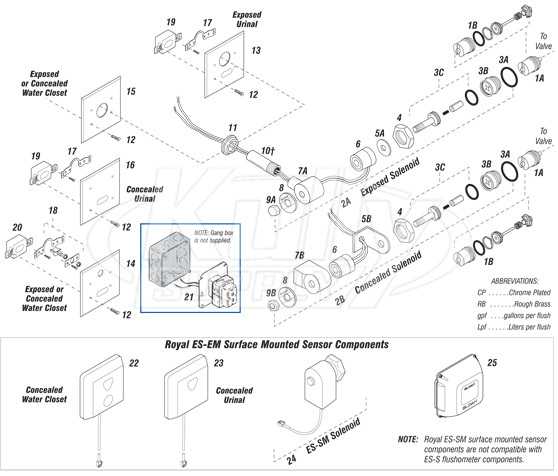

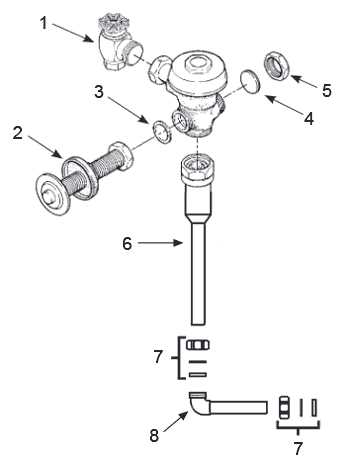

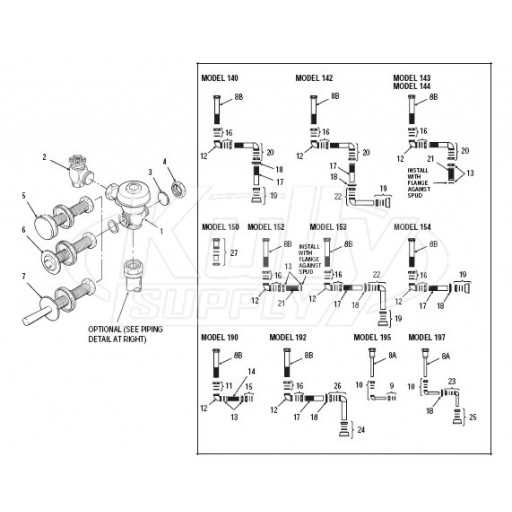

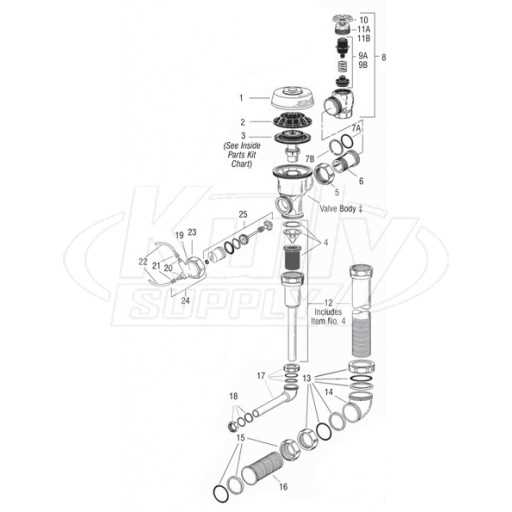

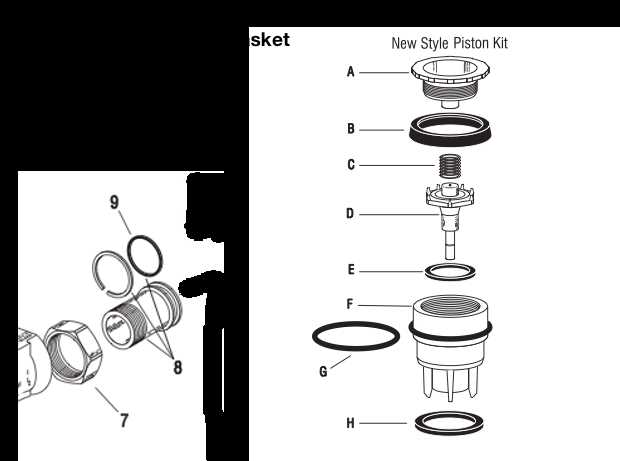

Diagram Overview for Sloan Repair

This section provides a detailed look at the visual representation used for maintenance guidance. It outlines the various components and connections, offering a clear view of how each element interacts within the system. By understanding this overview, troubleshooting and repairs can be handled with greater accuracy and efficiency.

Key Component Arrangement

The illustration highlights the primary elements, showing their placements and how they are linked together. This visual reference helps in identifying which areas may require adjustments or replacements during the repair process. It simplifies the identification of various elements, making maintenance more intuitive.

Understanding Connections and Flow

The layout emphasizes the flow pathways, providing insights into how different sections connect and work together. This helps in understanding the overall operation, making it easier to diagnose issues and ensure proper reassembly after repairs. This approach aids in maintaining optimal performance and longevity.

Identifying Common Flushometer Parts

Understanding the different elements within a water control system is key to maintaining efficient operation. These components work together to ensure proper flow, regulate pressure, and provide a smooth release of water. Each piece plays a crucial role in achieving consistent performance, and recognizing their functions can assist in troubleshooting and repairs.

Among the essential elements, you’ll find mechanisms that control the opening and closing of water flow, ensuring the correct timing and volume. Additionally, pressure-regulating pieces help maintain balance within the system, preventing overflows or weak flow. Other integral parts include seals and gaskets, which ensure a tight connection between various sections, avoiding leaks and maintaining efficiency.

By familiarizing yourself with these elements, you can better diagnose common issues and perform basic maintenance. A clear understanding of their roles allows for a more straightforward approach to keeping the system in optimal working condition, ensuring long-term reliability and functionality.

Replacement Guide for Flushometer Components

This section provides essential guidance for replacing various elements of a water control mechanism in restrooms. Proper maintenance ensures optimal performance and longevity, making it crucial to understand the key components involved.

When it comes to replacements, consider the following:

- Identify the malfunctioning component.

- Gather necessary tools and replacement items.

- Follow a step-by-step approach for effective installation.

Here is a detailed checklist for your replacement process:

- Shut off the water supply to avoid leaks.

- Remove the cover to access the internal mechanisms.

- Carefully detach the faulty piece.

- Install the new part, ensuring a snug fit.

- Reassemble the unit and turn the water supply back on.

Regular inspections and timely replacements contribute to the reliability of restroom fixtures. Ensuring all components function seamlessly will enhance user satisfaction and reduce service interruptions.

How to Maintain Sloan Devices

Proper upkeep of sanitary fixtures is essential for optimal performance and longevity. Regular attention not only enhances efficiency but also prevents unexpected malfunctions. Following a systematic approach ensures these essential components remain functional and reliable.

To effectively maintain these devices, consider the following steps:

- Conduct routine inspections to identify any wear or damage.

- Ensure all connections are secure to prevent leaks.

- Clean components regularly to remove debris and buildup.

Implement the following maintenance tasks:

- Check and replace worn washers and seals to ensure a tight fit.

- Lubricate moving parts to minimize friction and wear.

- Test for proper operation periodically to catch issues early.

By following these guidelines, you can ensure your sanitary fixtures operate smoothly and efficiently, providing reliable service for years to come.

Troubleshooting Flushometer Part Issues

Addressing challenges with water control systems can often be straightforward. Recognizing the symptoms and understanding the typical problems can lead to effective solutions. This section focuses on common difficulties faced during the operation of these mechanisms and offers guidance on how to resolve them efficiently.

Common Problems

- Inconsistent water flow

- Unexpected leaks

- Continuous running

- Weak or no flushing power

Resolution Steps

- Identify the issue: Observe the behavior of the system to pinpoint the exact problem.

- Inspect components: Check seals, gaskets, and other critical elements for wear and tear.

- Clean thoroughly: Remove any debris or buildup that may obstruct function.

- Replace faulty parts: If specific components are damaged, consider replacing them with compatible alternatives.

By following these guidelines, users can effectively diagnose and address issues, ensuring optimal performance of their water management systems.

Installation Tips for Sloan Parts

Proper installation of components in water control systems is essential for optimal functionality and durability. Following a few straightforward guidelines can ensure a smooth setup process and prevent common issues.

Preparation and Tools

Before beginning the installation, gather all necessary tools and components. Having everything on hand reduces the likelihood of interruptions. Ensure that you have adjustable wrenches, screwdrivers, and any specific tools required for the components being installed. Review the assembly instructions carefully to familiarize yourself with each part and its placement.

Step-by-Step Installation

Start by shutting off the water supply to the system. Carefully remove any old components before installing the new ones. Make sure to clean the surfaces to ensure a tight seal. Follow the installation steps outlined in the manual, paying close attention to the orientation and alignment of each piece. After installation, gradually turn the water supply back on and check for any leaks, making adjustments as necessary.