When working with heavy-duty equipment designed to process wood, it’s important to have a clear understanding of how various elements come together to ensure efficient operation. Each component plays a critical role in maintaining smooth functionality, and knowing how these elements interact can help improve performance and longevity.

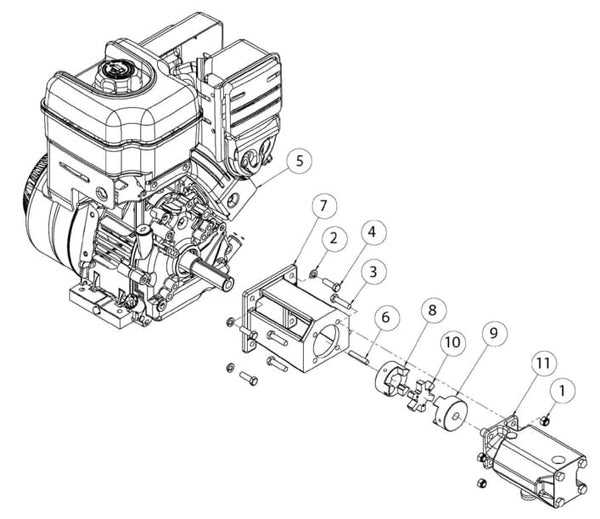

Proper maintenance requires a detailed look at the internal mechanisms that drive the equipment. Identifying and familiarizing oneself with these mechanisms can prevent unexpected breakdowns and enhance the overall effectiveness of your machinery.

Comprehensive knowledge of the equipment’s structure not only allows for better troubleshooting but also ensures that replacements and repairs are carried out with precision. By having a clear overview of the layout, one can efficiently handle any maintenance tasks.

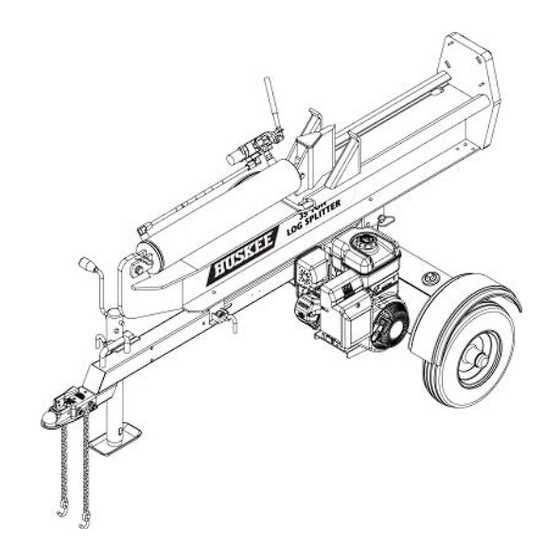

Understanding the Components of a Huskee Log Splitter

To operate a wood processing machine effectively, it is important to understand its key mechanical and hydraulic systems. Each part plays a vital role in ensuring efficient performance, and recognizing these elements can help with both operation and maintenance. This guide provides an overview of the essential components and their functions.

Hydraulic Mechanism

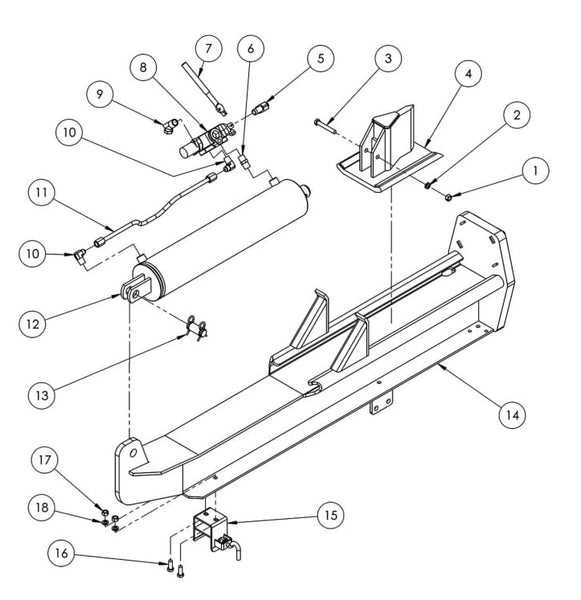

The core of the machine’s power lies in its hydraulic system. This includes a pump, reservoir, and various valves, all working together to generate the force needed for the machine’s function. The hydraulic fluid moves under pressure, enabling the machine to handle even the toughest materials. Proper fluid maintenance is crucial for avoiding malfunctions.

Mechanical Structure

The frame and supporting structure ensure stability during operation. Reinforced beams and durable metal components hold the entire assembly in place, allowing for consistent performance over time. Regular inspection of

Key Parts for Smooth Operation

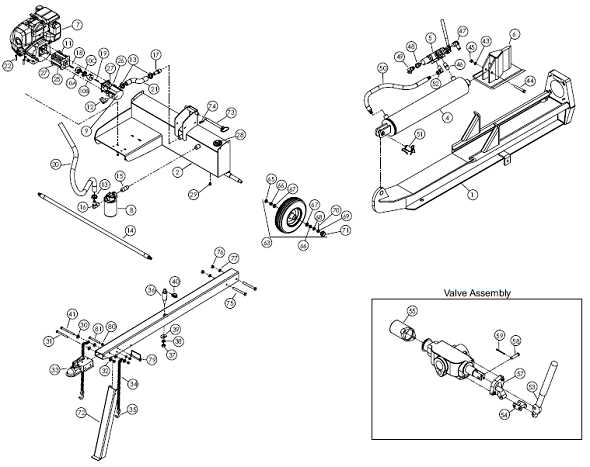

To ensure flawless performance, it’s essential to understand the components that drive the machine’s functionality. These elements work in harmony to maintain efficiency and prevent potential malfunctions. Recognizing the critical elements can help in identifying issues early and keeping everything running optimally.

Hydraulic System

The hydraulic system plays a crucial role in providing the necessary force to perform its task. This system comprises multiple elements that ensure the consistent delivery of power. Regular maintenance of these elements ensures uninterrupted operation and extends the machine’s lifespan.

Control Mechanism

The control mechanism ensures smooth operation by allowing the user to direct the machine’s actions. Accurate adjustments and quick response times are vital for safe and efficient handling. Keeping this mechanism in proper working condition is key to preventing operational errors and maintaining safety.

Hydraulic System Overview and Maintenance

The hydraulic system plays a critical role in the functionality of machines by enabling smooth and powerful movement of components. Understanding its structure and ensuring proper upkeep are essential for maintaining optimal performance. Regular checks and timely interventions can extend the lifespan of the system, prevent malfunctions, and ensure safe operation.

To keep the hydraulic system in top condition, it is important to follow a maintenance schedule. Below is a basic guide to essential tasks:

| Maintenance Task | Frequency | Description | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fluid Level Check | Before Each Use | Ensure that hydraulic fluid levels are within recommended limits to prevent air contamination or pump damage. | |||||||||||||||||||||

| Filter Replacement | Every 500 Hours | Replace hydraulic filters to maintain fluid

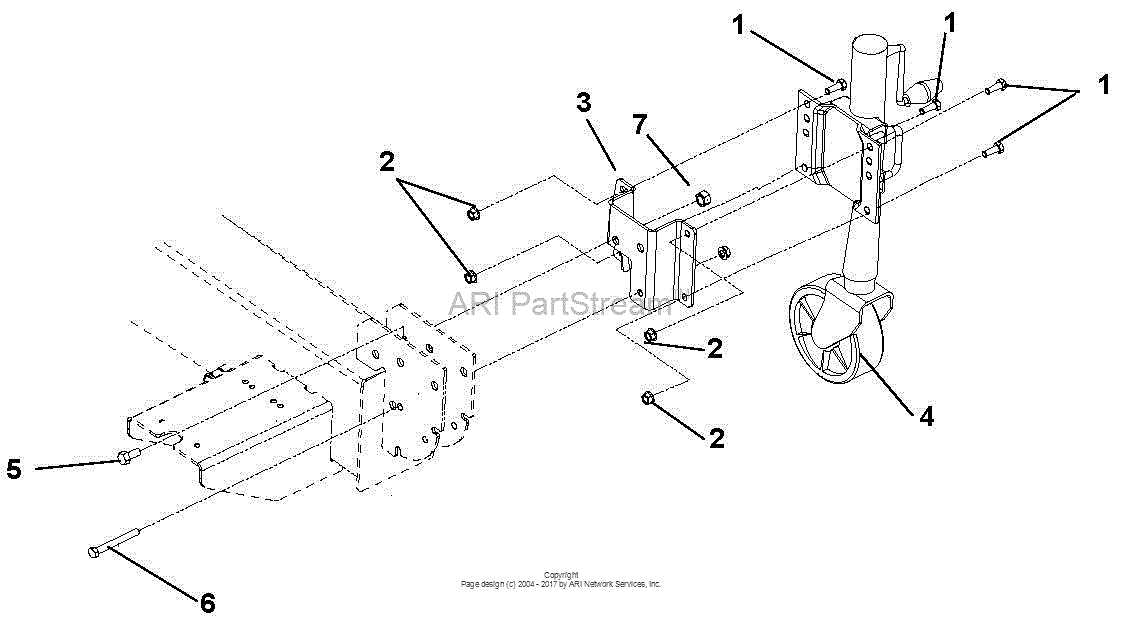

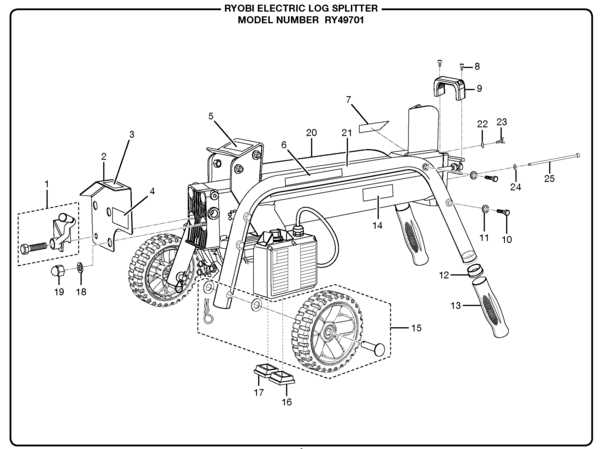

Replacing Worn Out Log Splitter ValvesOver time, the valves in hydraulic machinery can wear out due to constant use and pressure. When this happens, it is crucial to replace them to maintain the equipment’s efficiency and functionality. The process involves careful removal and installation of new components to restore the hydraulic flow and control systems. Step 1: Preparation Step 2: Removing the Old Valve Step 3: Installing the New Valve How to Identify and Order Replacement PartsWhen your equipment experiences wear and tear, it’s essential to know how to find the correct components to ensure its proper function. By examining the specific model and understanding the mechanism, you can easily pinpoint what needs replacing and proceed with ordering the necessary items. Step 1: Begin by identifying the model number and serial information. These details are usually located on a label or engraved on the device. Accurate identification of the model helps in narrowing down compatible components. Step 2: Once you have the details, consult the manufacturer’s documentation or an online resource that lists compatible parts for your equipment. Ensure the specifications match exactly to avoid compatibility issues.

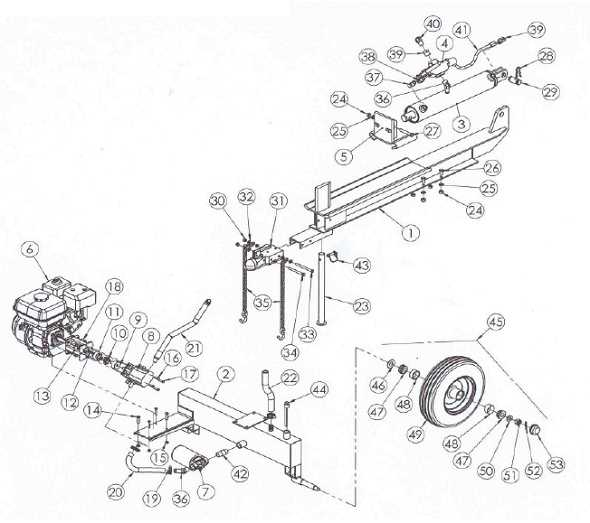

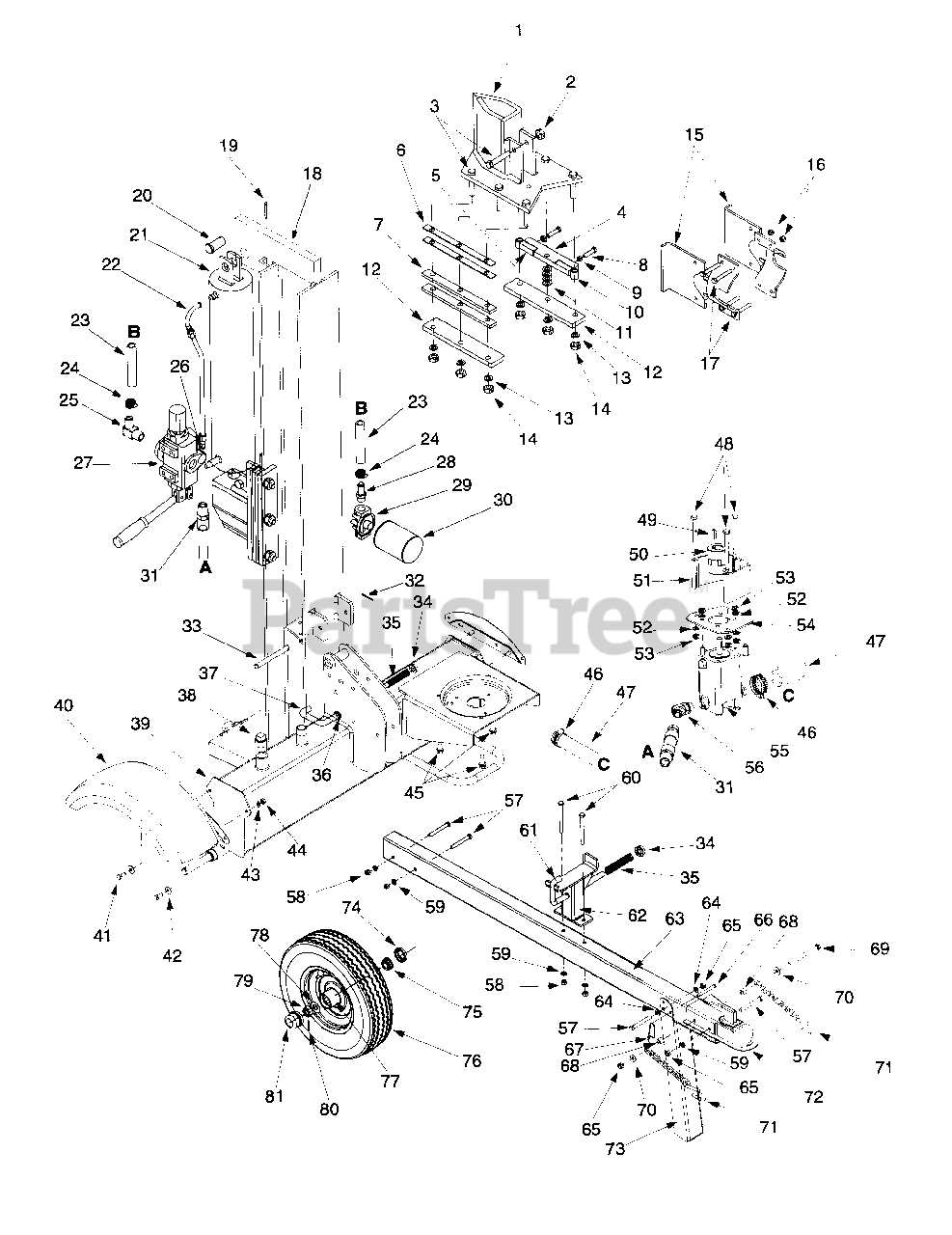

Assembly Guide for a Huskee Log Splitter

This section provides a comprehensive guide for assembling the equipment designed for cutting wood efficiently. Proper assembly is crucial to ensure optimal performance and safety during operation. The following instructions outline the steps necessary to correctly put together the components of your machinery, allowing you to achieve effective results. Necessary Components

Before beginning the assembly process, ensure you have all the necessary elements at hand. Refer to the following table to familiarize yourself with each component required for the setup:

Assembly Steps

To begin the assembly, follow these steps carefully: 1. Start by attaching the frame to a stable surface, ensuring it is level. Secure it with appropriate fasteners. 2. Next, mount the engine on the designated area of the frame. Ensure all bolts are tightened adequately to prevent any movement during operation. 3. Install the hydraulic cylinder by aligning it with the frame and securely fastening it in place. 4. Attach the wedge at the front of the hydraulic cylinder, ensuring it is firmly in place to perform its function effectively. 5. Install the control handle within easy reach of the operator’s position. 6. Finally, attach the wheels at the base of the frame for enhanced portability. After following these steps, conduct a thorough inspection to ensure everything is securely attached and functioning properly. This will enhance both safety and perfor Choosing the Right Accessories for Your Splitter

When it comes to enhancing the efficiency of your machine, selecting the appropriate tools and attachments is essential. These accessories can significantly improve performance, making your tasks easier and more productive. Understanding the available options and their benefits will help you make informed choices tailored to your specific needs. Consider the following categories when evaluating the best additions for your equipment:

Additionally, investing in quality accessories can improve the longevity of your equipment. Always opt for trusted brands that guarantee durability and reliability. Take time to research and select the right tools to ensure optimal performance and safety. Troubleshooting Common Log Splitter Issues

Understanding how to diagnose and resolve frequent mechanical problems is essential for maintaining optimal performance in any wood processing equipment. This section outlines common challenges users may encounter and offers effective solutions to enhance the functionality of your device. Here are some typical issues you might face:

To effectively troubleshoot, follow these steps:

By following these guidelines, you can effectively manage and rectify common issues, ensuring your equipment remains reliable and efficient. Ensuring Longevity with Proper Part CareMaintaining the durability of machinery components is essential for optimal performance and extended lifespan. By adopting best practices for upkeep, users can enhance the efficiency and reliability of their equipment. This section outlines key strategies to ensure that every element functions smoothly and remains in peak condition. Routine Maintenance PracticesImplementing a consistent maintenance schedule can prevent premature wear and tear. Consider the following steps:

Storage and ProtectionProper storage techniques significantly contribute to the longevity of equipment. Follow these recommendations:

By adhering to these maintenance and storage guidelines, users can significantly prolong the life of their machinery, ensuring reliable performance over time. |