For enthusiasts and professionals alike, comprehending the intricacies of a well-known lawn care machine is essential for its optimal performance. This section delves into the various elements that constitute the equipment, enabling users to maintain, troubleshoot, and enhance its functionality. By exploring these components, one can ensure longevity and reliability in operation.

Each segment of this device plays a pivotal role in its overall efficiency. Recognizing how these parts interact and contribute to the machine’s operation can greatly assist in diagnosing issues and facilitating repairs. The information provided here aims to empower users with the knowledge necessary for effective maintenance and improved user experience.

Through a detailed examination of the components, users will gain insights into the assembly and function of this essential tool. Whether you’re replacing a worn element or performing routine maintenance, understanding the layout and significance of each section will enhance your familiarity with the equipment, ultimately leading to better care and operation.

Overview of John Deere JS40

This section provides a comprehensive examination of a popular model known for its reliability and efficiency in maintaining lawns and gardens. Designed for ease of use and durability, this machine is suitable for both residential and light commercial applications.

The equipment features a powerful engine that ensures optimal performance, while its cutting system is engineered to deliver a clean and precise finish. With an ergonomic design, it offers comfort during operation, making yard work less strenuous. Additionally, the machine incorporates various innovative technologies to enhance user experience and overall productivity.

Maintenance and serviceability are also key aspects of this model, with accessible components that facilitate quick repairs and routine checks. This ensures that users can keep their equipment in peak condition with minimal downtime. Overall, this model stands out as a reliable choice for anyone seeking a dependable solution for outdoor grass management.

Identifying Key Components

Understanding the essential elements of a lawn maintenance machine is crucial for effective operation and maintenance. Familiarity with these critical components ensures optimal performance and longevity of the equipment. This section will outline the main features to consider when assessing the structure and function of the device.

Major Elements

- Engine: The powerhouse that drives the machine, responsible for generating the necessary energy.

- Deck: The housing that encases the cutting mechanism, protecting it while allowing for efficient grass trimming.

- Handle: Provides control and maneuverability, designed for comfort during use.

- Wheels: Enable smooth movement across various terrains, crucial for stability and ease of operation.

Supporting Features

- Fuel System: Supplies energy to the engine, consisting of a tank, lines, and filters.

- Cutting Blade: The sharp component that performs the actual cutting of grass, requiring regular inspection for wear.

- Starter Mechanism: Engages the engine, often using a recoil or electric starter.

- Exhaust System: Directs emissions away from the user, ensuring safe operation.

Recognizing these vital parts aids in proper maintenance, enhances efficiency, and contributes to the overall lifespan of the machine.

Parts Replacement Procedures

Replacing components of outdoor equipment is essential for maintaining optimal performance and longevity. This section outlines the steps involved in effectively substituting various elements, ensuring that users can complete the task efficiently and safely.

Step 1: Begin by gathering all necessary tools and new components before commencing the replacement process. This preparation will facilitate a smoother workflow and minimize downtime.

Step 2: Disconnect the equipment from its power source to ensure safety during the procedure. It is vital to follow proper safety protocols to prevent accidents.

Step 3: Carefully remove the old component, taking note of its placement and any connecting elements. This attention to detail will help when installing the new part.

Step 4: Install the new element by reversing the removal process. Ensure that all connections are secure and that the new part is properly aligned.

Step 5: Reconnect the power source and test the equipment to confirm that the replacement was successful. Monitoring performance after installation is crucial to identify any issues early.

Following these steps will help ensure that your equipment remains in excellent working condition, prolonging its lifespan and enhancing efficiency.

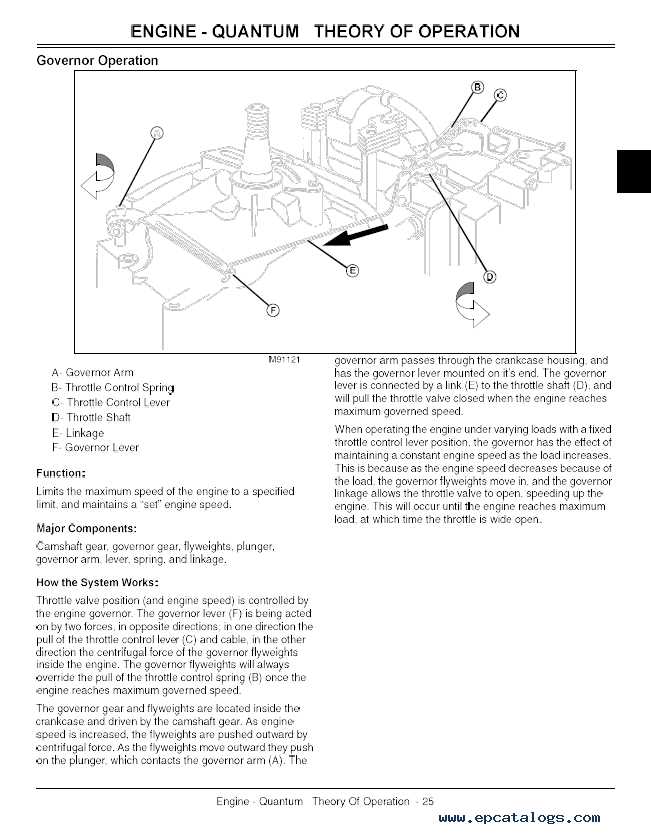

Understanding the Diagram Layout

The layout of a mechanical illustration is essential for comprehending the various components and their interconnections. It serves as a visual guide that allows users to identify each element’s position and function within the overall assembly. By interpreting these schematics, individuals can effectively navigate the complexities of machinery, ensuring proper maintenance and repair.

Typically, these representations are organized in a way that groups similar items together while highlighting their relationships. This arrangement aids in understanding how different sections interact, facilitating a clearer grasp of the system’s operation. Notably, the use of symbols and color coding can enhance the clarity of the visual representation, allowing for quicker identification of parts and functions.

Furthermore, being familiar with the layout can significantly streamline the troubleshooting process. When an issue arises, having a solid understanding of how components are arranged enables technicians to locate potential problem areas swiftly. Overall, a well-structured illustration is a valuable resource for anyone involved in the maintenance or repair of mechanical equipment.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your equipment requires diligent care and attention to detail. By implementing a routine maintenance schedule and being proactive about repairs, you can significantly enhance performance and durability. Here are some essential practices to consider for optimal upkeep.

- Regular Inspections: Conduct frequent checks for any signs of wear and tear. Look for loose components, leaks, and corrosion.

- Cleanliness: Keep the machinery clean by removing dirt and debris after each use. This helps prevent damage and maintains efficiency.

- Lubrication: Regularly lubricate moving parts to reduce friction and minimize wear. Follow the manufacturer’s recommendations for suitable lubricants.

- Air Filter Maintenance: Check and replace air filters as necessary to ensure optimal airflow and performance. A clean filter can improve fuel efficiency and engine performance.

- Sharp Blades: Keep cutting edges sharp for efficient operation. Dull blades can lead to increased strain on the engine and a poor finish.

By adhering to these simple yet effective maintenance tips, you can greatly improve the reliability and lifespan of your equipment, ensuring it operates at peak performance for years to come.

Common Issues and Solutions

When operating outdoor power equipment, users often encounter a range of common challenges that can affect performance. Understanding these issues and knowing how to address them can greatly enhance the reliability and longevity of your machine. Below are some typical problems and their corresponding solutions.

Engine Starting Difficulties

One frequent issue is the engine’s reluctance to start. This can stem from several factors, including a depleted fuel supply, clogged air filters, or faulty spark plugs. Regular maintenance, such as ensuring the fuel tank is filled with fresh fuel and inspecting the air filter for blockages, can help prevent this problem.

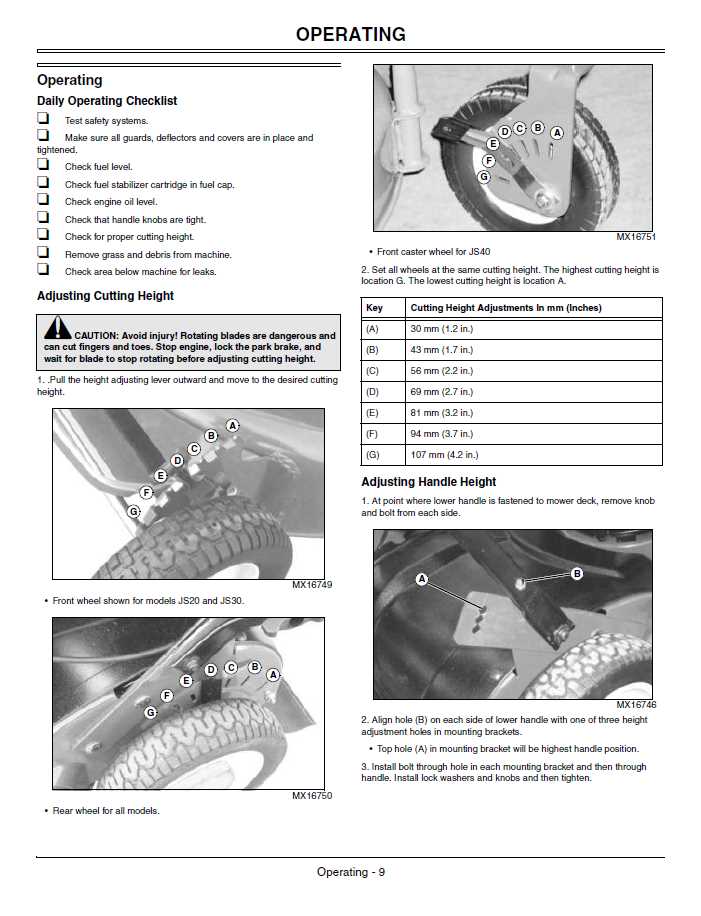

Cutting Performance Issues

Another common concern is subpar cutting performance, which may be due to dull blades or uneven tire pressure. To resolve this, it is essential to sharpen the blades regularly and check tire inflation levels. Additionally, ensuring that the cutting height is set appropriately for the type of grass can improve results.

By addressing these issues promptly, users can maintain optimal functionality and extend the life of their equipment.

Where to Find Replacement Parts

Finding suitable components for your machinery is essential for maintaining its optimal performance. There are various avenues to explore when searching for replacements, ensuring that you can restore functionality effectively and efficiently.

Online Retailers

- Numerous websites specialize in offering a wide range of components, often at competitive prices.

- Popular platforms include e-commerce giants where users can easily compare prices and availability.

- Manufacturer’s websites typically provide direct access to original components and specifications.

Local Dealers and Distributors

- Visiting local dealerships can provide immediate access to authentic components.

- Dealers often have knowledgeable staff who can assist in identifying the correct replacements.

- Networking with local distributors may yield options for sourcing hard-to-find items.

Utilizing these resources ensures that you can find the necessary items to keep your equipment running smoothly.

Safety Guidelines for Repairs

When undertaking maintenance or repair tasks on machinery, adhering to safety protocols is essential to prevent accidents and injuries. Proper preparation and awareness of potential hazards can significantly enhance the safety of the repair process.

1. Personal Protective Equipment (PPE): Always wear appropriate safety gear, including gloves, goggles, and sturdy footwear. This equipment acts as a barrier against injuries from sharp objects and harmful substances.

2. Workspace Organization: Maintain a clean and organized work area to minimize the risk of slips, trips, and falls. Ensure that tools and components are stored securely when not in use.

3. Tool Inspection: Regularly inspect tools for any signs of wear or damage before use. Using defective tools can lead to accidents and ineffective repairs.

4. Machine Stability: Ensure the equipment is stable and secured before starting any work. Utilize jack stands or other supports as needed to prevent unintended movement during repairs.

5. Follow Manufacturer Instructions: Always refer to the specific guidelines provided by the manufacturer. These instructions often include vital safety information and procedures tailored for the equipment.

6. Electrical Safety: When working with electrical components, ensure the power source is disconnected. This reduces the risk of electrical shock and short circuits.

7. Emergency Preparedness: Be aware of emergency procedures and have first-aid supplies readily accessible. Knowing how to respond in case of an accident can save lives.

By following these safety measures, individuals can create a safer working environment, reducing the likelihood of incidents while performing essential repairs.

Resources for Further Information

For those seeking additional insights and knowledge related to maintenance and repair of outdoor machinery, numerous resources are available. These platforms can provide valuable guidance, enhancing your understanding and ability to address specific issues effectively.

Online Communities and Forums

- Mechanic Forums: Engage with fellow enthusiasts and professionals who share their experiences and solutions.

- Social Media Groups: Join dedicated groups on platforms like Facebook or Reddit, where members discuss various topics and share advice.

Official Manufacturer Resources

- Manufacturer Websites: Access manuals, troubleshooting guides, and maintenance tips directly from the source.

- Authorized Dealers: Consult with local dealers for expert advice and support on specific models and their requirements.

Utilizing these resources can significantly improve your capability to maintain and repair outdoor equipment, ensuring optimal performance and longevity.