In the realm of heavy machinery maintenance and repair, having a clear visual reference for the various components is essential for effective troubleshooting and replacement. This knowledge enables operators and technicians to navigate the intricate systems that make up these robust machines, ensuring optimal performance and longevity. By exploring the relationships between different parts, one can gain insights into how these machines function as a cohesive unit.

The importance of detailed illustrations in the field cannot be overstated. They provide invaluable assistance in identifying specific components, understanding their functions, and facilitating easier repairs. With a comprehensive understanding of each element, users can approach maintenance tasks with confidence, reducing downtime and enhancing productivity. This guide serves as a resource to demystify the intricate web of components, making it easier for anyone involved in machinery upkeep.

By delving into the structure and layout of essential components, one can foster a greater appreciation for the engineering behind heavy equipment. Each piece plays a vital role in the overall operation, and recognizing their interdependencies is key to effective management and repair strategies. Whether you are a seasoned technician or a newcomer to the industry, a clear overview of these elements can significantly enhance your operational capabilities.

Understanding the John Deere 450C

The machinery in discussion represents a robust and versatile solution for various construction and agricultural tasks. With its unique design and engineering, it provides an efficient means to perform heavy-duty operations. This section aims to delve into the essential components and features that define this machine, offering insights into its functionality and utility.

Equipped with advanced technology, this model excels in maneuverability and durability, making it an ideal choice for professionals in the field. Its user-friendly interface ensures that operators can easily manage its capabilities, leading to enhanced productivity on-site. Understanding the key elements of this equipment allows for better maintenance practices, ensuring longevity and reliability.

| Component | Description |

|---|---|

| Engine | Powerful motor designed for high performance in various conditions. |

| Transmission | Efficient system that optimizes power transfer for smooth operation. |

| Hydraulics | Robust hydraulic system facilitating precise control of attachments. |

| Frame | Sturdy structure providing stability and support during heavy tasks. |

| Cab | Ergonomically designed operator area enhancing comfort and visibility. |

By comprehensively exploring these components, operators can appreciate the engineering that goes into such machinery. This knowledge not only aids in effective usage but also plays a crucial role in identifying potential issues early, thereby ensuring optimal performance.

Key Features of the 450C Model

This section highlights the distinctive characteristics of a robust and reliable piece of heavy machinery. Designed for efficiency and versatility, this model has become a favorite in various applications, offering operators an impressive blend of power and functionality.

Powerful Engine Performance

The engine is a critical component that defines the machine’s capabilities. It delivers substantial horsepower, allowing it to tackle demanding tasks with ease.

- High torque output for optimal performance in challenging environments

- Fuel efficiency, reducing operational costs

- Advanced cooling system to prevent overheating during extended use

Durable Construction and Design

The construction of this machinery reflects its ability to withstand harsh conditions while maintaining longevity. The design incorporates several features that enhance its durability.

- Reinforced frame that minimizes wear and tear

- Heavy-duty undercarriage for improved stability and traction

- Weather-resistant materials that protect internal components

Overall, these features combine to ensure that this heavy equipment remains operational in various settings, making it an invaluable asset for professionals in the industry.

Parts Overview for John Deere 450C

This section provides an essential look at the components of a specific model designed for heavy-duty applications. Understanding these elements is crucial for maintenance, repairs, and ensuring optimal performance. Each element plays a vital role in the overall functionality of the machinery, contributing to its efficiency and durability.

Key Components

Among the significant elements, the engine assembly stands out as the powerhouse of the machine. It is responsible for generating the necessary energy to perform various tasks. Additionally, the hydraulic system is pivotal for enabling smooth operations and precise control over attachments.

Maintenance Essentials

Regular upkeep of these vital components not only extends the lifespan of the equipment but also enhances its reliability. Key maintenance activities include checking fluid levels, inspecting filters, and ensuring all moving parts are properly lubricated. Neglecting these tasks can lead to performance issues and costly repairs.

In conclusion, a thorough understanding of the individual components and their functions is imperative for effective management of heavy machinery. This knowledge empowers operators and technicians to make informed decisions regarding repairs and maintenance.

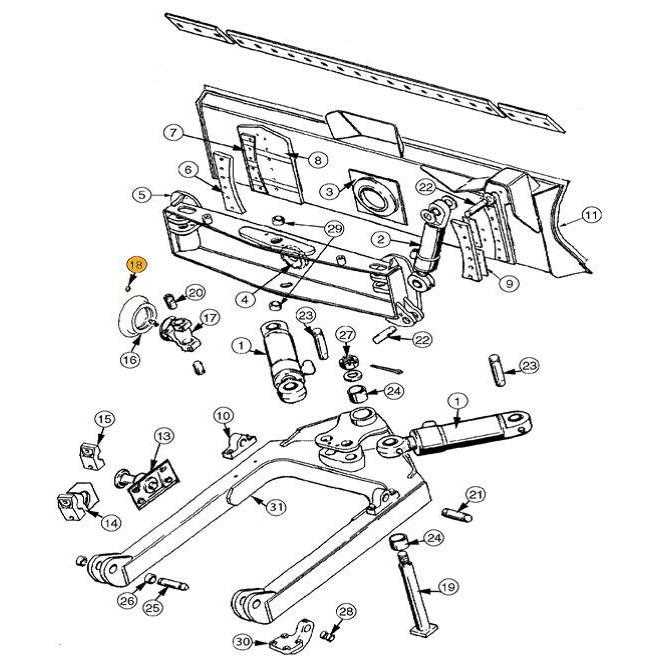

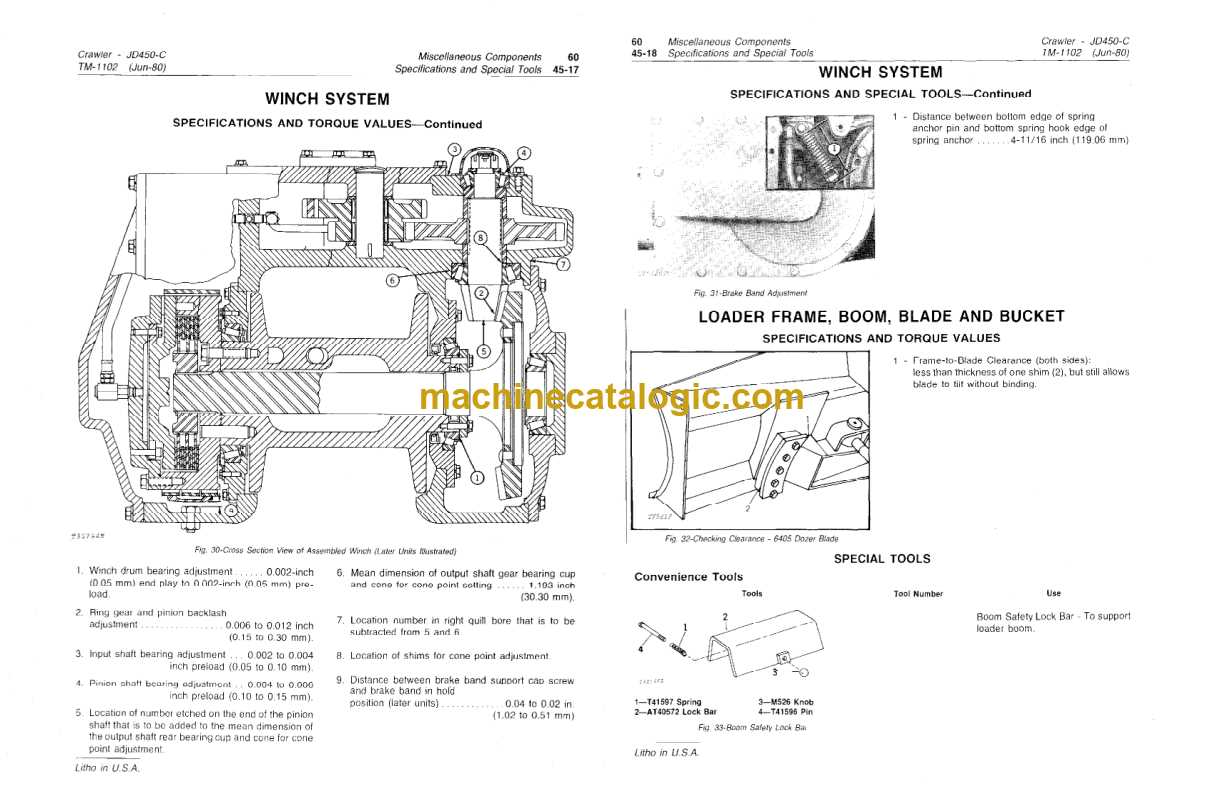

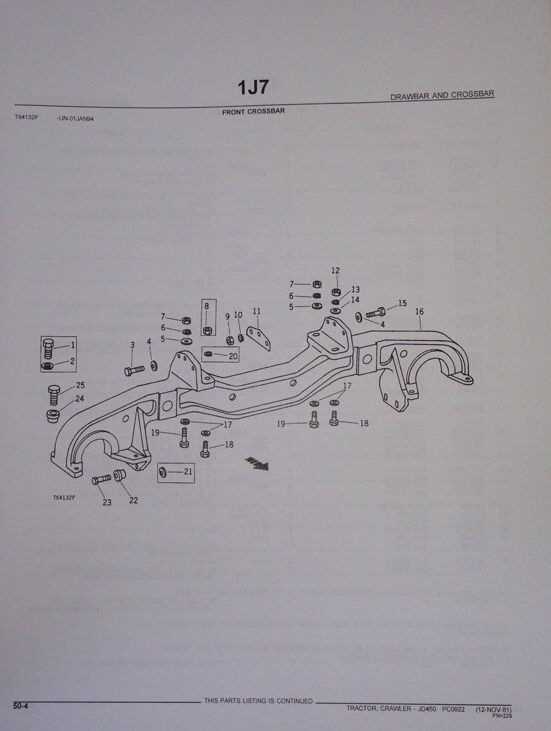

Importance of Parts Diagrams

Visual representations of mechanical components play a crucial role in the maintenance and repair of machinery. These illustrations provide a clear overview of the assembly and organization of various elements, aiding technicians and operators in understanding the structure and function of each part. By using these visual guides, individuals can efficiently identify components, troubleshoot issues, and ensure proper reassembly after repairs.

Furthermore, such visuals serve as essential tools for training and education. New users can quickly familiarize themselves with the layout and interconnections of different sections, enhancing their ability to perform repairs and maintenance tasks. This not only reduces the likelihood of errors during service but also contributes to safer operations and longer equipment lifespans.

In addition, detailed illustrations can help streamline the ordering process for replacements. By clearly labeling each element, these guides enable users to easily specify the required items, minimizing the chances of miscommunication with suppliers. This efficiency ultimately leads to reduced downtime and increased productivity, as operators can swiftly acquire the necessary components to keep their equipment running smoothly.

Common Parts for Replacement

When maintaining heavy machinery, it’s crucial to know which components are most frequently subject to wear and tear. Regular inspections and timely replacements can enhance performance and extend the lifespan of the equipment. Understanding the common elements that often need to be replaced helps in planning maintenance schedules and ensuring that the machinery operates smoothly.

Engine Components

Among the essential elements are engine components that may require regular replacement due to their vital role in the machine’s operation. Filters are one such item, including oil and air filters, which ensure that contaminants do not interfere with engine performance. Additionally, belts and hoses should be monitored closely, as they can deteriorate over time, potentially leading to significant operational issues if not addressed promptly.

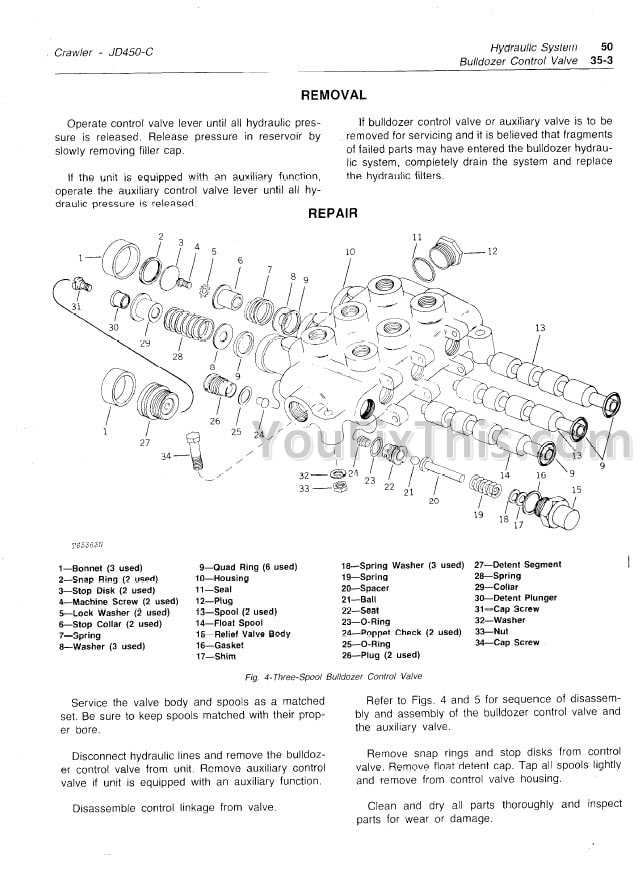

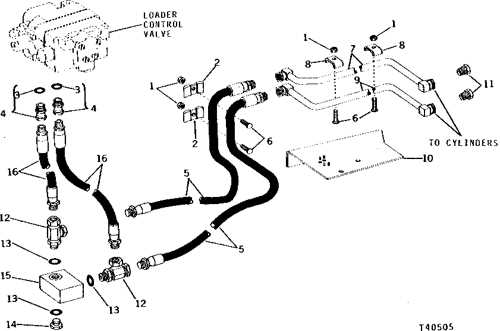

Hydraulic System Parts

The hydraulic system is another area where replacements are often necessary. Cylinders and pumps play a crucial role in the machinery’s functionality, and their failure can halt operations. Regularly checking for leaks and assessing the condition of these components can prevent costly downtime and repairs. Moreover, seals and filters in the hydraulic system should be replaced periodically to maintain optimal performance and efficiency.

How to Read Parts Diagrams

Understanding technical illustrations is essential for anyone involved in machinery maintenance and repair. These visuals provide a detailed view of components, helping users identify and locate necessary items for servicing or replacement. Mastering the interpretation of these graphics can significantly streamline the repair process and enhance overall efficiency.

Familiarizing with the Layout

Begin by examining the overall structure of the illustration. Each section typically includes labels and references to specific items, accompanied by numbers or letters. This arrangement allows for easy identification and retrieval of components. Pay attention to the arrangement of elements, as it often reflects their assembly sequence or functional relationships.

Utilizing Reference Numbers

Many visuals will incorporate reference numbers next to each component. These numbers correspond to a detailed list, often included alongside the illustration, that provides additional information such as part names, sizes, and compatibility. Cross-referencing these numbers with the list ensures that you acquire the correct replacements for your machinery.

In summary, grasping the essentials of interpreting technical illustrations is crucial for effective machinery upkeep. By familiarizing yourself with the layout and utilizing reference numbers, you can navigate these resources with confidence and improve your repair strategies.

Where to Find OEM Parts

When it comes to maintaining machinery, sourcing high-quality original equipment manufacturer components is crucial for optimal performance and longevity. Authentic replacements ensure compatibility and reliability, making it essential to know where to locate these resources effectively.

Online Resources

The internet is a valuable tool for locating genuine components. Numerous platforms specialize in offering OEM items, catering to various machinery needs. Online marketplaces and dedicated websites provide extensive catalogs, often with user-friendly search functions to streamline the selection process.

Local Dealers and Distributors

Another reliable avenue for acquiring original components is through authorized local dealers. These establishments often have direct access to manufacturer inventory, ensuring the availability of genuine items. Additionally, knowledgeable staff can assist in identifying the right components based on specific requirements.

| Source Type | Benefits | Considerations |

|---|---|---|

| Online Retailers | Wide selection, often competitive pricing | Verify seller reputation and return policies |

| Local Dealers | Personalized service, immediate availability | Potentially higher prices compared to online |

| Manufacturer Websites | Direct access to the latest components | May require navigating complex catalogs |

Maintenance Tips for Longevity

Ensuring the prolonged functionality of heavy machinery requires consistent care and attention. By adopting proper maintenance practices, operators can significantly enhance the lifespan of their equipment and minimize unexpected failures. Regular upkeep not only improves performance but also ensures safety during operation.

1. Routine Inspections: Conducting frequent assessments of the machine is crucial. Check for signs of wear and tear, loose components, or fluid leaks. Early detection of issues can prevent costly repairs and downtime.

2. Regular Cleaning: Keeping the equipment clean is essential. Remove dirt, mud, and debris from critical areas, especially around the engine and cooling systems. A clean machine operates more efficiently and has reduced risk of overheating.

3. Fluid Changes: Regularly changing lubricants and fluids according to the manufacturer’s guidelines is vital. Fresh oil and hydraulic fluid help maintain optimal performance and protect engine components from wear.

4. Proper Storage: When not in use, store the machinery in a sheltered location. Protecting it from harsh weather conditions will prevent corrosion and deterioration of external components.

5. Operator Training: Ensure that all operators are well-trained in using the machinery. Knowledgeable operators are less likely to misuse the equipment, thereby reducing the risk of damage.

6. Scheduled Maintenance: Adhering to a regular maintenance schedule is imperative. Following the manufacturer’s recommendations for inspections and replacements ensures that all parts remain in good working condition.

By implementing these strategies, owners can ensure their equipment remains reliable and efficient for years to come.