Exploring detailed illustrations of mechanical assemblies provides valuable insight into how each element functions within a system. These visual guides ensure a smooth understanding of structural relationships, offering clarity for both routine maintenance and complex repairs. When every component has its place, troubleshooting becomes more efficient.

Whether you’re maintaining outdoor equipment or troubleshooting an issue, having access to accurate schematics helps streamline the process. They allow technicians to identify necessary replacements with precision, ensuring optimal operation. A clear understanding of these designs minimizes downtime and prevents costly mistakes during disassembly or repair.

Detailed layouts not only support repairs but also assist in proactive upkeep. Regular inspections using these diagrams help spot early signs of wear and tear, reducing the risk of major failures. Familiarizing yourself with these configurations ensures your machinery performs at peak levels, extending its lifespan and enhancing productivity.

Overview of Key Components

This section provides insight into the essential elements ensuring the smooth functionality and performance of the equipment. Understanding these components is crucial for proper maintenance and optimization, allowing users to troubleshoot issues and replace necessary elements effectively.

Engine and Drive System

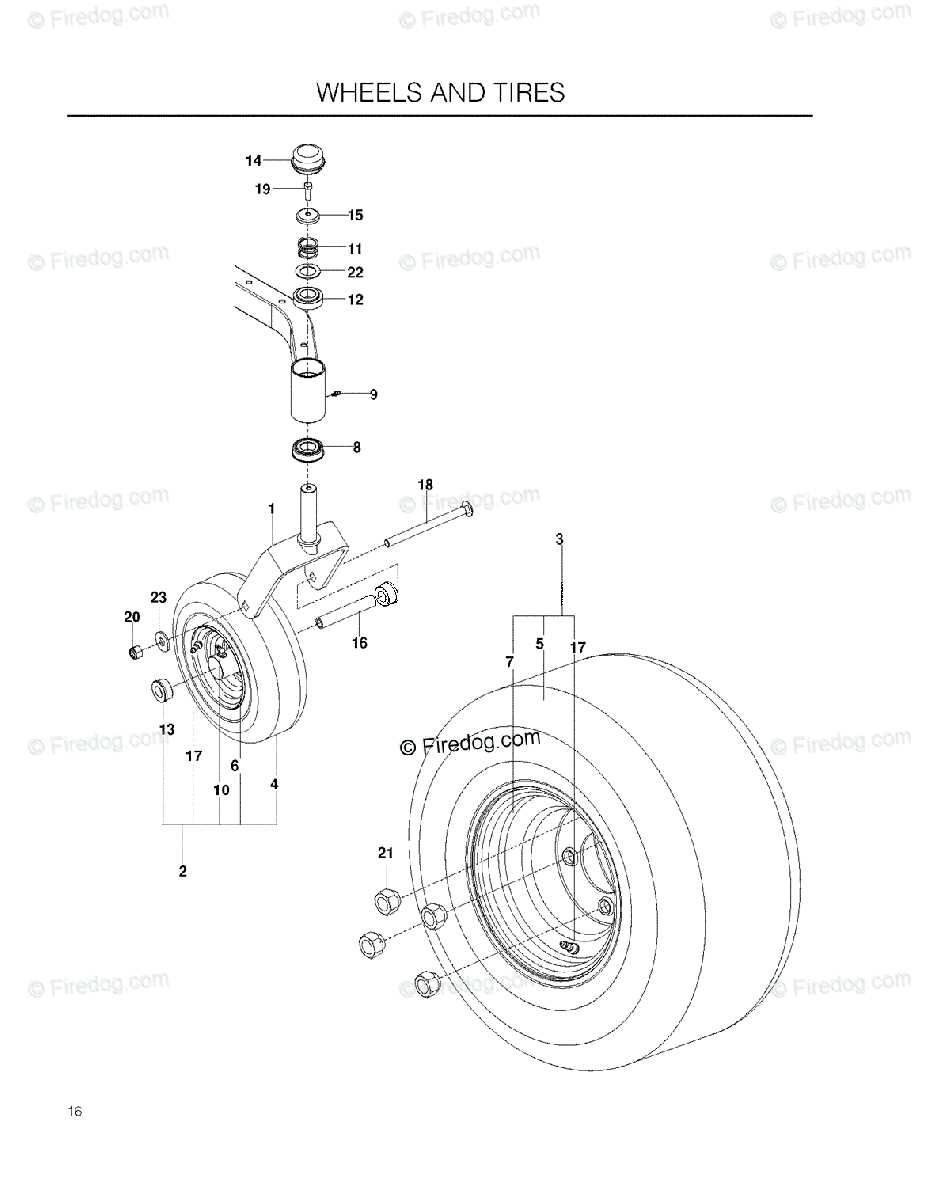

The power source and transmission system work together to propel the machine efficiently. A well-tuned engine delivers the required force, while the drive system distributes this power to the wheels, ensuring stable movement across various surfaces.

Cutting Deck Assembly

The cutting mechanism is designed to provide consistent results. Key elements include rotating blades, spindles, and belts, all contributing to even grass trimming. Regular inspection of these components ensures smooth operation and prevents performance degradation over time.

| Component | Function | Maintenance Tip | ||||||

|---|---|---|---|---|---|---|---|---|

| Engine | Provides mechanical power | Check oil levels regularly | ||||||

| Component | Function |

|---|---|

| Cutting Blades | Ensure a clean cut by rotating at high speeds beneath the deck assembly. |

| Spindle Assembly | Supports the rotation of blades and connects them to the engine’s drive mechanism. |

| Deck Shell | Encases the blades and prevents debris from being ejected outward. |

B

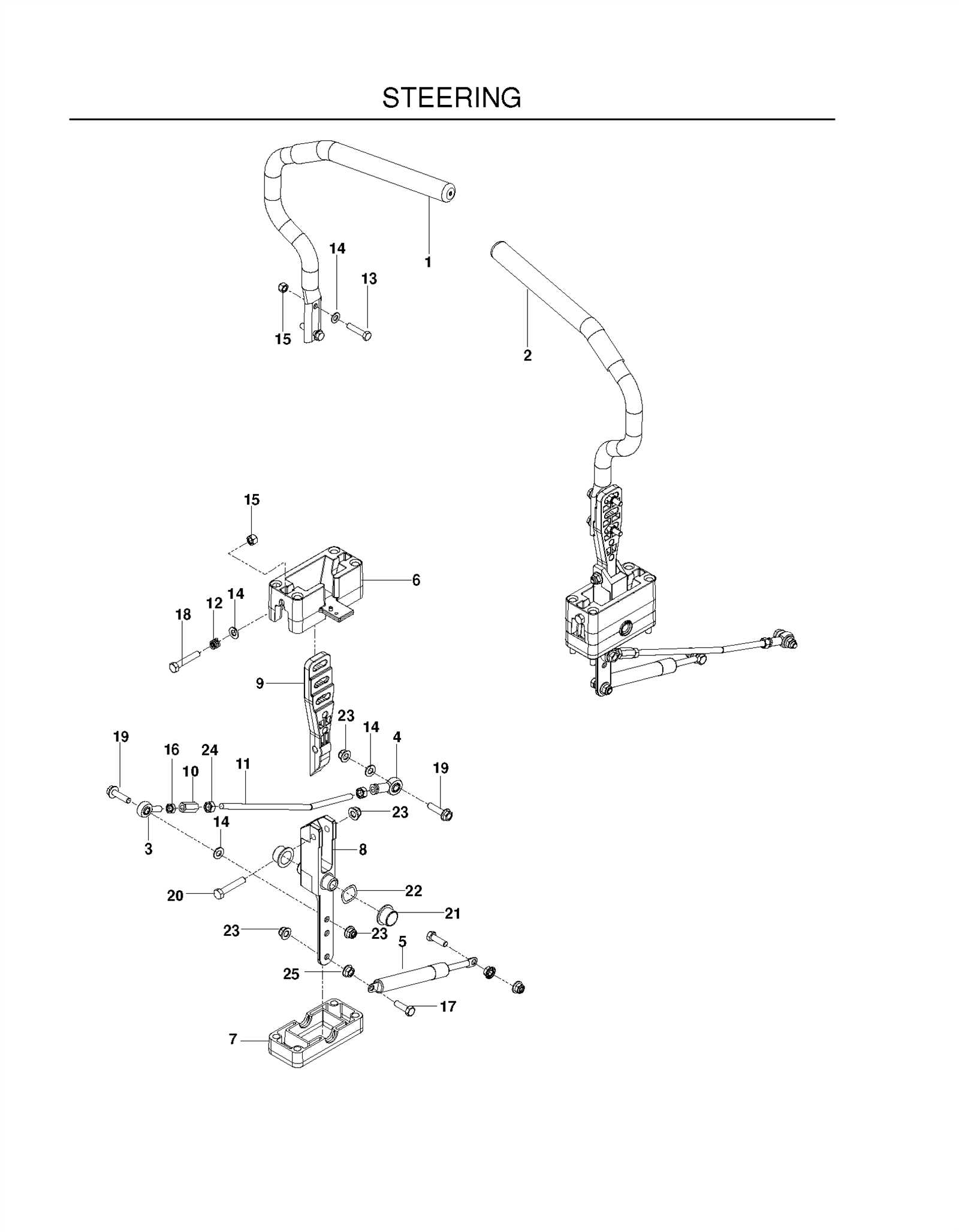

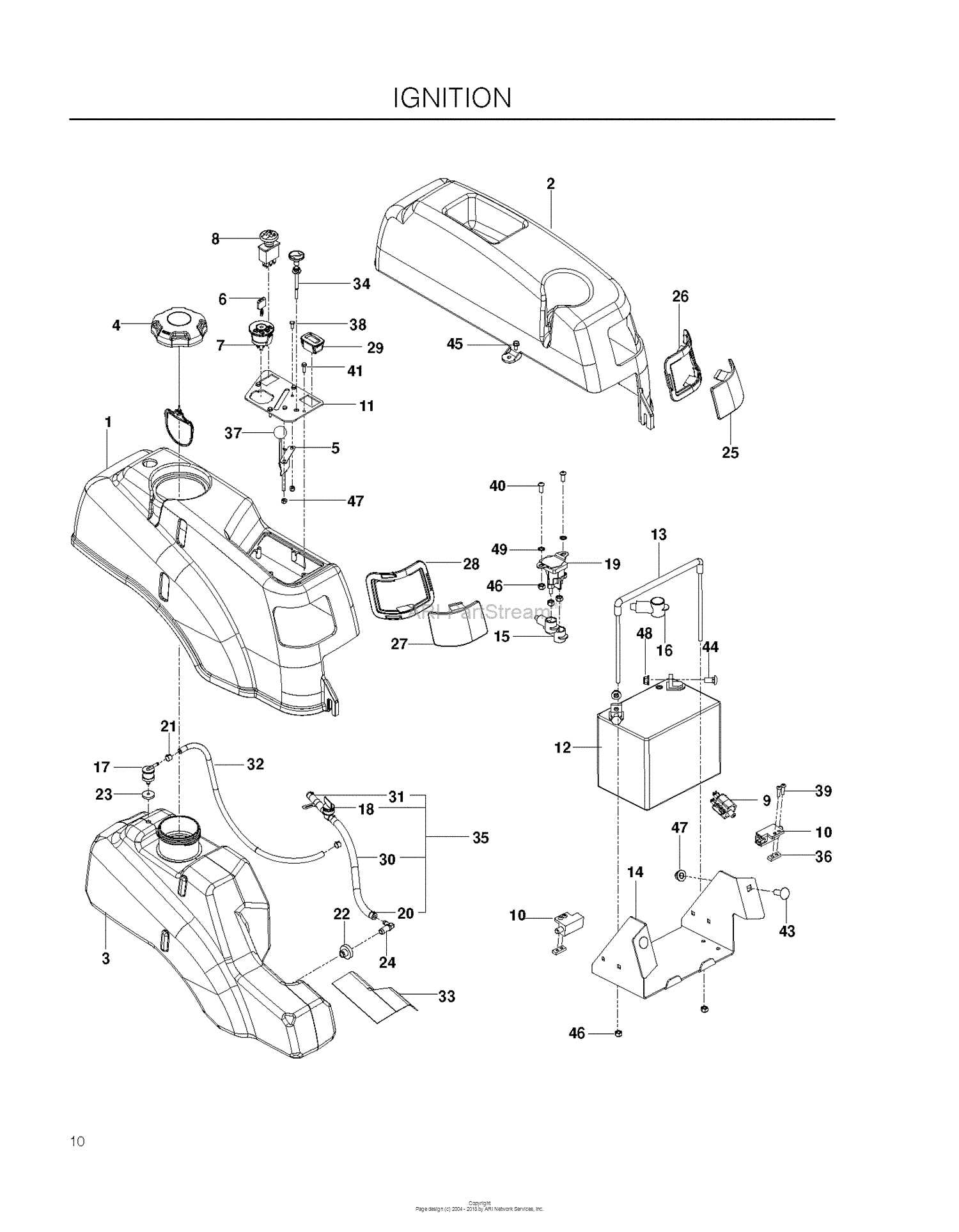

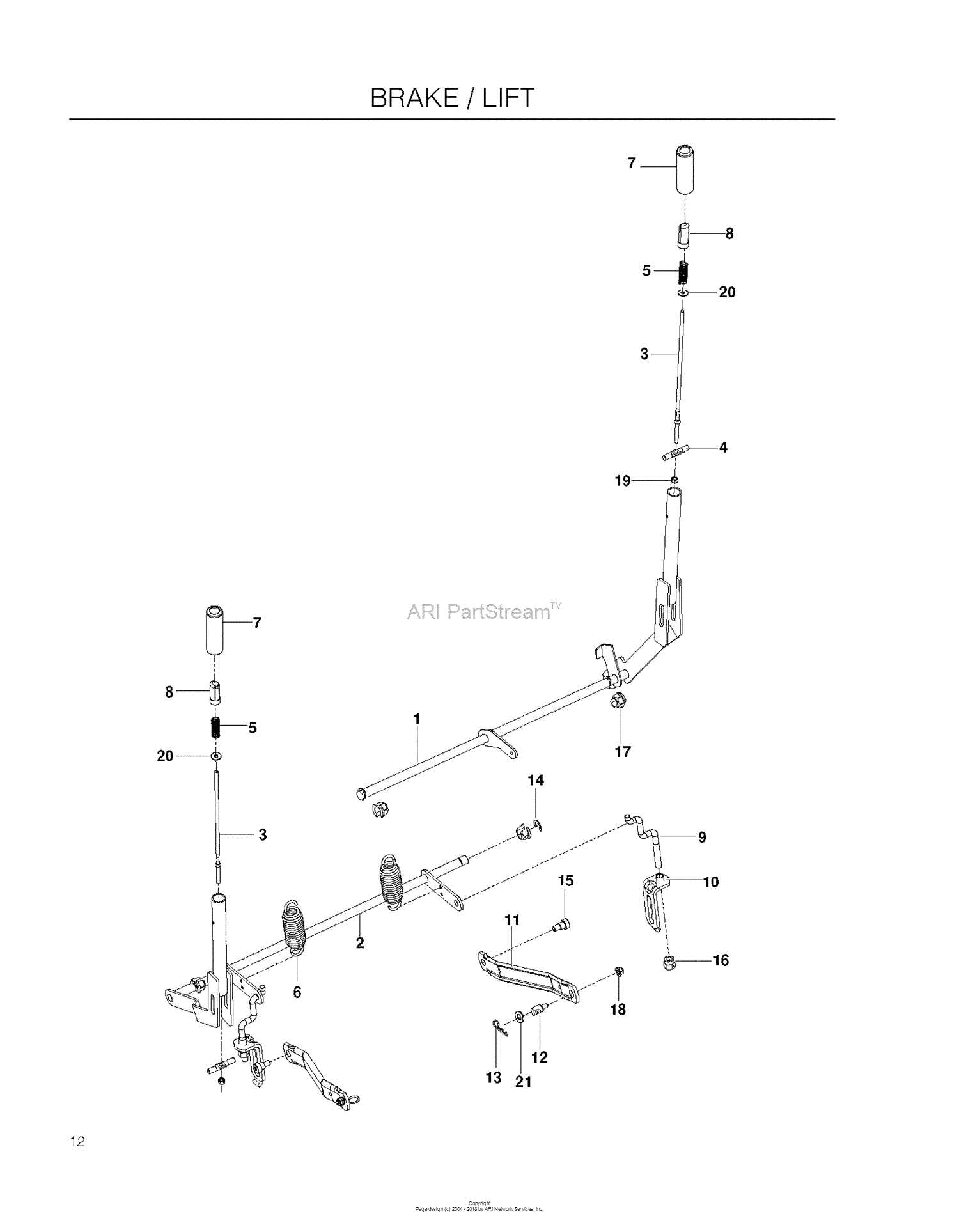

Engine Assembly and Drive SystemThe heart of any riding machine relies on the proper arrangement of its power unit and propulsion mechanism. This section explores how the motor integrates with the transmission elements to ensure smooth and efficient operation. A well-coordinated system is essential to deliver consistent performance across various terrains, minimizing wear and maximizing longevity. Core Components of the Power UnitThe motor assembly consists of several interconnected elements, including the combustion chamber, cooling system, and fuel delivery components. Precision alignment between these parts guarantees seamless energy conversion, resulting in optimal output. The configuration also ensures reduced vibration, enhancing operator comfort during extended use. Transmission and Propulsion MechanismThe drive system connects the engine to the wheels, utilizing belts, pulleys, or hydrostatic transmissions to transfer power. Accurate synchronization between the transmission and the motor allows for responsive acceleration and precise maneuvering. Regular maintenance of these components is vital to prevent slippage and maintain reliability over time. Steering Control and Linkage SetupThe alignment of steering components is essential for smooth operation and responsive handling. This section focuses on the configuration and adjustment of the steering system, ensuring balanced movement and precise navigation. Proper setup minimizes friction and enhances the interaction between various mechanical elements.

|