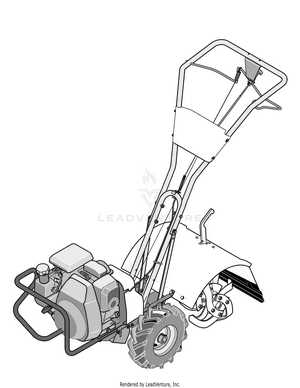

When it comes to maintaining a flourishing garden, having the right machinery is essential. This section delves into the intricate components that contribute to the effective functioning of gardening machinery, specifically focusing on a popular model known for its reliability. By breaking down each element, users can gain insight into the operational mechanics and enhance their gardening experience.

Identifying the Elements of the machinery allows for improved maintenance and troubleshooting. Familiarizing oneself with the various sections ensures that users can quickly address any issues that may arise during operation. An overview of these segments will facilitate a deeper understanding of how each piece plays a vital role in overall performance.

Additionally, having a comprehensive visual representation of the components aids in both assembly and disassembly processes. This clarity ensures that users can efficiently navigate the complexities of their equipment, ultimately leading to a more productive gardening endeavor.

Regular upkeep and timely repairs are crucial for the longevity and efficiency of any mechanical equipment. Neglecting these practices can lead to diminished performance, increased wear and tear, and ultimately, costly breakdowns. By prioritizing maintenance, users can ensure optimal functionality and extend the lifespan of their machinery.

Scheduled inspections and routine servicing help identify potential issues before they escalate. This proactive approach not only enhances performance but also contributes to safety and reliability during operation. Understanding the significance of these tasks can result in better investment returns and reduced operational costs.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Oil Change | Every 50 hours | Reduces engine wear and improves efficiency |

| Air Filter Replacement | Every 25 hours | Enhances airflow and engine performance |

| Blade Sharpening | As needed | Ensures effective cutting and minimizes strain |

| Inspection of Belts and Cables | Every 100 hours | Prevents unexpected failures and improves safety |

Investing time and resources into maintenance and repairs not only safeguards the equipment but also enhances productivity. By following a systematic approach to care, operators can enjoy a smoother experience and greater reliability in their operations.

Common Issues and Troubleshooting Tips

When operating garden cultivation equipment, various complications can arise, impacting performance and efficiency. Understanding these common challenges and how to resolve them is essential for maintaining optimal functionality. This section outlines frequent issues encountered and offers practical solutions to help you address them effectively.

Frequent Problems

- Engine Won’t Start: This can occur due to several reasons, including fuel blockage, dead battery, or a faulty ignition system.

- Difficulty in Turning: Resistance in the steering mechanism may be caused by worn-out components or inadequate lubrication.

- Poor Tillage Performance: Insufficient soil penetration can result from dull blades or incorrect depth settings.

- Excessive Vibration: This issue may arise from imbalanced parts or loose fasteners, leading to a rough operation.

Troubleshooting Steps

- Engine Troubles:

- Check the fuel level and ensure it is fresh and clean.

- Inspect the battery for charge and connections.

- Examine the ignition system for any signs of damage or wear.

- Steering Issues:

- Lubricate moving parts to reduce friction.

- Inspect and replace worn components as needed.

- Tillage Performance:

- Sharpen or replace blades for improved cutting efficiency.

- Adjust depth settings according to soil conditions.

- Vibration Concerns:

- Tighten any loose bolts or screws to secure components.

- Balance the rotating parts to minimize oscillation.

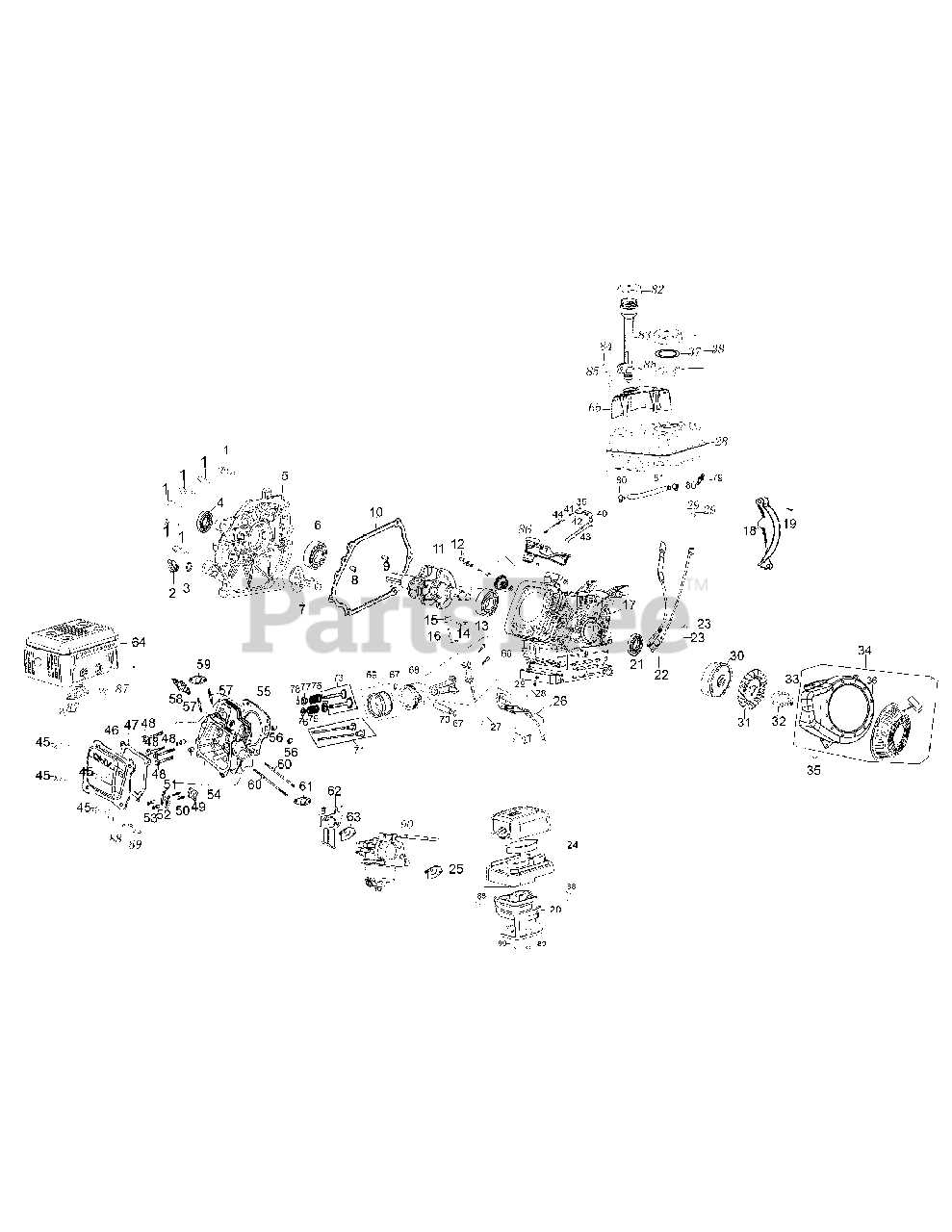

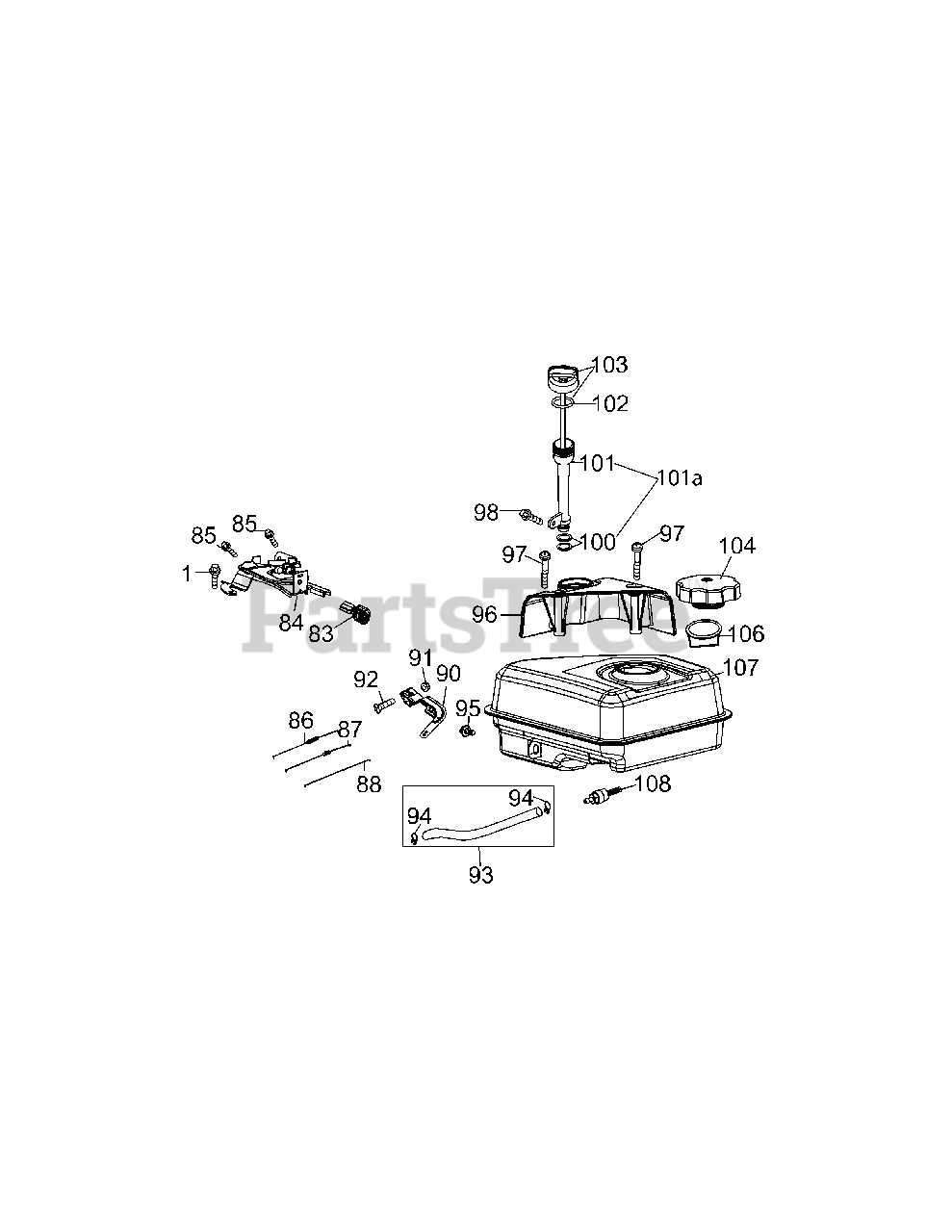

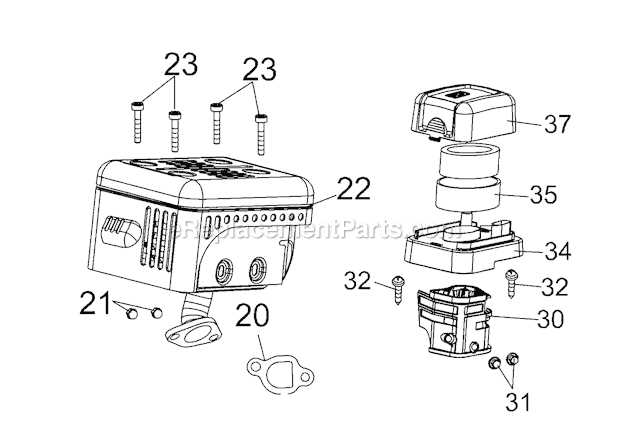

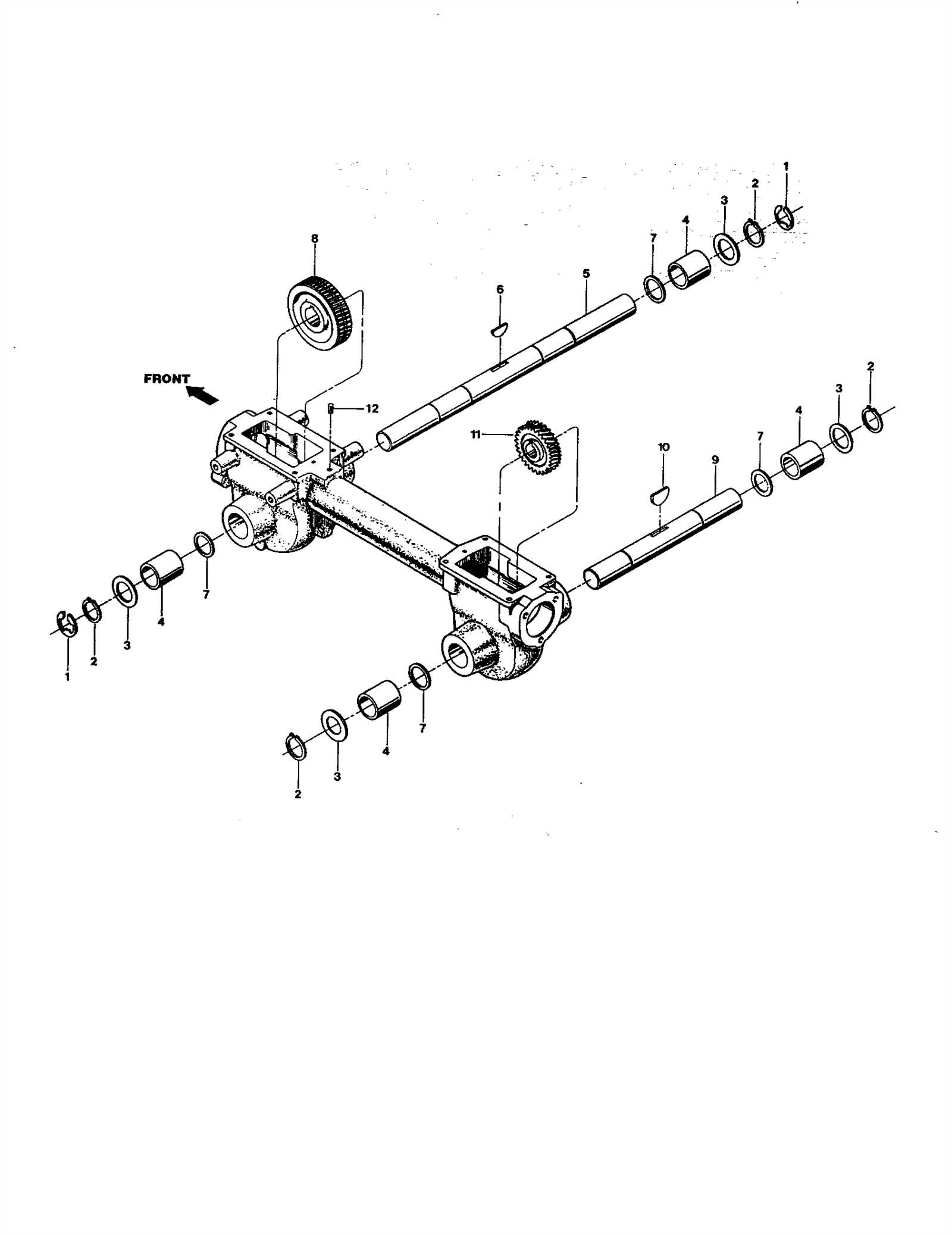

Understanding the Parts Diagram

Grasping the layout of various components within a mechanical system is crucial for effective maintenance and repair. A comprehensive visual representation assists users in identifying each element’s role, functionality, and relationship to other pieces. This knowledge not only simplifies troubleshooting but also enhances overall operational efficiency.

Key Elements to Consider

- Component Identification: Recognizing each element allows for informed decision-making during repairs.

- Functionality: Understanding how each part contributes to the system’s performance is vital for efficient use.

- Interconnections: Knowing how components interact can prevent misalignment and potential damage.

Benefits of a Visual Guide

- Facilitates quick reference during assembly or disassembly.

- Aids in sourcing replacements or upgrades accurately.

- Enhances comprehension of mechanical systems for users of all skill levels.

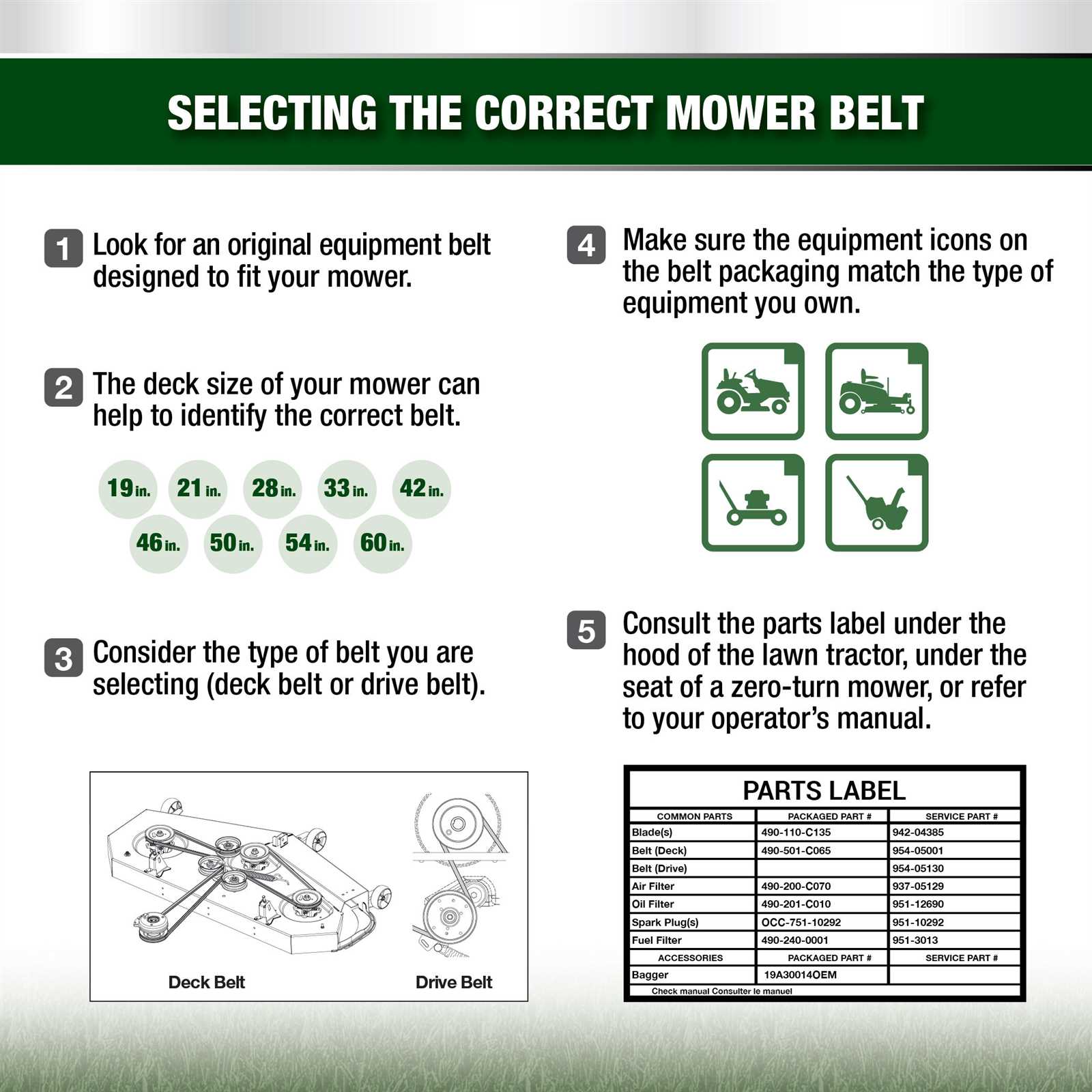

How to Order Replacement Parts

Maintaining the efficiency of your gardening equipment often requires acquiring new components. Understanding the process for securing these essential items can save time and ensure the proper functioning of your machinery. Follow the steps outlined below to facilitate your order.

Identify the Required Components

Before placing an order, make a comprehensive list of the necessary items. Check your equipment manual for specifications and part numbers. If the manual is unavailable, examining the unit directly for model identifiers can also prove beneficial. Taking clear notes will streamline your ordering experience.

Choosing a Supplier

Once you have identified what you need, search for reliable sources. Numerous retailers and online marketplaces offer a wide range of components. Look for providers with positive reviews and clear return policies. Compare prices across various platforms to ensure you’re getting the best deal. Many suppliers provide detailed information regarding compatibility and installation, which can be helpful.

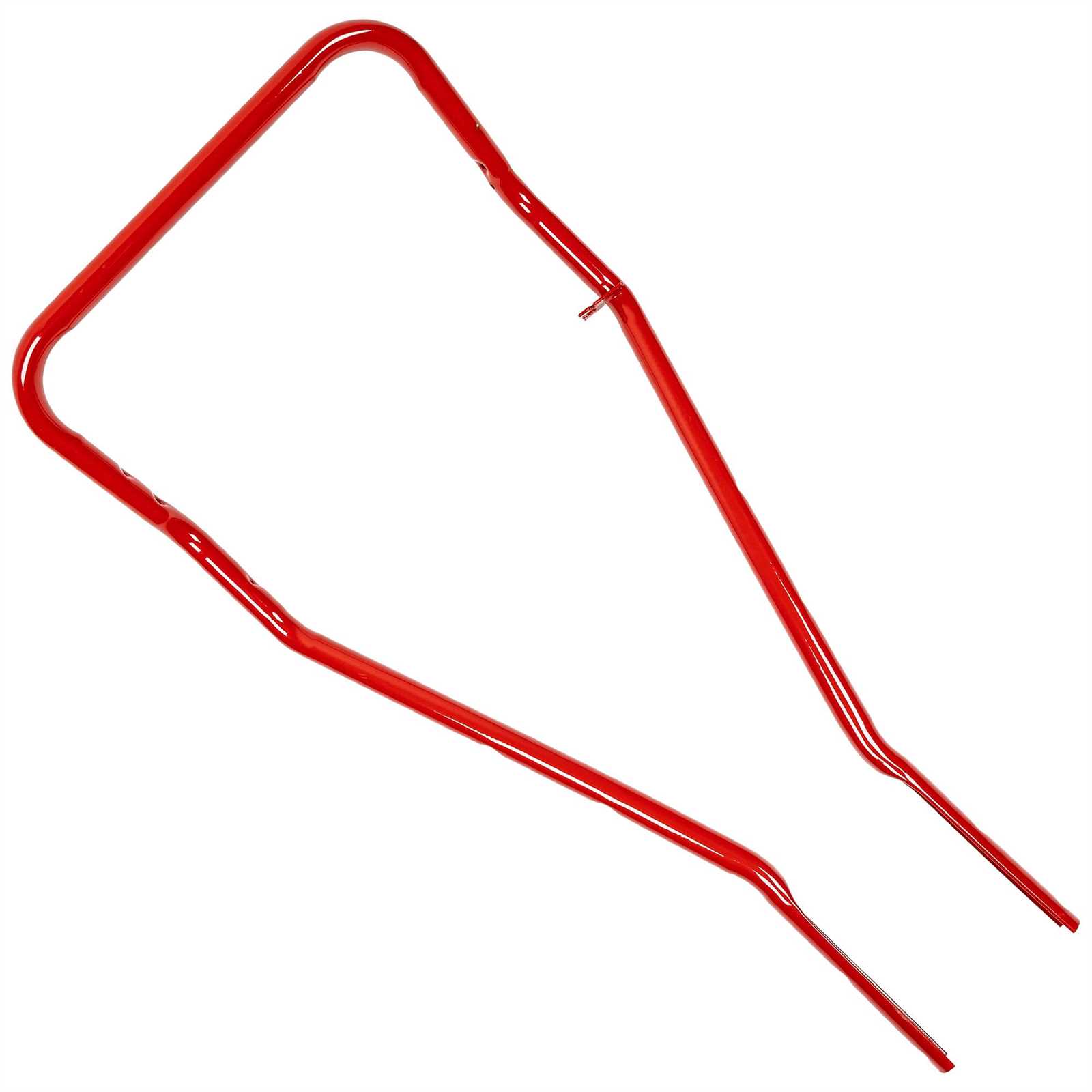

Step-by-Step Assembly Instructions

Assembling your gardening equipment can enhance its performance and ensure it operates smoothly. Following a systematic approach will help you efficiently piece together all components while minimizing errors. The following guidelines outline a clear method for assembling the machine, making the process straightforward and manageable.

Begin by laying out all components on a flat surface. This allows for easy identification and access to each part. Ensure you have all necessary tools at hand, as this will facilitate a more efficient assembly process.

Next, refer to the included instructions or documentation that accompany the equipment. Each step should clearly detail the order of assembly, along with any specific requirements for attaching or securing each component. It is crucial to follow these instructions carefully to avoid complications later.

As you progress, regularly check the alignment and fit of each part. Making adjustments during assembly can prevent misalignment that may affect the overall functionality of the equipment. If any components seem out of place, review the previous steps to ensure everything is assembled correctly.

Once all parts are connected, perform a thorough inspection to ensure all connections are secure and functioning as intended. Testing the assembled equipment before use will help identify any potential issues, ensuring a smooth operation during your gardening tasks.

Benefits of Using Original Parts

Utilizing authentic components for machinery maintenance offers numerous advantages that enhance performance and longevity. These elements are specifically designed to fit seamlessly, ensuring optimal functionality and reliability. By choosing genuine replacements, users can avoid potential issues that often arise from inferior alternatives.

One key benefit is the assurance of quality. Authentic components undergo rigorous testing and meet stringent standards, resulting in superior durability and efficiency. In contrast, generic options may compromise the overall operation, leading to increased wear and tear on the equipment.

Moreover, using original components often provides a warranty, offering peace of mind in case of defects. This added security can save users from unexpected repair costs and downtime, making maintenance more manageable. Additionally, the compatibility of these elements with the existing system is guaranteed, simplifying the installation process.

| Advantages | Generic Options |

|---|---|

| Quality Assurance | Often Subpar Quality |

| Warranty Protection | No Warranty Coverage |

| Guaranteed Compatibility | Possible Fit Issues |

| Enhanced Longevity | Increased Risk of Failures |

In conclusion, opting for authentic components not only improves machinery performance but also reduces the likelihood of complications during operation. This strategic choice ultimately contributes to a more efficient and enjoyable experience.