The intricate assembly of a marine engine plays a crucial role in ensuring optimal performance and reliability on the water. This section delves into the essential elements that make up these powerful machines, providing insights into their functionality and interconnections. By grasping the configuration of various components, users can enhance their maintenance practices and troubleshooting skills.

Each segment of the engine is meticulously designed to work in harmony with others, contributing to the overall efficiency of the vessel. A comprehensive overview of the configuration allows enthusiasts and technicians alike to identify specific sections, facilitating informed decisions when it comes to repairs or upgrades. Understanding this framework empowers users to navigate the complexities of engine care with confidence.

In this discussion, attention will be directed toward the specific configurations and roles of individual components within the engine. By exploring the layout, one can appreciate the engineering behind these remarkable machines and ensure they operate at peak capacity throughout their lifespan.

Understanding the Yamaha F150 Components

This section delves into the essential elements that contribute to the overall functionality and performance of the engine. A comprehensive grasp of these components enhances maintenance and repair, ensuring optimal operation over time. Each part plays a vital role, whether in propulsion, control, or efficiency, making familiarity with them invaluable for any user.

Key Elements and Their Functions

Every engine is composed of various critical components, each serving a specific purpose. From the power-generating units to the control mechanisms, understanding how these parts interact is crucial for effective operation. Below is a summary of some key components and their functions:

| Component | Function |

|---|---|

| Powerhead | Generates power through combustion, driving the propulsion system. |

| Lower Unit | Transmits power from the engine to the propeller, allowing movement. |

| Fuel System | Delivers the appropriate fuel-air mixture for combustion efficiency. |

| Cooling System | Regulates engine temperature, preventing overheating during operation. |

| Control System | Enables user to operate and navigate the vessel effectively. |

Importance of Regular Maintenance

Regular upkeep of each component is vital to ensure longevity and reliability. Proper care can prevent costly repairs and enhance overall performance. Understanding how each part functions and recognizing signs of wear or malfunction can significantly extend the service life of the engine.

Key Features of the F150 Engine

The design of this particular marine power unit showcases several remarkable attributes that enhance its performance and reliability. Understanding these characteristics provides valuable insights for enthusiasts and professionals alike.

- High Power Output: The engine is engineered to deliver impressive horsepower, ensuring robust acceleration and excellent handling in various water conditions.

- Fuel Efficiency: Innovative engineering techniques contribute to reduced fuel consumption, allowing for longer journeys with fewer refuels.

- Lightweight Construction: The use of advanced materials results in a reduced overall weight, improving both speed and agility.

- Corrosion Resistance: Enhanced protection against marine environments ensures longevity and durability, reducing maintenance needs.

- Advanced Cooling System: An efficient cooling mechanism maintains optimal operating temperatures, enhancing performance during prolonged use.

In summary, the attributes of this marine engine exemplify a blend of power, efficiency, and durability, making it a top choice for boating enthusiasts.

Importance of Maintenance for Longevity

Regular upkeep is crucial for ensuring the extended life of any machinery or equipment. By adhering to a systematic maintenance schedule, users can significantly reduce the likelihood of unexpected failures and costly repairs. This practice not only enhances performance but also preserves the integrity of essential components, allowing for optimal operation over time.

Consistent servicing plays a vital role in identifying potential issues before they escalate. Routine inspections can reveal wear and tear that might not be immediately noticeable, enabling timely interventions. Moreover, maintaining clean and well-lubricated parts contributes to smoother functionality, which is essential for efficiency.

Furthermore, neglecting maintenance can lead to severe consequences, including decreased performance and operational failures. It is vital to recognize that even minor oversights can result in significant long-term repercussions. By prioritizing regular checks and necessary repairs, users can ensure that their equipment remains in peak condition, thereby enhancing its reliability and overall lifespan.

In summary, the importance of maintenance cannot be overstated. It serves as a proactive measure that protects investments and fosters long-term satisfaction. Committing to a routine maintenance plan is essential for anyone looking to maximize the longevity and efficiency of their machinery.

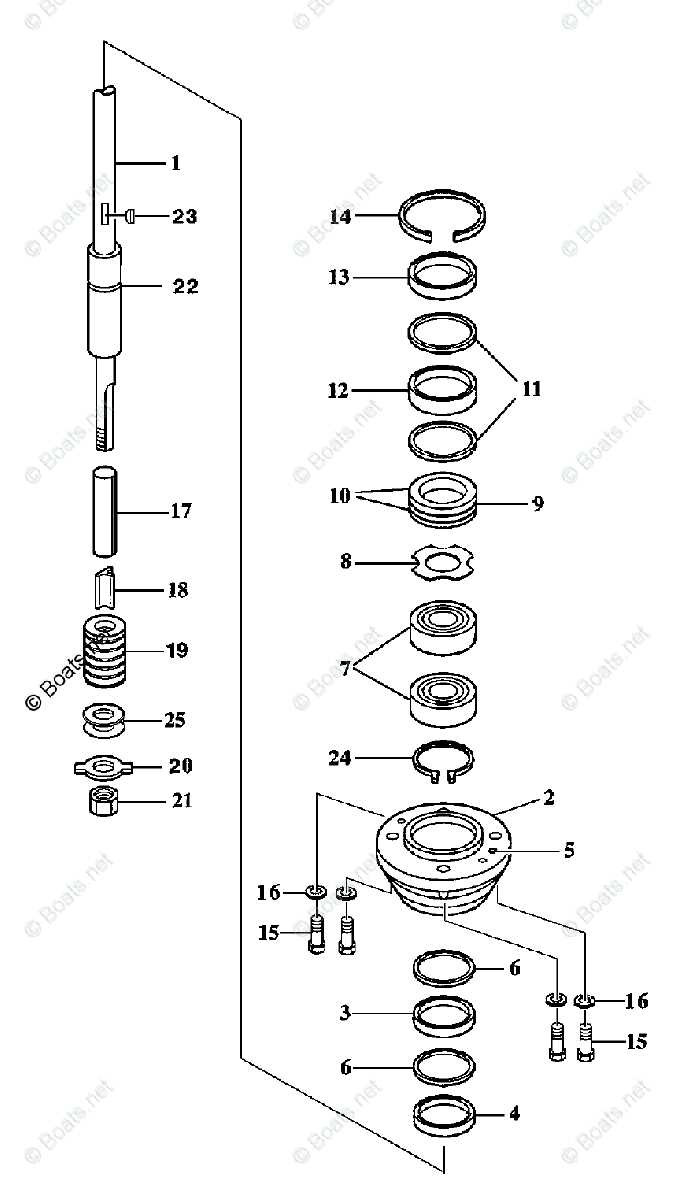

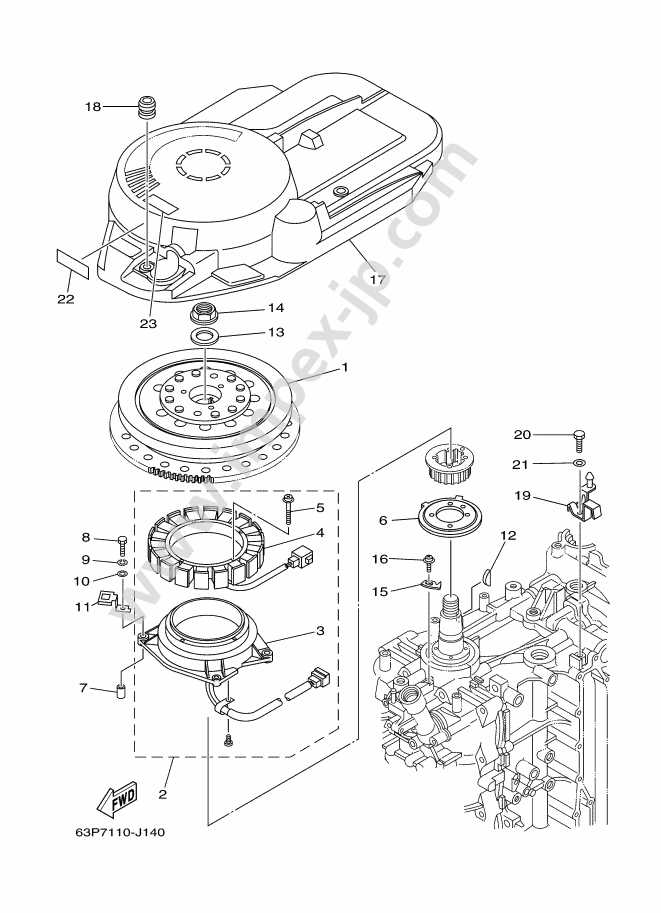

Identifying Essential Replacement Parts

Understanding the key components necessary for maintenance and repairs is crucial for ensuring optimal performance. Recognizing these elements can help in making informed decisions when sourcing replacements, ultimately enhancing the longevity and efficiency of the machinery.

To begin, it is important to familiarize yourself with the core elements that may require replacement over time. This includes critical components such as the ignition system, fuel delivery mechanisms, and cooling systems. Each of these parts plays a vital role in the overall functionality, and knowing their specifications can aid in the selection process.

In addition, paying attention to wear indicators and maintenance schedules can assist in preemptively identifying which components may need replacement. Regular inspections can reveal signs of deterioration, enabling timely interventions and reducing the risk of more significant issues down the line.

Finally, consulting with reliable sources for component specifications and compatibility can streamline the replacement process. Whether through manuals or professional guidance, acquiring the right information is essential for achieving satisfactory results and ensuring the machinery operates as intended.

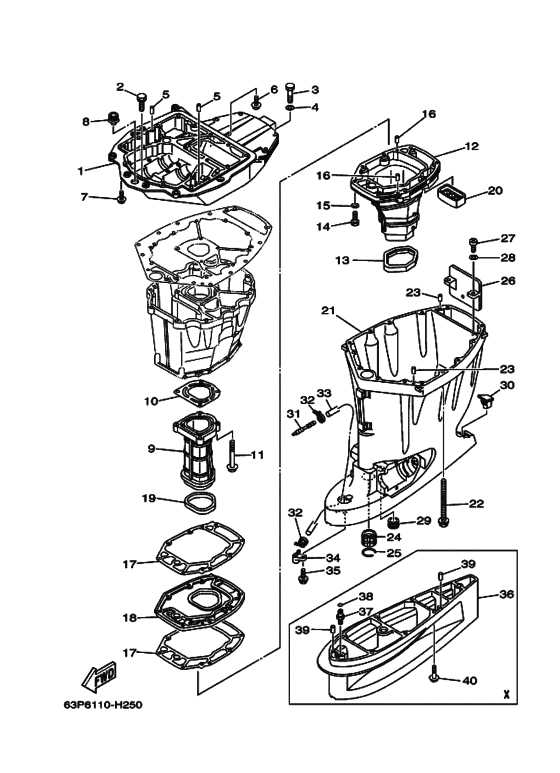

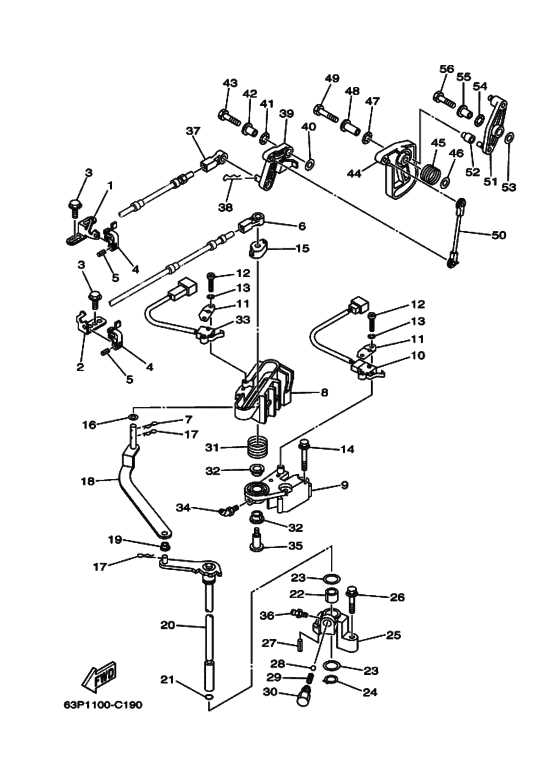

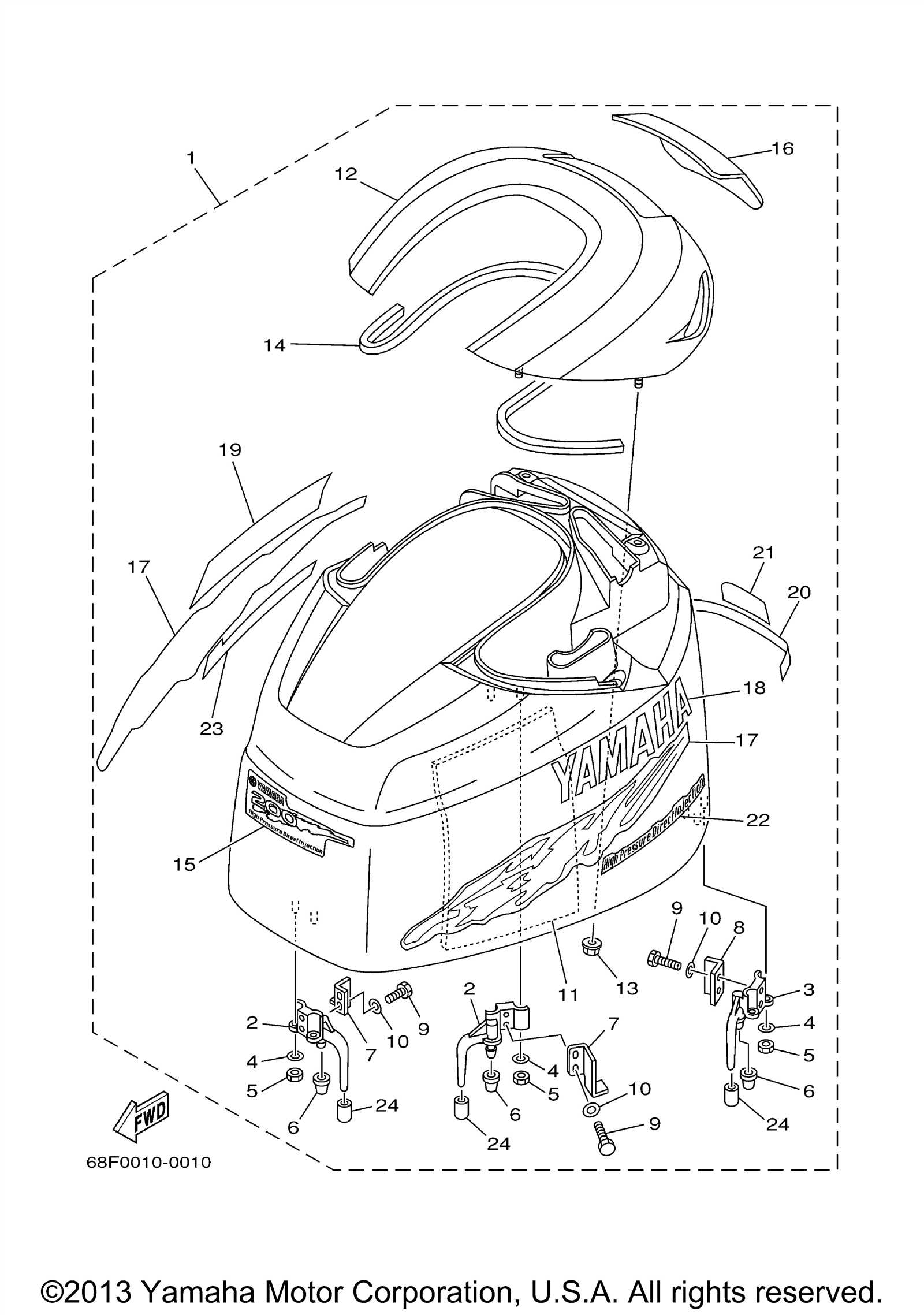

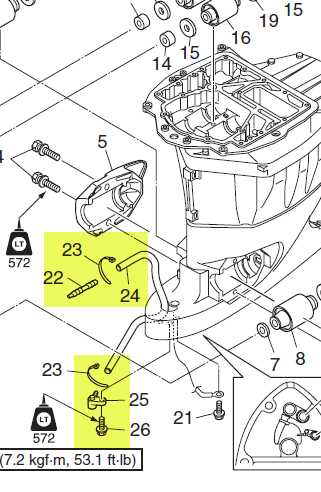

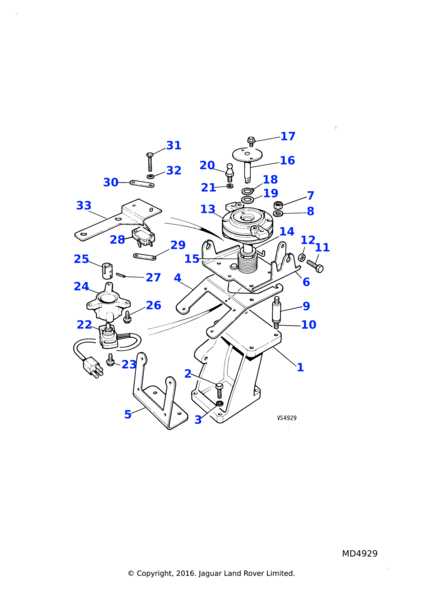

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations provide a clear view of the various elements involved, helping users to identify and locate each item accurately.

To effectively interpret these visuals, consider the following steps:

- Familiarize Yourself with the Layout:

Each representation typically follows a specific structure, including labels, sections, and numbers that correspond to individual components. Start by reviewing the overall layout to understand how it is organized.

- Identify Key Components:

Look for highlighted or numbered elements that indicate critical parts. These notations are crucial for understanding the function and relationship of each item within the system.

- Consult the Legend or Key:

Most illustrations will include a legend or key that explains symbols and annotations used. This reference will help clarify any unfamiliar markings.

- Cross-Reference with Manuals:

For detailed information, cross-reference the visual representation with service manuals or technical guides. This will provide additional context and specific details about each element.

By following these steps, anyone can effectively navigate and comprehend visual representations of components, facilitating smoother maintenance processes and repairs.

Common Issues and Their Solutions

Maintaining optimal performance of marine engines often involves addressing various challenges that can arise during operation. Identifying these problems and implementing effective solutions can significantly enhance longevity and efficiency.

Frequent Problems

- Overheating: Insufficient cooling can lead to engine failure.

- Starting Difficulties: Issues with ignition or fuel supply may prevent the engine from starting.

- Strange Noises: Unusual sounds can indicate mechanical wear or damage.

- Excessive Vibration: This may result from misaligned components or imbalanced parts.

Proposed Solutions

- Regularly check and clean the cooling system to prevent blockages.

- Inspect electrical connections and fuel lines to ensure proper functionality.

- Conduct routine maintenance to address wear and tear on mechanical components.

- Balance rotating parts and ensure alignment during installation to minimize vibrations.

Where to Buy Authentic Parts

When it comes to maintaining your marine equipment, sourcing genuine components is crucial for optimal performance and longevity. Ensuring that you acquire authentic replacements will not only enhance the functionality of your vessel but also contribute to safety and reliability on the water.

Authorized Dealers

One of the most reliable sources for authentic components is through authorized dealers. These establishments are certified to sell genuine items, guaranteeing their quality and compatibility. Here are some advantages of purchasing from them:

- Expert assistance in selecting the right component.

- Access to a complete range of items specific to your needs.

- Potential for warranty coverage on items purchased.

Online Retailers

For those who prefer shopping from the comfort of their home, numerous online retailers specialize in genuine marine components. When choosing an online source, keep the following in mind:

- Verify that the retailer is an authorized distributor.

- Check customer reviews for authenticity and service quality.

- Look for a return policy that protects your purchase.

Upgrading Your Yamaha F150 Performance

Enhancing the capabilities of your outboard motor can lead to improved efficiency, speed, and overall enjoyment on the water. Various modifications can be made to optimize performance, ensuring that you get the most out of your investment. This section will explore several key upgrades that can significantly elevate your engine’s functionality.

1. Propeller Selection: Choosing the right propeller is crucial for achieving maximum thrust and speed. Consider experimenting with different pitch sizes and materials to find the ideal match for your specific boating conditions. A well-matched propeller can enhance acceleration and fuel efficiency.

2. ECU Remapping: Adjusting the engine’s control unit can unlock additional power and torque. This modification allows for fine-tuning of fuel delivery and ignition timing, resulting in a more responsive engine. Ensure that you work with a qualified technician to achieve optimal results.

3. Performance Exhaust: Upgrading the exhaust system can improve airflow, reducing back pressure and enhancing engine efficiency. A high-performance exhaust not only contributes to power gains but also provides a more aggressive sound, adding to the overall experience.

4. Regular Maintenance: Keeping your motor in peak condition is essential for performance. Routine maintenance, such as oil changes, filter replacements, and thorough inspections, can prevent potential issues and maintain optimal operation.

5. Lightweight Components: Replacing stock components with lightweight alternatives can reduce overall weight, improving handling and acceleration. Consider lightweight batteries or performance-enhancing materials to increase efficiency.

Implementing these upgrades can lead to a more enjoyable and powerful experience on the water. Tailoring modifications to your specific needs will ensure that you achieve the best possible performance from your engine.