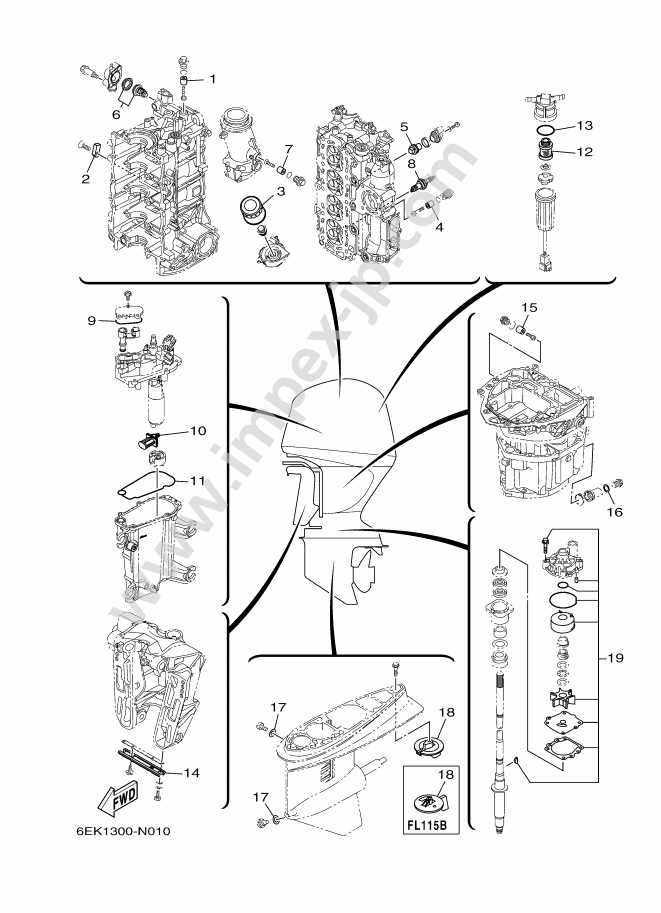

Exploring the intricacies of hydraulic systems is essential for effective maintenance and operation of marine vessels. A well-functioning hydraulic mechanism plays a pivotal role in enhancing the performance of various marine applications. This section delves into the essential components that contribute to the seamless operation of these systems.

By familiarizing oneself with the structure and functionality of hydraulic systems, operators can troubleshoot issues more effectively and ensure longevity. Detailed visual representations serve as valuable tools for identifying each component’s role and interconnections. Such insights are crucial for anyone looking to optimize their marine equipment and enhance overall performance.

Whether you are a seasoned professional or a novice, grasping the fundamentals of these hydraulic components will empower you to make informed decisions. A thorough understanding will not only aid in repairs and maintenance but also improve the efficiency of your marine operations.

Understanding Yamaha Tilt and Trim Components

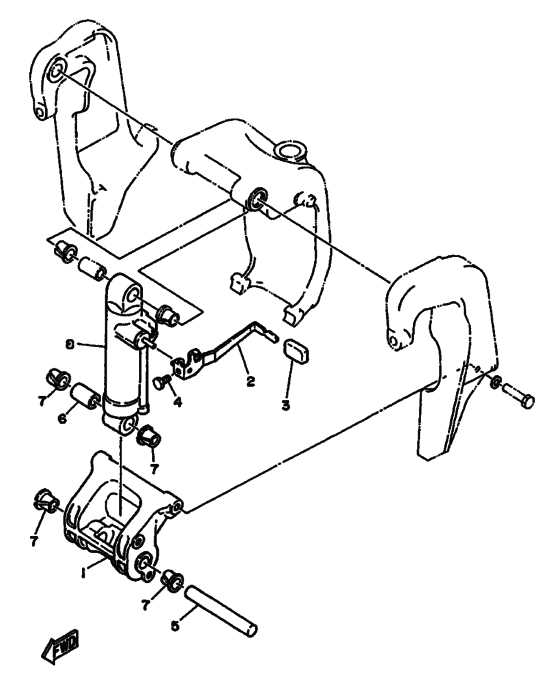

Exploring the mechanisms that facilitate the adjustment of the engine’s position is essential for maintaining optimal performance in aquatic vehicles. These systems allow operators to modify the angle of propulsion units, enhancing maneuverability and efficiency. A thorough understanding of these elements can lead to better maintenance practices and improved overall functionality.

Key Mechanisms in the Adjustment System

The adjustment mechanism consists of several critical components that work in harmony. Key elements include hydraulic cylinders, which facilitate smooth movement, and control switches that enable the operator to make precise adjustments. Additionally, a robust framework is necessary to support these components, ensuring stability during operation.

Maintenance and Care

Regular inspection and upkeep of these systems are crucial to prevent malfunctions. Key maintenance tasks involve checking hydraulic fluid levels, inspecting seals for wear, and ensuring all electronic connections are secure. By adhering to these practices, users can prolong the lifespan of the adjustment system and ensure reliable performance on the water.

Importance of Tilt and Trim System

The mechanism that adjusts the angle of a boat’s propulsion unit plays a crucial role in enhancing performance and efficiency. This system enables operators to optimize the vessel’s position relative to water conditions, significantly impacting speed and fuel consumption. Understanding its significance helps in maintaining and operating marine vehicles effectively.

Benefits of Effective Adjustment Mechanisms

Properly functioning angle adjustment mechanisms offer numerous advantages:

| Benefit | Description |

|---|---|

| Improved Handling | Enables smoother navigation through varying water conditions. |

| Enhanced Fuel Efficiency | Reduces drag, leading to lower fuel consumption over time. |

| Increased Speed | Allows for optimal performance at different speeds and loads. |

Maintenance Considerations

Regular checks and maintenance of the adjustment system are essential for optimal performance. Neglecting this can lead to performance issues, increased fuel consumption, and potential damage to the propulsion unit. Regular inspections and timely repairs ensure the longevity and efficiency of the vessel.

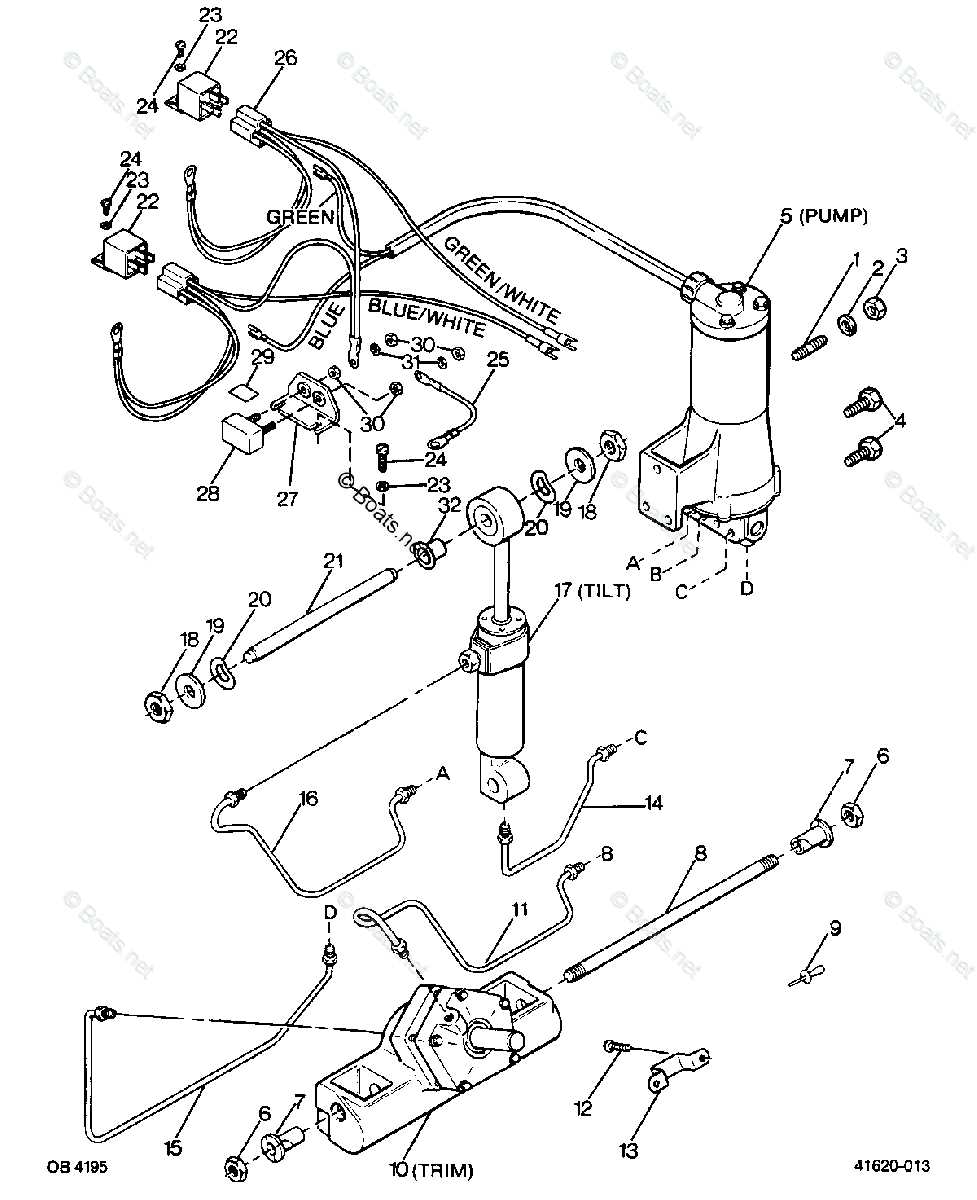

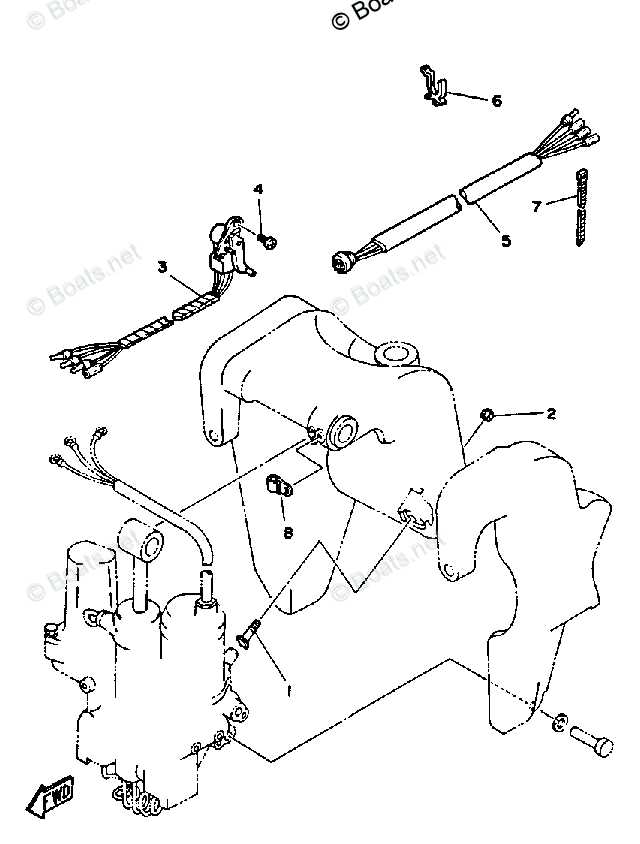

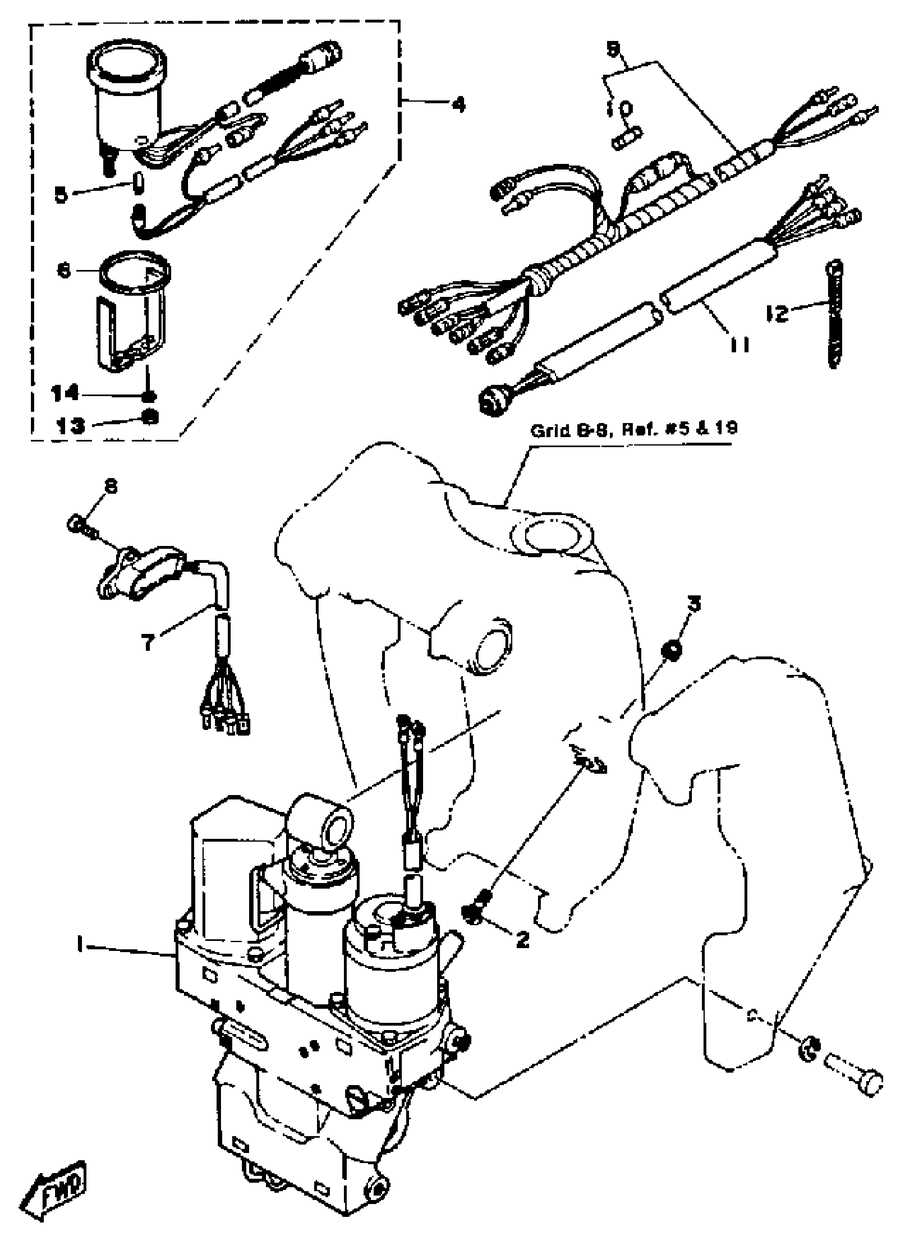

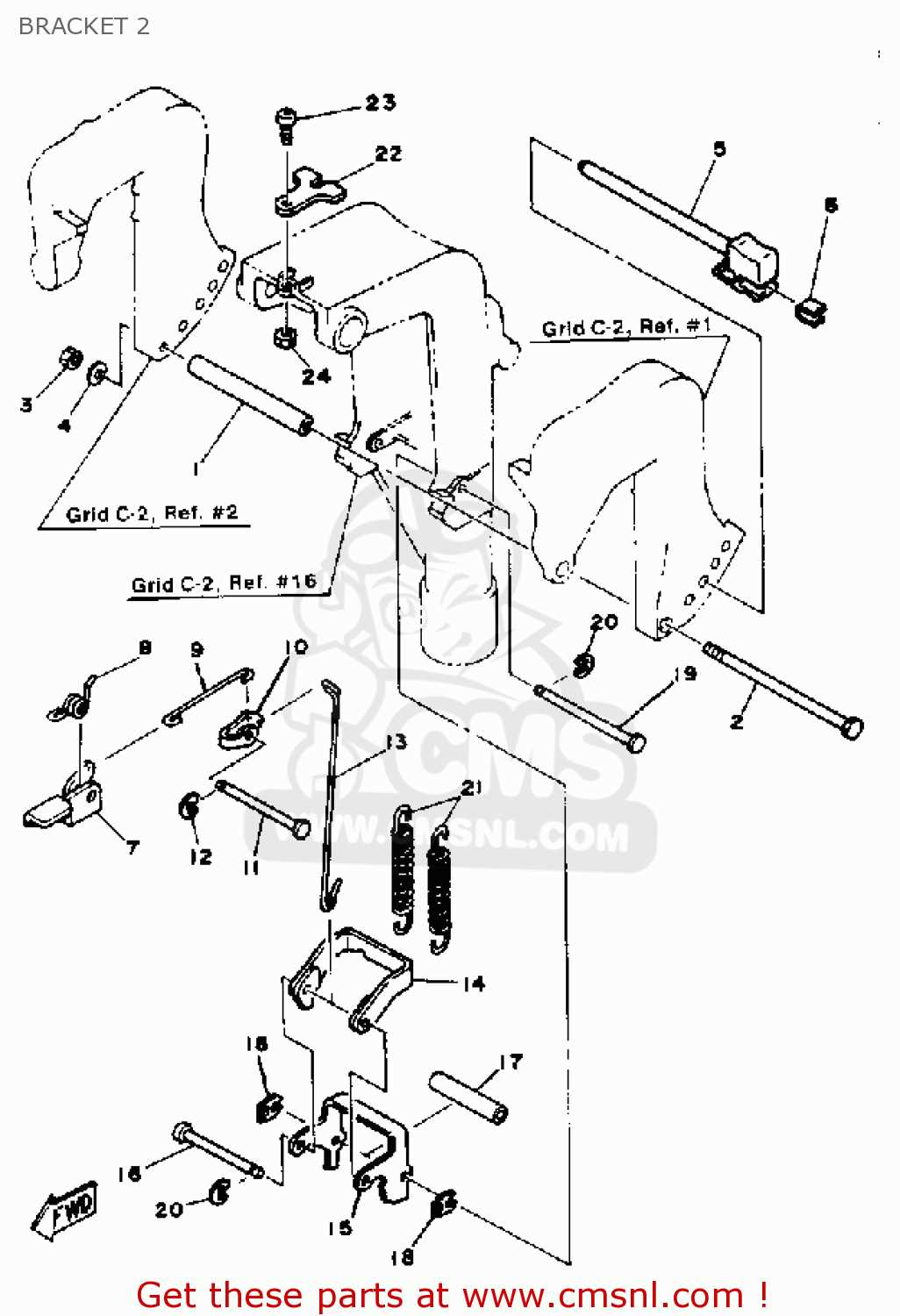

Key Parts in the Diagram

The illustration showcases essential components that play a significant role in the functionality of the system. Each element is meticulously designed to ensure optimal performance and reliability, contributing to the overall efficiency of the mechanism.

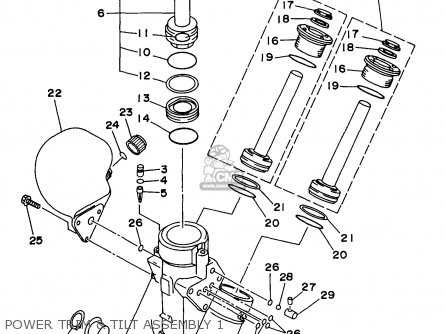

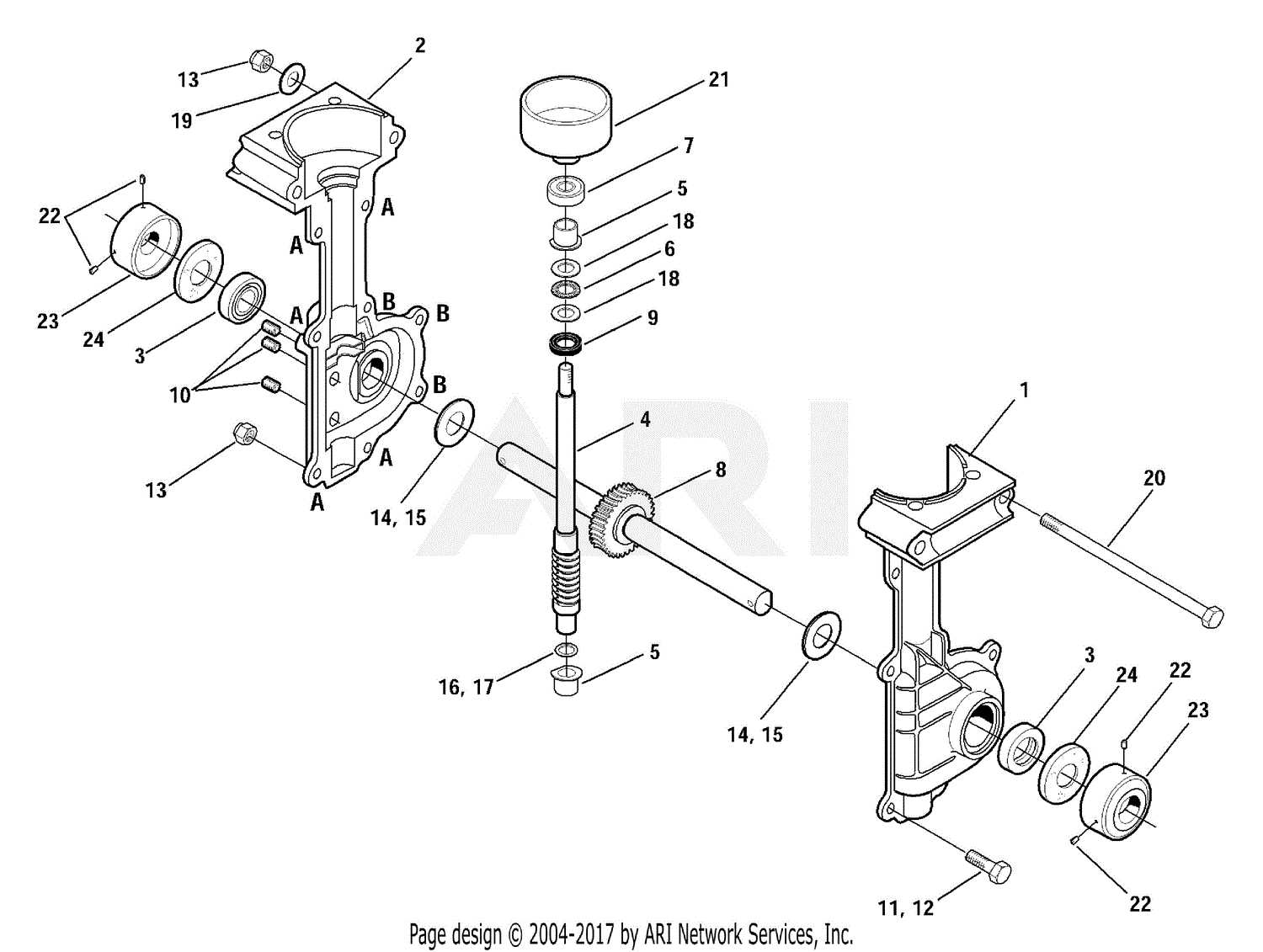

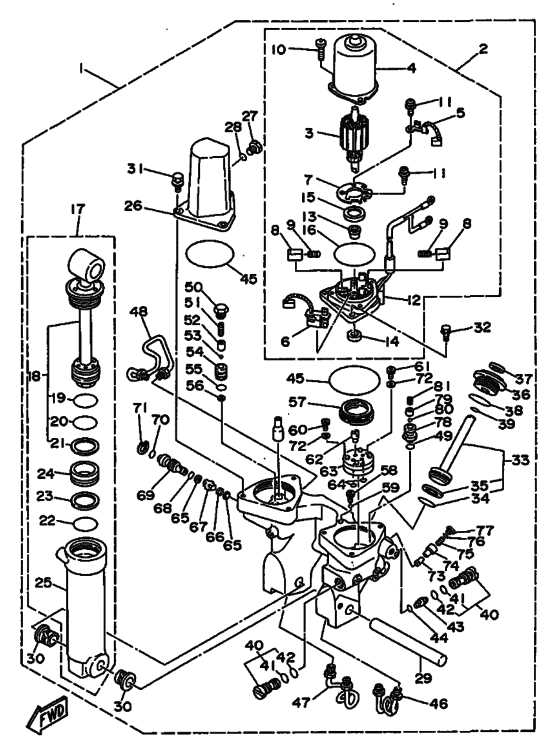

Hydraulic Cylinder: This crucial component facilitates movement and adjustment, allowing the system to operate smoothly and effectively. Its design ensures durability under various conditions.

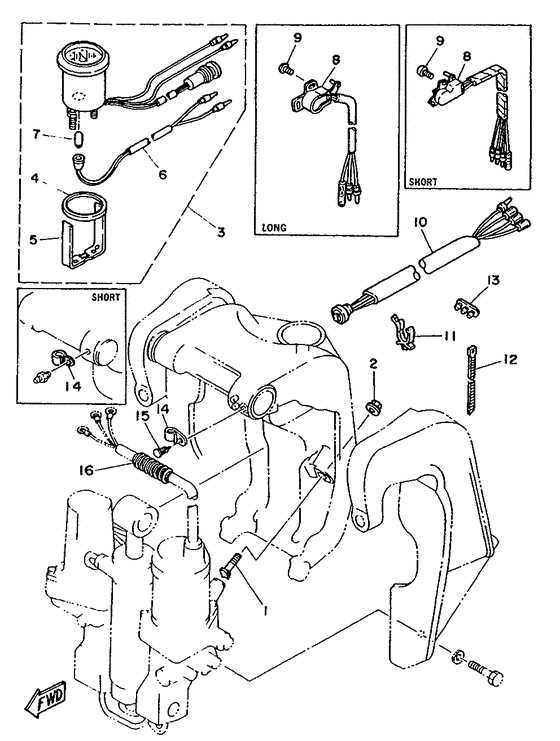

Pump Assembly: Serving as the heart of the operation, this unit generates the necessary pressure to drive the hydraulic fluid, enabling precise control of the system’s movements.

Fluid Reservoir: This container holds hydraulic fluid, ensuring a consistent supply to the system. Its capacity and design are vital for maintaining proper operation and preventing overheating.

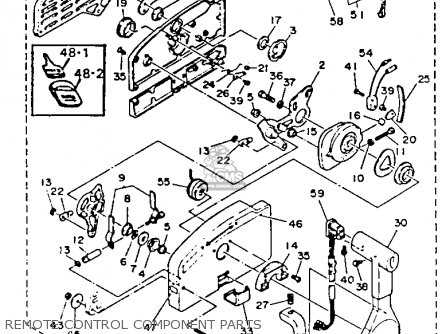

Control Switch: This interface allows users to manage the system’s movements effortlessly. Its ergonomic design provides ease of use and accessibility for operators.

Mounting Brackets: These support structures secure the components in place, ensuring stability and alignment during operation. Their robust construction withstands various environmental factors.

Functionality of Each Component

This section provides an overview of the roles and functions of various elements within the hydraulic lifting system used in marine applications. Understanding how each component operates is essential for effective maintenance and troubleshooting.

Hydraulic Cylinder

The hydraulic cylinder is a vital element that converts fluid pressure into mechanical force. It enables the movement necessary for adjusting the position of the equipment, allowing for precise control when navigating different water conditions.

Control Mechanism

The control mechanism is responsible for regulating the hydraulic fluid flow. This component ensures that adjustments can be made effortlessly, enhancing the overall responsiveness of the system. A reliable control mechanism contributes significantly to the efficiency and safety of operations.

Common Issues with Tilt and Trim

Understanding frequent challenges related to lifting and lowering mechanisms can enhance the maintenance and functionality of marine equipment. These systems play a crucial role in ensuring optimal performance on the water, yet they may encounter specific problems over time.

One prevalent issue is fluid leakage, which can occur due to damaged seals or hoses. This loss of hydraulic fluid can lead to inadequate operation, resulting in slow or unresponsive movement. Regular inspection of the hydraulic components is essential to identify any signs of wear and tear.

Another common problem is electrical malfunctions, which may arise from corroded connections or faulty switches. Such electrical issues can disrupt the entire system’s operation, making it vital to keep connections clean and secure. Additionally, checking fuses and relays can help prevent unexpected failures.

Lastly, mechanical wear can affect the overall performance of the apparatus. Components like motors and gears can experience wear over time, leading to sluggish or inconsistent operation. Routine maintenance, including lubrication and component replacement, is crucial to extend the lifespan of these mechanisms.

Maintenance Tips for Longevity

Ensuring the durability of your equipment involves implementing effective care practices. Regular maintenance not only enhances performance but also extends the lifespan of various components. By following a few simple guidelines, you can keep your machinery functioning optimally for years to come.

Regular Inspections

Conducting routine checks helps identify wear and tear before they escalate into significant issues. Pay close attention to moving parts, looking for signs of corrosion or damage. Early detection can save time and costs associated with major repairs.

Proper Cleaning Techniques

Keeping your equipment clean is crucial for preventing buildup that can hinder functionality. Use appropriate cleaning solutions and tools to remove dirt and grime. Regularly washing components minimizes the risk of rust and other forms of deterioration.

How to Replace Tilt and Trim Parts

Changing components of the adjustment mechanism can significantly enhance the functionality of your watercraft. This process involves a few crucial steps to ensure proper installation and optimal performance.

First, gather all necessary tools and replacement items. Ensure you have a socket set, wrenches, and any additional equipment required for the task. Before beginning, make sure the vessel is securely supported and that the engine is turned off to avoid any accidents.

Next, locate the specific components that need to be replaced. Carefully detach the old items, taking note of how they are positioned. It can be helpful to take photos during disassembly for reference during reassembly.

Once the old components are removed, install the new ones, ensuring they fit securely in place. Follow any included instructions to ensure correct orientation and alignment. After installation, double-check all connections and fastenings before testing the mechanism.

Finally, test the newly installed mechanism to verify that everything operates smoothly. This step is crucial for confirming that the adjustments function correctly and safely.

Identifying Parts from the Diagram

This section aims to provide guidance on recognizing components from the schematic representation. Understanding the layout and function of each element is crucial for efficient maintenance and repairs.

To aid in identifying the various elements, a detailed overview of common components is presented below:

| Component Name | Description |

|---|---|

| Hydraulic Cylinder | Responsible for lifting and lowering mechanisms. |

| Control Switch | Enables the operator to adjust the position. |

| Oil Reservoir | Stores hydraulic fluid necessary for operation. |

| Mounting Bracket | Secures the assembly to the vessel. |

| Power Connection | Provides electrical energy to the system. |

Where to Find Replacement Parts

When seeking components for hydraulic mechanisms, various sources can provide the necessary elements for repair and maintenance. Identifying reliable vendors is essential for ensuring quality and compatibility with your equipment.

One effective approach is to explore online marketplaces that specialize in marine supplies. These platforms often offer a wide range of components, allowing users to compare prices and specifications. Additionally, visiting local marine shops can yield useful insights, as staff may provide recommendations based on their experience with specific brands.

Another option is to check manufacturer websites for authorized distributors. This can guarantee that the items meet industry standards and specifications. Forums and online communities dedicated to marine enthusiasts can also be valuable resources, as members frequently share their experiences and suggest trustworthy suppliers.

Before making a purchase, it is advisable to verify the compatibility of the components with your particular model. This ensures optimal performance and extends the lifespan of your equipment.