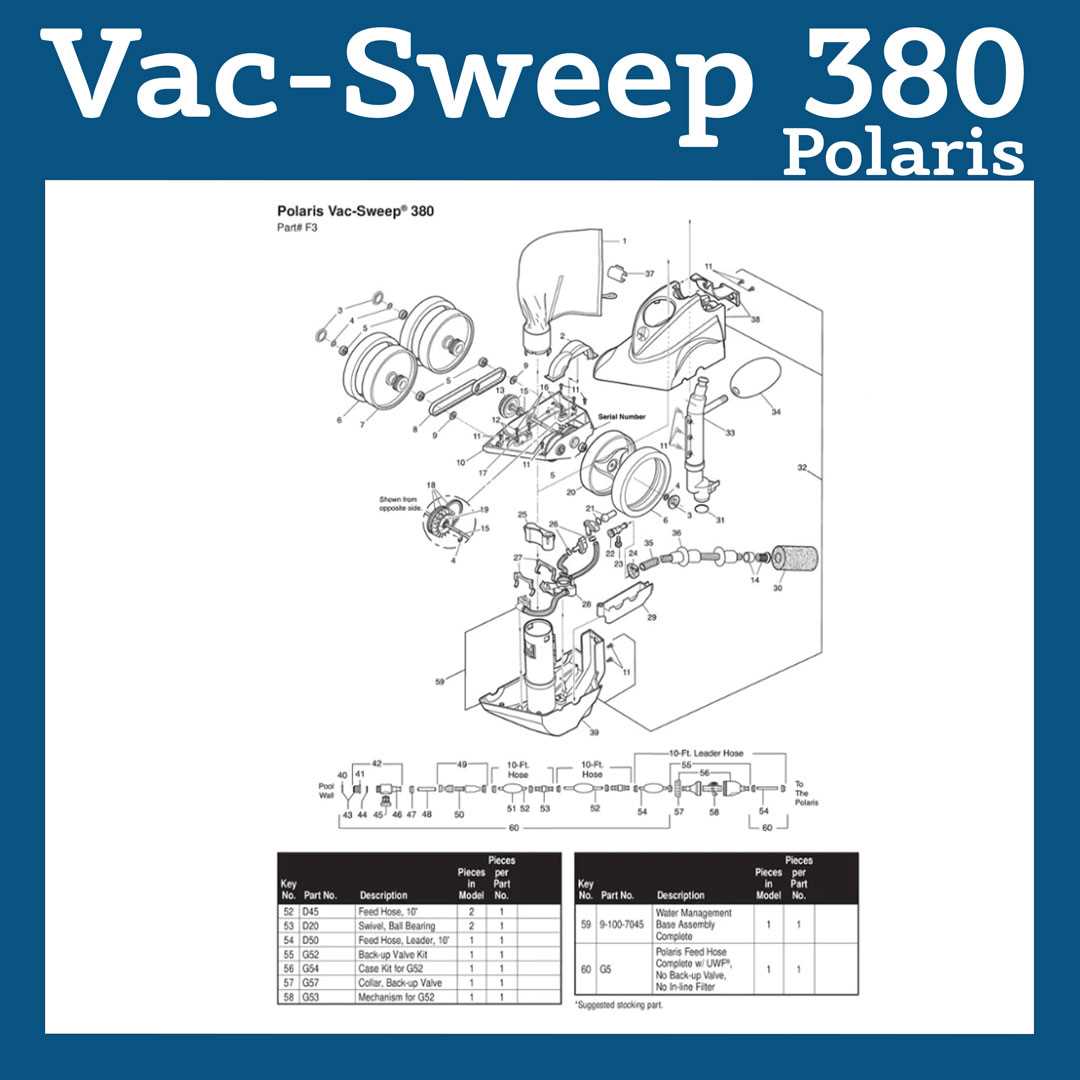

Understanding the individual elements of a specialized system can significantly enhance both maintenance and overall performance. Whether you are addressing routine upkeep or troubleshooting, having a detailed view of each component is essential for efficient operation. By exploring the structure and functions of the various elements, you gain a clear understanding of how each contributes to the smooth functioning of the entire unit.

In this guide, we will delve into the intricate workings of each core element. These components are designed to work together seamlessly, ensuring optimal performance. This breakdown will help you identify and locate specific elements, making it easier to manage repairs and replacements, ultimately improving the longevity and efficiency of your system.

Understanding the Booster Pump

The booster pump plays a crucial role in enhancing the performance of certain cleaning systems, offering the necessary power boost to ensure efficient water flow. This pump is designed to complement the main filtration system, working alongside it to maintain optimal operation. Understanding its components and how they interact can significantly improve the longevity and effectiveness of your system.

Key Features and Functions

This type of pump is specifically engineered to generate high pressure, making it ideal for systems that require additional force to operate at peak performance. It ensures that water is circulated effectively, driving cleaning mechanisms that rely on strong, consistent flow. The design of this pump allows for quiet, efficient operation while maintaining durability in various conditions.

Maintenance and Care

Regular upkeep is essential to maintain the pump’s efficiency. Inspecting and replacing components when necessary will help prevent common issues, such as loss of pressure or leaks. Understanding the maintenance schedule and recognizing signs of wear are vital steps to ensuring your pump continues to function optimally.

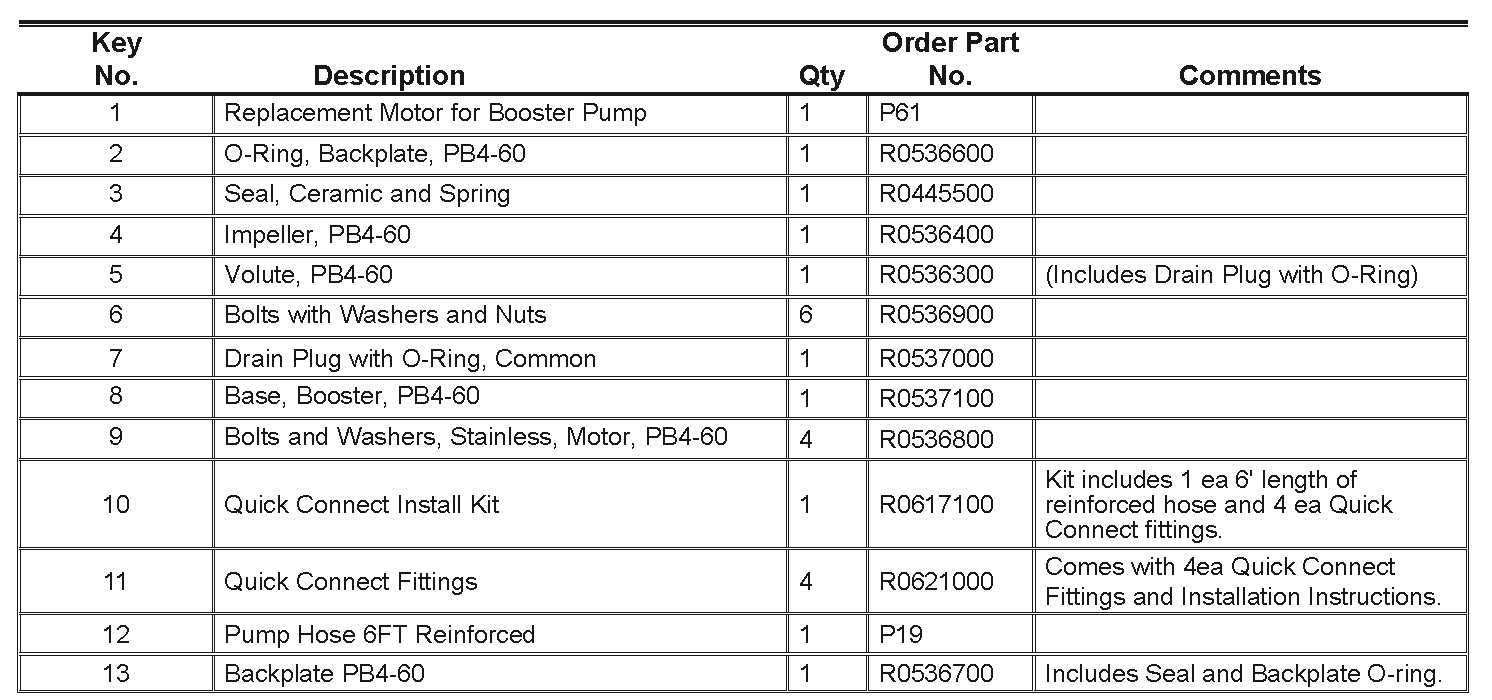

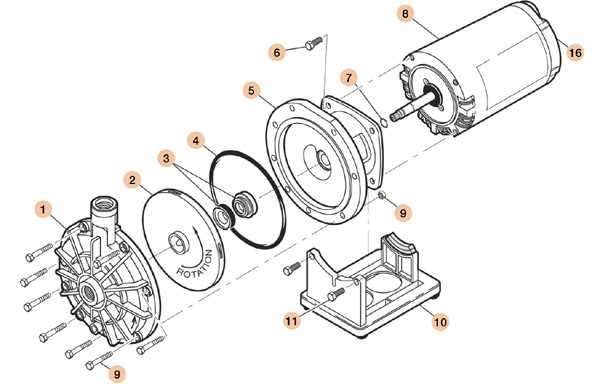

Key Components of the Polaris PB4-60 Pump

The pump system is built from essential elements that work together to ensure efficient water flow and reliable operation. Each component has a specific role, contributing to the overall performance and durability of the unit. Below, we outline the key elements of the system, providing an overview of their functionality and importance.

Motor Assembly

- Electric Motor: The heart of the system, providing the necessary power to drive water through the system. It’s designed for long-lasting performance and efficiency.

- Cooling Fan: Attached to the motor, this component prevents overheating during extended operation, ensuring optimal performance and extending the motor’s lifespan.

- Sealed Bearings: These are crucial for reducing friction and wear, allowing the motor to run smoothly with minimal maintenance.

Housing and Water Flow Components

- Volute Housing: The primary casing that directs water into the system, shaping the flow and optimizing efficiency.

- Impeller: A rotating part that draws water into the pump and pushes it outward, driving the water flow with high pressure.

- Inlet and Outlet Ports: These connections ensure smooth water intake and discharge, maintaining a steady flow throughout the operation.

Understanding these key components helps in maintaining the pump’s performance and recognizing potential issues early.

How to Identify Replacement Parts

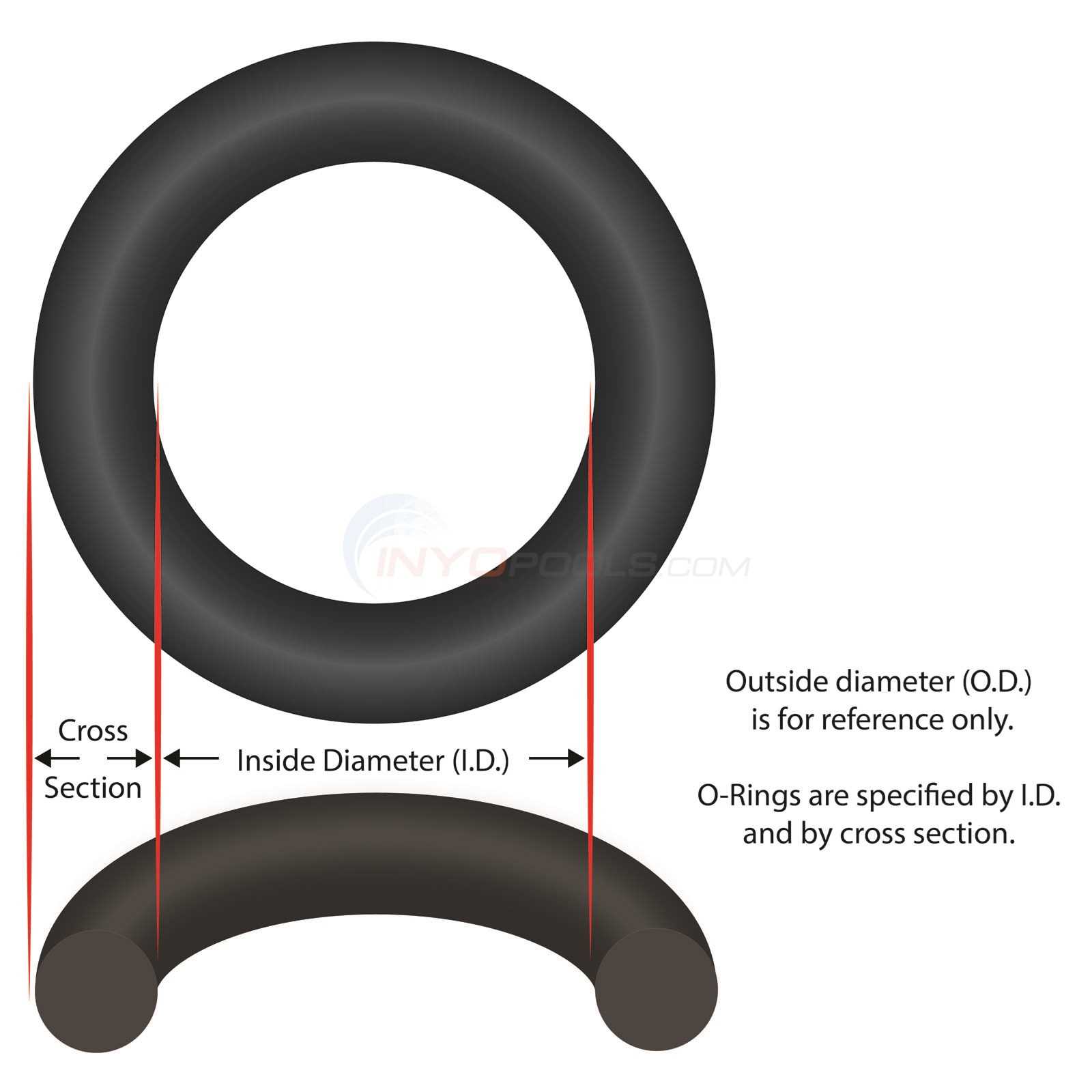

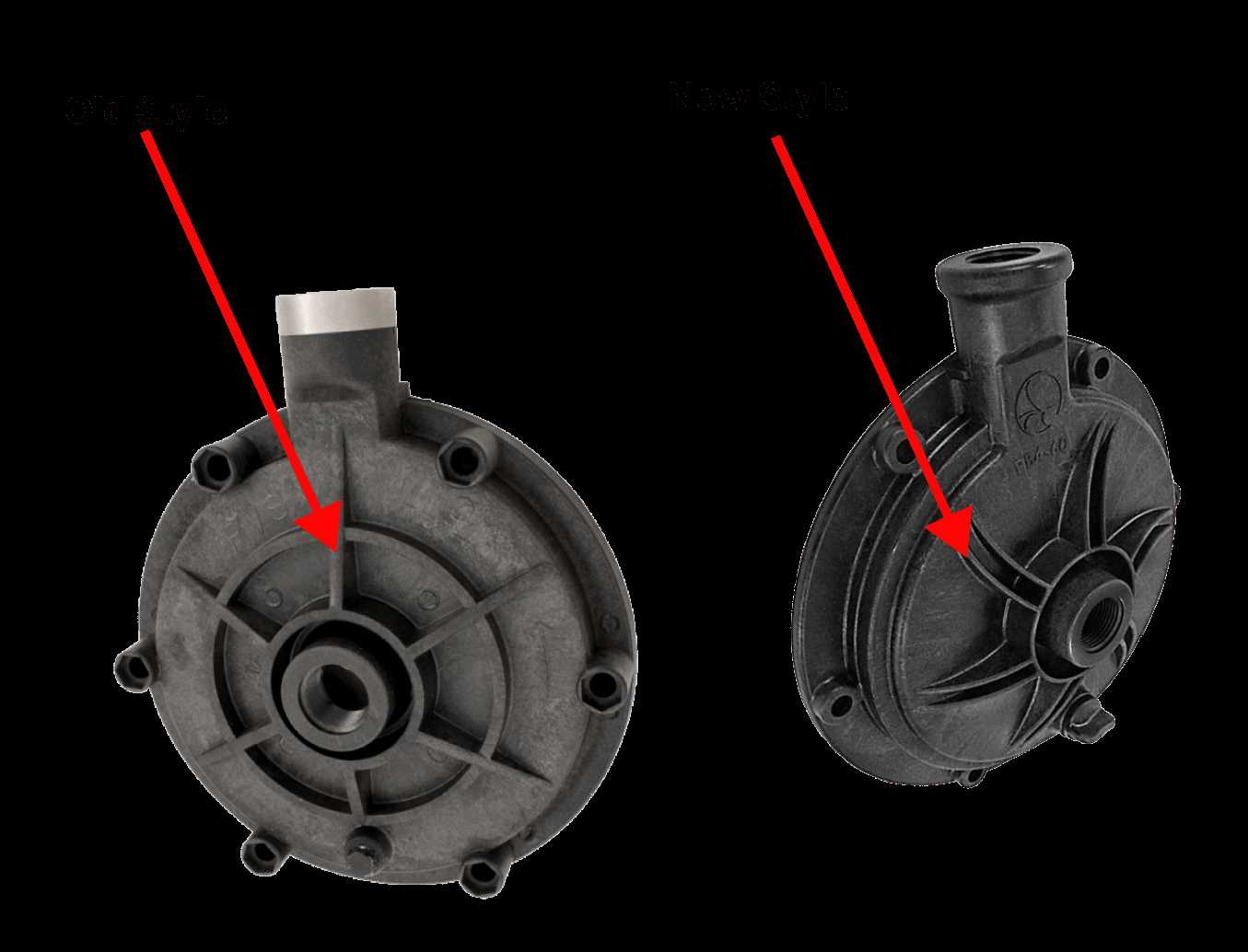

Recognizing the necessary components for a repair or maintenance task is essential to ensure proper system functionality. Knowing how to accurately identify these elements can help streamline the process of sourcing suitable replacements, reducing downtime, and avoiding costly errors.

First, examine the specifications provided in the user manual or service guide. These resources often include a detailed description or reference number for each component. If documentation is unavailable, carefully inspect the device itself. Look for labels, serial numbers, or other identifying marks that can provide clues about the exact type of component needed.

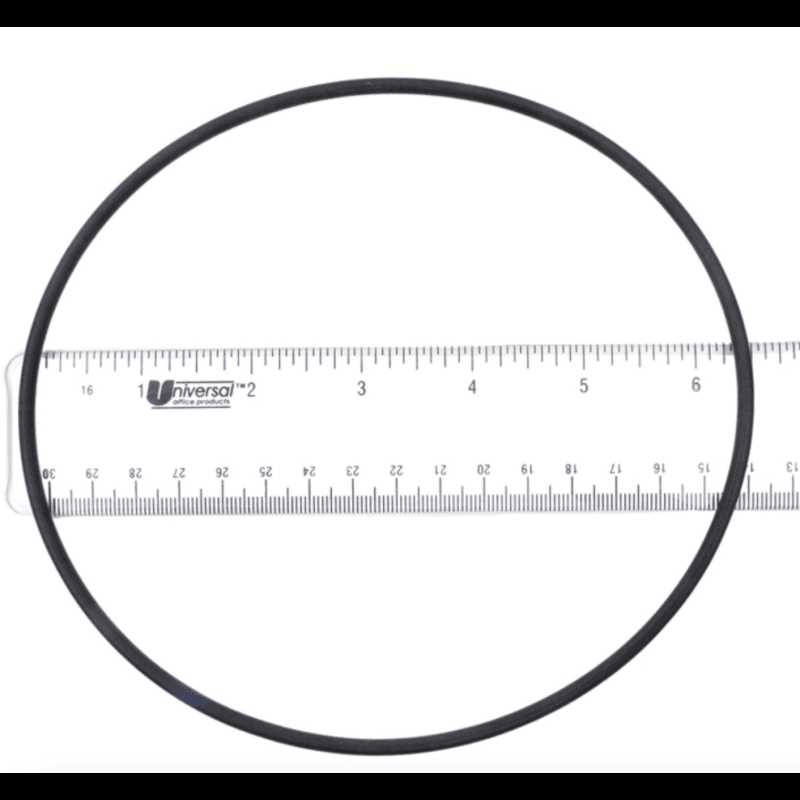

In cases where the component has worn out or broken, compare it with online resources or physical catalogs. Visual matching, as well as measurements, such as size and shape, can be crucial to finding the correct replacement. Always ensure compatibility by cross-referencing the identified component with available alternatives to avoid future issues.

Maintenance Tips for Longevity

Proper care and regular upkeep are essential to ensure that your equipment continues to function efficiently for many years. By following specific guidelines, you can prevent unnecessary wear and prolong the life of your device.

- Inspect seals and gaskets regularly to detect any signs of wear or damage. Replacing these components in a timely manner prevents leaks and further complications.

- Lubricate moving parts periodically to reduce friction and ensure smooth operation. Using the appropriate type of lubricant for your system is crucial to avoid premature wear.

- Check hoses for cracks or signs of degradation. Replace any worn-out hoses to maintain consistent pressure and prevent potential failures.

- Keep the system clean by removing debris from both internal and external components. This prevents clogging and improves overall efficiency.

- Periodically check for abnormal noises during operation. Unusual sounds can indicate an issue with internal components that should be addressed immediately.

By incorporating these practices into your routine maintenance, you will significantly extend the lifespan of your device and ensure optimal performance throughout its usage.

Troubleshooting Common Pump Issues

When working with water circulation systems, it’s important to be aware of potential malfunctions that may arise during operation. Understanding common issues helps prevent more serious damage and ensures smooth performance. Below, we will cover the most frequent challenges users face and practical solutions to address them.

Low Water Flow

A frequent problem with these systems is reduced water flow. This can be caused by blockages in the intake, air leaks, or worn-out internal components. To resolve this, inspect the inlet and outlet connections for any debris, ensure all seals are properly fitted, and check for wear in the key parts of the system. Regular maintenance is essential to avoid recurring issues.

Unusual Noises

Strange noises coming from the device usually indicate mechanical wear or trapped air in the system. If you hear grinding, rattling, or whining, turn off the system immediately and inspect the motor or impeller for signs of damage. Air bubbles in the water line can also cause noise, so ensure the system is properly primed before restarting.

Steps to Replace a Damaged Part

Replacing a faulty component can significantly enhance the performance of your equipment. Whether due to wear and tear or unexpected damage, addressing these issues promptly is crucial to maintaining functionality. This guide outlines the essential steps to ensure a smooth replacement process.

Follow these systematic instructions to effectively substitute a damaged item:

| Step | Description |

|---|---|

| 1 | Identify the damaged component by conducting a thorough inspection. Ensure that you have the necessary tools and replacement items ready for the task. |

| 2 | Disconnect the power supply to prevent any electrical hazards. Ensure all moving parts have come to a complete stop. |

| 3 | Carefully remove the damaged component. Take note of how it is attached, as this will assist in installing the new piece. |

| 4 | Install the new component by reversing the removal process. Ensure that it is securely fastened and properly aligned. |

| 5 | Reconnect the power supply and conduct a test run to confirm the successful installation of the replacement item. Monitor the equipment for any irregularities. |

By adhering to these steps, you can efficiently replace a damaged element, ultimately prolonging the lifespan of your machinery and ensuring optimal performance.

Where to Find Parts and Accessories

Locating essential components and add-ons for your equipment can enhance its performance and longevity. There are several avenues to explore when seeking these items, ensuring that you have the right resources at your disposal.

Online retailers are among the most convenient options, offering a wide variety of products with the ability to compare prices and read customer reviews. Websites dedicated to outdoor equipment and maintenance often have specific sections for various models, making it easier to find compatible items.

Local dealerships or specialized shops can provide personalized service and expertise. Engaging with knowledgeable staff can lead to valuable recommendations on compatible accessories, as well as insights on installation and maintenance.

Additionally, community forums and social media groups focused on outdoor activities can be beneficial. Here, enthusiasts share their experiences, recommend suppliers, and sometimes even offer items for sale or trade. Leveraging these platforms can connect you with others who have similar needs.

Lastly, manufacturer websites often feature catalogs of available accessories. Directly purchasing from the source ensures that you are getting high-quality products that meet the specifications for your equipment.

Installation Guide

This guide provides essential information for the effective setup of your equipment, ensuring optimal performance and longevity. Following these instructions will help users navigate the installation process smoothly and efficiently.

Before starting the installation, gather all necessary tools and components. Ensure the installation area is clean and free of obstructions.

- Tools Required:

- Wrench set

- Screwdriver set

- Level

- Sealant

- Components Included:

- Main unit

- Mounting brackets

- Hoses

- Instruction manual

Follow these steps for a successful installation:

- Prepare the Site: Ensure that the chosen location is stable and has adequate space for installation.

- Mount the Unit: Use the provided brackets to securely attach the main unit to the mounting surface. Ensure it is level to avoid operational issues.

- Connect the Hoses: Attach the hoses according to the specifications provided in the manual. Ensure all connections are tight to prevent leaks.

- Apply Sealant: Use sealant where required to enhance the integrity of the connections and prevent any potential leaks.

- Power Up: Once everything is connected, turn on the power and test the system for functionality.

After completing the installation, perform a thorough check to ensure everything is functioning correctly. Regular maintenance will help prolong the lifespan of your unit.

Signs Your Pump Needs a Replacement

Recognizing the signs that indicate your pump may require replacement is crucial for maintaining optimal performance and preventing further damage. Various symptoms can signal that it’s time to consider a new unit, ensuring that your system operates efficiently and effectively.

Decreased Performance

If you notice a significant drop in the pump’s efficiency, such as reduced water flow or pressure, it may be a sign that internal components are wearing out or failing. This decrease can lead to inadequate performance and strain on the entire system.

Unusual Noises or Vibrations

Uncommon sounds like grinding, rattling, or excessive vibrations often indicate mechanical issues within the pump. These symptoms can stem from damaged bearings or impellers, suggesting that immediate attention and possibly a replacement are necessary to avoid catastrophic failure.