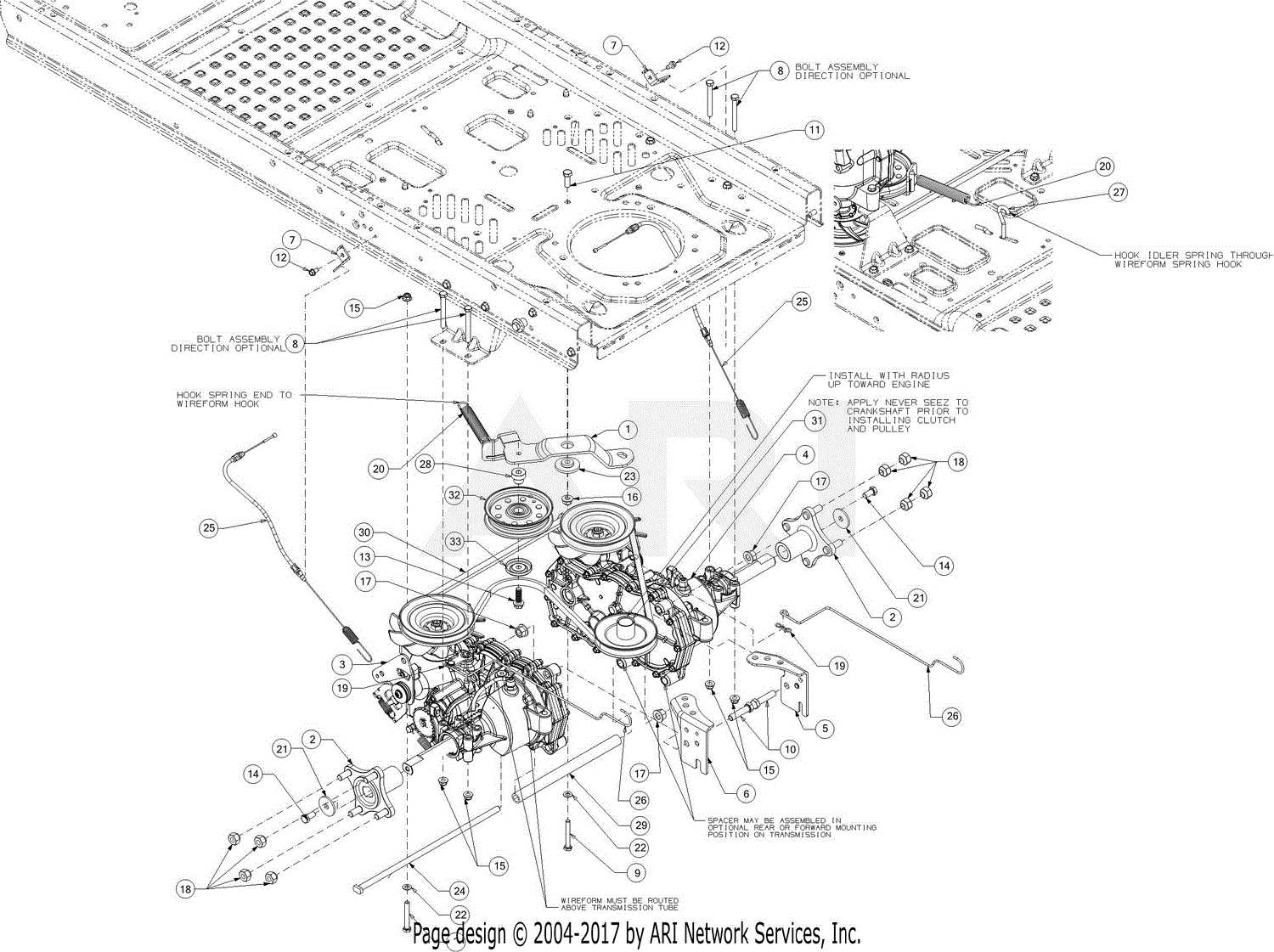

Understanding the internal structure and organization of outdoor power tools can be crucial for effective maintenance and repair. A detailed view of the internal workings allows users to easily identify and replace specific elements, ensuring smooth and reliable performance. This section provides a thorough exploration of the essential components, helping you grasp how different parts fit together and function.

By gaining insight into the arrangement of these key elements, you can more confidently tackle issues, whether you’re performing routine checks or troubleshooting. This resource simplifies the often complex internal configuration, making it easier to find what you need and address any problems efficiently.

Each section is meticulously crafted to highlight vital details, offering clear information for anyone looking to understand how these components work in unison. Whether you’re a seasoned technician or a novice, the organized layout provided here will support your efforts in keeping the machine in top shape.

Overview of Troy Bilt TB516 EC Components

This model of outdoor power equipment is built with various essential elements that ensure its efficiency and functionality. Each component plays a vital role in its overall operation, working together to provide a seamless experience during lawn care and maintenance tasks.

Key Mechanical Elements

The core mechanical parts include the engine and transmission, which are responsible for powering the machine. These elements work in tandem to produce the necessary force for cutting through thick grass and vegetation, delivering high performance even in challenging conditions. The system also includes a recoil starter, designed to initiate the engine with minimal effort.

Additional Features and Attachments

Beyond the primary functions, this model includes specialized attachments to enhance its versatility. For example, there are trimmer attachments that allow for different types of yard work beyond mowing, providing a complete solution for landscaping needs. The ergonomic design of the handle and controls ensures user comfort during extended periods of use.

| Component | Function | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine | Provides power for the machine’s operations |

| Step | Description | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Remove the air filter cover and set it aside. This will expose the carburetor for easier access. | ||||||||||||

| 2 | Disconnect the throttle linkage from the carburetor. Be cautious not to damage the linkage or surrounding components. | ||||||||||||

| 3 | Unscrew the bolts securing the old carburetor and

Common Issues with TB516 EC Starter AssemblyThe starter mechanism is a crucial part of any gas-powered tool, and when it malfunctions, it can lead to operational failures. This section outlines some frequent problems encountered with the starter assembly and provides insights into potential causes and solutions.

|