Understanding how mechanical systems are structured can greatly simplify maintenance and upgrades. Each individual piece contributes to the efficient operation of the whole system, requiring precise alignment and assembly. A visual representation of these elements helps users identify, repair, or replace components more efficiently.

Breakdowns and schematics provide a deeper look into how different sections connect and interact with each other. Such visual aids allow users to pinpoint potential issues and facilitate easier troubleshooting. These technical layouts also serve as a guide for proper reassembly during maintenance tasks.

Having access to a well-organized visual map of key mechanical elements ensures that users can confidently perform adjustments or replacements. Whether for routine checks or more com

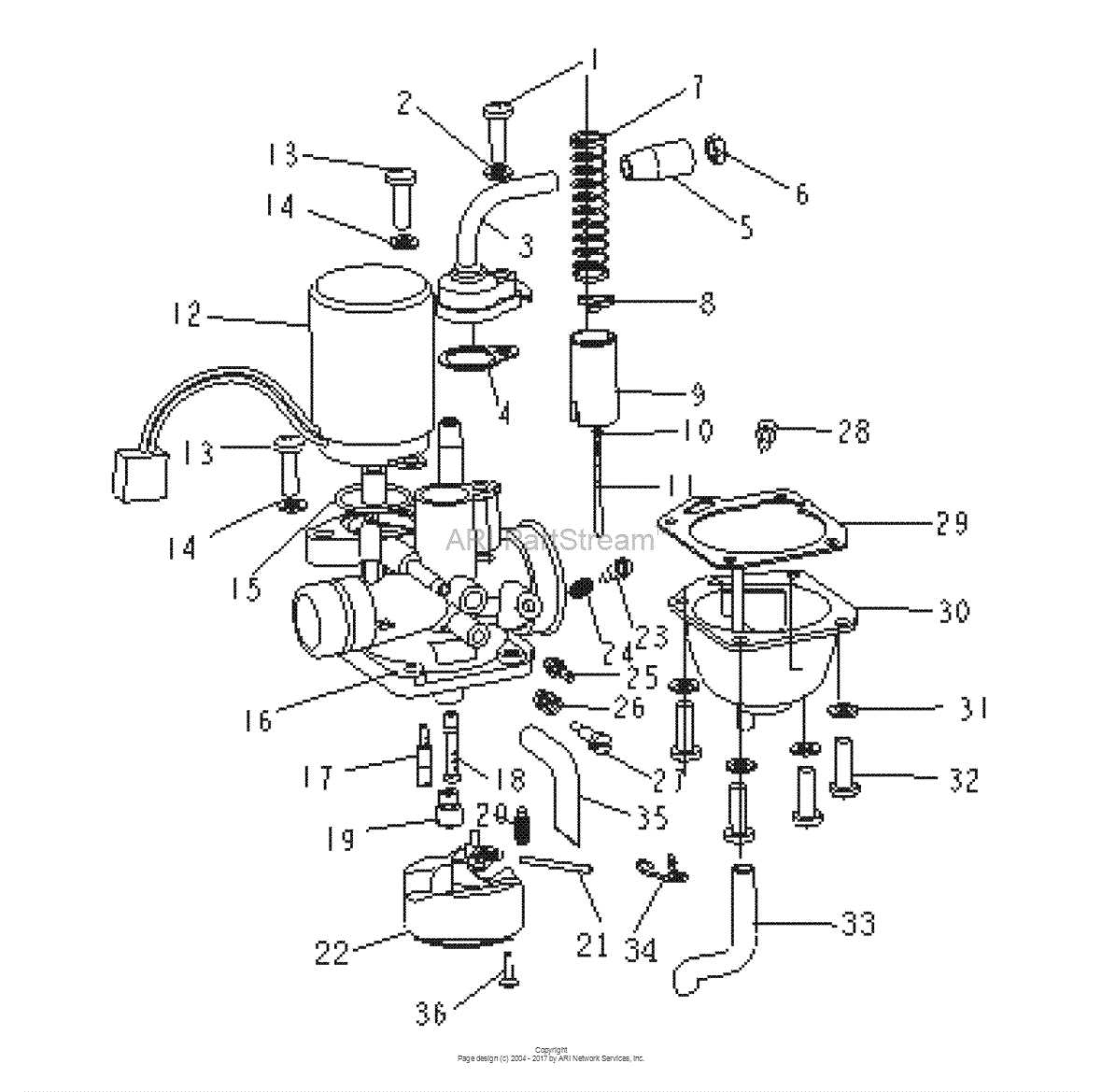

125cc Chinese ATV Parts Diagram Overview

This section provides a detailed look at the structure and key components of a small off-road vehicle. Understanding how individual elements connect helps ensure proper maintenance and smooth performance, making it easier to identify essential replacements or upgrades.

Engine and Powertrain Components

The heart of any off-road machine lies in its power source. It includes essential units like the cylinder, carburetor, and ignition systems. These elements work together to provide the energy needed for acceleration and stable driving on uneven terrain.

Frame, Suspension, and Controls

The frame supports the entire build, while the

Engine Components and Their Functions

The internal structure of a motor comprises interconnected elements, each playing a vital role in ensuring smooth performance. These mechanical parts work in unison to convert energy into motion, delivering consistent power and functionality. Understanding these components helps in maintaining and troubleshooting the system effectively.

Piston and Cylinder

The piston moves inside the cylinder to compress the fuel mixture and generate power. This back-and-forth movement initiates the combustion process, which is essential for creating motion. The cylinder serves as a guide, ensuring the piston remains aligned throughout its operation.

Crankshaft and Connecting Rod

The crankshaft transforms the piston’s linear motion into rotational force, enabling the engine

Electrical System Layout and Wiring

The electrical network plays a crucial role in ensuring smooth operation and reliable performance. Proper organization of wires, connectors, and components helps maintain stability, minimize malfunctions, and facilitate easy troubleshooting. A well-arranged system also ensures the safe distribution of power to all essential areas.

Key Components and Their Functions

Several essential elements are interconnected within the electrical layout. Batteries supply initial power, while ignition coils and spark plugs enable engine startups. Additionally, relays and fuses protect the system by regulating currents and preventing overloads. Lights, indicators, and switches are also part of this network, enhancing safety and usability during operation.

Common Wiring Patterns

Wiring configurations often follow logical paths

Frame, Suspension, and Chassis Parts

The core structure plays a crucial role in ensuring durability and stability during operation. The combination of framework and suspension components contributes to smooth handling on various surfaces, maintaining balance and control in challenging environments. A properly aligned system enhances both performance and safety, minimizing wear and tear over time.

Frame Components and Design

The mainframe serves as the backbone, connecting all critical elements. It must be sturdy yet lightweight, allowing for maneuverability without compromising strength. Essential elements include mounts for the engine and other systems, providing support and preventing vibrations from impacting the ride.

Suspension and Chassis Dynamics

The suspension system absorbs shocks from uneven terrain, ensuring a comfortable experience. Key

Fuel System Components and Setup

The fuel system ensures the efficient delivery of energy required for engine performance. A well-structured setup guarantees optimal combustion, smooth power output, and longevity of the motor. Each element within the system plays a crucial role in maintaining balance, preventing leakage, and ensuring consistent flow.

| Component | Description |

|---|---|

| Fuel Tank | Stores the gasoline and provides it to the system through a secure outlet. |

| Fuel Filter | Removes impurities and debris to protect the engine from contamination. |

| Carburetor | Mixes air and fuel in precise ratios to achieve efficient combustion. |

| Component | Description |

|---|---|

| Steering Wheel | The primary interface for the operator, allowing for directional control. |

| Steering Column | Connects the steering wheel to the steering mechanism, transmitting motion. |

| Steering Gear | Converts the rotational motion of the steering wheel into linear motion, facilitating turning. |

| Linkage System | A series of rods and joints that connect the steering gear to the wheels, ensuring effective communication. |

| Kingpin | The pivot point for the front wheels, allowing for smooth rotation when steering. |

By familiarizing oneself with these components, one can appreciate the complexities involved in steering system assembly, leading to better maintenance and troubleshooting practices.

Common Replacement Parts and Upgrades

Maintaining and enhancing the performance of your vehicle requires attention to various components that may need replacement or improvement over time. Understanding these elements can significantly impact functionality and longevity. Here, we explore frequently replaced components and popular upgrades that can elevate the overall experience of riding.

Frequently Replaced Components

- Brakes: Ensuring reliable stopping power is crucial; replacing brake pads and discs regularly can enhance safety.

- Filters: Air and fuel filters should be changed periodically to maintain optimal engine performance and efficiency.

- Battery: A reliable battery is essential for starting the engine and powering electrical systems; consider replacements every few years.

- Tires: Worn or damaged tires can compromise safety and handling; regular inspections and timely replacements are recommended.

Popular Upgrades

- Exhaust System: Upgrading to a performance exhaust can improve engine efficiency and provide a more powerful sound.

- Suspension: Enhanced suspension components can improve handling and comfort, especially on rough terrains.

- Lighting: Installing brighter or more efficient lighting can enhance visibility and safety during nighttime rides.

- Aftermarket Performance Kits: These kits can boost power output and overall performance, catering to various riding styles.