The intricate assembly responsible for transporting essential liquids within a vehicle plays a vital role in its overall functionality. Each element within this mechanism contributes to the seamless flow and efficiency of the entire operation. By exploring the various segments involved, one can appreciate the sophistication behind this engineering marvel.

In this section, we will delve into the key components that make up this system. Understanding how these individual parts interact with one another not only enhances knowledge but also aids in troubleshooting and maintenance. Grasping the ultimate configuration will empower enthusiasts and professionals alike to ensure optimal performance.

Furthermore, visual aids can significantly enhance comprehension, illustrating how each segment aligns within the broader assembly. As we navigate through this exploration, expect to uncover insights that will enrich your understanding and appreciation for the complexity of vehicle operations.

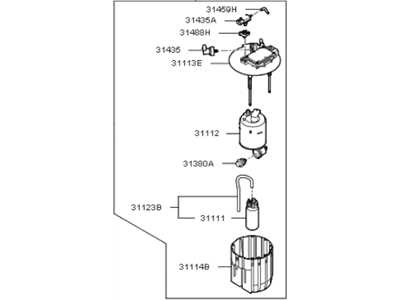

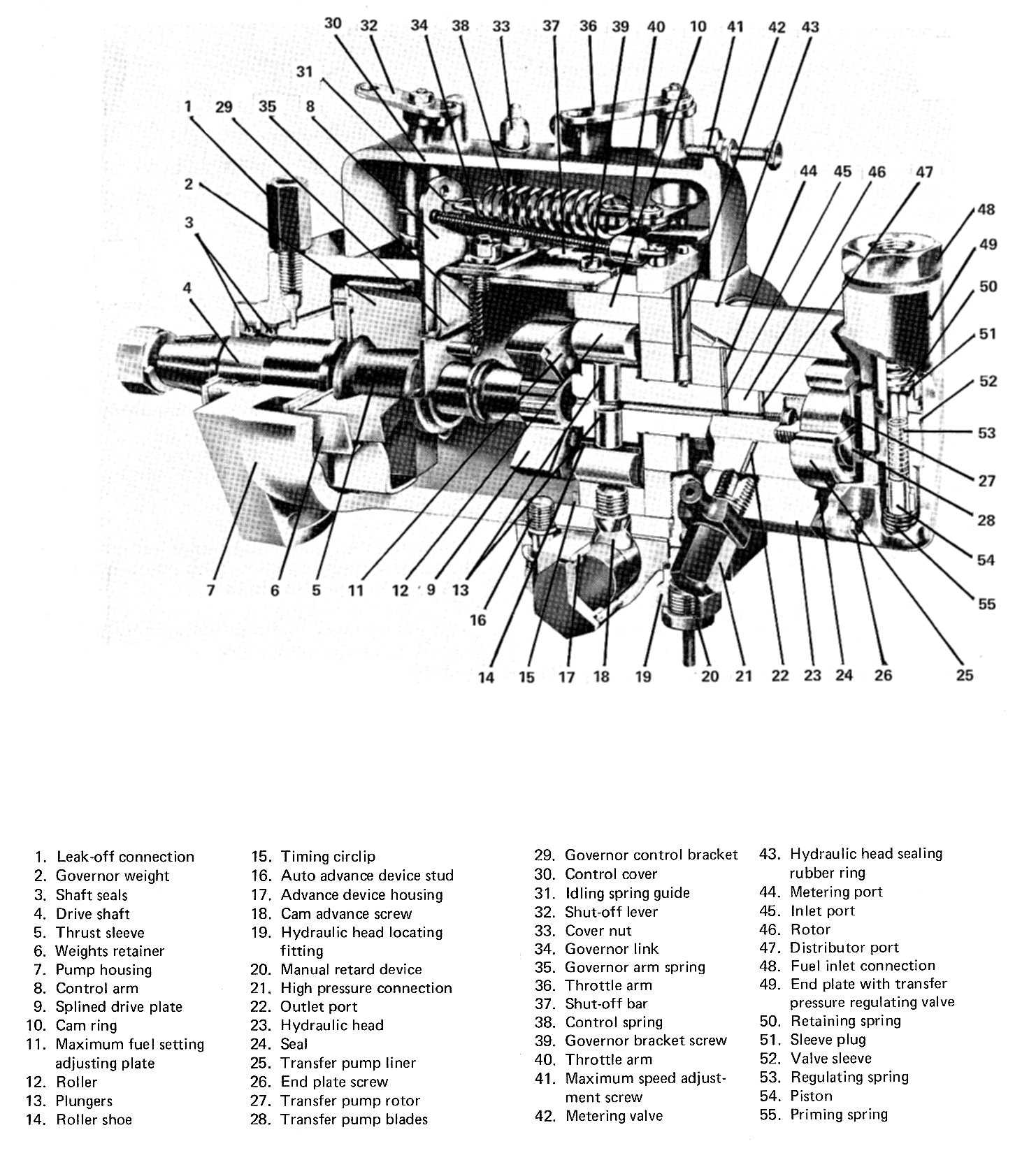

Understanding Fuel Pump Components

Grasping the essential elements involved in the mechanism of liquid delivery is crucial for ensuring optimal performance in various vehicles. Each component plays a significant role in facilitating the smooth transfer and regulation of fuel, making it vital to comprehend their functions and interconnections.

At the heart of this system lies a series of interconnected components, each contributing to the overall efficiency and reliability of the delivery process. Familiarity with these elements can aid in troubleshooting and maintenance, ultimately enhancing the longevity of the vehicle’s system.

| Component | Description |

|---|---|

| Motor | Powers the entire system, converting electrical energy into mechanical motion. |

| Strainer | Filters impurities from the liquid before it enters the main chamber. |

| Chamber | Holds the liquid, allowing for pressurization and controlled flow. |

| Regulator | Maintains consistent pressure levels, ensuring efficient delivery to the engine. |

| Outlet | Directs the processed liquid towards the engine or fuel rail. |

Understanding these components enables users to appreciate their significance and encourages proactive maintenance, which is essential for uninterrupted operation.

Key Functions of Fuel Pumps

The mechanisms responsible for delivering energy to an engine play crucial roles in ensuring optimal performance. Their efficiency and reliability are vital for smooth operation and overall vehicle health.

- Ensuring a consistent flow of energy to the engine.

- Maintaining adequate pressure to facilitate combustion.

- Preventing contamination by filtering out impurities.

- Regulating temperature to avoid overheating.

Each function contributes to the ultimate effectiveness of the engine, highlighting the importance of these essential components.

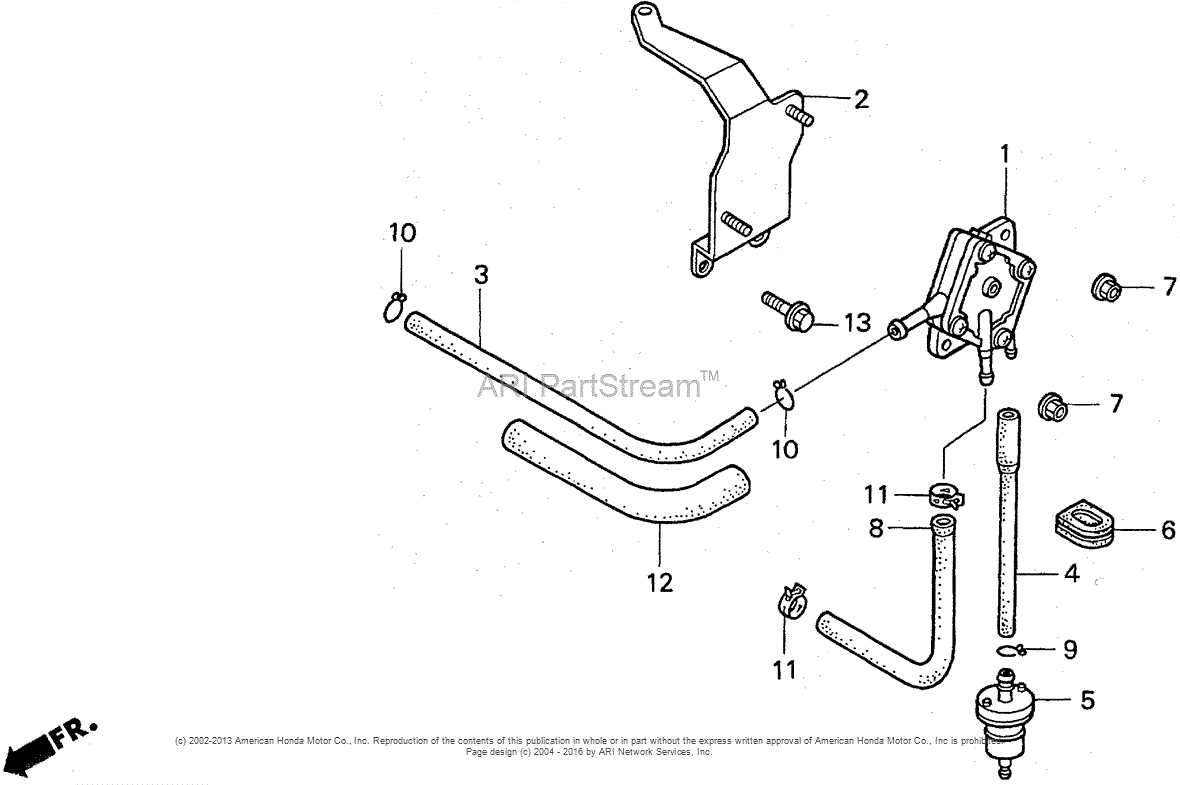

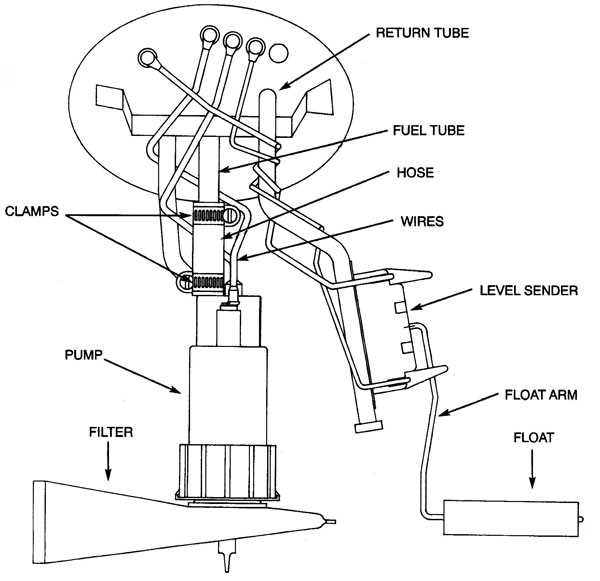

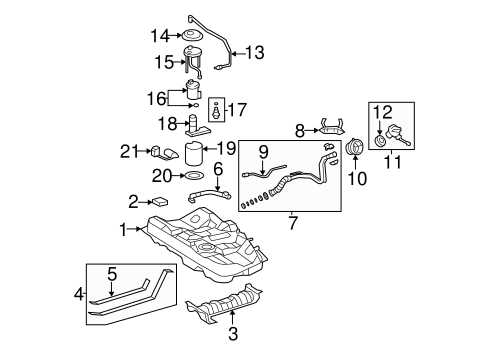

Visual Guide to Fuel Pump Parts

This section offers a comprehensive overview of the essential components involved in the operation of a liquid delivery system. Understanding these elements is crucial for effective maintenance and troubleshooting, ensuring optimal performance over time.

| Component | Description |

|---|---|

| Electric Motor | Drives the mechanism, converting electrical energy into mechanical energy. |

| Strainer | Filters out debris and impurities from the fluid before it enters the main assembly. |

| Rotor | Spins to create a pressure differential, enabling fluid movement. |

| Housing | Encases and protects internal components from external elements. |

| Check Valve | Prevents backflow, ensuring the fluid flows in the correct direction. |

| Connector | Facilitates the electrical connection between the power source and the motor. |

Familiarity with these components not only aids in effective repairs but also enhances the understanding of how these systems function collectively to ensure seamless operation.

Common Issues with Fuel Pumps

Understanding the frequent complications that arise with these vital components can help in timely diagnosis and maintenance. Various factors contribute to their malfunction, leading to performance issues in vehicles.

Typical Complications

- Clogged filters, restricting fuel flow.

- Electrical failures, causing inadequate power supply.

- Wear and tear, resulting from prolonged usage.

- Corrosion, leading to component breakdown.

Signs of Malfunction

- Difficulty starting the engine.

- Unusual noises during operation.

- Poor acceleration or sluggish performance.

- Frequent stalling while driving.

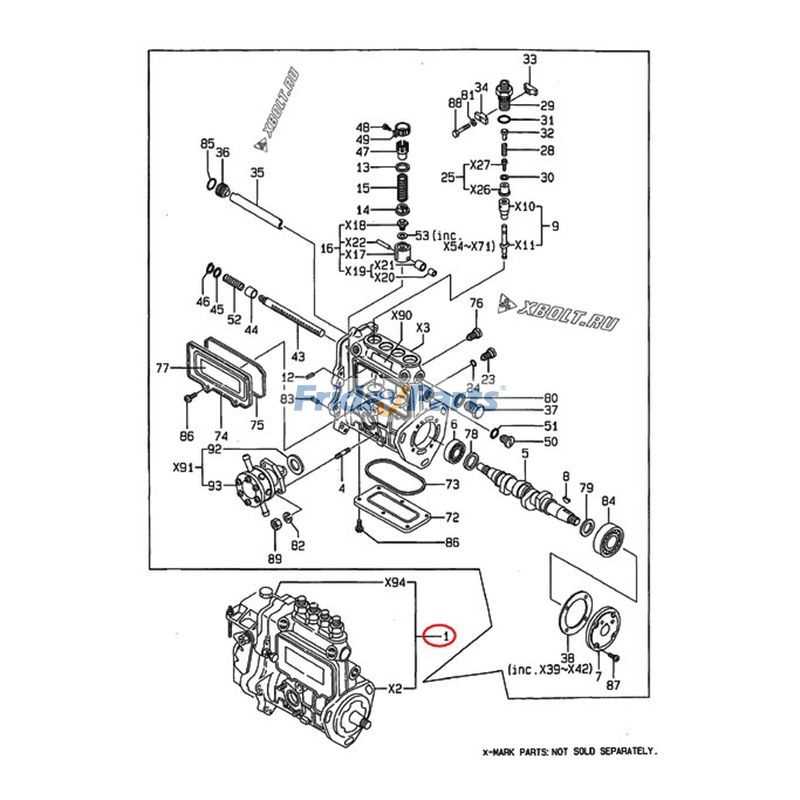

Maintenance Tips for Fuel Systems

Proper care and attention to the components that deliver energy to your engine can significantly enhance performance and longevity. Regular checks and maintenance can prevent costly repairs and ensure efficient operation.

Regular Inspections

- Check for leaks in the lines and connections.

- Inspect filters for clogs and replace as needed.

- Examine seals and gaskets for wear.

Cleaning and Replacement

- Clean or replace components that show signs of buildup.

- Use appropriate solvents for cleaning without causing damage.

- Consider replacing aging components to maintain optimal function.

By following these guidelines, you can ensure that your system operates at its best, ultimately leading to improved efficiency and performance.

Choosing the Right Fuel Pump

Selecting the appropriate component for your vehicle’s fuel delivery system is crucial for optimal performance. The right choice can enhance efficiency, ensure reliability, and prolong the lifespan of your engine. It’s essential to consider various factors that influence your decision.

Compatibility with your vehicle’s make and model is the first step. Different engines require specific types of systems to operate correctly. Always refer to your manufacturer’s recommendations to avoid potential issues.

Next, assess the capacity and pressure ratings. These specifications must match the demands of your engine, as insufficient or excessive output can lead to operational problems. Pay attention to both the flow rate and the pressure levels.

Moreover, consider the design and material quality. High-quality components are generally more durable and resistant to wear and tear, contributing to long-term reliability. Look for products that are built to withstand harsh conditions and offer a warranty for added peace of mind.

Finally, consult customer reviews and expert opinions to gauge the performance of different options. Personal experiences can provide valuable insights and help you make a well-informed choice. Selecting the right component is vital for maintaining your vehicle’s efficiency and functionality.

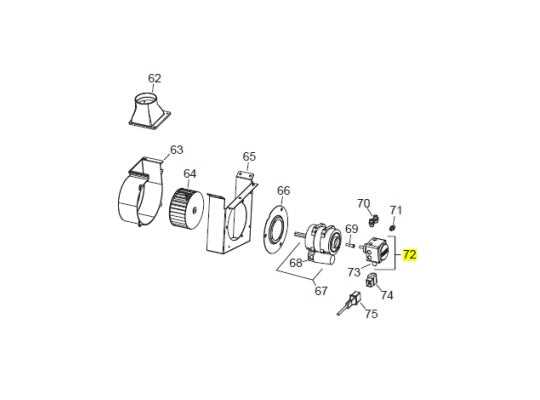

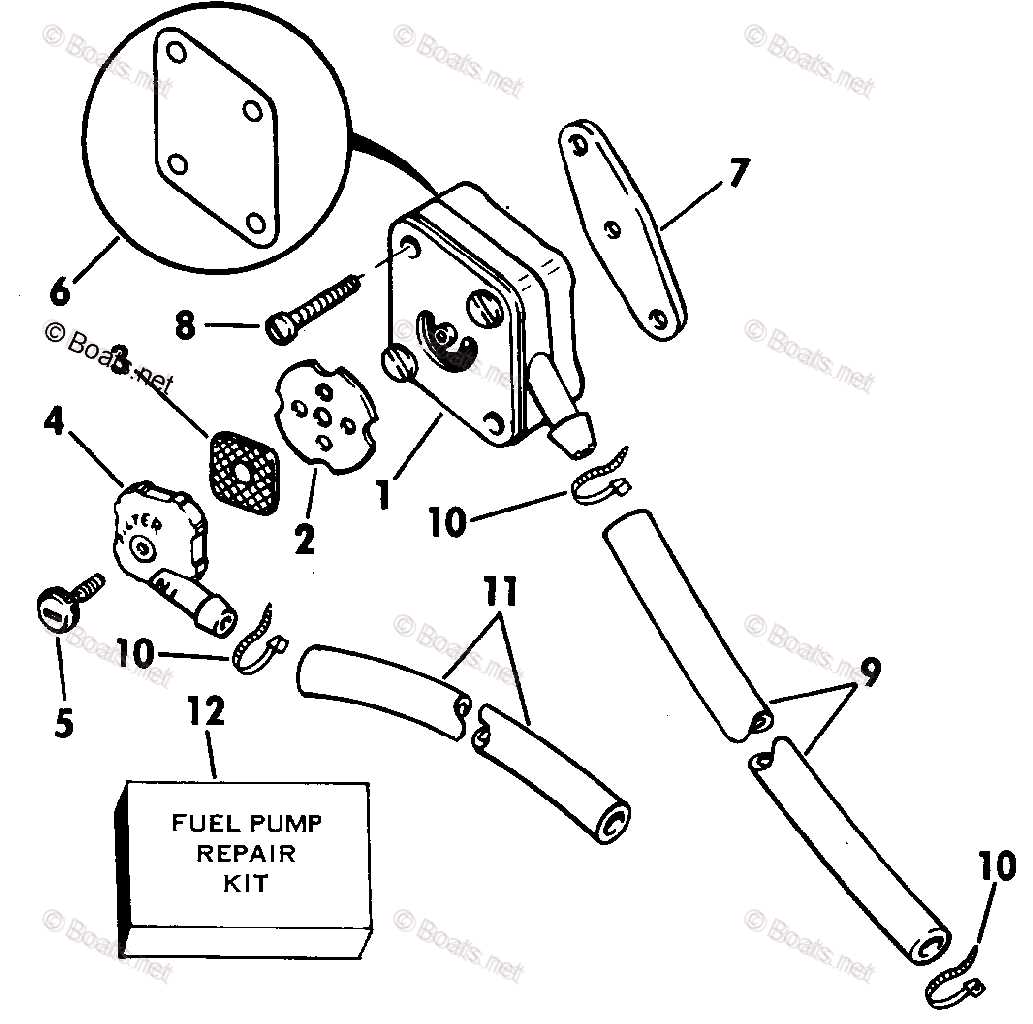

Fuel Pump Installation Basics

Understanding the essential components and processes involved in the installation of a vital component can enhance performance and reliability. This section outlines the fundamental steps required to ensure proper setup and functionality.

Before beginning the installation, consider the following steps:

- Gather necessary tools and materials.

- Ensure you have a clean workspace to avoid contamination.

- Review the manufacturer’s instructions for specific guidelines.

During the installation, follow these key practices:

- Disconnect the power supply to ensure safety.

- Remove the existing component carefully, taking note of all connections.

- Inspect the new component for any damage before installation.

- Securely attach the new unit, ensuring all connections are tight.

- Reconnect the power and perform a test to verify proper operation.

Following these guidelines will lead to a successful installation and optimal performance of the system.

Signs Your Fuel Pump Needs Replacement

Understanding the indicators that signal the need for a replacement is essential for maintaining your vehicle’s performance. When certain symptoms arise, it may suggest that the component responsible for delivering the essential fluid to the engine is failing. Recognizing these signs early can prevent more extensive damage and costly repairs.

| Signs | Description |

|---|---|

| Engine Struggling | If the engine struggles to start or runs unevenly, it could indicate that the fluid delivery is compromised. |

| Noisy Operation | Unusual noises from the rear of the vehicle, such as whining or grinding, may signal an issue with the component. |

| Stalling | Frequent stalling, especially during acceleration, can be a clear sign of inadequate fluid supply. |

| Check Engine Light | If the warning light activates, it often points to an issue with the system responsible for fluid management. |

| Decreased Performance | A noticeable drop in power, especially under load, may indicate that the mechanism is struggling to function correctly. |