In the world of mechanical assemblies, the importance of comprehending the arrangement of individual elements cannot be overstated. A well-organized layout not only enhances functionality but also simplifies maintenance and repairs. Familiarity with these configurations provides users with the insight needed to troubleshoot issues effectively and optimize performance.

Exploring the intricacies of these configurations reveals a wealth of information about how different components interact. By studying these structures, one can gain a deeper understanding of the engineering principles that govern their design. This knowledge ultimately aids in making informed decisions during upgrades or replacements, ensuring a seamless experience.

Moreover, recognizing the relationships between various components fosters a sense of confidence in handling mechanical systems. The ability to navigate these layouts empowers individuals to engage with their equipment more effectively, leading to enhanced productivity and satisfaction. Understanding these elements is essential for anyone looking to maximize the potential of their mechanical devices.

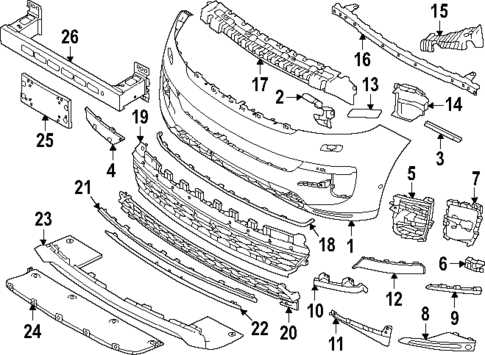

Key Features of Parts Diagrams

The visual representation of components plays a crucial role in various fields, offering clarity and insight into the assembly and functionality of complex systems. These illustrations not only enhance understanding but also facilitate efficient maintenance and troubleshooting processes.

One of the most significant aspects is the ability to convey intricate details through a simplified format. This allows users to easily identify individual elements and their relationships within the overall structure. Below are some essential characteristics:

| Feature | Description |

|---|---|

| Clarity | Provides a clear view of each component’s placement and function. |

| Accessibility | Enables users to quickly locate necessary parts for replacement or repair. |

| Reference | Serves as a reliable source for technical specifications and assembly instructions. |

| Visual Guidance | Offers visual cues that aid in the understanding of complex assembly processes. |

Incorporating these attributes into design enhances usability and ensures that users can effectively engage with the content, leading to more informed decisions during maintenance and repairs.

Benefits of Using Diagrams

Visual representations offer numerous advantages in understanding complex information. They simplify intricate concepts, allowing for quicker comprehension and better retention of knowledge. By breaking down elements into manageable sections, these illustrations facilitate effective communication and streamline the learning process.

Enhanced Clarity

Employing visual aids can significantly improve clarity in conveying information. Users can easily identify components and their relationships, minimizing confusion. This clear depiction enables individuals to grasp essential details swiftly, making it easier to follow instructions or troubleshoot issues.

Improved Problem Solving

Visual tools foster effective problem-solving by providing a structured overview. When faced with challenges, having a visual reference allows users to pinpoint the source of issues quickly. This approach encourages systematic analysis, leading to more efficient solutions and reduced downtime.

Common Issues in Parts Identification

Identifying components in a system can often present a variety of challenges that hinder effective maintenance and repair. Misunderstandings and inaccuracies in recognizing the correct elements can lead to significant complications in functionality and performance. Below are some of the most frequent obstacles encountered in this process.

- Inconsistent Terminology: Different manufacturers may use varying names or codes for similar components, creating confusion during identification.

- Outdated References: Manuals or diagrams may contain outdated information, making it difficult to match current components accurately.

- Visual Similarities: Many components appear similar, which can lead to misidentification and incorrect replacements.

To effectively navigate these issues, it is essential to utilize comprehensive resources and cross-reference multiple materials. Here are some strategies to enhance the identification process:

- Consult multiple sources, such as online databases and manufacturer websites, to verify component details.

- Utilize high-quality images and detailed descriptions for comparison.

- Engage with professional forums or support groups for advice and shared experiences.

By addressing these common hurdles, one can improve accuracy and efficiency in the identification of components within any system.

Step-by-Step Assembly Guide

This section provides a comprehensive approach to constructing your appliance effectively and efficiently. By following the outlined stages, you can ensure that all components are correctly aligned and secured, promoting optimal performance.

Step 1: Begin by gathering all necessary components and tools. Ensure that you have a clean workspace to facilitate easy access to everything needed during the assembly process.

Step 2: Carefully examine each component. Familiarize yourself with their functions and how they interconnect. This understanding will be essential for a seamless assembly experience.

Step 3: Start the assembly by connecting the primary structure. Align the designated parts and secure them using appropriate fasteners. Be mindful of the orientation to avoid misalignment.

Step 4: Proceed to attach secondary elements. Ensure that each piece fits snugly into its designated position. Utilize a torque wrench to tighten screws if specified in the instructions.

Step 5: Once the main components are assembled, perform a thorough inspection. Check for any loose connections or misalignments that could affect functionality.

Step 6: Finally, conduct a test run to confirm that everything operates as intended. This step is crucial to identify any issues before full utilization.

Following these steps will guide you through a successful assembly, enhancing the longevity and effectiveness of your equipment.

Maintenance Tips for Optimal Performance

To ensure long-lasting efficiency and reliability, regular upkeep is essential. By following a few straightforward practices, you can significantly enhance the functionality of your equipment and reduce the likelihood of unexpected failures.

Regular Cleaning

Keep surfaces clean and free of debris. Accumulated dust and grime can hinder performance and lead to overheating. Use appropriate cleaning solutions and tools to maintain the condition of the equipment, paying special attention to areas prone to buildup.

Periodic Inspections

Conduct routine checks to identify any wear or damage. Look for signs of deterioration, loose components, or leaks. Early detection of issues can prevent more significant problems, ensuring that everything operates smoothly and efficiently.

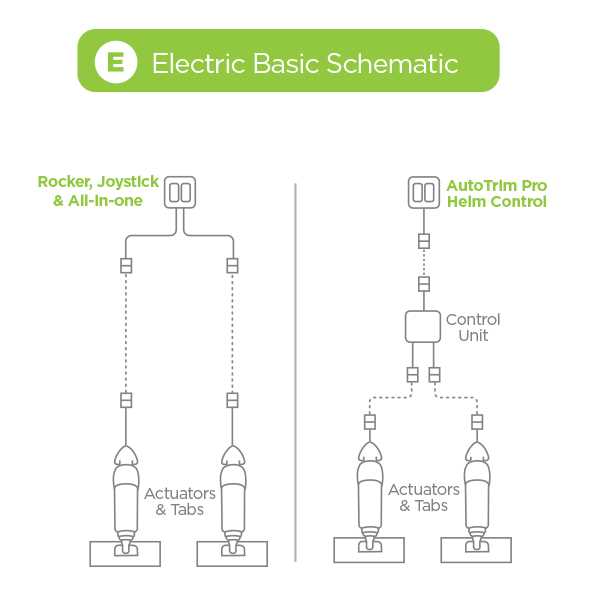

Tools Required for Diagram Reference

When engaging with complex schematics, having the appropriate equipment is crucial for accurate interpretation and effective application. The right selection of instruments not only enhances the understanding of the layout but also facilitates a smoother workflow during any related tasks.

Essential Instruments

Basic items like pens, pencils, and highlighters are vital for marking and annotating the necessary details. Additionally, rulers and scales assist in measuring components accurately, ensuring precision when referencing different sections of the schematic.

Advanced Equipment

For those seeking a deeper insight, tools such as digital calipers and multimeters are invaluable. These instruments allow for a thorough examination of measurements and electrical characteristics, enabling users to correlate the visual data with real-world applications effectively.

Resources for Further Information

For those seeking to expand their knowledge and understanding of components and their functionalities, a variety of resources are available. These materials can provide insights into maintenance, specifications, and installation practices relevant to different models.

Online forums and communities often serve as valuable platforms where enthusiasts and professionals share their experiences, tips, and troubleshooting advice. Additionally, official manufacturer websites typically offer detailed manuals, technical sheets, and instructional videos that can guide users through various processes.

Furthermore, reputable technical publications and industry-related websites frequently publish articles and guides that delve into best practices and innovative solutions. Utilizing these resources can enhance one’s comprehension and facilitate effective management of various systems.