To fully appreciate the intricate functioning of timepieces, it’s essential to explore the essential components that drive their precision. Each unit within these intricate mechanisms serves a specific role in ensuring accurate time display. While the external casing and dial might seem straightforward, it’s the inner workings that truly determine their reliability and accuracy.

In this section, we will break down the fundamental elements that contribute to the operation of a time-indicating device. These pieces collaborate harmoniously to regulate movement, maintain consistency, and provide a reliable reading. From gears and springs to more specialized components, understanding how they interact is crucial for anyone interested in horology.

By delving into these mechanical structures, one can gain insight into how these marvels of engineering continue to perform with precision, generation after generation. Whether you’re a hobbyist or an expert, the complexity of these systems will no doubt inspire admiration for the artistry behind every tick and tock.

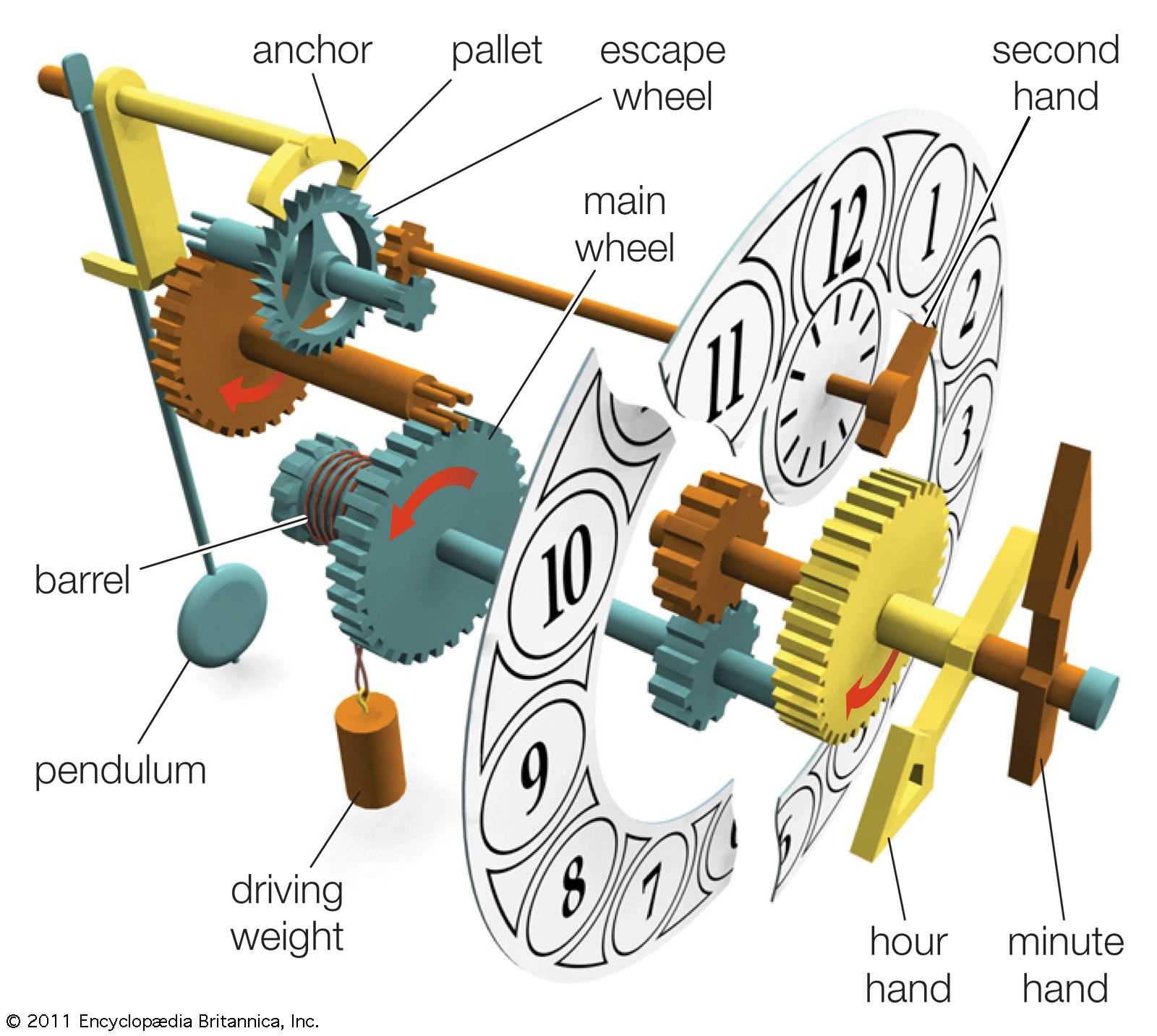

Understanding Clock Movement Basics

At the core of timekeeping devices lies a fascinating interplay of components that work harmoniously to measure and display time. This intricate system transforms energy into motion, allowing for the precise tracking of seconds, minutes, and hours. By delving into these essential elements, one can appreciate the craftsmanship and engineering that contribute to accurate time measurement.

Essential Components

Each mechanism typically includes a source of power, a regulator, and an indicator. The power source, often a battery or winding mechanism, initiates the process. The regulator, which could be a pendulum or quartz crystal, ensures consistency in timing. Finally, the indicator visually represents the passage of time, guiding the observer with its hands or digital display.

Understanding Functionality

Examining how these elements interact reveals the complexity behind what may seem like a simple device. Adjustments in one area can significantly influence the entire system’s performance. Knowledge of this functionality is crucial for anyone looking to maintain, repair, or appreciate these remarkable instruments.

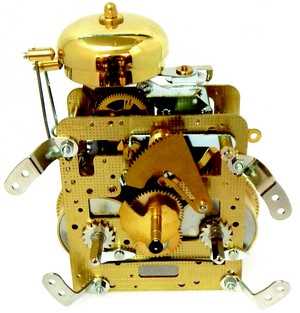

Components of Mechanical Clocks

Understanding the intricate elements that work together in traditional timekeeping devices reveals the sophistication behind their functionality. Each element plays a vital role in ensuring accurate time measurement, reflecting a blend of artistry and engineering.

Key Elements

The primary components include a source of energy, a gear train, and a mechanism for indicating time. These interact seamlessly to create a reliable system that is both precise and elegant.

Energy Sources and Gear Train

| Component | Description |

|---|---|

| Mainspring | Stores energy by winding and releases it gradually. |

| Weight | Utilizes gravitational pull to drive the mechanism. |

| Gear Train | Transmits energy and regulates the flow to the escapement. |

How Quartz Movements Function

This section explores the intricate mechanism behind timekeeping technology that relies on quartz. By harnessing the unique properties of quartz crystals, these devices maintain remarkable accuracy and reliability. Understanding their operation reveals the blend of science and craftsmanship involved in their design.

The Role of Quartz Crystals

- Quartz crystals vibrate at a consistent frequency when subjected to an electrical charge.

- This vibration serves as a precise time reference.

- The frequency is typically 32,768 Hz, allowing for accurate timekeeping.

How the Mechanism Operates

- The crystal is powered by a battery, generating an electric field.

- The oscillation of the crystal is converted into a steady pulse.

- This pulse drives the gears, moving the hands of the device.

- Feedback circuits ensure consistent performance and adjust for any drift.

This combination of electrical and mechanical processes leads to the ultimate precision that defines modern timekeeping instruments.

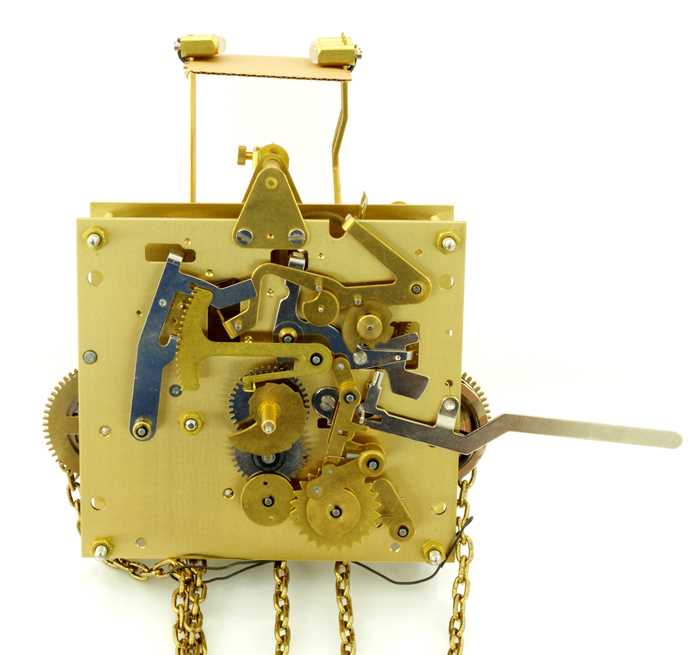

Importance of Clock Gears

The intricate mechanism behind timekeeping relies heavily on the precise interaction of various components. Among these, the system responsible for transmitting energy and ensuring accurate function plays a pivotal role. These components, often made of metal, serve as the foundation for motion, transforming energy from a power source into regulated intervals that we can rely on. Their design and functionality are essential for the reliable operation of any timepiece, allowing it to serve its intended purpose with precision.

Gears are particularly crucial in ensuring that each section of the apparatus moves in perfect harmony. Their ability to transfer rotational energy between different elements without loss or error ensures that every tick is accounted for. Without these intricate wheels and cogs, even the most sophisticated timekeeping device would fail to perform its intended task.

Efficiency in the arrangement and functioning of these components is key to maintaining long-term accuracy. The teeth of each gear mesh together to regulate speed and synchrony, preventing unwanted errors and fluctuations. As time passes, these parts must work in unison to prevent wear and ensure continued performance. The quality of materials and design plays a significant role in how well the system stands the test of time, both literally and figuratively.

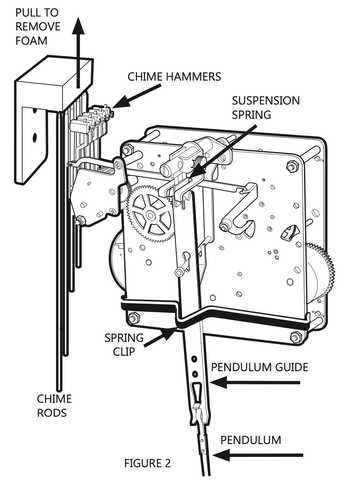

Role of the Escapement Mechanism

The escapement mechanism plays a crucial role in regulating the timekeeping process of a timepiece. It serves as a mediator between the energy source and the timekeeping element, ensuring that the release of energy occurs at a controlled rate. This precision is vital for maintaining accurate time measurement.

Key functions of the escapement include:

- Energy Transfer: It transmits energy from the power source to the oscillating element, allowing for consistent operation.

- Regulation: The escapement controls the rate of release of energy, which directly impacts the timekeeping accuracy.

- Interruption of Motion: It periodically halts the gear train, preventing the uncontrolled release of energy and ensuring precise intervals of time are measured.

- Feedback Mechanism: It provides a feedback loop that enhances stability and reliability in the timekeeping process.

In summary, the escapement mechanism is essential for achieving precision in the measurement of time, ensuring that each tick is a reflection of carefully regulated energy release.

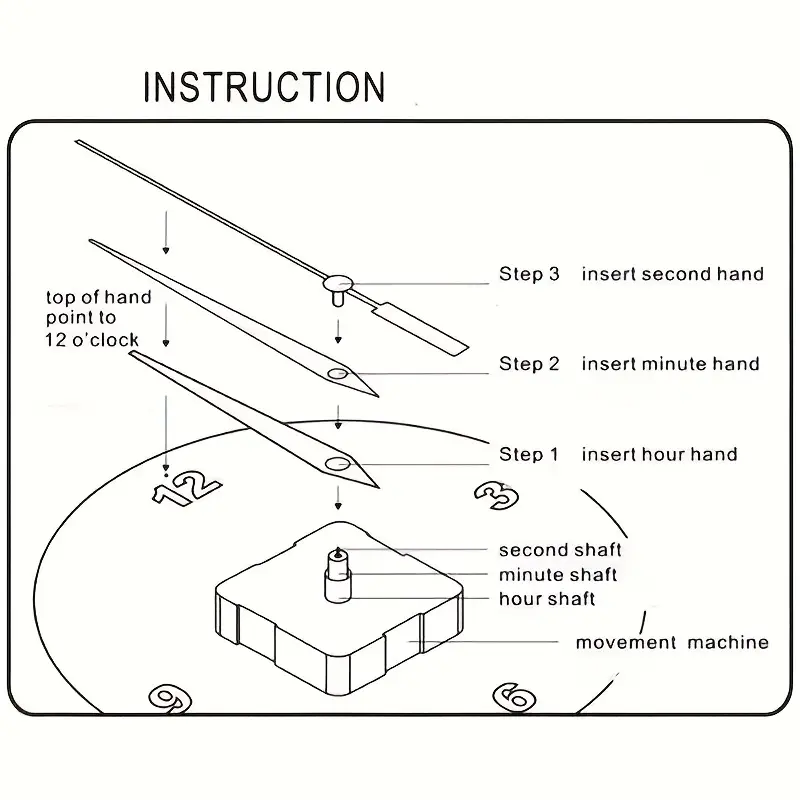

Types of Clock Hands Explained

Timepieces feature various indicators that perform the essential task of displaying the passage of hours, minutes, and seconds. These indicators, often referred to as “hands,” are key elements that define the functionality and visual appeal of a timekeeping device. Each hand has a distinct role, and their design can vary significantly based on both aesthetic preferences and technical needs.

Hour Hand: This is the shortest and thickest of all the hands. It moves slowly, making a full revolution over the course of 12 hours. Its main function is to point to the hour, and its size ensures it stands out even at a distance.

Minute Hand: Longer and narrower than the hour hand, the minute hand moves more swiftly. It completes a full rotation every 60 minutes, often pointing to the minute markings along the perimeter of the dial.

Second Hand: The thinnest and usually the most delicate, the second hand constantly moves, sweeping in a smooth, continuous motion or in small ticks. It indicates the passage of seconds and can be either a simple straight line or an ornate design depending on the style of the timepiece.

Specialized Hands: In addition to the basic trio, some watches or timekeepers feature additional hands, such as a 24-hour hand, chronograph hand, or even a date hand. These can provide more specific information, such as the date, stopwatch functionality, or a 24-hour time scale.

Overall, each hand plays a pivotal role in ensuring the accuracy and readability of the time, making them indispensable elements in the design of time-telling devices.

Power Sources for Clock Movements

In the realm of timekeeping devices, energy sources play a crucial role in ensuring accurate functionality and reliability. Various types of power supply methods are employed, each offering distinct advantages and suitability for different designs and applications.

Types of Energy Sources

- Batteries: One of the most common forms of energy supply, batteries provide portability and convenience. They come in various sizes and chemistries, such as alkaline and lithium, catering to diverse needs.

- Electric Power: Devices that plug into wall outlets benefit from continuous energy, eliminating the need for replacements. This option is ideal for large installations or fixed units.

- Solar Energy: Harnessing sunlight, solar-powered options are eco-friendly and reduce dependence on traditional energy sources. They often include rechargeable batteries for use in low-light conditions.

- Mechanical Energy: Wind-up mechanisms utilize stored energy from a wound spring, allowing for a unique, traditional approach to timekeeping without reliance on external power.

Considerations for Selection

When choosing a suitable energy source, several factors should be taken into account:

- Duration: Consider how long the device will operate before requiring a recharge or replacement.

- Environment: Assess whether the setting is suitable for solar or electric options, especially in areas with limited access to sunlight or outlets.

- Cost: Analyze the initial investment versus long-term expenses, particularly when considering rechargeable vs. disposable options.

- Maintenance: Evaluate the ease of maintaining the energy source, as some may require more frequent attention than others.

Understanding these various energy supply methods allows for informed decisions when designing or selecting timekeeping devices, ensuring they meet the specific requirements of users and environments alike.

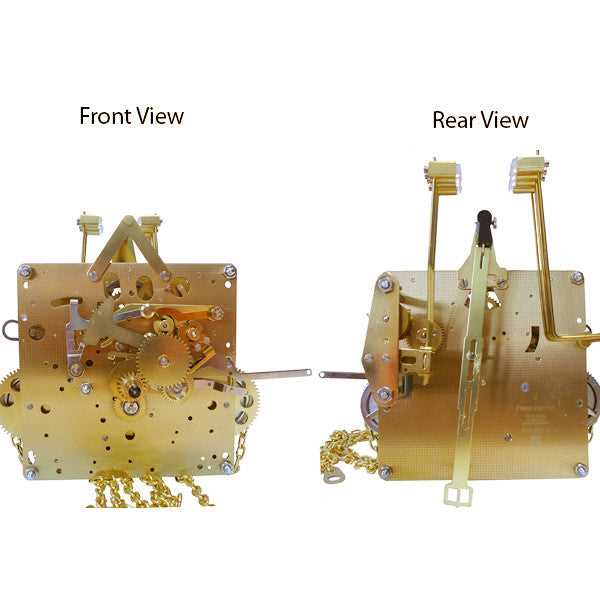

Maintenance Tips for Clock Parts

Proper care and attention to mechanical components are crucial to ensure the longevity and accurate functioning of timekeeping devices. Regular maintenance helps prevent wear and tear, improves performance, and reduces the risk of costly repairs. Keeping the internal elements clean, lubricated, and properly aligned is essential for smooth operation.

Regular Cleaning

Over time, dust and dirt can accumulate on moving elements, leading to friction and potential damage. It is important to carefully clean these components to avoid clogging or interference with their motion. Use a soft brush or compressed air to remove any particles, ensuring that no residue remains. Avoid using harsh chemicals that could damage delicate surfaces.

Lubrication and Adjustment

For the smooth functioning of gears and other moving parts, applying appropriate lubrication is essential. A small amount of oil or grease can reduce friction and prevent excessive wear. However, over-lubrication can attract dust and dirt, so it is important to use the right amount. Periodically check for any misalignment or loose components and make necessary adjustments to ensure optimal performance.

Common Issues and Troubleshooting Guide

Maintaining the functionality of timekeeping devices often involves identifying and resolving various technical challenges. Even with the most precise craftsmanship, mechanical systems can develop issues over time. This section will address some of the most frequent malfunctions, providing practical solutions to keep everything running smoothly. Whether it’s irregular ticking, inaccurate timekeeping, or complete inoperability, understanding the common sources of these problems will help in diagnosing and fixing them effectively.

Irregular Ticking or Unsteady Movement

If the ticking sound is inconsistent or the hands are moving erratically, this could be a sign of friction, misalignment, or wear within the internal components. The cause may lie in parts rubbing against each other or a misaligned gear. First, ensure that all components are properly lubricated and that none of the moving elements are obstructed. If the issue persists, inspect for damaged gears or worn bearings that may require replacement.

Inaccurate Timekeeping

When the device is not keeping time correctly, it can be due to an imbalance or a mechanical fault in the regulating mechanism. Check if the pendulum or balance wheel is functioning properly, and ensure there is no dust or debris in the escapement system. Additionally, environmental factors such as temperature changes or improper placement can affect precision. Adjust the settings or re-calibrate the device if necessary. If the issue is persistent, more advanced diagnostics may be needed to address worn or malfunctioning internal components.

In many cases, regular maintenance and careful attention to detail can restore proper operation. If troubleshooting doesn’t resolve the issue, consulting a professional with experience in intricate time-measuring devices may be required for a more thorough repair.