When exploring the functionality of lifting entrances, one encounters a complex interplay of various elements that ensure seamless operation. Each component plays a critical role, contributing to the overall efficiency and reliability of the mechanism. Grasping the relationship between these elements is essential for anyone involved in maintenance or installation.

In this section, we delve into the intricate structure that supports the smooth ascent and descent of these access points. By breaking down the individual components, readers will gain valuable insights into how they interact and function together. This knowledge is not only useful for troubleshooting but also enhances one’s understanding of the entire system.

Furthermore, recognizing the specific roles of each element empowers users to make informed decisions regarding repairs or upgrades. Whether you are a professional or a DIY enthusiast, familiarizing yourself with these vital components will enhance your ability to manage and optimize the performance of your elevating entrance.

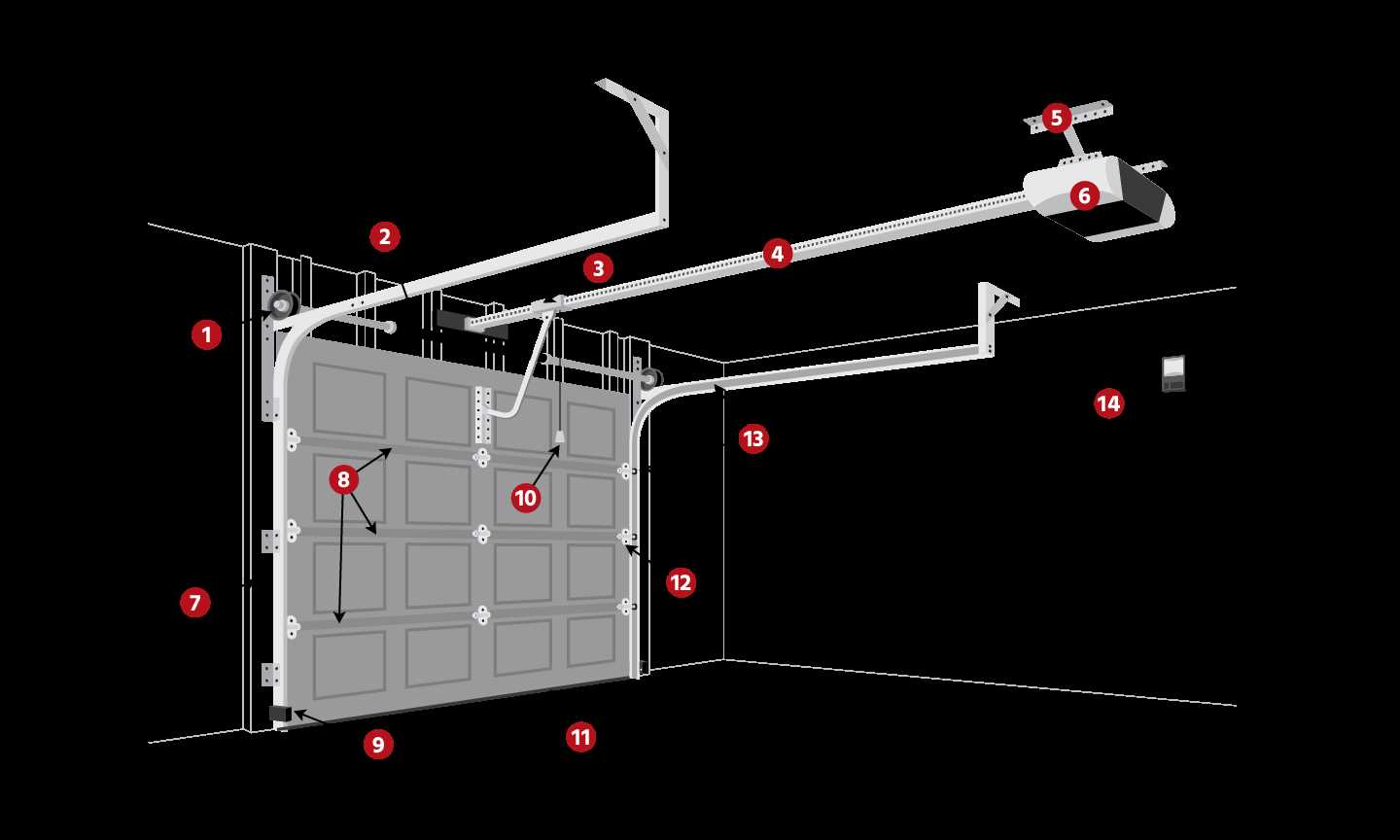

Understanding Overhead Door Components

Grasping the intricacies of lifting systems is essential for effective maintenance and operation. Each element plays a pivotal role in ensuring functionality and safety, making it crucial to familiarize oneself with their characteristics and interactions.

Key Elements of the System

The core structure includes a variety of mechanisms, each contributing to the overall performance. Tracks guide movement, while sensors enhance safety by detecting obstacles. Understanding these features enables users to address issues promptly.

Maintenance and Care

Regular upkeep of individual components is vital. Lubrication and inspection of springs and cables can prolong lifespan and enhance efficiency. By prioritizing these practices, one can ensure optimal operation and reduce the likelihood of malfunctions.

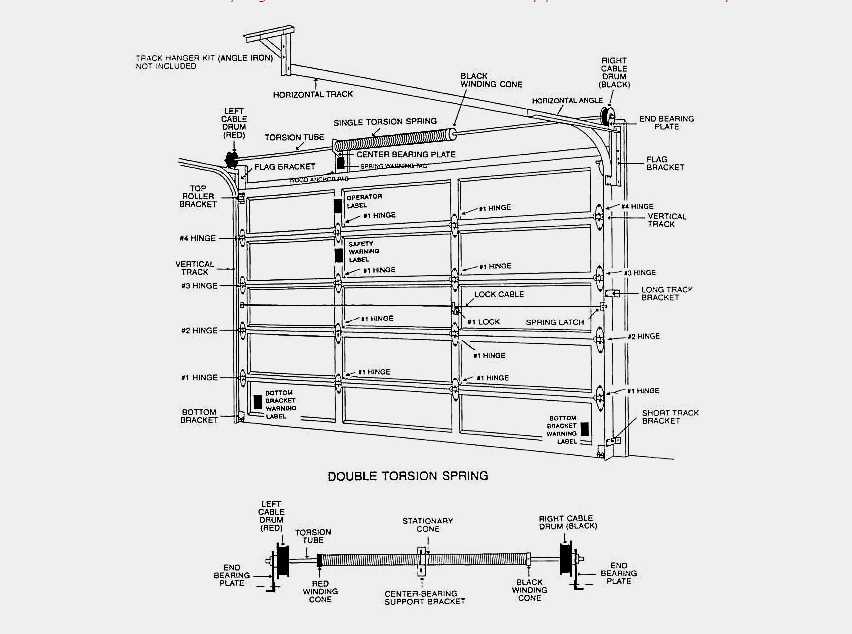

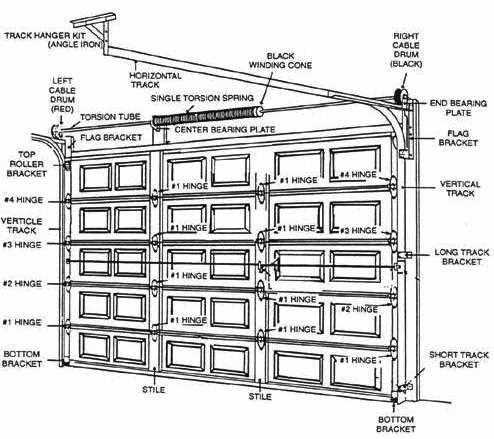

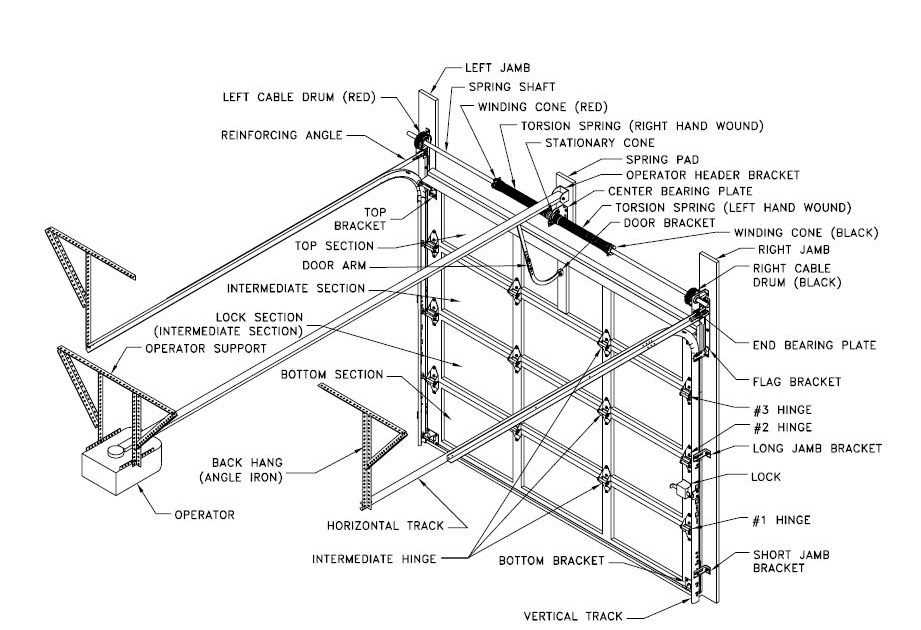

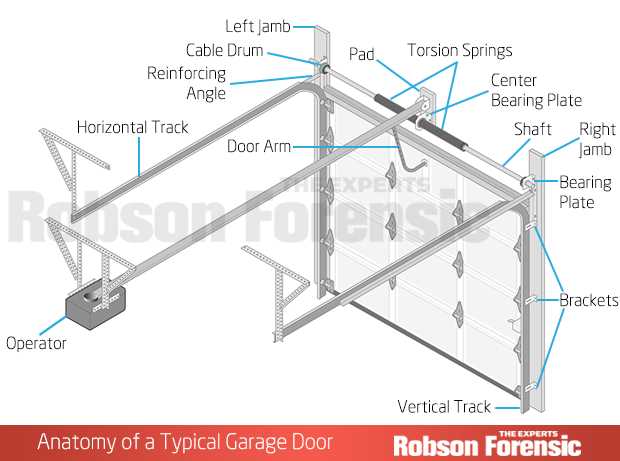

Essential Parts of Garage Doors

A functional garage entry system relies on a variety of crucial components that work together to ensure smooth operation and safety. Understanding these elements is key for maintenance and repair, as each plays a significant role in the overall performance.

Main Components

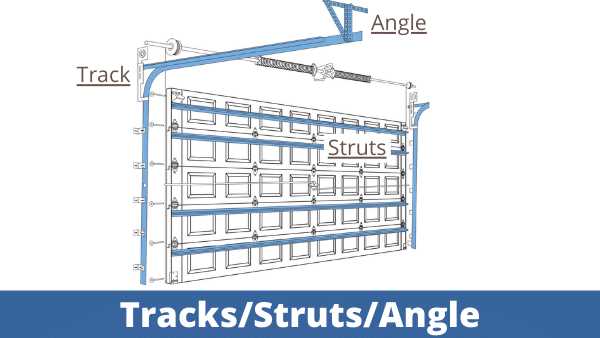

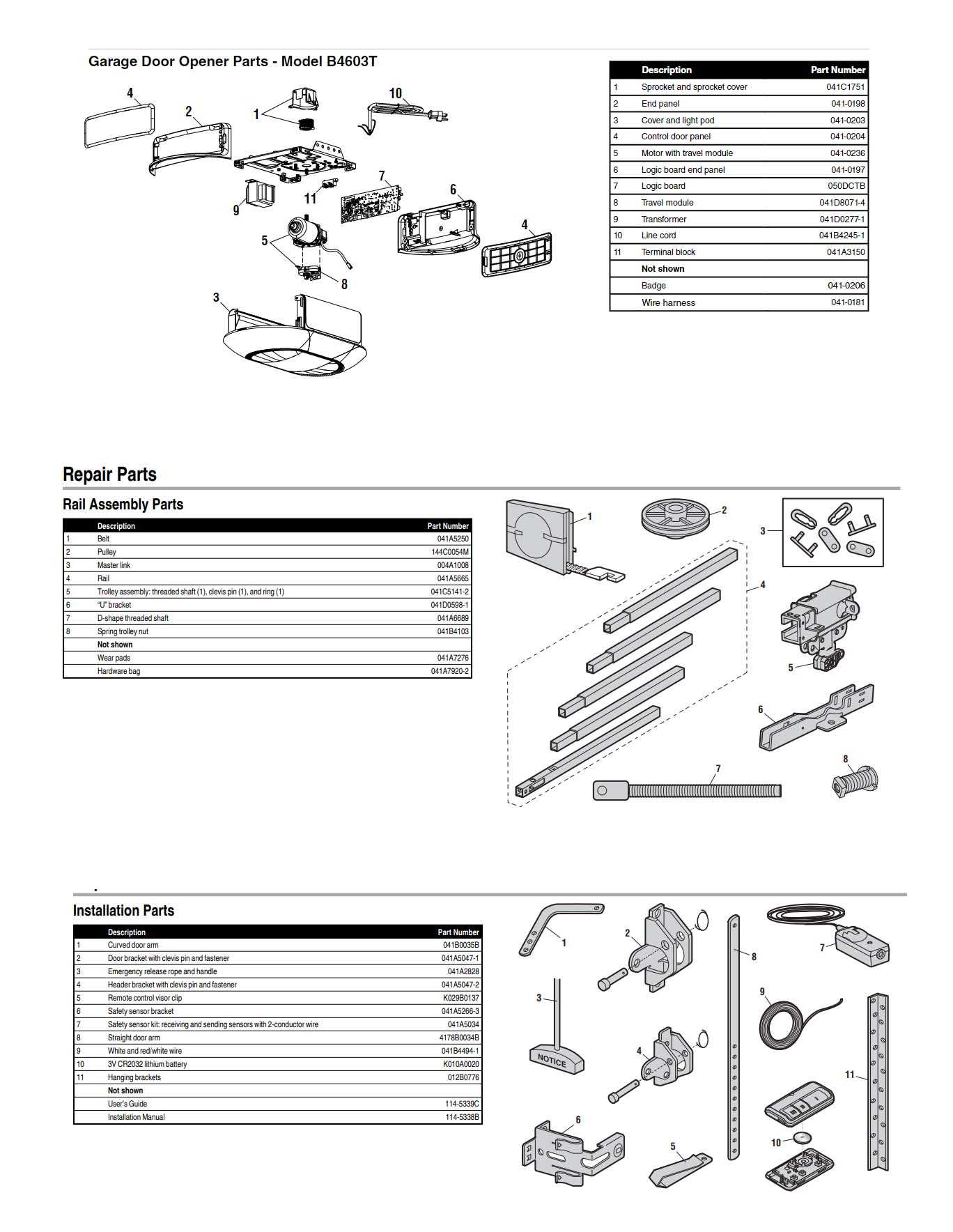

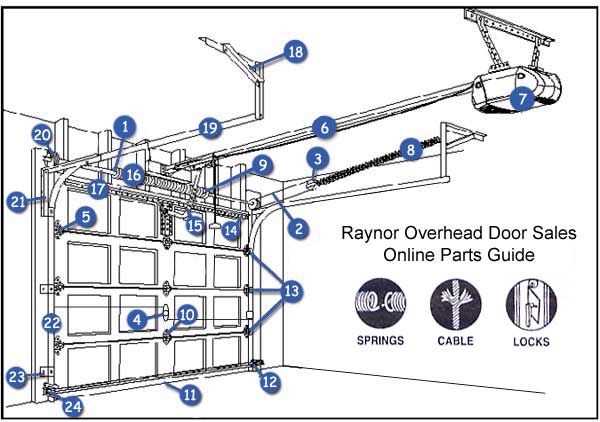

- Tracks: These metal rails guide the movement of the entry system, ensuring it opens and closes correctly.

- Rollers: Attached to the sides of the entry, these small wheels enable smooth movement along the tracks.

- Spring Mechanism: Vital for lifting the weight of the entry, this system reduces strain on the opener and allows for easy operation.

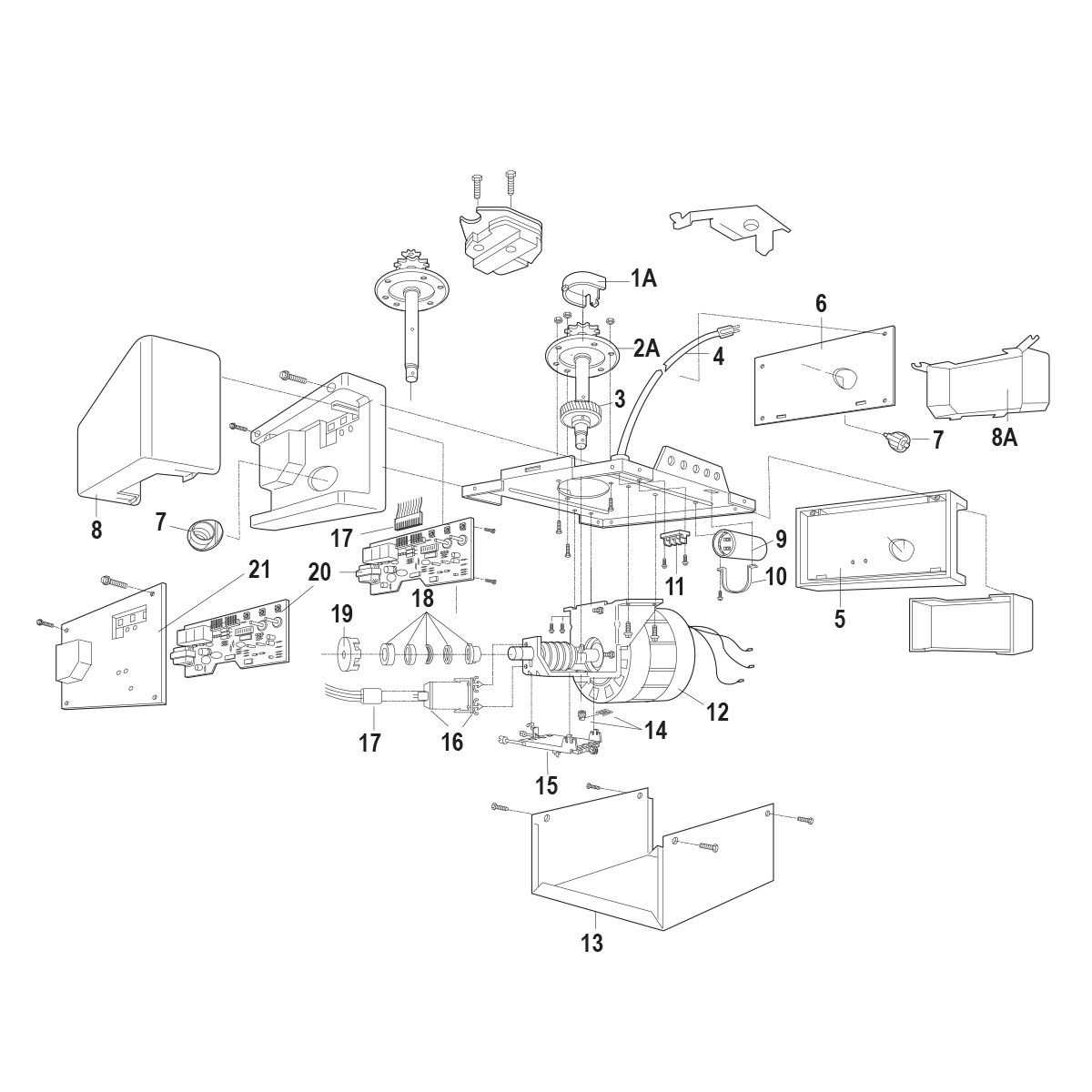

- Opener Unit: An electric device that powers the entry’s movement, typically operated by a remote control or wall switch.

Additional Elements

- Cables: These strong wires support the weight and balance of the entry, connecting the springs to the rollers.

- Weatherstripping: Installed around the edges, this material helps seal the entry against the elements, improving insulation.

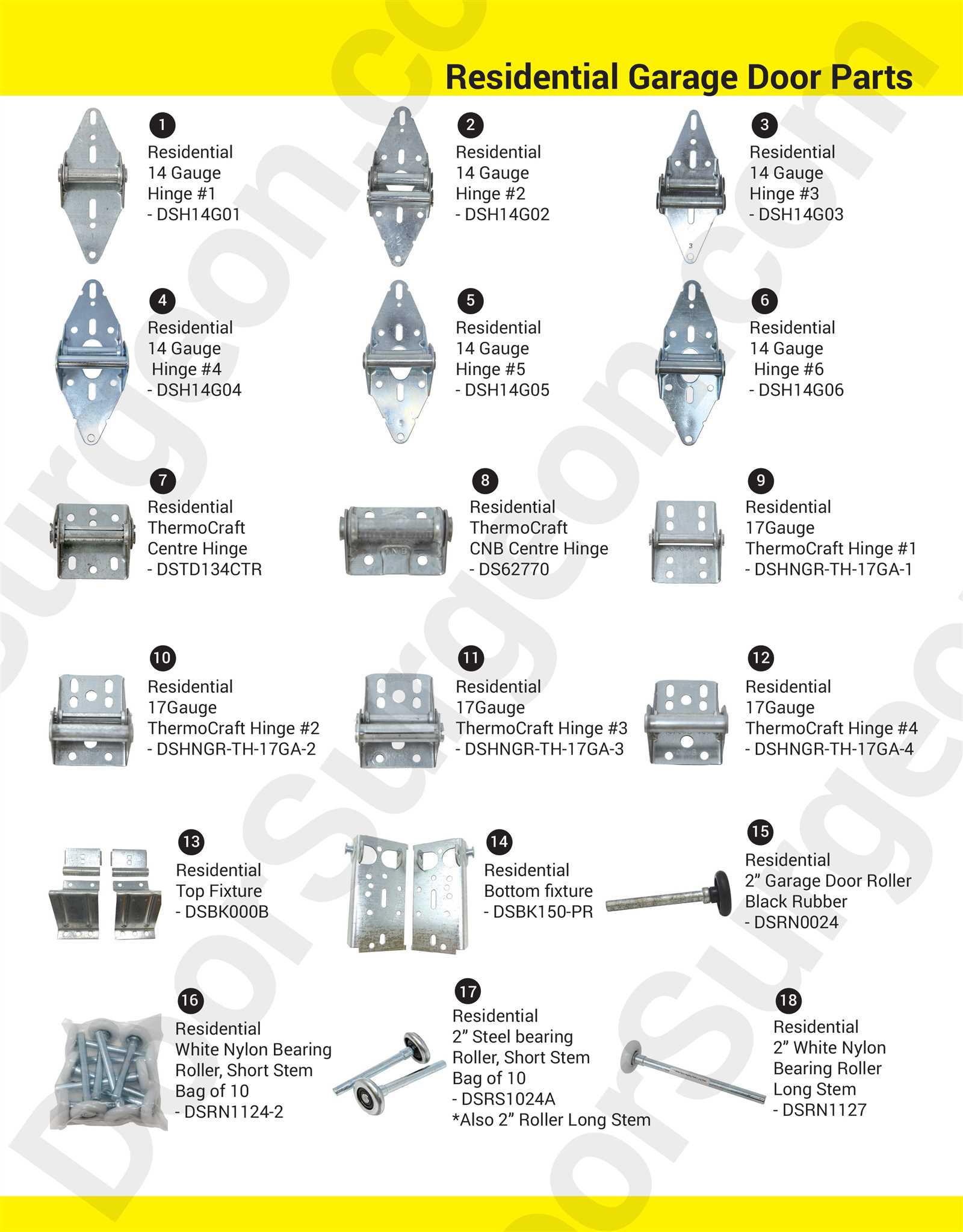

- Hinges: Allow for flexibility and movement, these components connect different sections of the entry.

- Safety Sensors: Crucial for preventing accidents, these devices detect obstructions and stop the entry from closing when necessary.

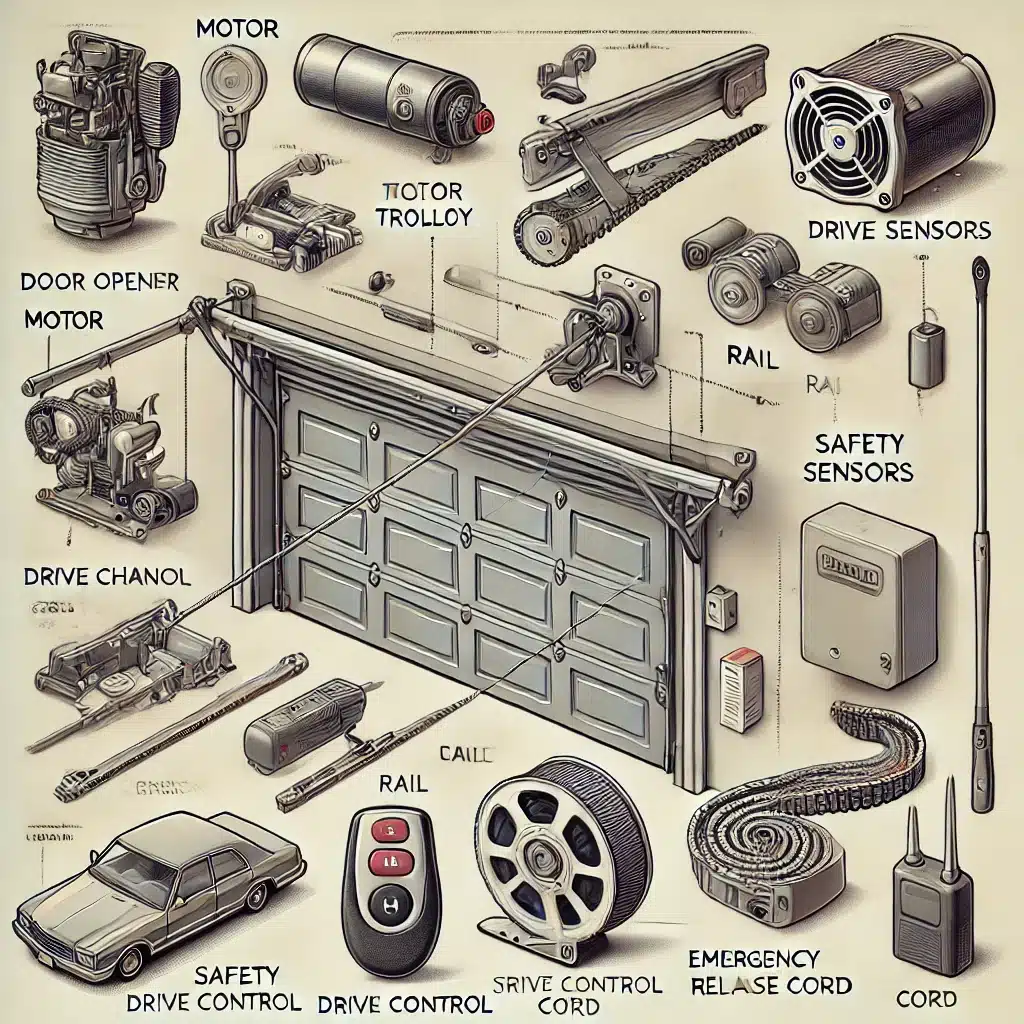

Functionality of Each Component Explained

Understanding the roles of various elements in a lifting system is essential for effective operation and maintenance. Each component plays a crucial part, ensuring seamless movement and safety, ultimately contributing to the system’s efficiency.

Support Mechanisms

Tracks guide the system’s movement, allowing for smooth transitions. Rollers facilitate this motion, reducing friction and wear. Together, they ensure stability and reliability during operation.

Control Elements

Motors provide the necessary power to initiate movement, while sensors enhance safety by detecting obstacles. This combination allows for both manual and automated control, adapting to user needs effectively.

Common Issues with Door Mechanisms

In the realm of entry systems, various challenges can arise, impacting functionality and reliability. These complications may stem from mechanical wear, environmental factors, or improper maintenance, often leading to inconvenience for users. Understanding these common obstacles is essential for effective troubleshooting and ensuring longevity.

One frequent issue involves misalignment, where components fail to fit together seamlessly. This can result in difficulty during operation and increased wear on moving parts. Regular inspections and adjustments can help mitigate this problem, ensuring smooth movement.

Another prevalent challenge is the accumulation of debris or grime, which can hinder performance. Regular cleaning is vital to prevent buildup that can obstruct mechanisms and lead to more serious malfunctions over time.

Additionally, springs and other tension-based components may experience fatigue, causing them to lose effectiveness. Recognizing the signs of wear early can prevent sudden failures and potential safety hazards.

Lastly, inadequate lubrication can contribute to increased friction, leading to premature wear and tear. Ensuring that all moving parts are properly lubricated is key to maintaining optimal performance and extending the lifespan of the entire system.

Maintenance Tips for Longevity

Ensuring the durability and functionality of your equipment requires regular upkeep and attention. Implementing simple maintenance practices can significantly extend the lifespan of your system and enhance its performance. Below are essential tips to help you maintain optimal condition.

Regular Inspections

- Check for wear and tear on all components.

- Inspect for signs of rust or corrosion.

- Ensure all moving parts are operating smoothly without obstruction.

Lubrication and Cleaning

- Apply lubricant to hinges, rollers, and tracks to minimize friction.

- Use a soft cloth to remove dirt and debris from surfaces.

- Regularly clean and inspect any seals for damage or degradation.

By adhering to these guidelines, you can significantly improve the efficiency and reliability of your system, ensuring it remains in excellent condition for years to come.

Choosing Quality Replacement Parts

When it comes to maintaining the functionality of your entryway system, selecting high-grade components is crucial. Quality replacements not only ensure longevity but also enhance the overall performance of the mechanism. This section explores essential factors to consider when making your choice.

Factors to Consider

Several key elements should guide your decision-making process. Firstly, compatibility with your existing framework is paramount; mismatched components can lead to inefficiencies and even safety hazards. Additionally, the material and construction quality play significant roles in durability. Finally, reviews and brand reputation should not be overlooked, as these can provide insights into the reliability of the items.

Comparison of Material Types

| Material Type | Durability | Cost |

|---|---|---|

| Steel | High | Moderate |

| Aluminum | Moderate | Variable |

| Plastic | Low | Low |

In summary, investing time in selecting quality replacements can save you from future headaches. Prioritize compatibility, material quality, and brand reputation to ensure the best outcomes for your setup.

Safety Features in Overhead Doors

Ensuring protection and reliability in automated systems is crucial for user safety. Various mechanisms and technologies are integrated to minimize risks associated with operation. Understanding these features helps users appreciate their significance in everyday use.

Common Safety Mechanisms

Several systems are commonly employed to enhance safety. These include sensors, emergency release systems, and robust construction materials.

| Feature | Description |

|---|---|

| Sensors | Detect obstacles and prevent closure if something is in the way. |

| Emergency Release | Allows manual operation in case of power failure. |

| Durable Materials | Enhances structural integrity and withstands impacts. |

Importance of Regular Maintenance

Routine checks and servicing are essential to ensure all safety features function correctly. This proactive approach significantly reduces the likelihood of accidents and extends the lifespan of the system.

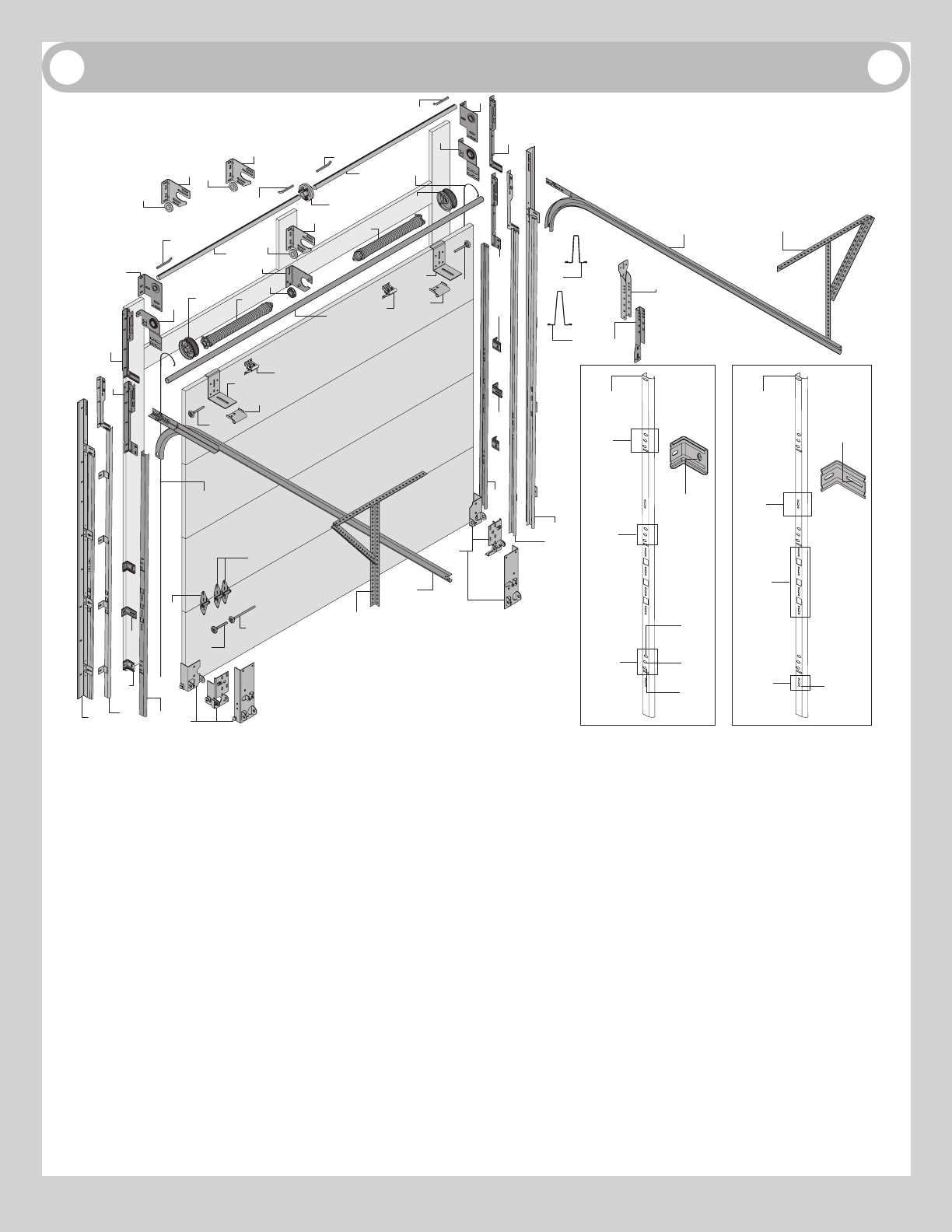

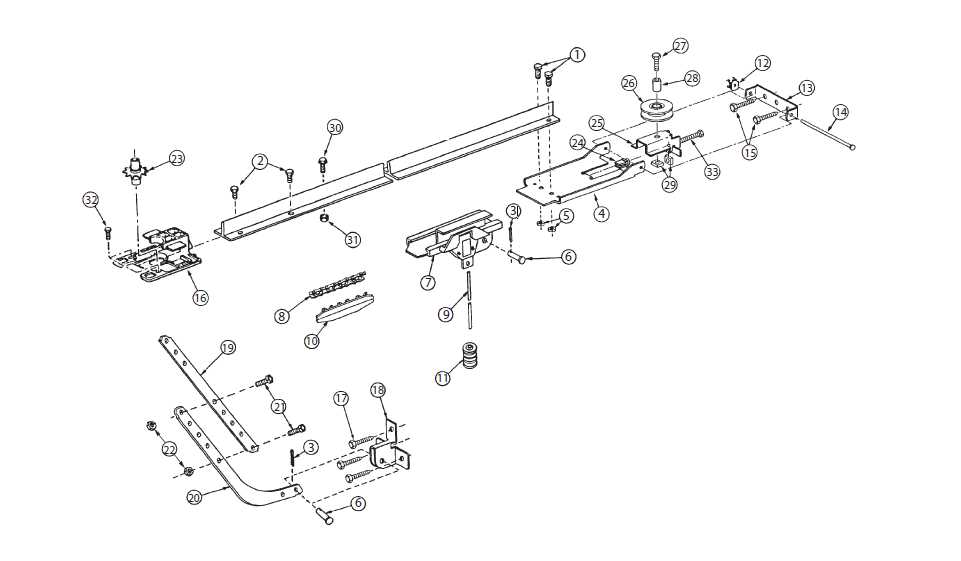

Installation Process Overview

This section provides a comprehensive outline of the steps involved in the setup of an automated entry system. A clear understanding of the procedure is crucial for achieving optimal functionality and safety. Proper preparation and adherence to guidelines can significantly enhance the efficiency of the installation.

Preparation and Tools

Before beginning, ensure you have all necessary tools and components at hand. Familiarize yourself with the equipment and review the manufacturer’s instructions thoroughly. This preparatory phase is essential for a seamless installation.

Step-by-Step Assembly

Follow a systematic approach during the assembly. Begin by securing the frame, then proceed to attach the mechanisms. Pay close attention to alignment and connections, as these factors are vital for the ultimate performance. Regularly check your progress against the guidelines to ensure everything is in order.

Upgrading to Smart Garage Systems

Enhancing your garage with intelligent technology can transform convenience and security. By integrating advanced features, users can remotely manage and monitor their space, ensuring peace of mind while optimizing functionality. These modern systems offer a seamless experience that adapts to various lifestyles and needs.

Smart technologies often include sensors, cameras, and mobile applications, allowing homeowners to receive real-time alerts and control access from anywhere. This connectivity not only enhances safety but also provides insights into usage patterns, enabling smarter decisions regarding energy consumption and maintenance.

Implementing these innovative solutions can increase the value of your property while simplifying daily routines. Whether it’s automating opening mechanisms or integrating with home security networks, the transition to a smart setup represents the ultimate advancement in modern home management.