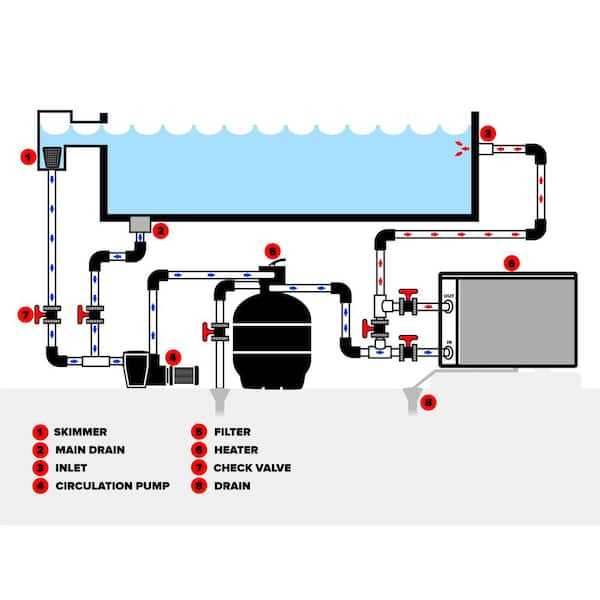

The maintenance and efficiency of swimming facilities rely heavily on the functionality of their key components. A comprehensive overview of these essential elements can greatly enhance the longevity and performance of the system. By delving into the intricate details of each part, users can ensure optimal operation and address any issues that may arise.

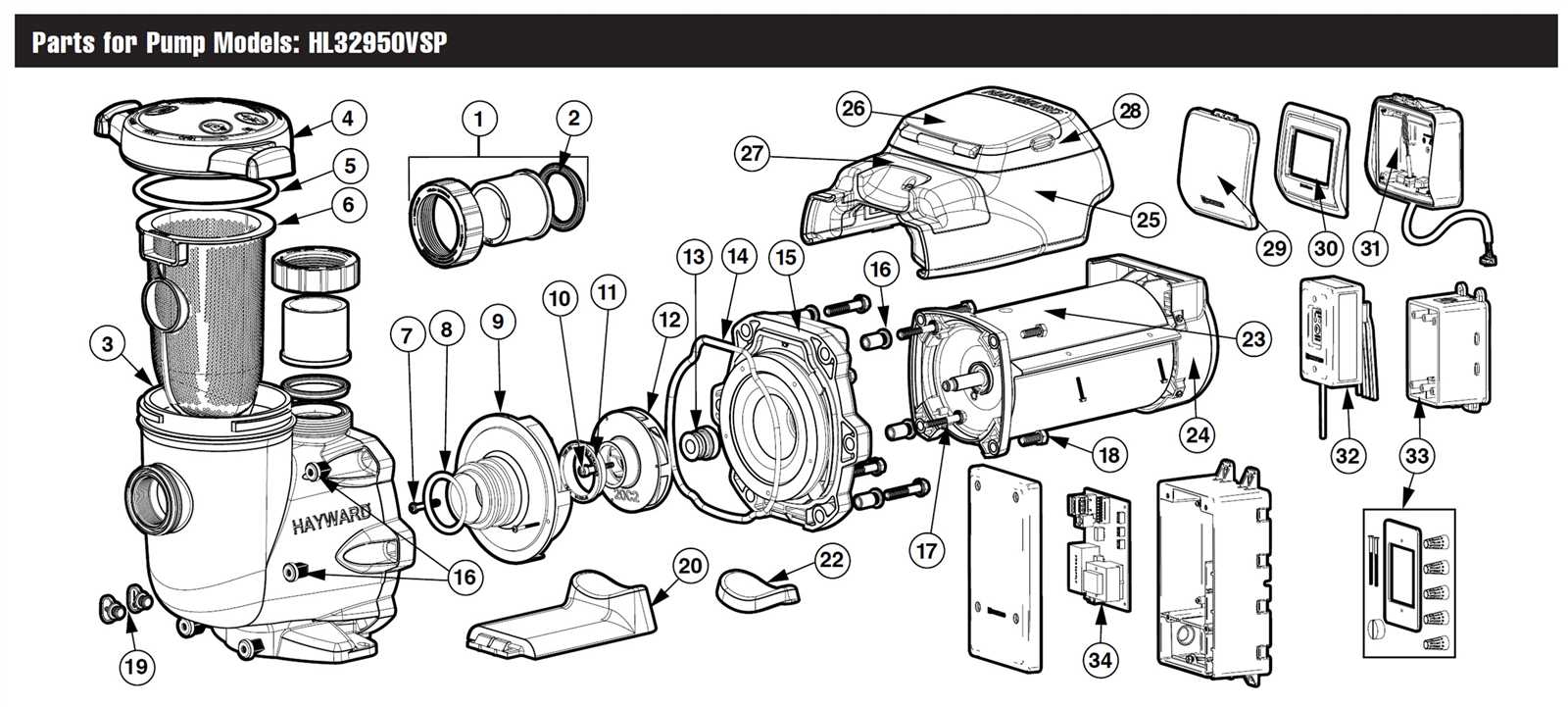

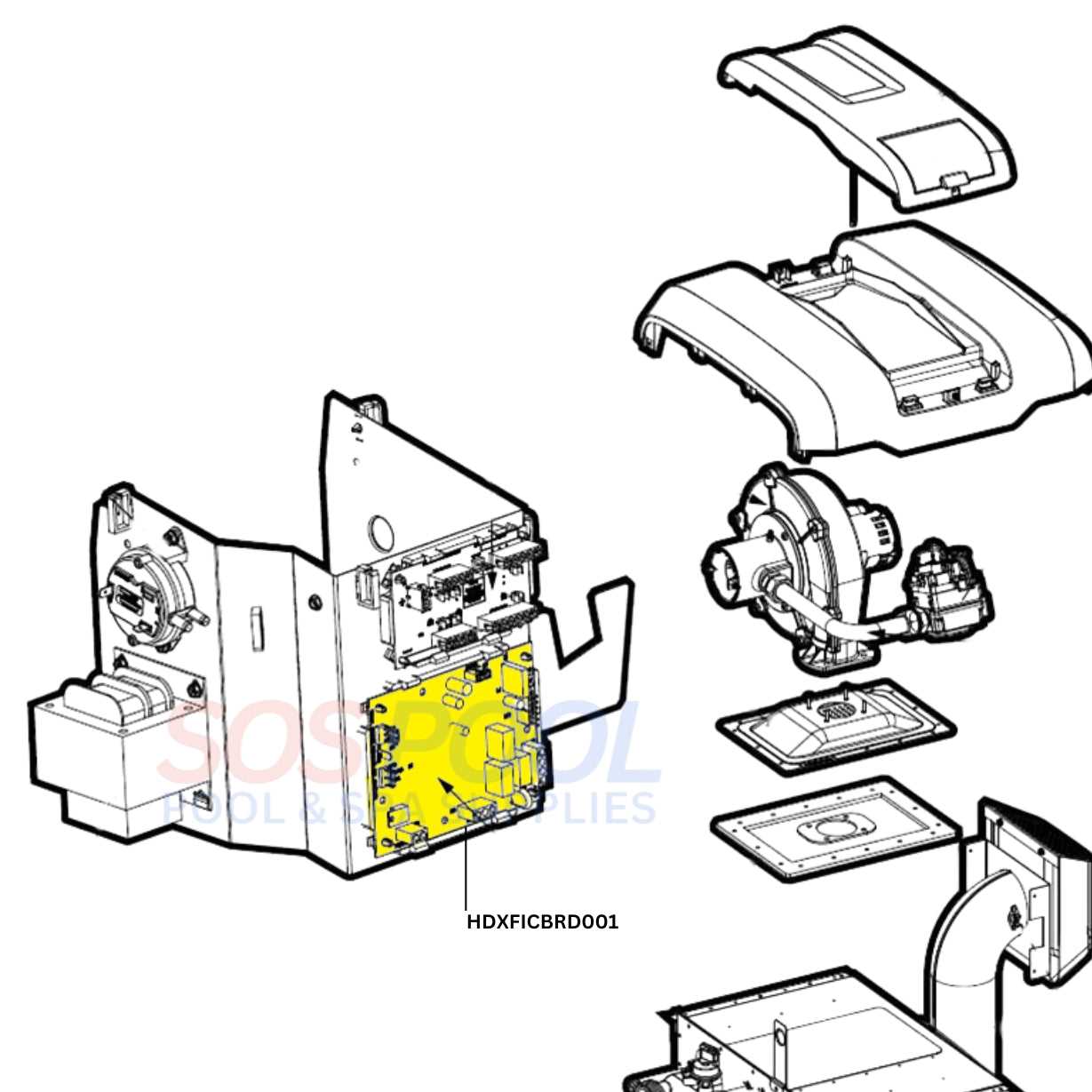

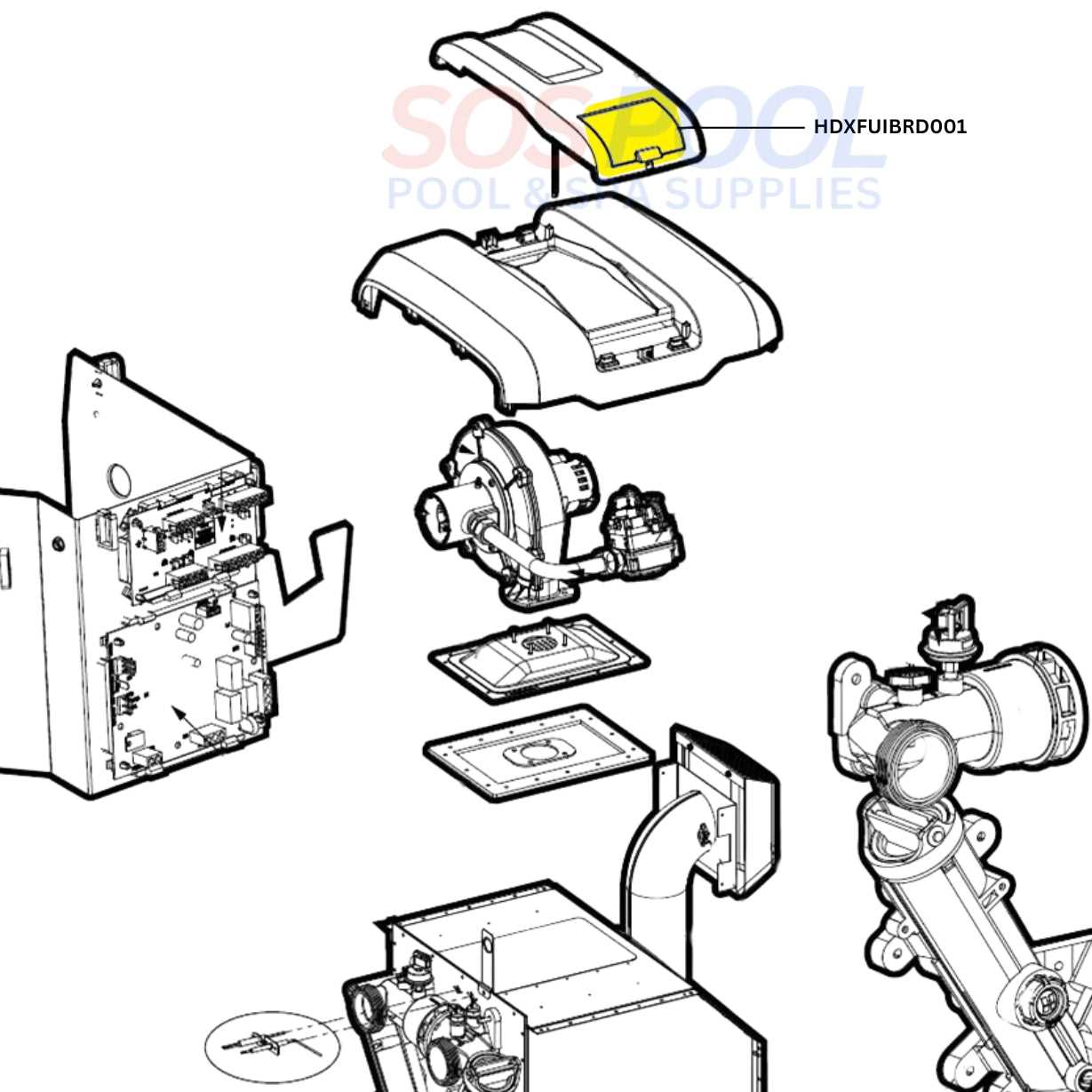

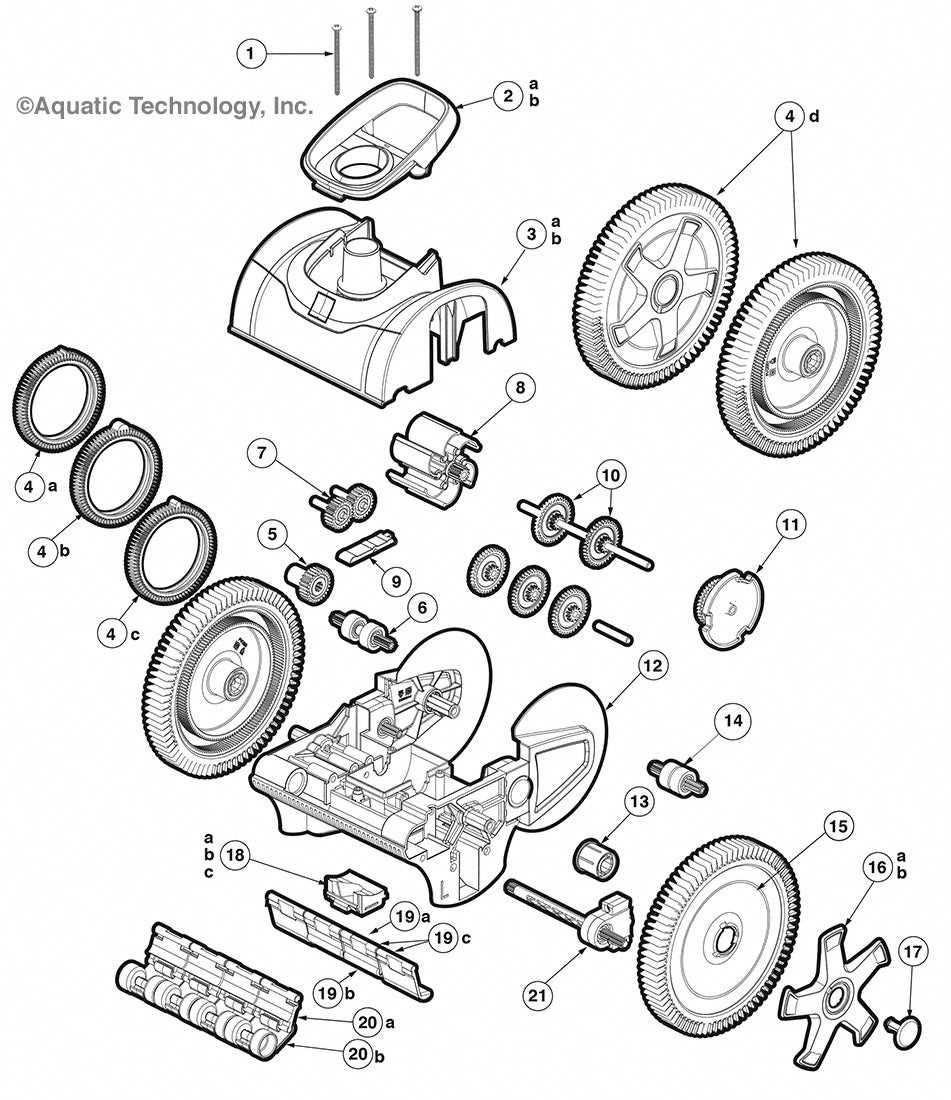

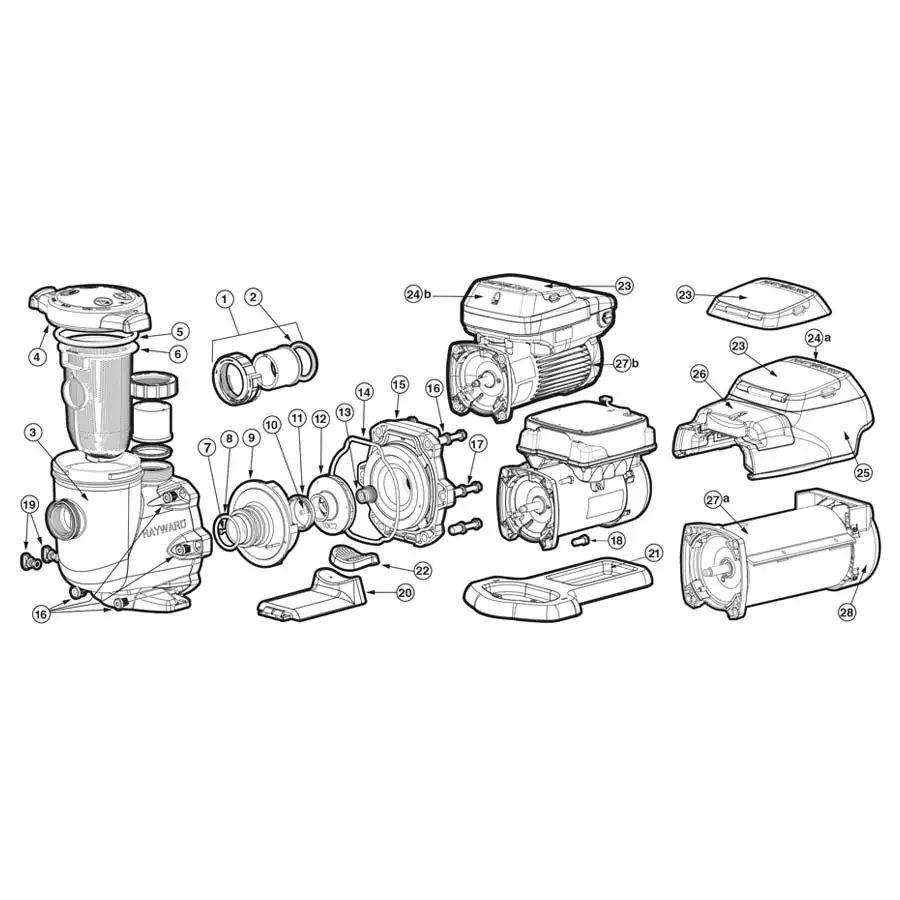

In this section, we will explore a detailed illustration of the various elements that comprise a specific type of water circulation apparatus. This visual representation serves as a valuable reference, providing insights into the arrangement and interconnectivity of the components. Understanding these relationships can aid in troubleshooting and routine maintenance.

Moreover, having a clear understanding of these intricacies not only empowers users to perform necessary repairs but also fosters a deeper appreciation for the engineering behind such devices. A well-informed approach can lead to more efficient use and better management of aquatic environments.

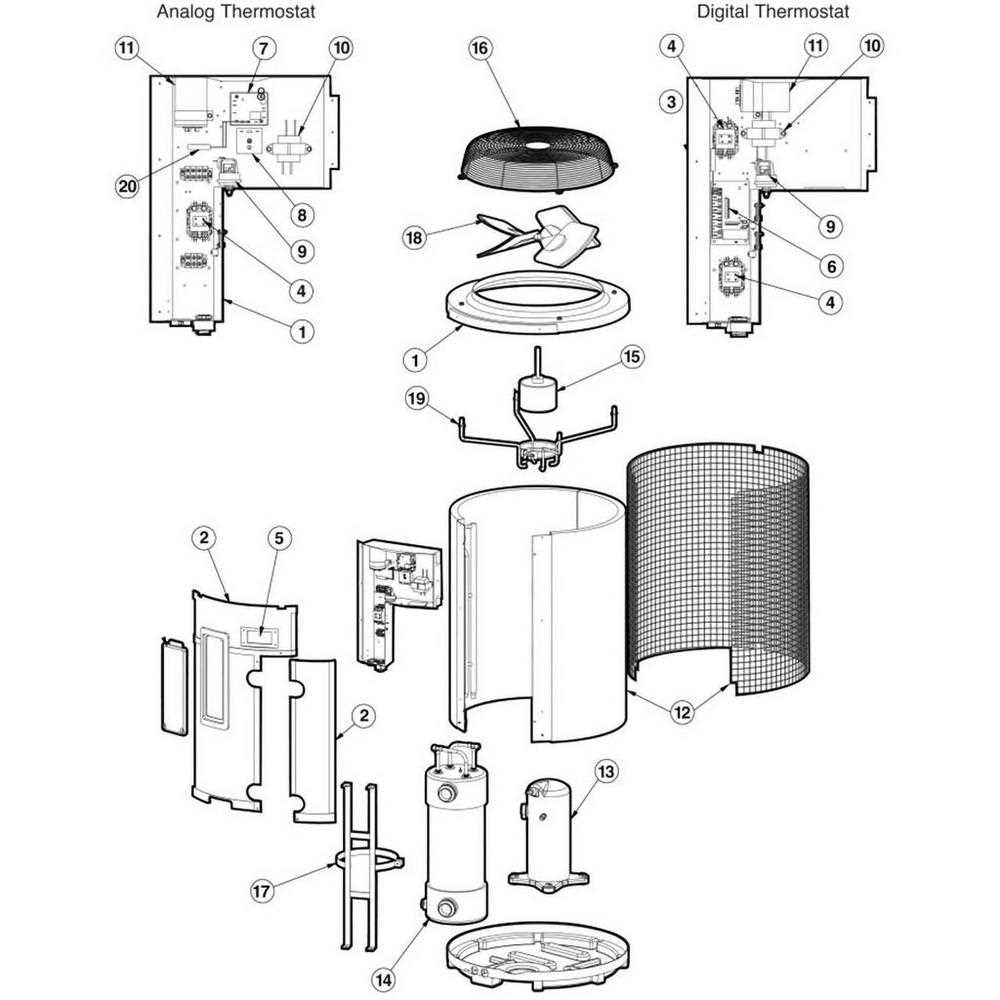

Understanding Hayward HDF400 Components

Grasping the intricate elements of a pool heating system is essential for effective maintenance and optimal performance. Each component plays a vital role in the overall functionality, ensuring that the water remains at a comfortable temperature while maximizing energy efficiency.

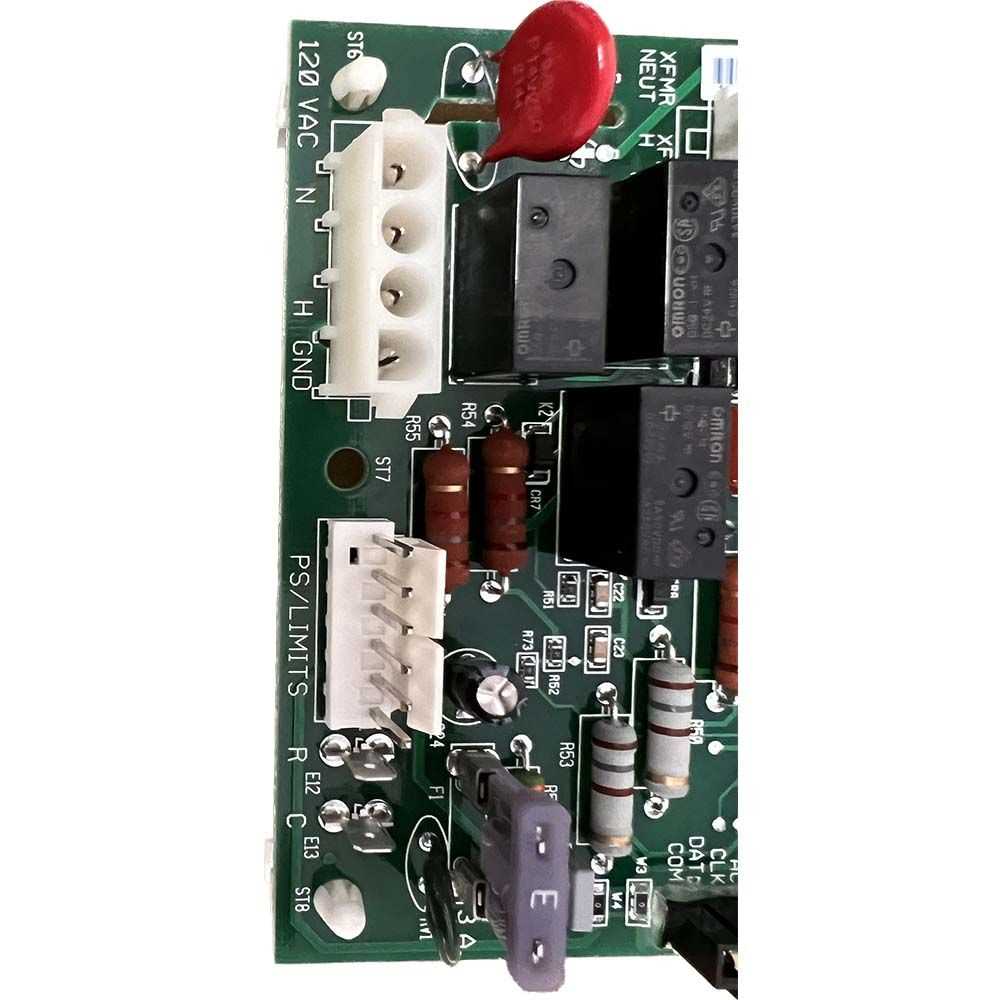

Key components of a typical heating unit include:

- Heating Element: Responsible for raising the water temperature through electrical or gas energy.

- Control Panel: The user interface that allows for temperature adjustments and operational settings.

- Thermostat: Monitors the water temperature and regulates the heating element accordingly.

- Water Flow Sensor: Ensures that the system operates only when there is adequate water flow, preventing potential damage.

- Heat Exchanger: Transfers heat from the heating element to the water efficiently.

- Safety Features: Includes pressure relief valves and temperature sensors to protect against overheating and excess pressure.

Understanding these elements helps in troubleshooting issues and making informed decisions about repairs or upgrades. Regular maintenance can extend the lifespan of the system, ensuring uninterrupted enjoyment of a warm pool.

Importance of Accurate Parts Diagrams

Precision in technical illustrations is crucial for effective maintenance and repair. When users have access to detailed visual representations, they can quickly identify components and understand their functions within a system. This clarity not only streamlines the troubleshooting process but also minimizes the risk of errors during assembly or replacement tasks.

Enhanced Understanding: Detailed visuals provide a comprehensive overview of each element, allowing users to grasp the relationships and interdependencies between different components. This understanding is essential for anyone looking to perform repairs or upgrades efficiently.

Time Efficiency: Access to well-structured illustrations saves time. Instead of guessing which part needs attention, individuals can directly refer to accurate representations. This expedites repairs and reduces downtime, ultimately improving overall productivity.

Improved Safety: Clear and precise visuals help prevent mishandling of components. By clearly outlining each part, users are less likely to make mistakes that could lead to safety hazards or damage to the equipment.

Cost-Effectiveness: Investing in high-quality technical illustrations can lead to significant savings. Reducing the likelihood of errors means fewer costly mistakes, less wasted time, and ultimately lower maintenance expenses.

In conclusion, accurate technical illustrations play a vital role in ensuring efficient operation and maintenance. They not only foster a deeper understanding but also enhance safety, save time, and reduce costs.

Common Issues with HDF400 Parts

When dealing with pool equipment components, several frequent challenges can arise that affect performance and longevity. Understanding these issues can help users maintain their systems effectively and avoid costly repairs.

1. Wear and Tear: Over time, components may experience degradation due to exposure to chemicals, sunlight, and water. This natural process can lead to decreased efficiency and functionality.

2. Leaks: A common problem is the development of leaks at various connection points. These leaks can stem from improper sealing, worn gaskets, or damaged fittings, leading to reduced water circulation and potential damage.

3. Clogging: Debris and buildup can obstruct flow pathways, resulting in decreased performance. Regular cleaning and maintenance are crucial to preventing this issue.

4. Corrosion: Exposure to chlorinated water can cause certain materials to corrode, impacting both appearance and structural integrity. Choosing corrosion-resistant options can mitigate this problem.

5. Malfunctioning Sensors: Electronic components can sometimes fail, leading to incorrect readings or operational issues. Regular checks and prompt replacements can ensure reliability.

By being aware of these common complications, users can take proactive measures to ensure the smooth operation of their equipment, ultimately enhancing the overall swimming experience.

Step-by-Step Parts Replacement Guide

Maintaining the efficiency of your equipment often involves the timely replacement of worn components. This guide will provide a clear process to assist you in identifying and substituting essential elements effectively. By following these steps, you can ensure optimal performance and extend the lifespan of your system.

Identifying the Necessary Components

The first step is to assess the condition of your current components. Look for signs of wear, leaks, or inefficiency. Refer to your user manual or technical documentation for a comprehensive list of elements that may require attention. It’s crucial to note the specific part numbers and specifications to ensure accurate replacements.

Replacement Process

Once you’ve identified the components needing replacement, gather the required tools and new items. Start by turning off the power supply to avoid any hazards. Carefully remove the damaged components, taking care to note how they are connected. Install the new items by following the reverse order of removal. Ensure all connections are secure and double-check that everything is properly aligned before restoring power.

By adhering to this systematic approach, you will facilitate a smooth replacement process, ensuring your equipment runs efficiently and reliably.

Where to Find HDF400 Diagrams

Locating comprehensive visual guides for specific equipment components can significantly enhance your understanding of maintenance and repair tasks. These resources are crucial for both seasoned professionals and enthusiasts looking to ensure optimal performance. Fortunately, there are various avenues available to access detailed illustrations that can aid in the identification and replacement of individual elements.

Online Resources

The internet is a treasure trove of information. Websites dedicated to pool equipment often provide downloadable manuals and schematics. Engaging with forums or communities focused on pool maintenance can also yield valuable links and shared experiences from other users. These platforms can often guide you directly to the materials you need.

Manufacturer Support

Reaching out to the manufacturer directly can be an effective strategy. Many companies offer customer service that includes access to technical documents upon request. Additionally, official websites frequently host a section for documentation that includes necessary illustrations for their products. Utilizing these resources ensures that you receive accurate and reliable information.

Whether you’re troubleshooting issues or planning upgrades, having access to these visual aids is essential for efficient management and repair tasks.

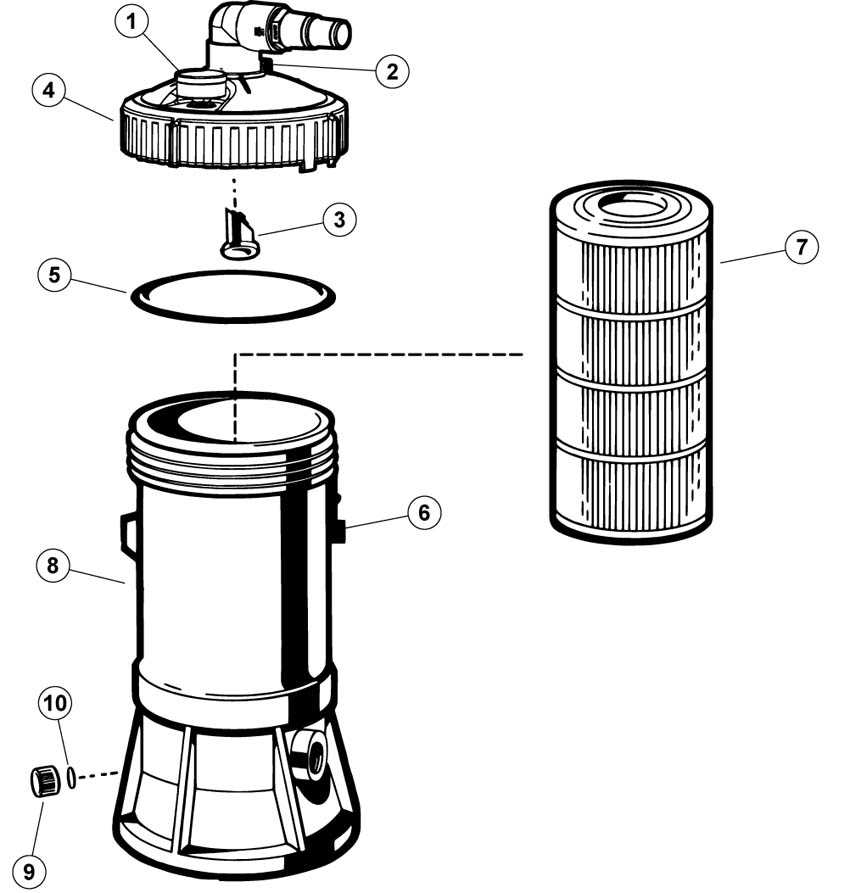

Essential Tools for Maintenance Tasks

Effective upkeep of equipment requires a selection of key instruments that ensure both efficiency and precision. Whether performing routine checks or addressing specific issues, having the right tools on hand can significantly streamline the process and enhance overall performance.

Firstly, a comprehensive toolkit should include wrenches, screwdrivers, and pliers, which serve as the foundation for various mechanical tasks. These basic tools allow for adjustments and repairs, making them indispensable for any maintenance routine.

In addition, measuring devices such as calipers and rulers are crucial for ensuring accurate alignment and fit, which can prevent further complications down the line. For tasks requiring a deeper examination, diagnostic tools like multimeters or pressure gauges can provide valuable insights into the operational status of the system.

Moreover, specialized instruments, including lubricators and cleaning brushes, are essential for maintaining optimal performance and extending the lifespan of components. Keeping these tools organized and easily accessible will facilitate quicker responses to any maintenance needs that arise.

Comparing HDF400 with Other Models

When evaluating the effectiveness of various filtration systems, it is essential to consider the distinctions and similarities among different models. Each design has its own unique features that cater to specific needs, making it crucial for users to understand what sets one unit apart from another. This comparison helps in making an informed choice, ensuring optimal performance and efficiency for any aquatic environment.

Performance and Efficiency

In terms of performance, some systems excel in flow rate and energy consumption, which directly impacts their operational costs. Certain models utilize advanced technology to enhance filtration, while others may focus on ease of maintenance. Users should weigh these factors against their own requirements, such as pool size and usage frequency, to determine which system provides the best balance of efficiency and effectiveness.

Features and Usability

Features such as automated controls, programmable settings, and user-friendly interfaces vary significantly across different systems. Some options offer advanced monitoring capabilities, allowing for real-time assessments of water quality. In contrast, others prioritize straightforward functionality, appealing to users who prefer simplicity. Evaluating these aspects can greatly influence user satisfaction and overall experience.

Frequently Asked Questions About HDF400

This section addresses common inquiries regarding a popular filtration model, providing clarity and insights for users. Below are frequently posed questions that can help in understanding its features, maintenance, and functionality.

-

What is the typical lifespan of this filtration system?

The longevity of the unit largely depends on usage and maintenance. Regular cleaning and timely replacement of worn components can significantly extend its service life.

-

How often should I replace the internal components?

It is advisable to inspect and replace internal elements at least once a year, or more frequently if the system is used heavily.

-

Are there specific maintenance tips for optimal performance?

- Regularly check for clogs and clean the filtration elements.

- Monitor the pressure gauge to ensure it operates within the recommended range.

- Inspect seals and connections for wear or leaks.

-

Can I perform repairs myself, or should I hire a professional?

Many users find simple repairs manageable with the right tools and instructions. However, for complex issues, consulting a professional is recommended to avoid further damage.

-

Where can I find replacement components?

Replacement items can typically be sourced from authorized dealers, online retailers, or directly from the manufacturer’s website.

Tips for Long-lasting Equipment Performance

Maintaining optimal performance of your machinery is crucial for extending its lifespan and ensuring efficient operation. By following a few essential practices, you can minimize wear and tear, reduce downtime, and enhance overall functionality.

- Regular Maintenance: Schedule routine inspections and servicing to identify and address potential issues before they escalate.

- Proper Cleaning: Keep your equipment clean from debris and buildup, as this can hinder performance and lead to damage.

- Quality Lubrication: Use the appropriate lubricants as recommended by the manufacturer to reduce friction and prevent overheating.

- Environmental Considerations: Protect your machinery from extreme weather conditions, which can cause premature degradation.

- Training and Usage: Ensure that operators are well-trained and aware of best practices for using the equipment effectively.

Implementing these strategies will help you maintain the integrity of your machinery, ultimately leading to improved performance and longevity.