When delving into the intricacies of mechanical systems, a clear understanding of the various elements involved is essential. Each component plays a pivotal role, contributing to the overall functionality and efficiency of the system. By examining these elements closely, users can gain valuable insights into how they interact and work together.

Visual representations serve as powerful tools for comprehending the arrangement and relationship between different parts. They not only simplify complex information but also enhance one’s ability to troubleshoot and maintain the equipment effectively. Familiarizing oneself with these layouts can lead to more informed decisions regarding repairs and upgrades.

Ultimately, having a solid grasp of the individual components and their placements is vital for anyone looking to optimize performance or conduct thorough assessments. This knowledge empowers users to make precise adjustments and improvements, ensuring the longevity and reliability of the machinery in question.

This section provides an overview of the essential components that contribute to the overall functionality of the system. Each element plays a crucial role in ensuring seamless operation and optimal performance, making it vital to understand their purposes and interactions.

Component Overview

Understanding the primary components helps in grasping how they collectively enhance the efficiency and reliability of the entire mechanism. Each part is designed with specific functions in mind, working in harmony to facilitate smooth operation.

Functionality Table

| Component | Description |

|---|---|

| Power Unit | Supplies energy necessary for operation. |

| Control System | Regulates various functions and settings. |

| Transmission Mechanism | Ensures efficient power transfer between parts. |

| Safety Features | Protects the system from potential hazards. |

Identifying Essential Replacement Parts

Understanding the fundamental components required for maintenance is crucial for ensuring the longevity and efficiency of your equipment. Recognizing the key elements that may need to be replaced allows users to keep their devices in optimal working condition.

Several vital components often require attention. Here is a list of common replacements:

- Air filter: Essential for maintaining airflow and engine performance.

- Fuel filter: Keeps impurities from entering the fuel system.

- Spark plug: Critical for ignition and engine start-up.

- Blade: Important for effective cutting performance.

- Belt: Transfers power between components, ensuring smooth operation.

Regular inspection of these elements can prevent unexpected breakdowns and enhance overall functionality. Keeping a stock of these essential replacements ensures that maintenance can be performed promptly, minimizing downtime.

Common Issues and Their Solutions

When dealing with machinery, it is common to encounter various challenges that can affect performance and efficiency. Understanding these frequent problems and knowing how to address them can significantly enhance operational reliability. Below are some prevalent issues faced and their corresponding solutions.

1. Difficulty Starting: One of the most typical complaints is the difficulty in starting the equipment. This may result from a weak battery, stale fuel, or faulty ignition components. To resolve this issue, check the battery’s charge and connections, ensure fresh fuel is used, and inspect the ignition system for any defects.

2. Overheating: Overheating can lead to severe damage and operational downtime. This issue may arise from insufficient coolant, clogged air filters, or malfunctioning fans. Regularly monitor coolant levels, clean or replace air filters, and ensure that cooling fans are functioning correctly to prevent overheating.

3. Uneven Performance: If the equipment exhibits inconsistent performance, it might indicate fuel delivery issues or problems with the air intake system. Check for any blockages in the fuel lines and ensure that air filters are clean. Addressing these factors can help maintain smooth operation.

4. Unusual Noises: Strange sounds during operation often signal underlying issues. These may stem from loose components, worn bearings, or damaged belts. Conduct a thorough inspection to tighten any loose parts, replace worn components, and ensure proper alignment to mitigate noise problems.

By proactively addressing these common challenges, users can ensure more efficient operation and extend the lifespan of their machinery.

Maintenance Tips for Optimal Performance

Ensuring the longevity and efficiency of your equipment requires regular upkeep and attention to detail. Adopting effective maintenance practices can prevent potential issues and enhance the overall functionality of your machinery. Below are essential suggestions for maintaining optimal performance.

| Tip | Description |

|---|---|

| Regular Inspection | Conduct frequent checks to identify wear and tear, ensuring all components function smoothly. |

| Cleanliness | Keep the machinery free from debris and dirt, which can hinder performance and lead to malfunctions. |

| Lubrication | Apply the appropriate lubricants to moving parts to reduce friction and prevent overheating. |

| Parts Replacement | Replace worn or damaged components promptly to avoid further complications and maintain efficiency. |

| Follow Guidelines | Adhere to the manufacturer’s recommendations for maintenance schedules and procedures for optimal results. |

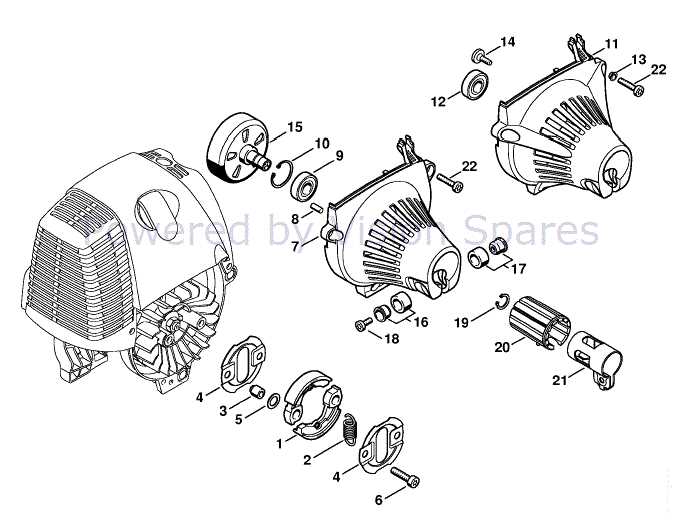

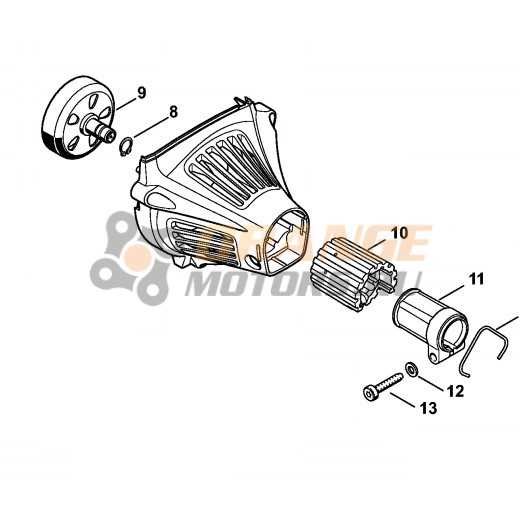

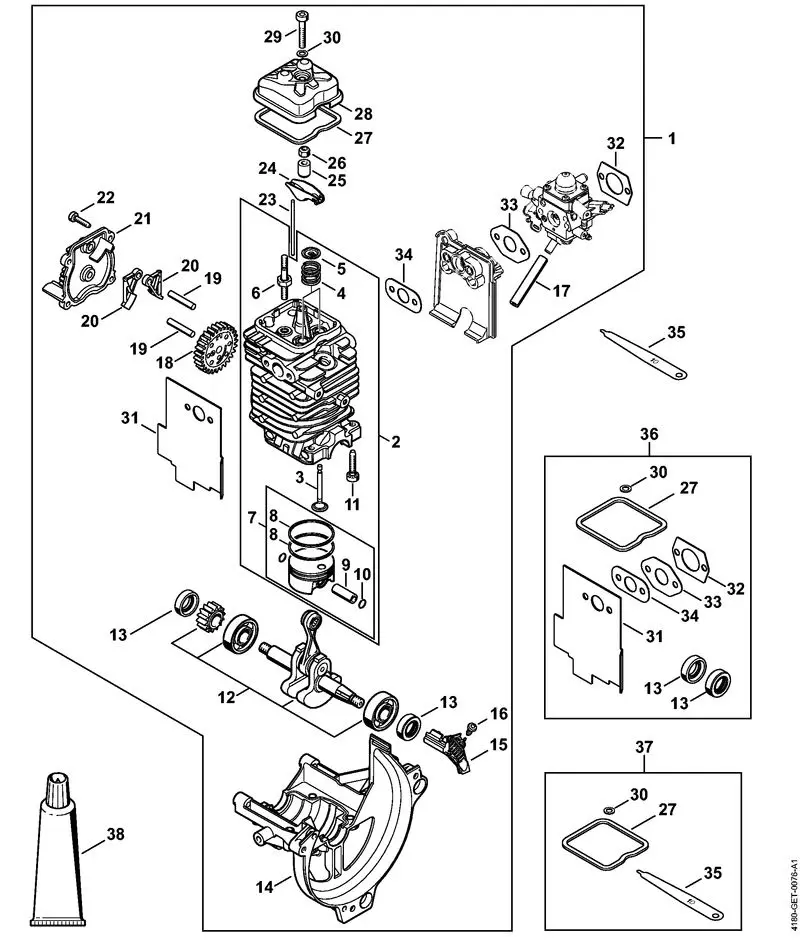

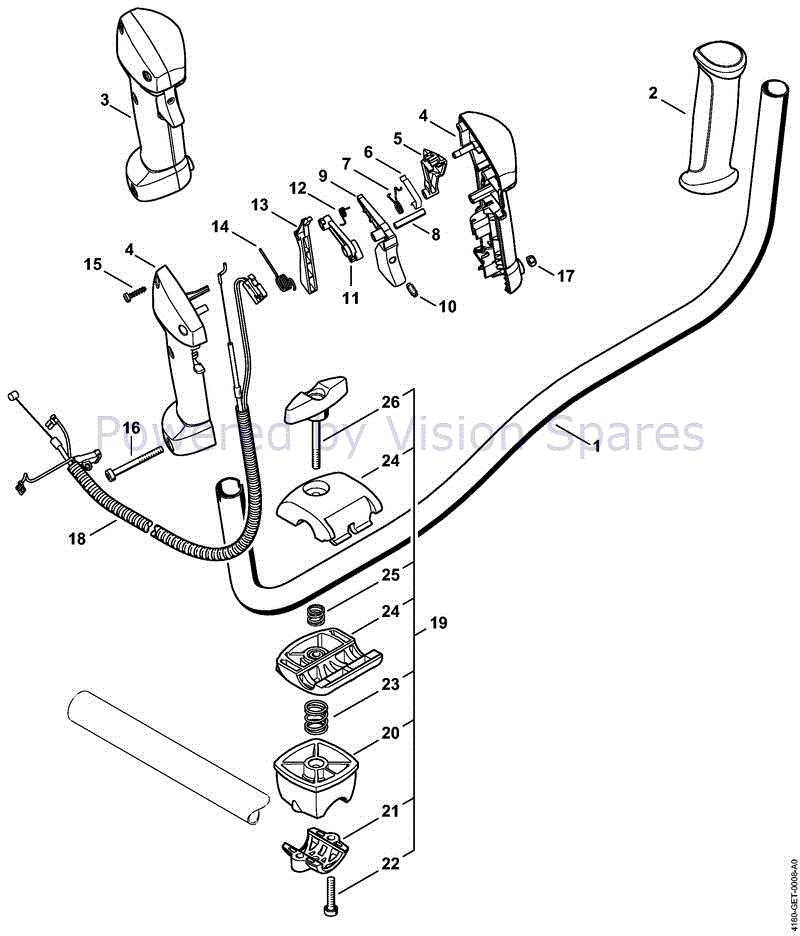

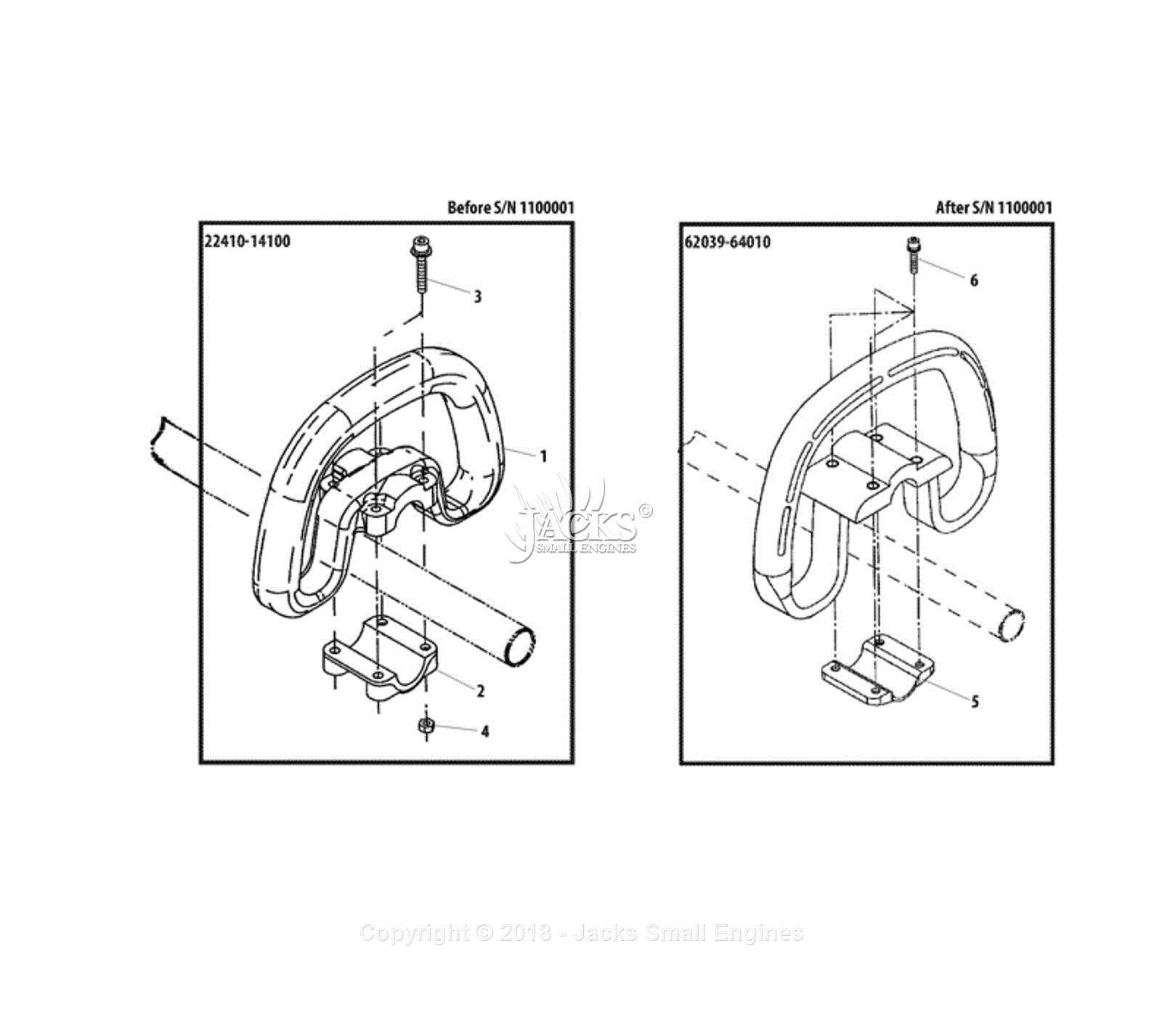

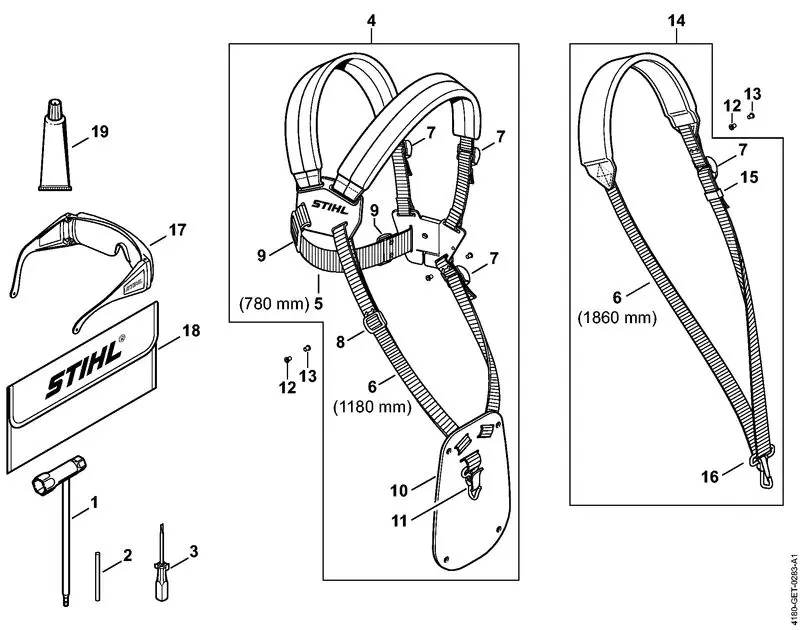

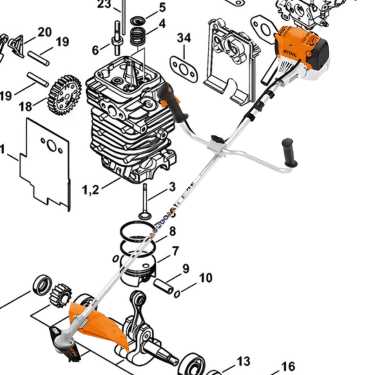

Diagram Interpretation and Usage

Understanding the visual representations of mechanical components is essential for effective maintenance and repair tasks. These illustrations provide insights into the arrangement and relationships of various elements, facilitating a clearer understanding of how each part contributes to the overall functionality. This knowledge enables users to identify, troubleshoot, and replace elements as needed.

When utilizing these illustrations, it is important to recognize the symbols and notations that represent different components. Each representation serves as a guide, indicating how parts fit together and interact within the larger system. A well-organized visual representation can simplify complex assemblies and enhance the efficiency of maintenance procedures.

| Symbol | Description |

|---|---|

| Fastener | |

| Tool Required | |

| ⚙️ | Rotating Component |

| ⚡ | Electrical Part |

By familiarizing oneself with these representations, users can enhance their capability to execute repairs efficiently and accurately. Engaging with these visual tools not only improves comprehension but also ensures that maintenance activities are conducted with precision and care.

Benefits of Accurate Parts Identification

Precise identification of components is essential in various fields, significantly enhancing efficiency and productivity. It ensures that the correct elements are used during assembly, repair, or maintenance, thereby minimizing errors and reducing operational delays.

Accurate recognition of elements fosters effective communication among team members, as everyone refers to the same specifications. This clarity is crucial in preventing misunderstandings and streamlining workflows, which ultimately leads to improved outcomes.

Moreover, proper identification can significantly impact cost management. By selecting the right components, organizations can avoid unnecessary expenditures on replacements or repairs, contributing to better financial efficiency. Additionally, it aids in inventory management, ensuring that resources are effectively utilized and reducing waste.

In summary, the advantages of precise component identification are manifold, ranging from enhanced operational efficiency to improved cost management, making it a vital practice in any technical endeavor.