When it comes to keeping your outdoor space pristine, having a thorough understanding of your gardening equipment is essential. This section aims to provide insights into the various elements that contribute to the functionality of these vital machines. By grasping how each part operates, you can enhance their efficiency and prolong their lifespan.

Maintenance of your tools not only ensures optimal performance but also saves you time and effort in the long run. Knowing the intricate details of each component allows for easier troubleshooting and repairs. This knowledge empowers users to tackle issues head-on and make informed decisions regarding replacements.

Whether you are a professional landscaper or a weekend warrior, delving into the specifics of these devices will ultimately elevate your gardening experience. With the right information, you can achieve that perfectly manicured look that every homeowner desires.

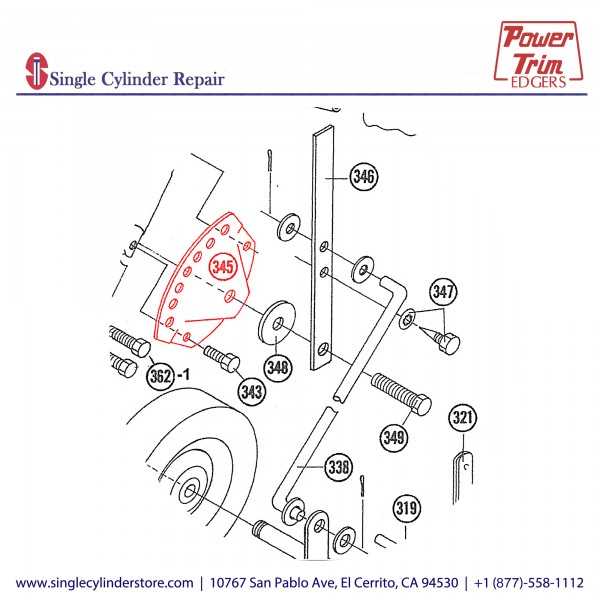

Understanding Power-Trim Edger Components

This section aims to explore the essential elements of a trimming tool, highlighting their significance in ensuring efficient operation. By comprehending each component, users can enhance their maintenance practices and improve overall performance.

Engine: The heart of the machine, the engine provides the necessary power to drive the cutting mechanism. Its efficiency directly impacts the tool’s functionality.

Cutting Head: This part houses the blades or strings responsible for executing precise cuts. Understanding its design can lead to better selection and replacement choices.

Handle: A critical interface between the user and the equipment, the handle should offer comfort and control, influencing the overall trimming experience.

Guard: This protective feature shields users from debris and hazards during operation. Its design and placement are crucial for safety.

Fuel System: Comprising the tank and delivery lines, this system ensures the engine receives the right mixture for optimal performance. Regular checks can prevent malfunctions.

By delving into these components, operators can gain insights into their tool’s functionality, leading to informed decisions regarding usage and upkeep.

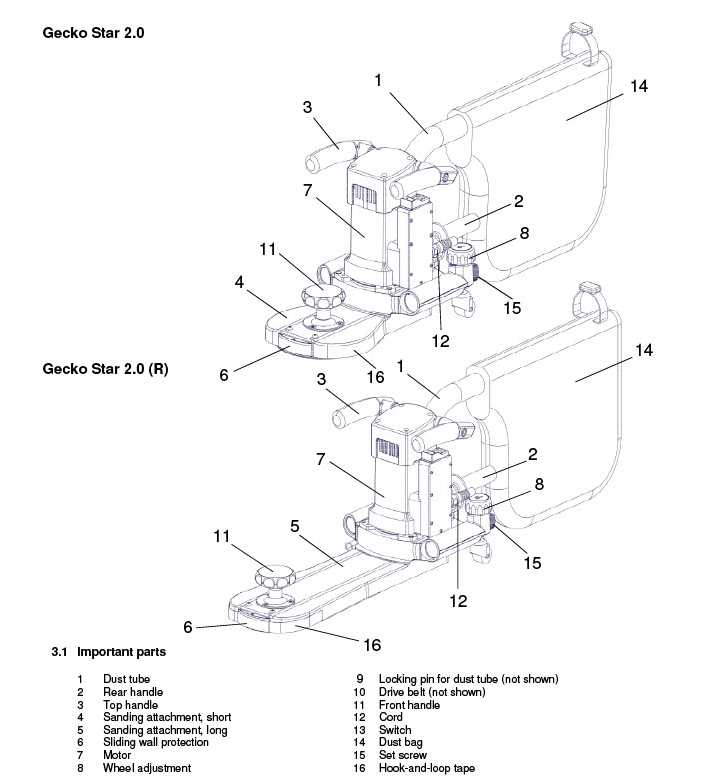

Key Features of Power-Trim Edgers

When it comes to maintaining a pristine landscape, certain tools stand out for their efficiency and effectiveness. These devices are designed to deliver precision in cutting and trimming, ensuring that edges are neat and well-defined. Understanding the essential attributes of these machines can help users make informed decisions and enhance their gardening experience.

Durability and Performance

Robust construction is a hallmark of high-quality trimming tools. Made from resilient materials, these devices can withstand the rigors of regular use while maintaining peak performance. Their powerful motors ensure that users can tackle thick grass and stubborn weeds with ease, making yard work less of a chore and more of a pleasure.

Ease of Use and Versatility

Many modern models come equipped with user-friendly features that enhance convenience. Adjustable handles and lightweight designs allow for comfortable maneuvering, reducing fatigue during extended use. Furthermore, the versatility of these tools enables users to tackle various tasks, from edging flower beds to creating sharp lines along pathways, showcasing their multifunctional capabilities.

Benefits of Regular Maintenance

- Enhanced Performance: Regular checks and servicing can significantly improve the efficiency of your equipment.

- Cost Savings: Investing time in maintenance can reduce repair costs by addressing minor issues before they escalate.

- Extended Lifespan: Consistent care helps prolong the life of your machinery, maximizing your investment.

- Safety: Regular inspections ensure that all components function properly, reducing the risk of accidents and injuries.

- Optimal Results: Well-maintained equipment operates more effectively, providing better results in various tasks.

Incorporating a routine maintenance schedule fosters reliability and efficiency, allowing users to achieve their goals with confidence.

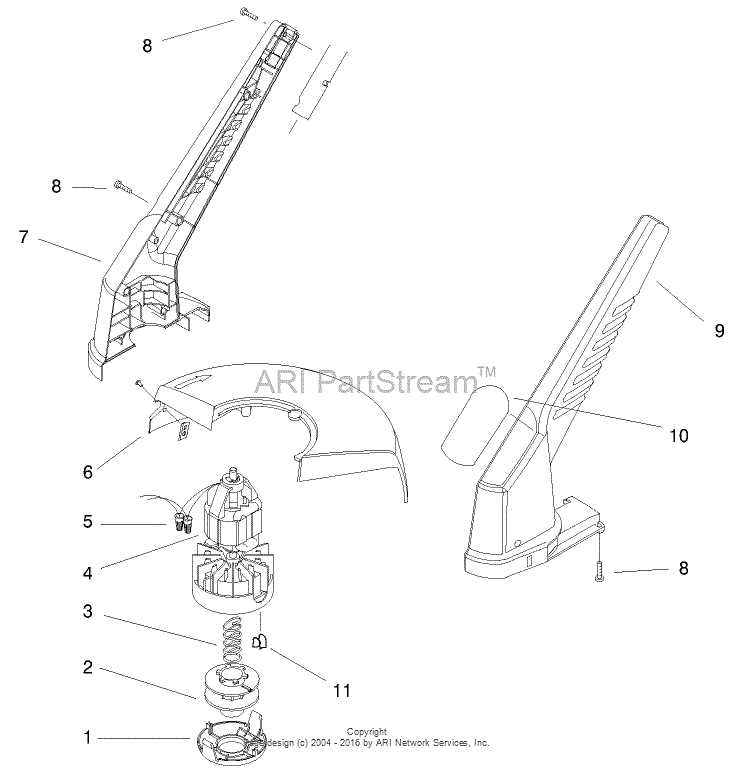

Identifying Common Wear Parts

Regular maintenance of outdoor equipment is essential to ensure optimal performance and longevity. Understanding the components that experience wear over time is crucial for effective upkeep. By recognizing these elements, users can proactively replace them, preventing potential issues that may arise from neglect.

One of the most frequently affected items is the cutting blade, which can become dull or damaged through extended use. Additionally, the spool or line used for trimming often requires replacement, as it can fray or break under stress. Another vital element is the guard, which may suffer from wear and tear, impacting both safety and functionality.

Finally, examining the motor’s air filter is essential, as a clogged filter can hinder performance. Regularly assessing these common components can help maintain efficiency and extend the life of the equipment.

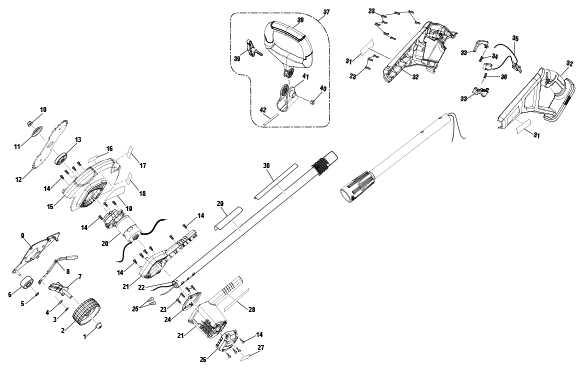

How to Read Parts Diagrams

Understanding mechanical layouts is crucial for anyone who needs to assemble, repair, or maintain equipment. These visual guides provide a comprehensive view of the components, showing how various elements fit together. By studying these illustrations carefully, you can identify each element’s function and relation to the whole system.

Identifying Key Components

The first step in reading any technical illustration is to recognize the main elements. Typically, each item will be labeled with a unique identifier or number. These labels help you find the specific item in the accompanying list or instructions, ensuring you know exactly which part you’re dealing with.

Interpreting Connections and Relationships

Once you’ve identified the components, the next step is to focus on their connections. Pay attention to lines, arrows, and other markers that show how different pieces interact with each other. This will help you understand the sequence of assembly and ensure proper alignment during reassembly or repair.

Tools Needed for Edger Repairs

When working on the maintenance or repair of outdoor equipment, having the right set of tools is crucial for smooth and efficient work. Proper tools not only make the process easier but also help ensure that the equipment is restored to optimal functionality. Below is a breakdown of essential tools that are commonly needed for these types of repairs.

Basic Hand Tools

- Screwdrivers: Both flathead and Phillips screwdrivers are essential for removing and reattaching various components.

- Wrenches: Adjustable and combination wrenches are often necessary to loosen or tighten bolts and nuts during disassembly or reassembly.

- Pliers: Needle-nose pliers help with handling small parts and providing a better grip for delicate tasks.

Specialized Tools

- Socket set: A comprehensive socket set is useful for

Replacing Worn-Out Edger Parts

Over time, various components of lawn tools may experience wear and tear due to regular use. Regular maintenance is key to ensuring optimal performance and preventing more serious issues. By replacing old or damaged elements, you can extend the life of your tool and keep it functioning as efficiently as possible.

Identifying Signs of Wear

Before any replacements, it’s important to inspect your equipment for common signs of deterioration. Look for symptoms like uneven cutting, reduced power, or strange noises. If you notice any of these indicators, it may be time to switch out specific parts to restore full functionality.

Steps for Replacement

When swapping out components, always follow manufacturer instructions for safe handling and assembly. Make sure to use compatible replacements to avoid damage. Properly maintained and replaced elements ensure smooth operation, keeping your tool ready for action during peak season.

Troubleshooting Common Edger Issues

Maintaining outdoor equipment requires understanding potential malfunctions and knowing how to address them effectively. Various issues can arise during regular use, ranging from performance drops to mechanical failures. Recognizing these problems early can prevent more serious damage and keep your device operating smoothly.

Engine Fails to Start

One frequent problem is a failure of the engine to start. This could be due to old fuel, clogged filters, or a worn spark plug. Checking and replacing these components regularly ensures smoother functionality. Ensuring proper fuel levels and cleaning the air filter can often resolve this issue quickly.

Uneven Cutting Performance

If the cutting mechanism leaves an uneven finish, it might be related to dull blades or incorrect height settings. Sharpening the blade and adjusting the cutting height can improve precision. Additionally, make sure that debris or grass clippings are not obstructing the moving parts.

Choosing Quality Replacement Parts

When it comes to maintaining outdoor equipment, selecting the right components for replacement is crucial to ensure optimal performance and longevity. High-quality substitutes not only fit better but also reduce the risk of premature wear and tear. Investing in durable and reliable alternatives can prevent future breakdowns and keep your machinery running smoothly for a longer period.

One of the key factors in choosing reliable replacements is to consider the materials used in manufacturing. Components made from strong, weather-resistant materials are more likely to withstand harsh conditions, providing a longer service life. Additionally, compatibility with your machine’s specific model is essential to ensure efficient operation.

Lastly, always ensure that the chosen item comes from reputable suppliers who have a proven track record of delivering quality. Reviews and recommendations from other users can also be a helpful resource in determining the reliability of the product. In the end, selecting the right part is an investment in the future performance of your equipment.