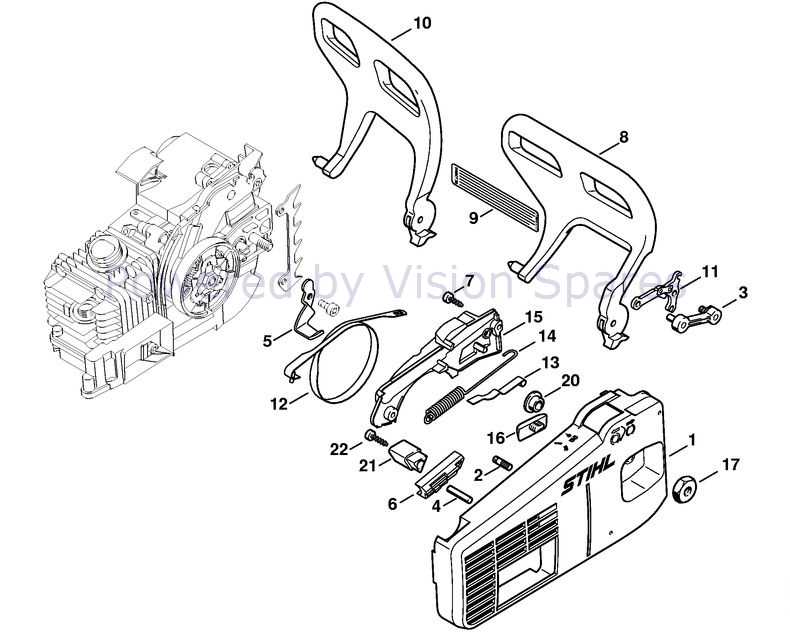

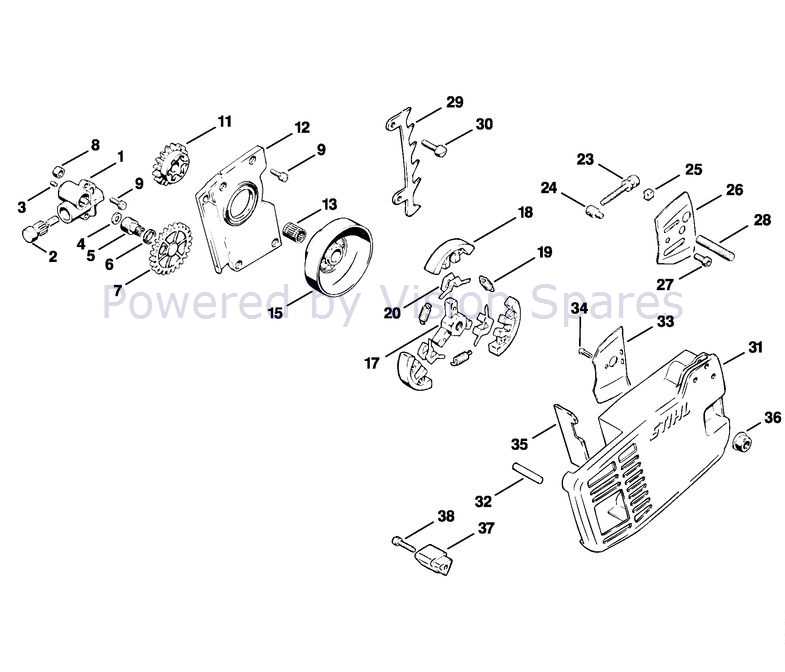

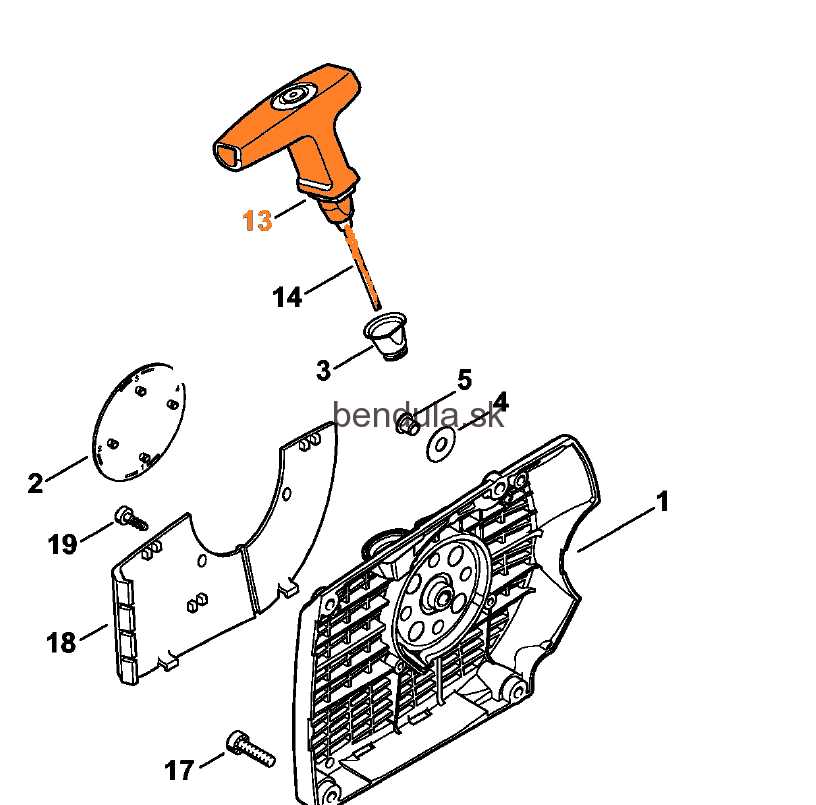

In the world of outdoor power equipment, maintenance and repair are crucial for ensuring longevity and optimal performance. Familiarity with the various elements that make up a specific model can greatly enhance the efficiency of troubleshooting and parts replacement. This section delves into the intricate relationships between these components, providing valuable insights for enthusiasts and professionals alike.

Each piece plays a significant role in the overall functionality of the machine. From the engine to the cutting mechanism, understanding how these parts interact can help users make informed decisions when it comes to repairs or upgrades. By visualizing the assembly and organization of these elements, one can easily identify potential issues and streamline the maintenance process.

Whether you are a seasoned technician or a novice user, having access to a detailed representation of the components can be invaluable. It not only aids in identifying specific issues but also fosters a deeper appreciation for the craftsmanship involved in the design of these powerful tools. With the right information at your fingertips, maintaining peak performance becomes a manageable task.

Understanding Stihl 020av Components

Exploring the intricacies of power tools requires a keen understanding of their individual elements and how they work together to ensure optimal performance. Each component plays a crucial role in the functionality and reliability of the equipment. Grasping the relationships among these parts can significantly enhance maintenance practices and troubleshooting efforts.

Key Elements and Their Functions

- Engine: The heart of the machine, responsible for generating power.

- Fuel System: Supplies the necessary fuel mixture for efficient operation.

- Ignition System: Initiates combustion, ensuring the engine starts and runs smoothly.

- Bar and Chain: The cutting components, designed for precision and durability.

- Air Filter: Maintains air quality entering the engine, crucial for performance.

- Clutch: Engages and disengages the power transfer to the cutting assembly.

Maintenance Tips for Longevity

- Regularly inspect and clean the air filter to ensure proper airflow.

- Check fuel lines for leaks and replace any worn components.

- Monitor the condition of the cutting chain, sharpening or replacing as needed.

- Keep the ignition system in good condition to prevent starting issues.

- Lubricate moving parts regularly to reduce wear and tear.

Understanding the various elements that contribute to the overall functionality of this equipment can lead to better care and extended lifespan. By paying attention to each part, users can ensure reliable performance and efficiency in their tasks.

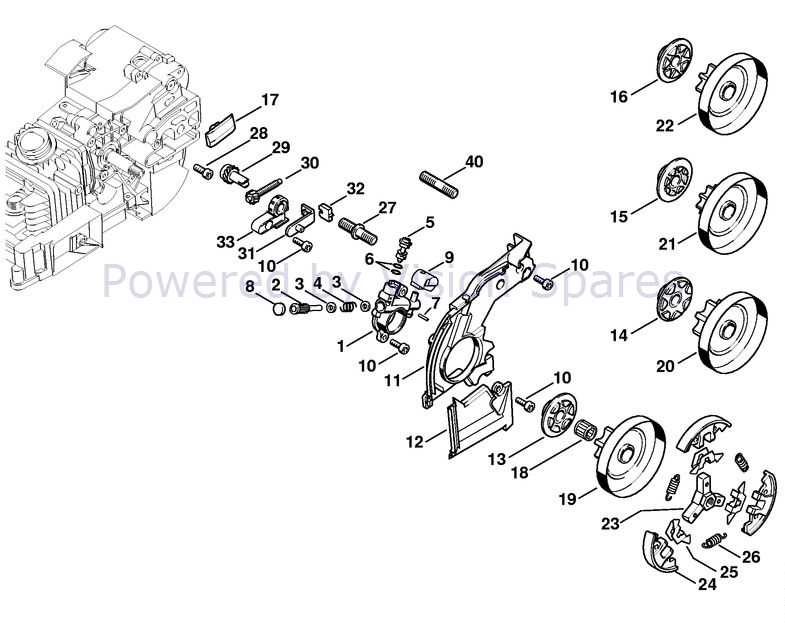

Importance of Parts Diagrams

Understanding the intricacies of machinery is crucial for efficient maintenance and repair. Visual representations play a significant role in simplifying complex assemblies, enabling users to identify components swiftly and accurately.

- Enhances comprehension of mechanical structures.

- Facilitates quick identification of individual elements.

- Aids in troubleshooting issues effectively.

- Supports proper reassembly after servicing.

Moreover, these visual guides contribute to the ultimate goal of minimizing downtime and maximizing operational efficiency, making them an essential tool for both novice and experienced technicians.

Key Features of Stihl 020av Model

This model is recognized for its innovative design and exceptional performance, catering to both professional and amateur users. It combines efficiency with user-friendly features, making it a preferred choice in the field of outdoor power equipment. Its robust construction ensures durability while providing the necessary power for various tasks.

Power and Performance

The engine delivers impressive torque, allowing for smooth operation even under demanding conditions. This power translates into high cutting speeds, making it ideal for both light trimming and heavier-duty applications.

Ergonomics and Usability

The design emphasizes user comfort, featuring a lightweight structure that minimizes fatigue during extended use. Additional elements such as vibration dampening and an easily adjustable throttle contribute to a seamless user experience.

| Feature | Description |

|---|---|

| Engine Type | High-performance two-stroke engine |

| Weight | Lightweight for easy maneuverability |

| Vibration Control | Reduces operator fatigue |

| Fuel Efficiency | Optimized for extended runtime |

| Maintenance | Easy access for quick servicing |

How to Access Parts Diagrams

Finding visual representations of components can greatly enhance your understanding of machinery maintenance and repair. These illustrations serve as valuable resources for identifying individual elements and their arrangement within the equipment. Accessing these resources is straightforward if you know where to look.

Here are several effective methods to obtain these illustrations:

- Manufacturer’s Website: Most companies provide downloadable resources directly on their official sites. Navigate to the support or resources section for comprehensive access.

- Authorized Dealers: Contacting local distributors can yield printed materials or direct you to online resources specific to your equipment.

- Online Forums and Communities: Engaging with enthusiasts and experts in relevant online groups can often lead to shared diagrams and helpful insights.

- Repair Manuals: Purchasing or downloading service manuals often includes detailed illustrations that assist with repairs and part identification.

Utilizing these avenues can simplify the process of finding the necessary visual aids, ensuring you have the correct information for your maintenance tasks.

Common Issues with Stihl 020av

Users often encounter several typical challenges with this particular model. Understanding these common problems can significantly enhance the maintenance and longevity of the equipment. Proper diagnosis is essential for effective resolution and optimal performance.

Engine Performance Problems

One prevalent issue relates to engine performance, such as difficulty starting or inconsistent power output. These symptoms can stem from fuel system blockages, air filter obstructions, or spark plug malfunctions. Regular checks and replacements can mitigate these concerns.

Mechanical Failures

Mechanical failures may also occur, including chain and bar issues. Wear and tear on components can lead to inefficient cutting and increased operational strain. Regular inspection and timely replacement of worn parts can help maintain efficiency and prevent further damage.

Replacing Worn-Out Parts

Maintaining the efficiency and longevity of your equipment often requires the replacement of components that have become worn or damaged over time. Identifying these deteriorated elements is crucial for optimal performance and safety. Regular inspection can help ensure that your machinery operates smoothly and effectively.

When addressing worn components, it’s essential to source high-quality replacements that meet or exceed the original specifications. This guarantees compatibility and reliability, helping to avoid further issues down the line. Before beginning the replacement process, familiarize yourself with the specific parts and tools needed for the job.

Following a systematic approach will make the replacement process more efficient. Start by carefully removing the affected component, ensuring that you don’t damage surrounding areas. Once removed, clean the installation site to prepare for the new part. Afterward, securely install the replacement and conduct a thorough check to confirm proper functionality.

By routinely replacing worn elements, you can extend the lifespan of your machinery, enhance its performance, and maintain safety standards. Regular maintenance not only saves time and money in the long run but also promotes a more enjoyable experience when using your equipment.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your equipment requires consistent care and attention. By following a few essential practices, you can enhance performance and minimize the risk of breakdowns.

| Tip | Description |

|---|---|

| Regular Cleaning | Remove debris and dirt after each use to prevent buildup and corrosion. |

| Proper Lubrication | Use the right lubricant to keep moving parts functioning smoothly and reduce friction. |

| Check Filters | Inspect and replace air and fuel filters regularly to ensure optimal airflow and fuel delivery. |

| Tighten Bolts | Periodically check and tighten loose bolts and screws to maintain structural integrity. |

| Store Correctly | Keep equipment in a dry, safe place to avoid damage from environmental factors. |

Where to Find Genuine Parts

Finding authentic components for your equipment is crucial for maintaining its performance and longevity. Ensuring that you use high-quality replacements can prevent issues and enhance the overall functionality of your tools. Here are some reliable sources to help you locate the right items for your machine.

Authorized Dealers

One of the best places to start your search is through authorized dealers. These establishments typically carry a comprehensive selection of original components and can offer expert advice on compatibility and installation. Visiting a dealer not only guarantees authenticity but also provides access to the latest updates and innovations.

Online Retailers

The internet has made it easier than ever to find genuine components. Reputable online retailers specialize in high-quality replacements, often with user reviews that can help guide your choices. When shopping online, ensure that the seller has a solid reputation and offers a return policy to safeguard your purchase.

Remember, investing in authentic components is essential for ensuring that your equipment operates efficiently and safely. Always do your research and choose trusted sources to maintain the integrity of your tools.