Maintaining a pristine outdoor space often hinges on the effective operation of specialized machinery. These advanced devices are designed to enhance the efficiency of landscaping tasks, making them indispensable for both homeowners and professionals. A comprehensive grasp of their components is essential for optimal performance and longevity.

In this section, we delve into the intricate assembly of these machines, exploring their various elements and how they interact. By familiarizing oneself with these components, users can ensure smooth functionality and quickly address any issues that may arise. Knowledge of each segment empowers operators to make informed decisions regarding maintenance and repairs.

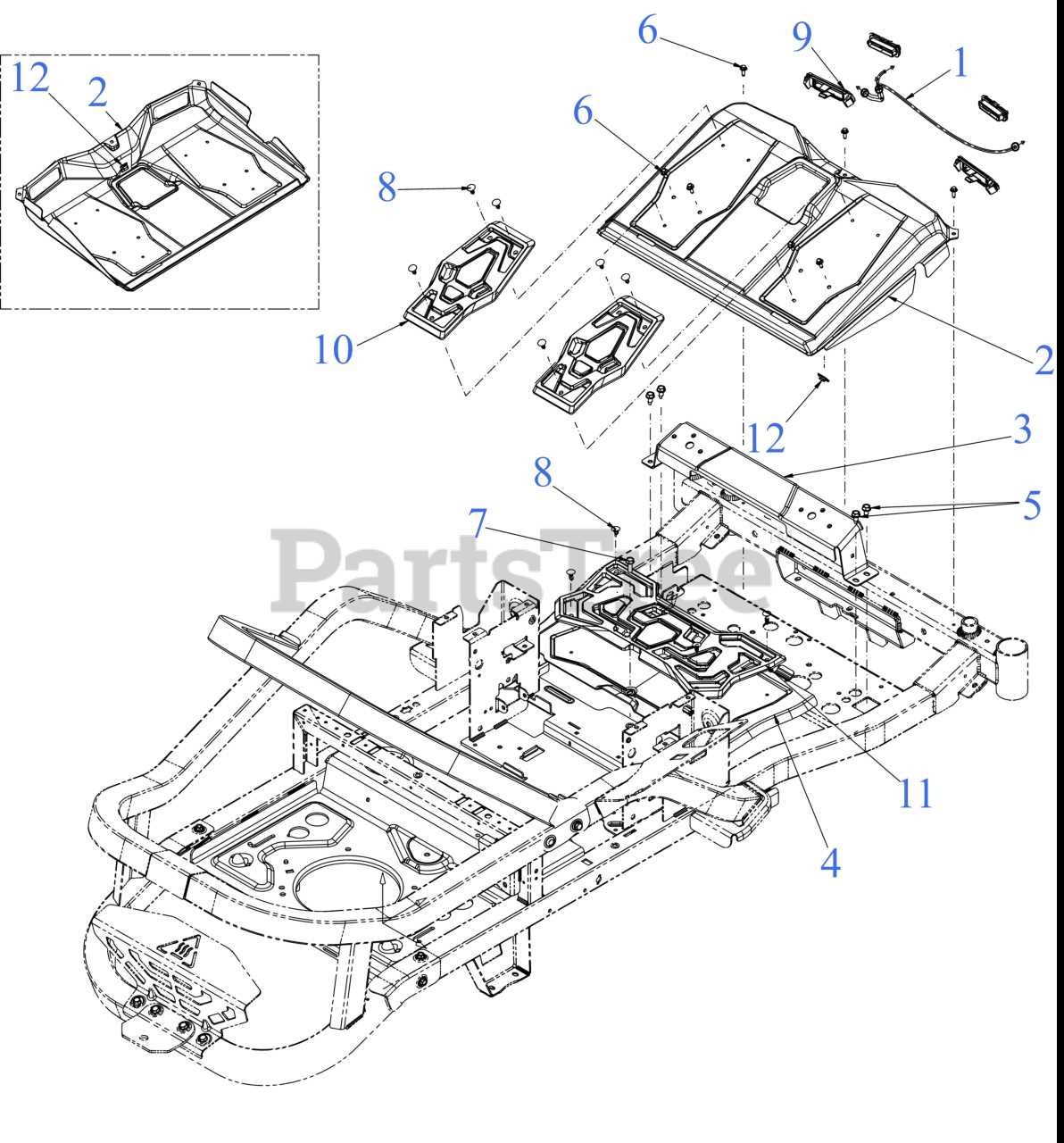

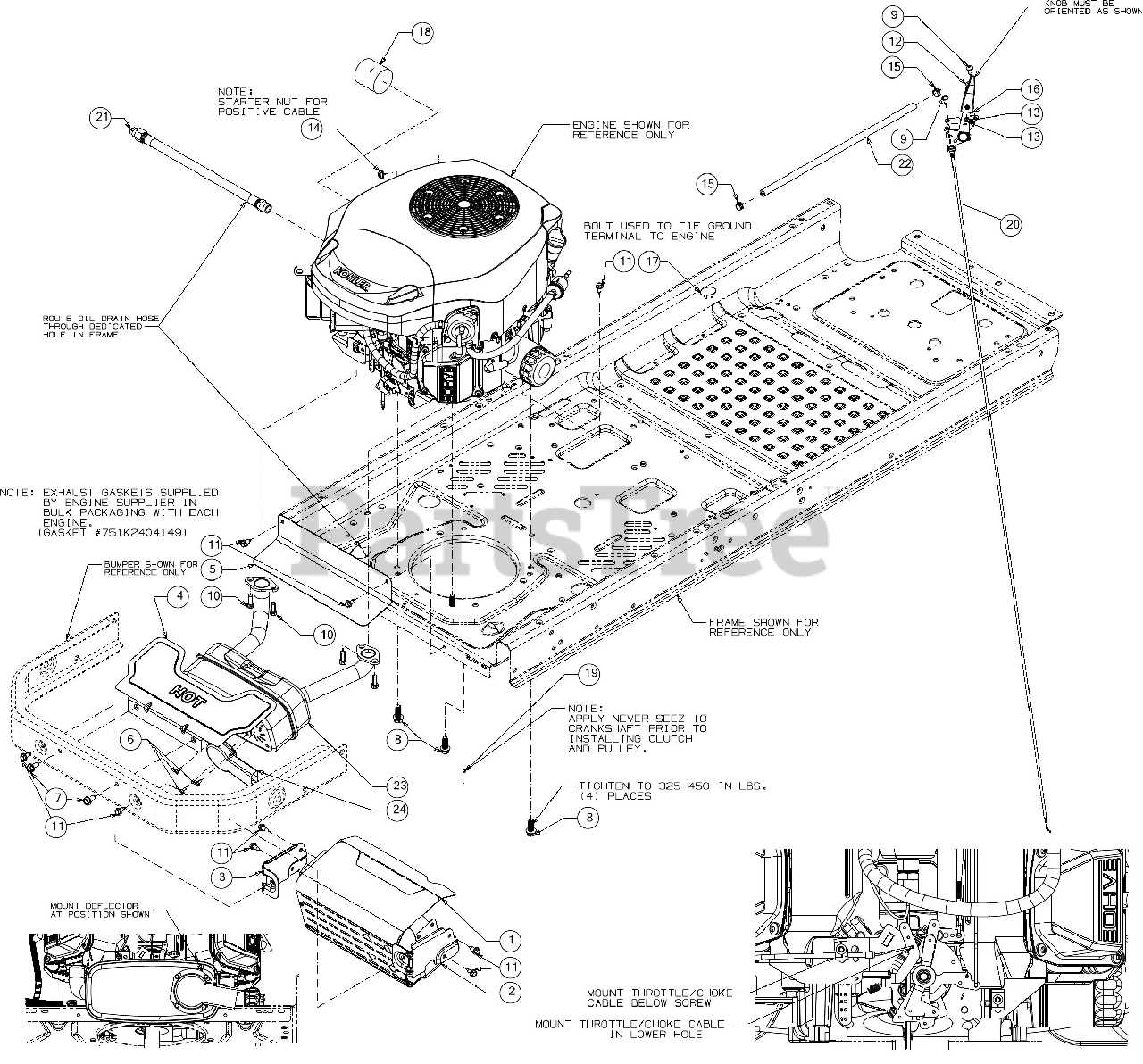

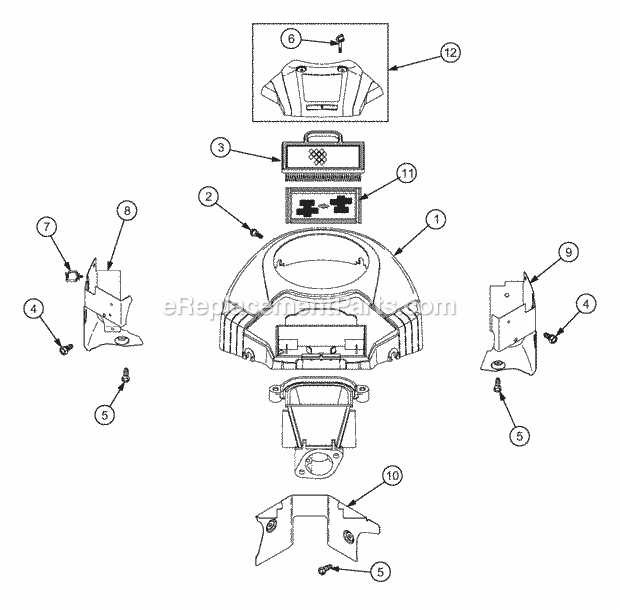

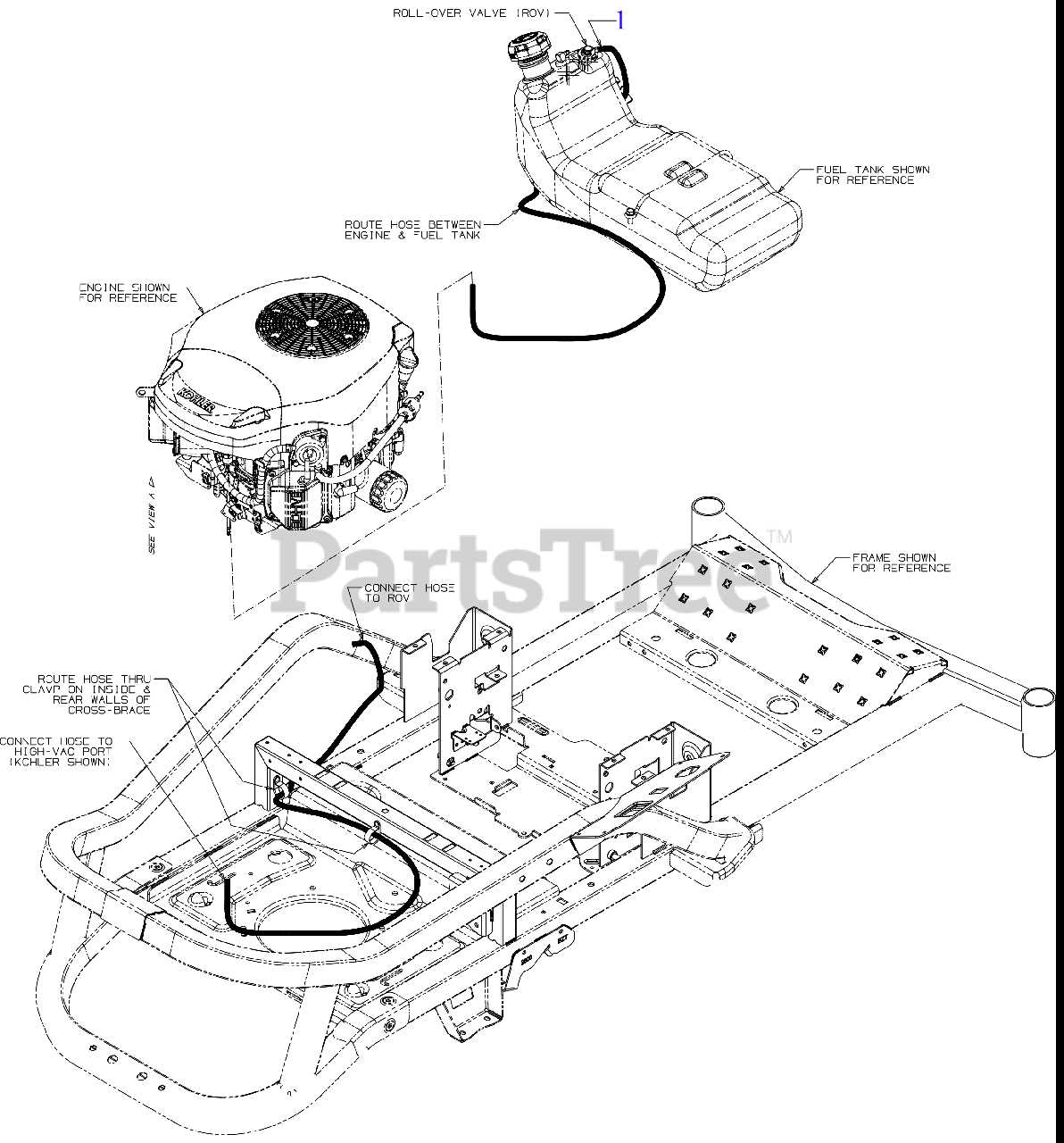

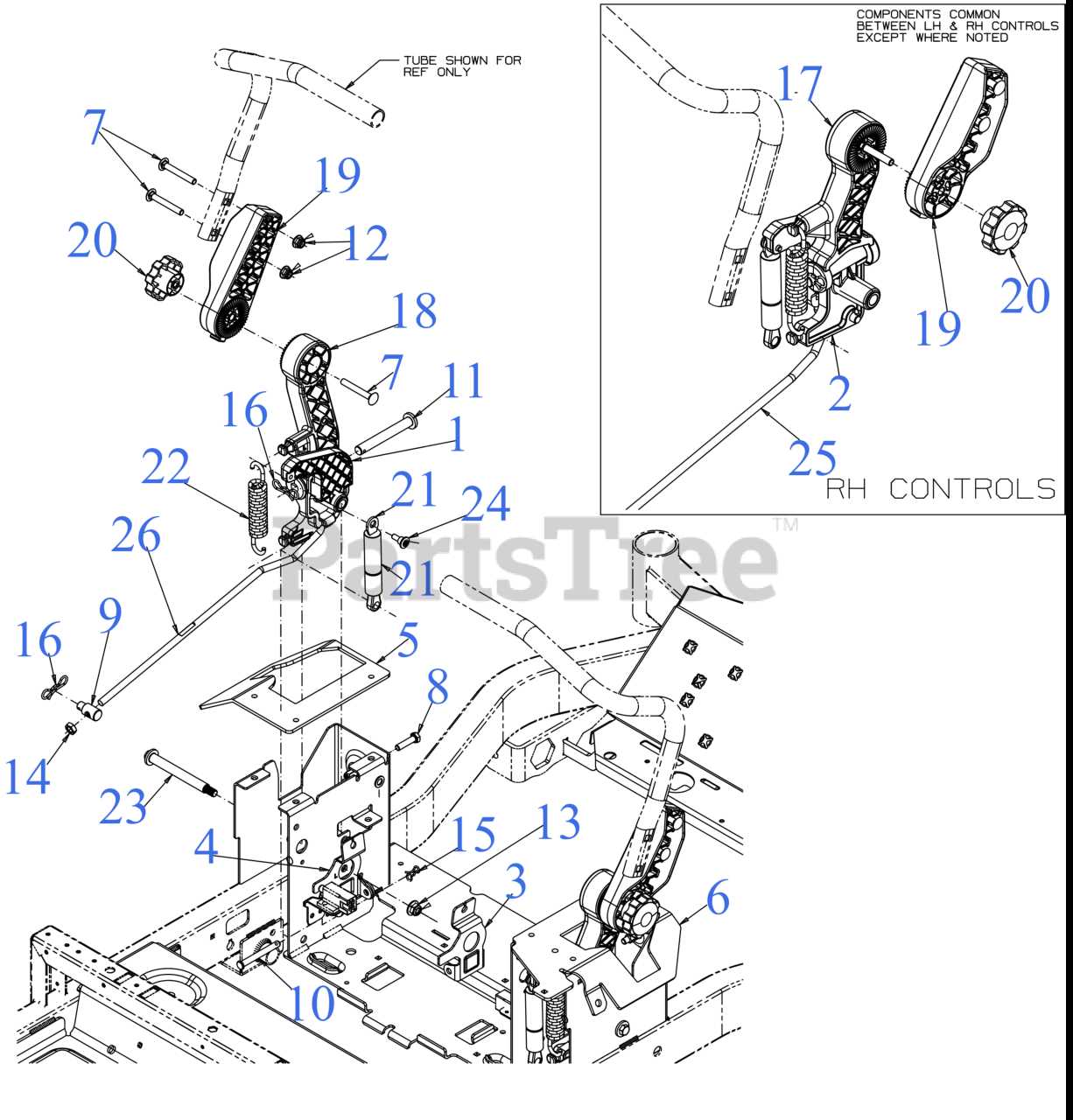

Moreover, visual representations of the equipment’s layout serve as invaluable tools for understanding the arrangement and purpose of each part. Such diagrams not only facilitate effective troubleshooting but also enhance the overall proficiency in handling the machinery. With this insight, one can approach lawn care tasks with greater confidence and efficiency.

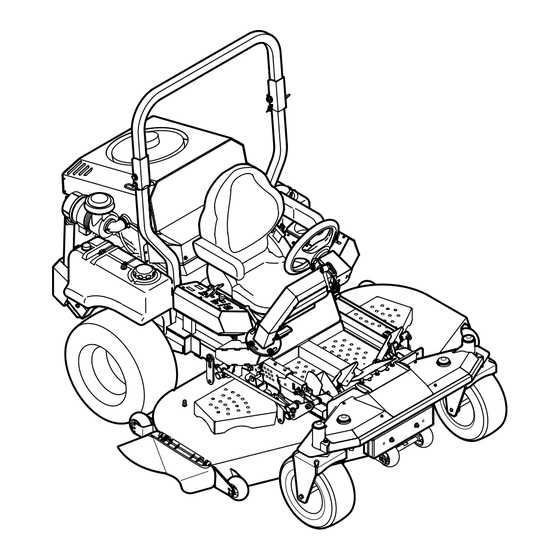

Cub Cadet Zero Turn Overview

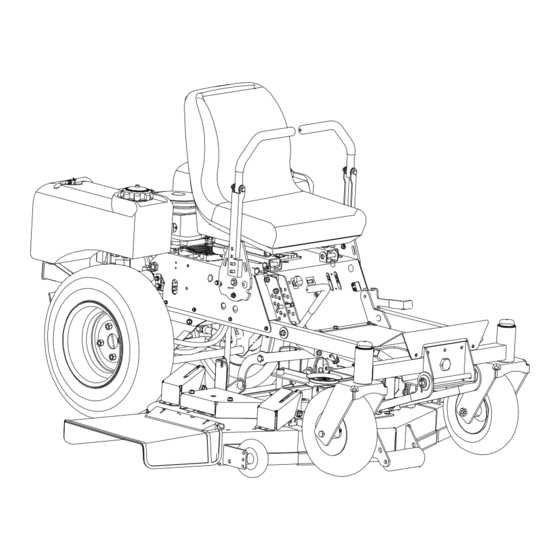

This section provides an insightful look into a popular type of lawn maintenance equipment designed for efficiency and precision. These machines are engineered to enhance maneuverability and control, allowing users to navigate around obstacles with ease. Their unique design offers a superior cutting experience, making them a favorite among both residential and commercial landscapers.

Equipped with advanced technology and user-friendly features, this type of mower stands out in the market. The intuitive steering mechanism allows for quick adjustments, while the powerful engine ensures optimal performance across various terrains. Additionally, the robust build quality guarantees durability, making it a worthwhile investment for anyone serious about lawn care.

Maintenance and repair of these machines can be straightforward when you have the right information and resources. Understanding the layout and functionality of each component is essential for keeping the equipment in top shape. With the right guidance, users can easily troubleshoot issues and perform routine checks, ensuring longevity and reliability.

Importance of Parts Diagrams

Understanding the layout and function of individual components is crucial for effective maintenance and repair of machinery. Visual representations of these elements provide users with essential insights, ensuring proper handling and replacement of items. Clarity in design can significantly reduce errors and enhance the efficiency of repair processes.

Benefits of Visual Representations

- Improved Clarity: A well-structured illustration clarifies the relationships between different components.

- Time Efficiency: Quick reference aids in identifying required components swiftly, saving time during repairs.

- Reduced Errors: Clear visual guides minimize the likelihood of mistakes during assembly or disassembly.

Enhancing Repair Skills

- Facilitates Learning: Visual aids assist users in understanding complex systems.

- Boosts Confidence: Knowledge of component placement enhances user confidence in conducting repairs.

- Promotes Safety: Awareness of how parts fit together helps prevent accidents during maintenance.

Identifying Key Components

Understanding the essential elements of your lawn maintenance machine is crucial for efficient operation and maintenance. Each component plays a specific role, contributing to the overall functionality and performance. Familiarizing yourself with these parts will help in troubleshooting and ensuring your equipment runs smoothly.

| Component | Description |

|---|---|

| Engine | The power source that drives the entire unit, providing the necessary horsepower. |

| Transmission | Responsible for controlling speed and direction, enabling smooth maneuverability. |

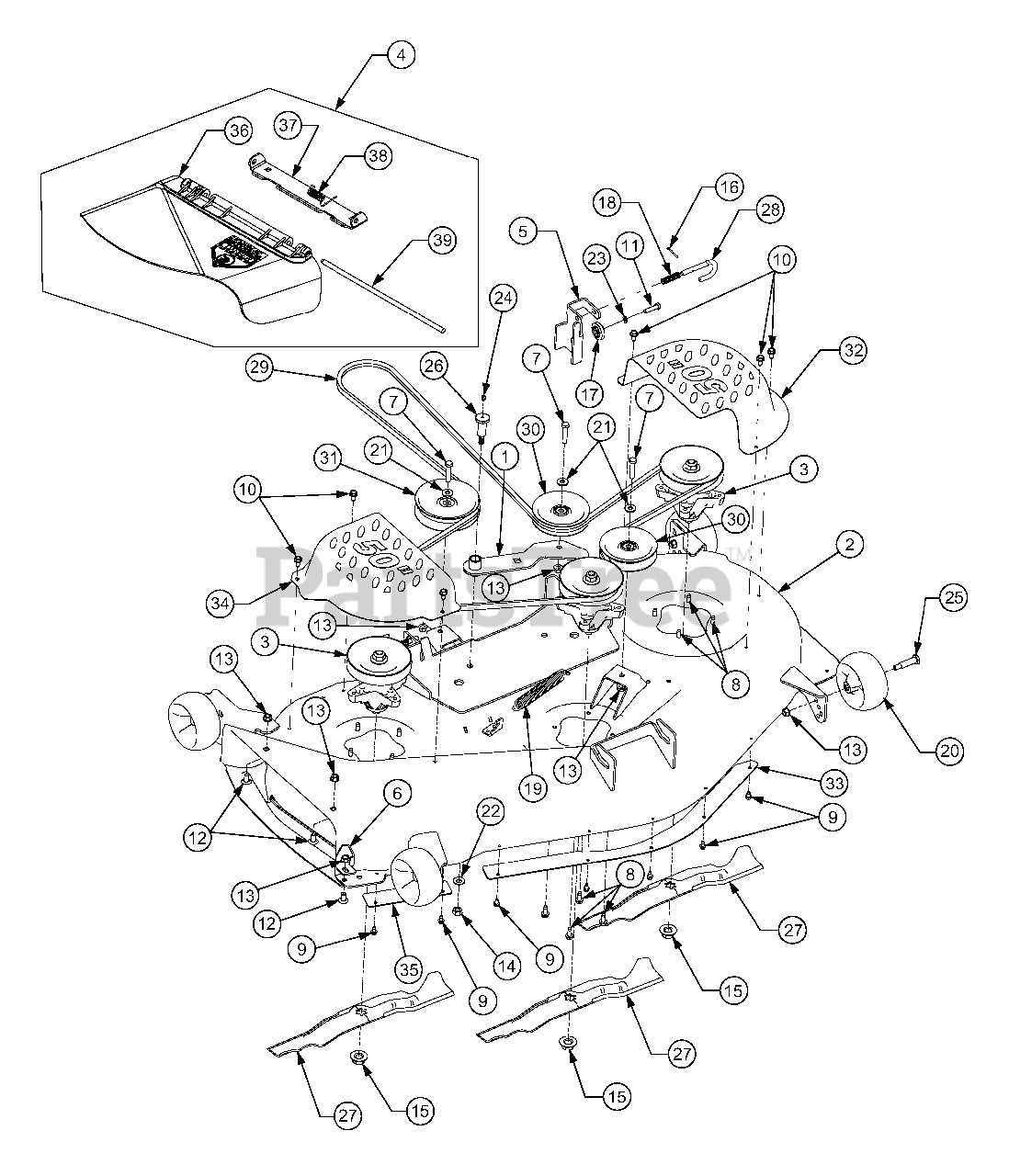

| Deck | The cutting platform that houses the blades and determines the cutting height. |

| Blades | Rotating elements that perform the actual cutting of grass, available in various sizes. |

| Wheels | Provide mobility, supporting the weight of the machine while allowing for easy navigation. |

| Control Levers | Enable the operator to steer and adjust speed, essential for precise handling. |

Common Replacement Parts Explained

When maintaining outdoor equipment, understanding the essential components that may need replacement is crucial. Regular wear and tear can affect performance, making it necessary to identify and address issues promptly. This section explores some frequently replaced items, their functions, and signs that indicate they may need attention.

Belts and Cables

One of the most critical elements in any mowing machine is the drive mechanism. Belts transfer power from the engine to the cutting deck, ensuring smooth operation. Over time, these components can become frayed or stretched, leading to decreased efficiency. If you notice slippage or unusual noises during operation, it may be time to inspect and replace the belts.

Blades and Filters

Another vital aspect of performance lies in the blades. Dull or damaged blades can result in uneven cuts and stress the engine. Regularly checking the sharpness and condition of the blades is essential for optimal performance. Additionally, filters play a key role in maintaining engine health by keeping contaminants at bay. Clogged filters can impede airflow and lead to overheating, so routine replacement is advisable.

Maintenance Tips for Zero Turn Mowers

Regular upkeep is essential for ensuring the longevity and efficiency of your mowing equipment. By implementing a few straightforward practices, you can enhance performance and reduce the likelihood of costly repairs. Below are some key strategies to maintain your machine effectively.

- Check the Oil: Regularly inspect the oil level and quality. Change the oil as recommended in the manufacturer’s guidelines to keep the engine running smoothly.

- Inspect the Blades: Keep the cutting blades sharp for a clean cut. Dull blades can damage your lawn and require more power to operate.

- Clean the Deck: After each use, remove grass clippings and debris from the mower deck. This prevents rust and ensures optimal performance.

- Examine Tires: Regularly check tire pressure and tread wear. Properly inflated tires improve traction and stability.

- Replace Air Filters: Change air filters periodically to maintain airflow and engine efficiency. A clean filter enhances performance and reduces fuel consumption.

- Fuel System Maintenance: Use fresh fuel and consider adding a fuel stabilizer if the machine will be idle for an extended period. This helps prevent fuel degradation.

By following these maintenance tips, you can enjoy a well-functioning mower that delivers optimal results throughout the mowing season.

Where to Find Parts Diagrams

Locating comprehensive visual references for machinery components can significantly enhance repair and maintenance efforts. These illustrations serve as essential guides for identifying individual pieces and understanding how they fit together within the overall assembly. Here, we explore the best resources for obtaining such valuable information.

Online Resources

The internet is a vast repository of information, and several websites specialize in providing detailed schematics for various machinery. Manufacturers often maintain official sites that offer downloadable resources, including technical illustrations and manuals. Additionally, independent repair forums and online communities can be excellent sources for user-shared diagrams and tips.

Local Dealerships and Repair Shops

Local dealerships and authorized repair centers typically possess printed materials and resources that can be beneficial for understanding component arrangements. Visiting these establishments can provide access to both physical and digital resources, ensuring you have the correct information for effective repairs.

| Resource Type | Examples |

|---|---|

| Official Manufacturer Websites | Company-specific portals |

| Online Repair Communities | Forums, social media groups |

| Local Dealerships | Authorized service centers |

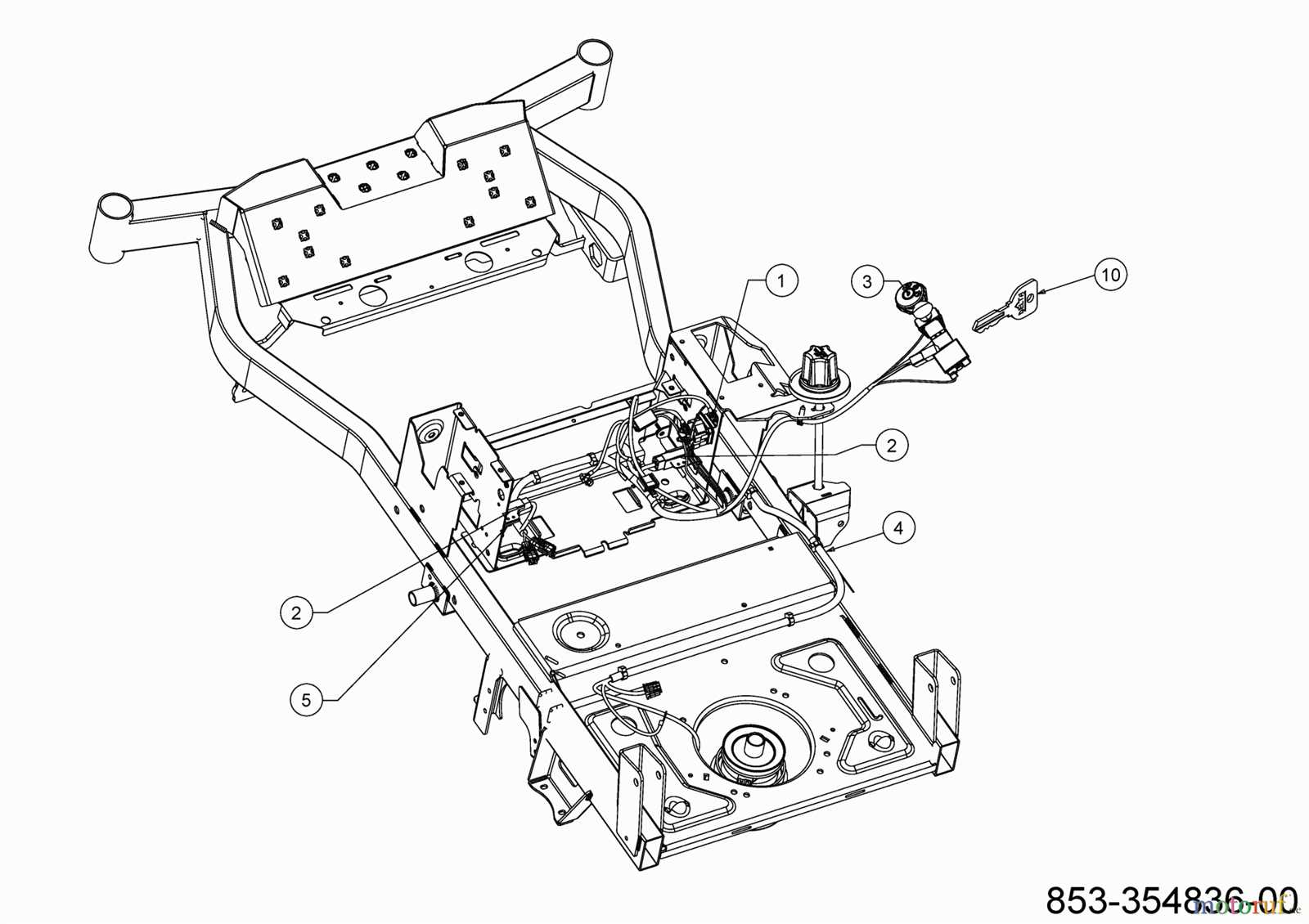

Understanding Assembly Instructions

Assembling machinery can seem daunting, but with clear guidance, the process can be streamlined and straightforward. Effective assembly instructions are essential for ensuring all components fit together correctly and function as intended. This section will provide insights into the key elements that make up successful assembly guidelines.

Key Components of Assembly Guides

A well-structured assembly guide typically includes a list of necessary components, detailed step-by-step procedures, and visual aids to enhance comprehension. Clarity is paramount; instructions should be easy to follow, avoiding technical jargon that could confuse the user. Diagrams and illustrations can significantly aid in visualizing the assembly process, helping to ensure each part is correctly positioned.

Common Challenges and Solutions

Users may encounter various challenges during assembly, such as misalignment of components or insufficient tools. Addressing these issues involves providing troubleshooting tips and alternative methods to correct mistakes. Encouraging users to double-check their work can prevent frustration and promote a smoother assembly experience.

Advantages of Using Genuine Parts

When it comes to maintaining machinery, the choice of components significantly impacts performance and longevity. Utilizing authentic components ensures optimal functionality and reduces the likelihood of issues arising from inferior alternatives.

Quality Assurance: Genuine components are manufactured to meet specific standards, ensuring they perform as intended. This reliability contributes to the overall efficiency of your equipment.

Compatibility: Original components are designed to fit perfectly, minimizing the risk of misalignment or operational disruptions. This precise compatibility enhances the overall user experience.

Longevity: Authentic parts tend to last longer, reducing the need for frequent replacements. This durability ultimately saves both time and money in the long run.

Warranty Protection: Many manufacturers offer warranties on their genuine components, providing peace of mind and financial protection against defects or failures.

Investing in authentic components is a strategic choice that leads to better performance, fewer headaches, and greater satisfaction.