Understanding the internal structure and arrangement of various components in a chainsaw can be crucial for maintenance and repairs. The layout of individual elements is designed to ensure smooth operation and long-term durability. By familiarizing yourself with these mechanical details, you can better handle any issues that arise during use.

Each mechanical element plays a specific role in the overall system, from ignition to cutting power. Identifying and locating each element can greatly assist in routine maintenance tasks, helping ensure that the equipment continues to operate efficiently over time. Clear knowledge of where each part belongs and how it interacts with others simplifies both repairs and replacements.

When disassembling or inspecting the machinery, it’s important to be mindful of how various elements connect. Knowing the correct position and alignment of the internal components helps prevent damage and extends the lifespan of the equipment. Whether you are performing simple maintenance or more complex repairs, this guide will help you navigate the process smoothly.

Overview of Key Components in Stihl 021

Understanding the essential elements of a small engine system is crucial for maintaining performance and ensuring long-term functionality. Each piece plays a significant role in the machine’s overall operation, contributing to its efficiency and durability. Familiarity with these elements helps in recognizing wear and tear, making necessary replacements, and performing regular maintenance.

Power Unit is the heart of the machine, responsible for converting energy into the necessary force to drive the mechanism. It is made up of several parts that work together to ensure reliable function and consistent performance.

The ignition system is another critical component, providing the spark needed to ignite the fuel mixture and start the engine. Without a properly functioning ignition, the engine would fail to start or run smoothly, affecting the entire operation.

Another vital element is the fuel system, which ensures the correct ratio of fuel and air for optimal combustion. Keeping this system clean and in good working order is essential for preventing issues related to engine efficiency.

Lastly, the filtration system plays an important role in protecting the engine from dust and debris, ensuring that the internal components remain clean and free from contaminants that could lead to premature wear or damage.

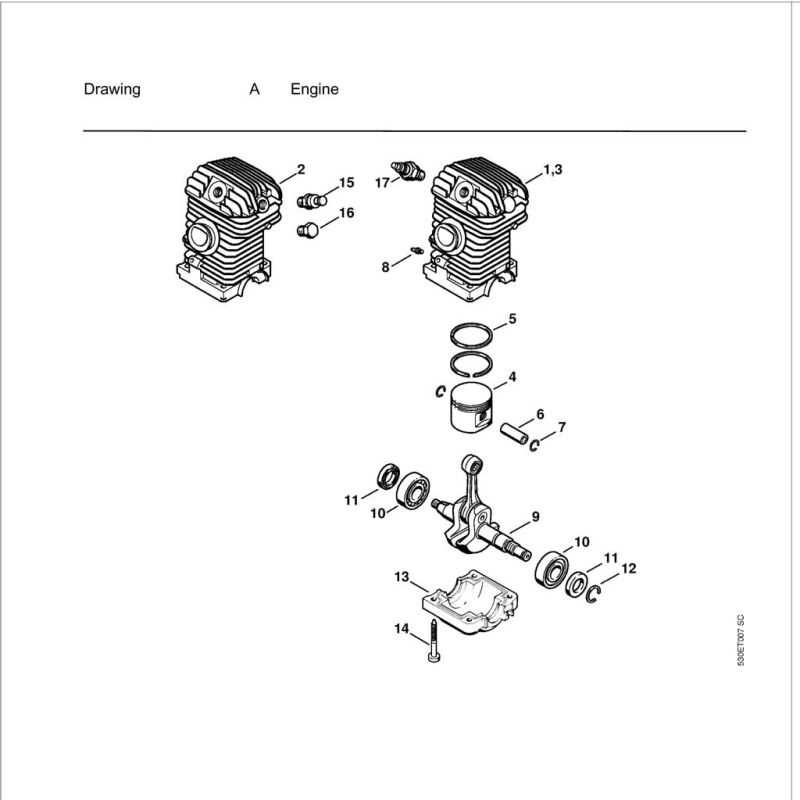

Main Engine Elements and Their Functions

The core components of an engine play a crucial role in ensuring efficient operation and optimal performance. Each part is specifically designed to fulfill a unique task, contributing to the overall functionality of the system. By understanding the role of these elements, it becomes easier to maintain and repair the engine when necessary.

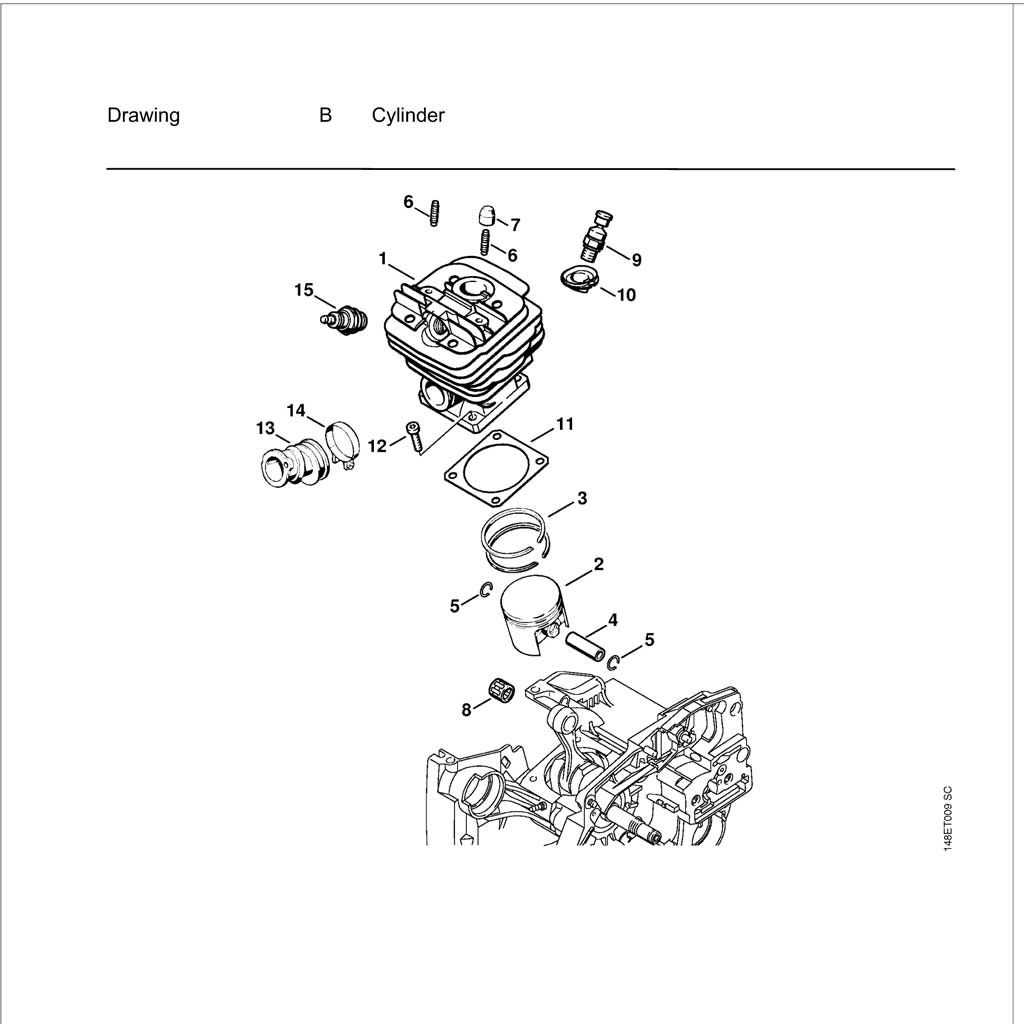

Cylinder: This is the central chamber where fuel combustion occurs, providing the force needed to power the machine. The cylinder must remain clean and well-maintained for proper efficiency.

Piston: A vital moving part, the piston moves up and down within the cylinder, converting the energy from combustion into mechanical motion. Its smooth operation is key to maintaining the engine’s rhythm.

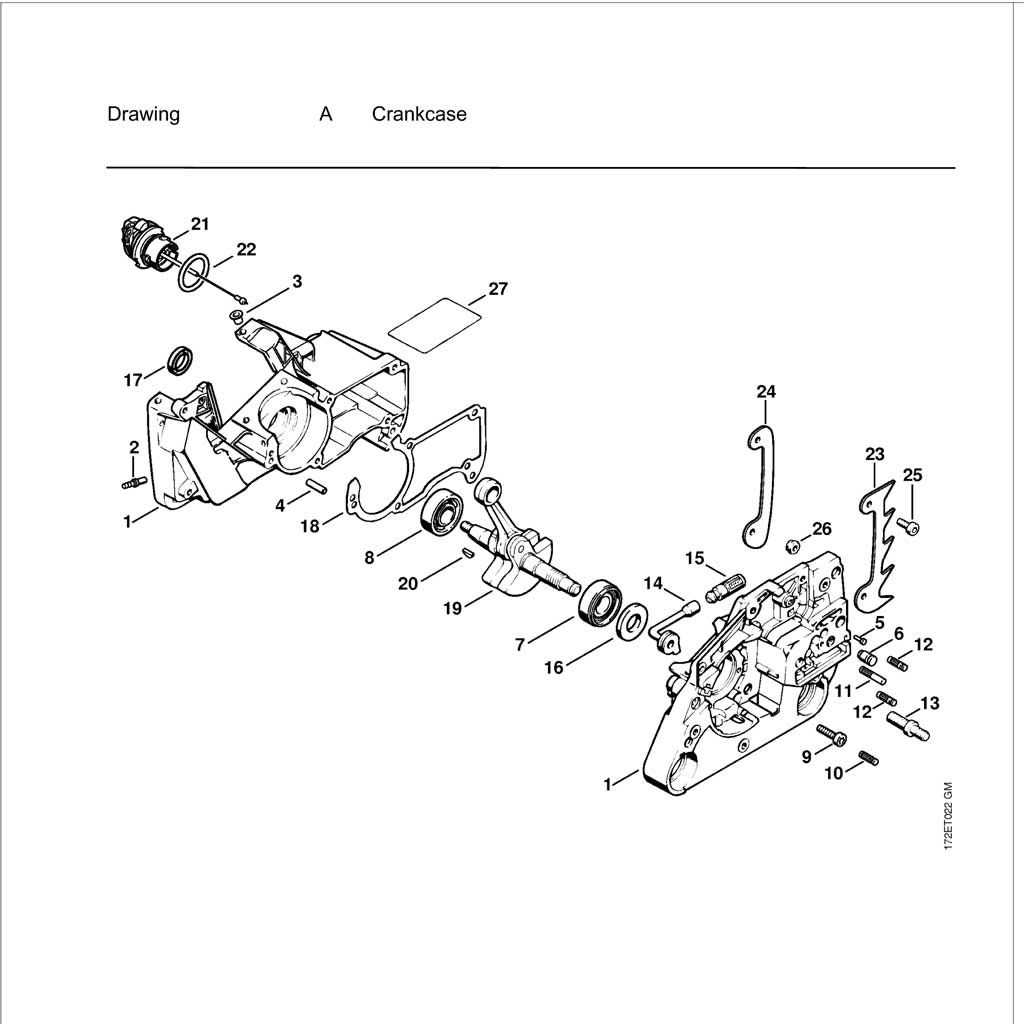

Crankshaft: The crankshaft transforms the linear motion of the piston into rotational energy. It is connected to the piston through rods and is essential for transferring energy to other parts of the engine.

Carburetor: This component regulates the mixture of air and fuel that enters the engine, ensuring the correct balance for combustion. Proper adjustment of the carburetor is critical for smooth engine performance.

Ignition System: The ignition system generates the spark that ignites the fuel-air mixture within the cylinder. This process is crucial for initiating the combustion cycle and keeping the engine running efficiently.

Understanding the main elements and their specific functions helps in maintaining the engine’s longevity and addressing any issues that may arise during operation.

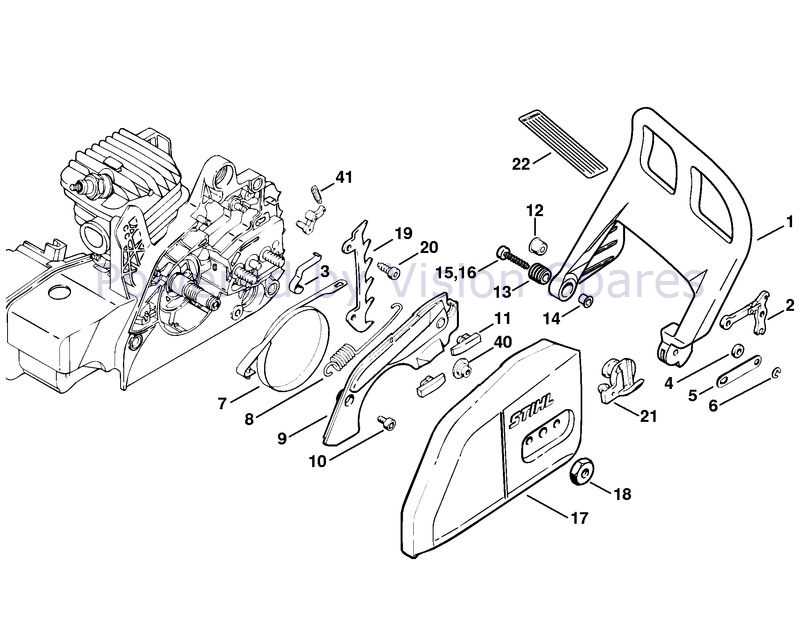

Chainsaw Safety Features Breakdown

Understanding the essential safety mechanisms of a chainsaw is crucial for anyone using this powerful tool. These features are designed to protect the operator from potential hazards during operation, ensuring both control and reduced risk of injury. By examining the various components aimed at improving safety, users can make informed decisions on how to handle the equipment safely.

Essential Safety Mechanisms

- Chain Brake: A device that halts the chain’s motion in case of kickback, preventing accidents and injuries.

- Throttle Lock: This feature ensures the throttle only engages when the operator has a firm grip on the saw, reducing the chance of accidental acceleration.

- Hand Guard: A protective shield that prevents hands from coming into contact with the chain, especially in case of unexpected movements.

Additional Protective Features

- Fuel and Oil System Parts

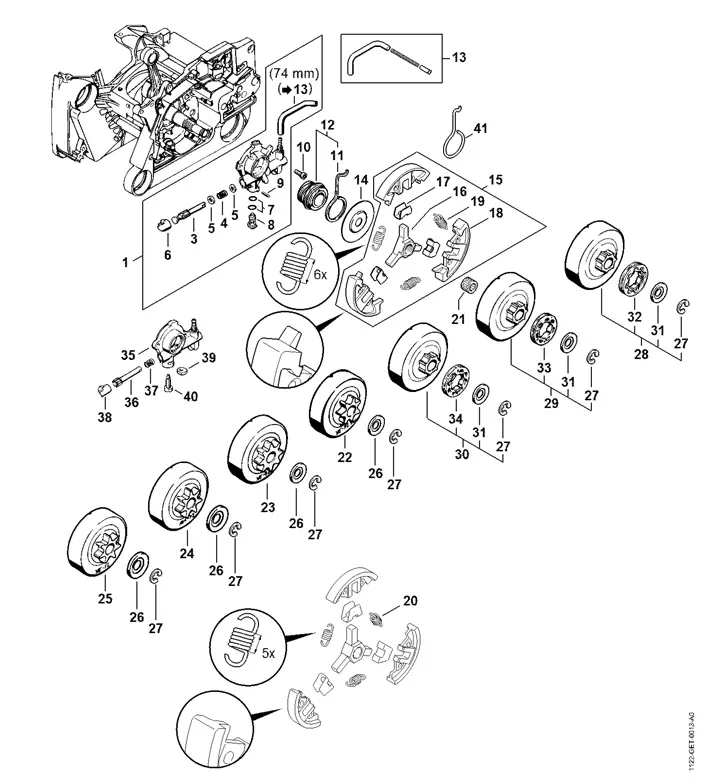

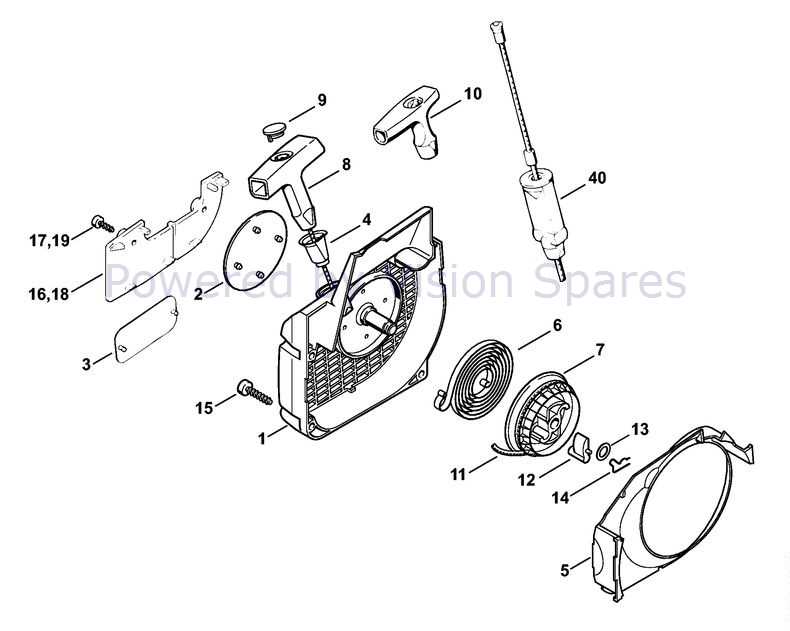

- Recoil Spring: This is responsible for storing energy when the cord is pulled and releasing it to spin the engine flywheel.

- Starter Rope: Connected to the handle, this cord triggers the mechanism by engaging the internal parts when pulled.

- Pulley: The rope is wound around this part, allowing it to recoil properly after each pull.

- Flywheel Engagement System: This component engages with the flywheel, enabling the transfer of the energy needed to start the engine.

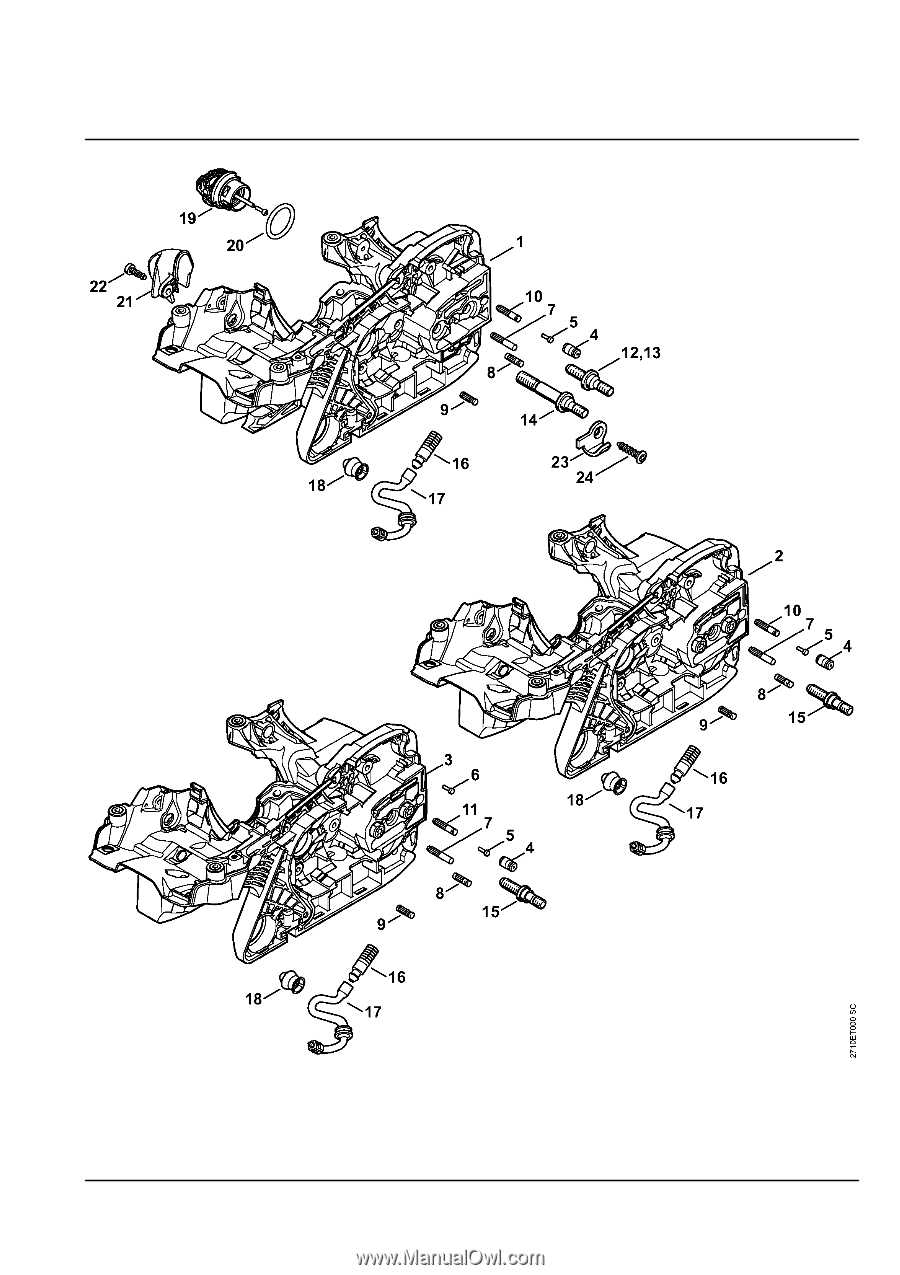

The fuel and oil systems in small engines play a crucial role in maintaining performance and efficiency. These systems ensure that the engine receives a steady flow of fuel and lubricant, contributing to smooth operation and preventing wear. Proper maintenance of these components is essential for long-term reliability.

Key Components of the Fuel System

The fuel system consists of several essential elements, including the tank, filters, and lines. These parts work together to deliver the right amount of fuel to the engine, ensuring optimal combustion. Regular inspection and cleaning of the filters and lines help prevent clogs and ensure a consistent fuel flow.

Essential Oil System Elements

The oil system ensures proper lubrication of the engine’s moving parts. Key elements include the oil tank, pump, and delivery lines. These components keep the engine running smoothly by reducing friction and minimizing wear on internal parts. Routine checks of oil levels and the condition of the pump are critical to avoiding potential damage.

| Component |

|---|

| Failure Type | Possible Causes | Suggested Solutions |

|---|---|---|

| Engine Won’t Start | Fuel blockage, spark plug issues, air filter clogging | Check fuel supply, replace spark plug, clean or replace air filter |

| Poor Performance | Dull chain, improper tension, fuel mixture problems | Sharpen or replace the chain, adjust tension, check fuel mixture ratio |

| Excessive Vibration | Worn parts, loose screws, unbalanced cutting tool | Inspect and replace worn components, tighten screws, balance the tool |

| Overheating | Insufficient lubrication, air intake blockage, extended operation | Check oil levels, clean air intake, allow for cooling breaks |