When it comes to maintaining or repairing a chainsaw, having a clear view of its internal structure is essential. Knowing how each element fits into the bigger picture can help ensure that the tool continues to operate smoothly and efficiently. This overview focuses on providing a deeper insight into the various mechanical elements, offering guidance on their functions and interactions.

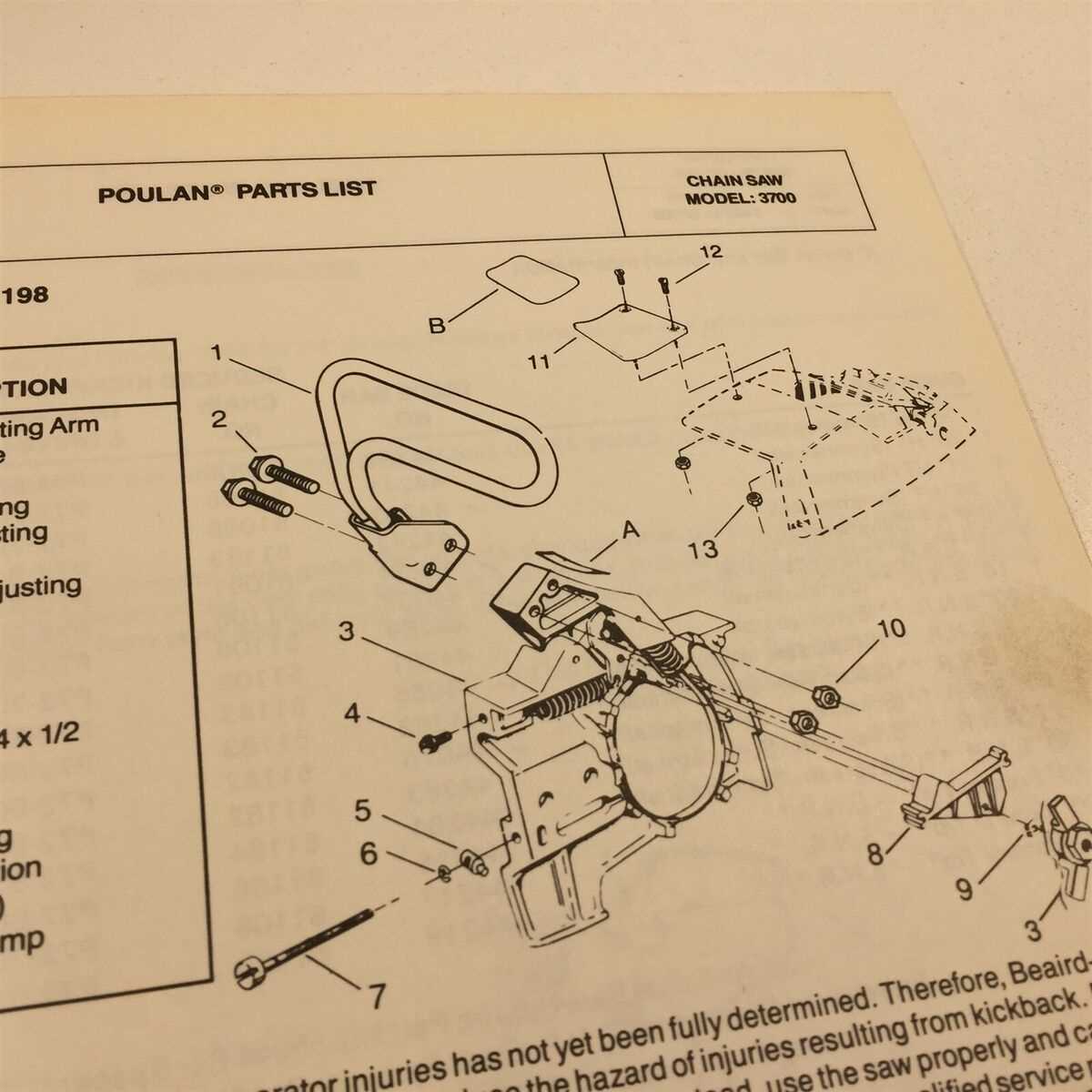

Detailed schematics of each component offer invaluable assistance for troubleshooting and ensuring proper assembly. Whether you’re handling regular upkeep or solving a specific issue, understanding the placement and purpose of different elements is crucial for both efficiency and safety. Familiarizing yourself with the layout makes working on such tools significantly easier, even for those new to maintenance tasks.

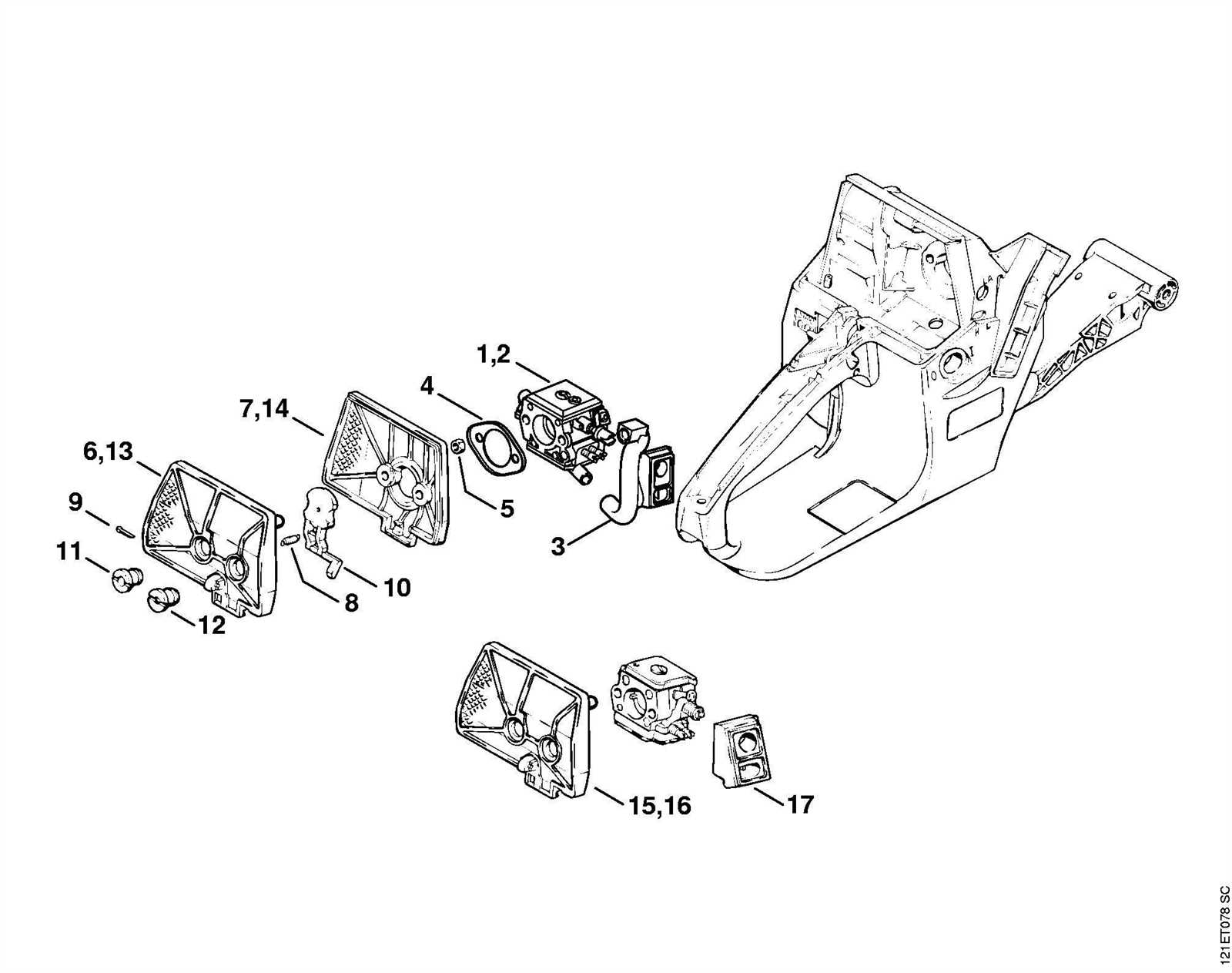

Exploring Key Components of the Stihl 026

Understanding the essential elements of this widely used machine is crucial for its effective operation and maintenance. These components work together to ensure smooth performance, allowing the tool to function efficiently across a variety of tasks. Knowing the role of each element will help in identifying potential issues and performing necessary repairs or adjustments.

The structure includes several vital parts, such as the engine, which powers the entire system, and the chain mechanism, which is responsible for cutting through various materials. Additionally, other features like the starter and handle assembly contribute to ease of use and control during operation. Keeping these components in good condition is key to extending the lifespan of the equipment.

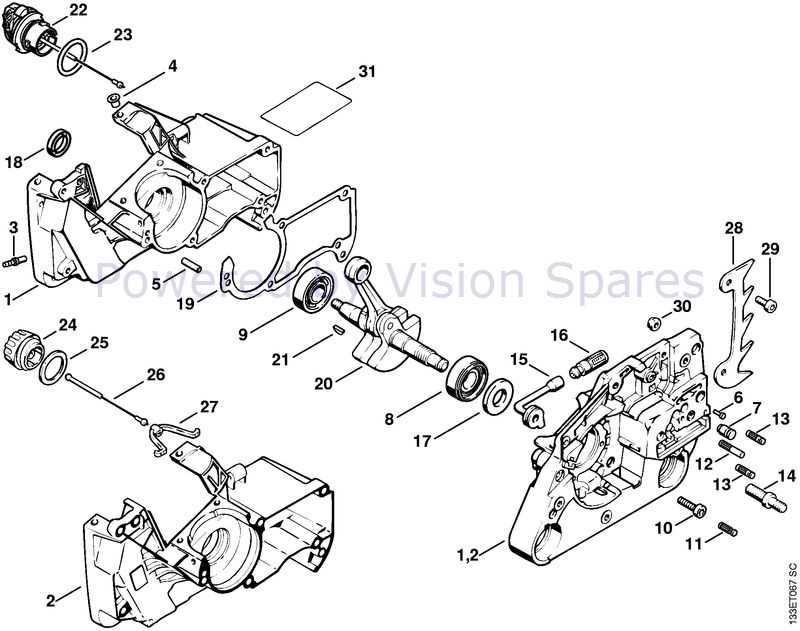

Understanding the Engine Assembly Layout

The engine assembly layout is a crucial aspect to consider when maintaining or repairing mechanical systems. It provides insight into how the various components interact and function together, ensuring smooth operation. Recognizing the overall structure and relationships between elements helps in identifying potential issues and optimizing performance.

Within the engine, each section plays a specific role, from the combustion process to the regulation of air and fuel intake. Gaining a clear understanding of this setup allows for better troubleshooting and maintenance, making it easier to address any malfunctions and keep the machinery running efficiently.

Guide to the Chainsaw’s Ignition System

The ignition system in a chainsaw plays a crucial role in ensuring smooth and efficient operation. Without a properly functioning ignition, the engine cannot start or run effectively. This guide will provide an overview of how the ignition components work together to power the tool and maintain its performance over time.

Main Components of the Ignition System

The ignition system is made up of several key parts that work in sync to ignite the fuel-air mixture in the engine. These components are vital for generating the necessary spark at the right moment.

- Flywheel: Spins rapidly to create the magnetic field needed for ignition.

- Ignition coil: Transforms low voltage into the high voltage required to produce a spark.

- Spark plug: Delivers the spark that ignites the fuel in the engine cylinder.

Common Issues and Troubleshooting

Issues in the ignition system can prevent the chainsaw from starting or cause it to stall unexpectedly. Below

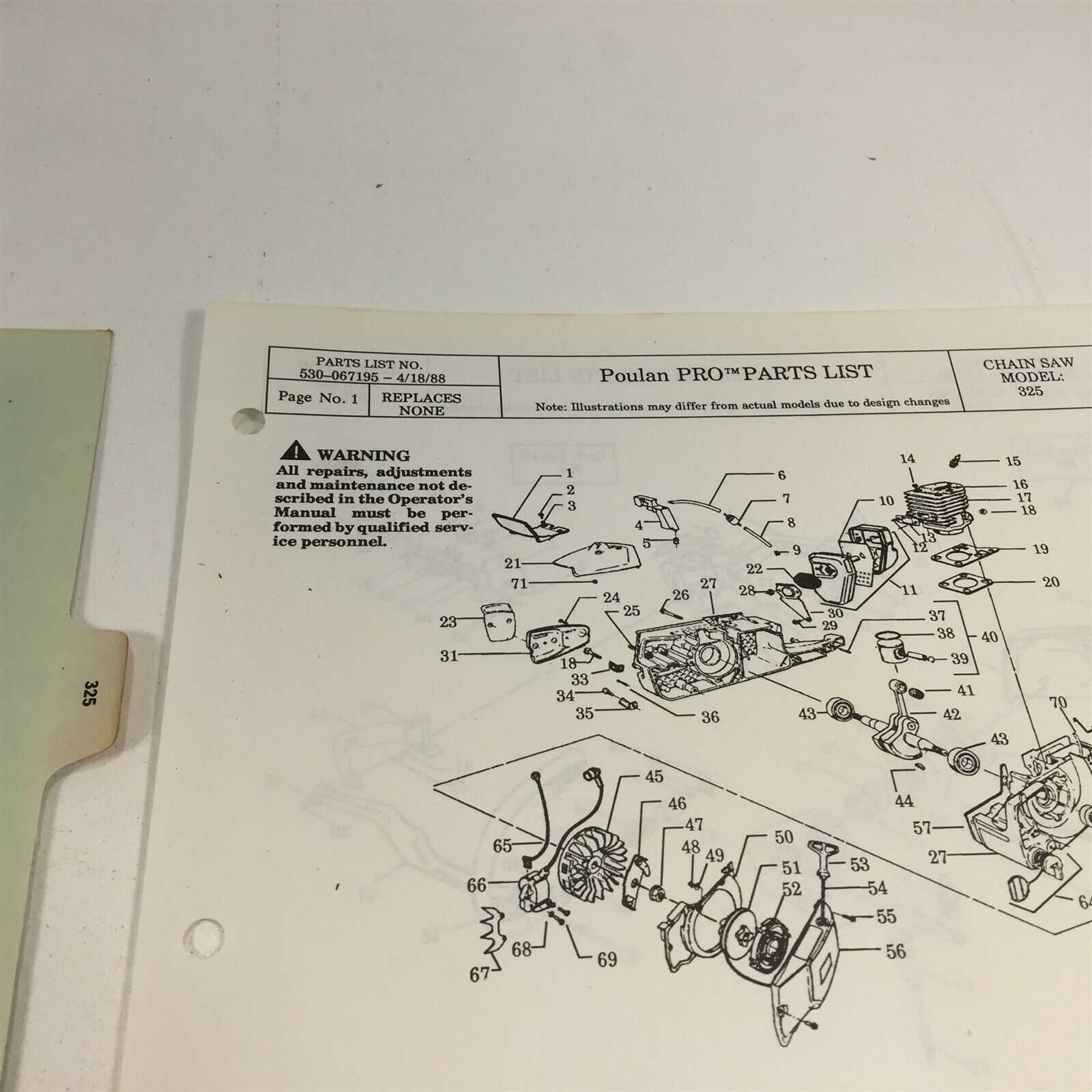

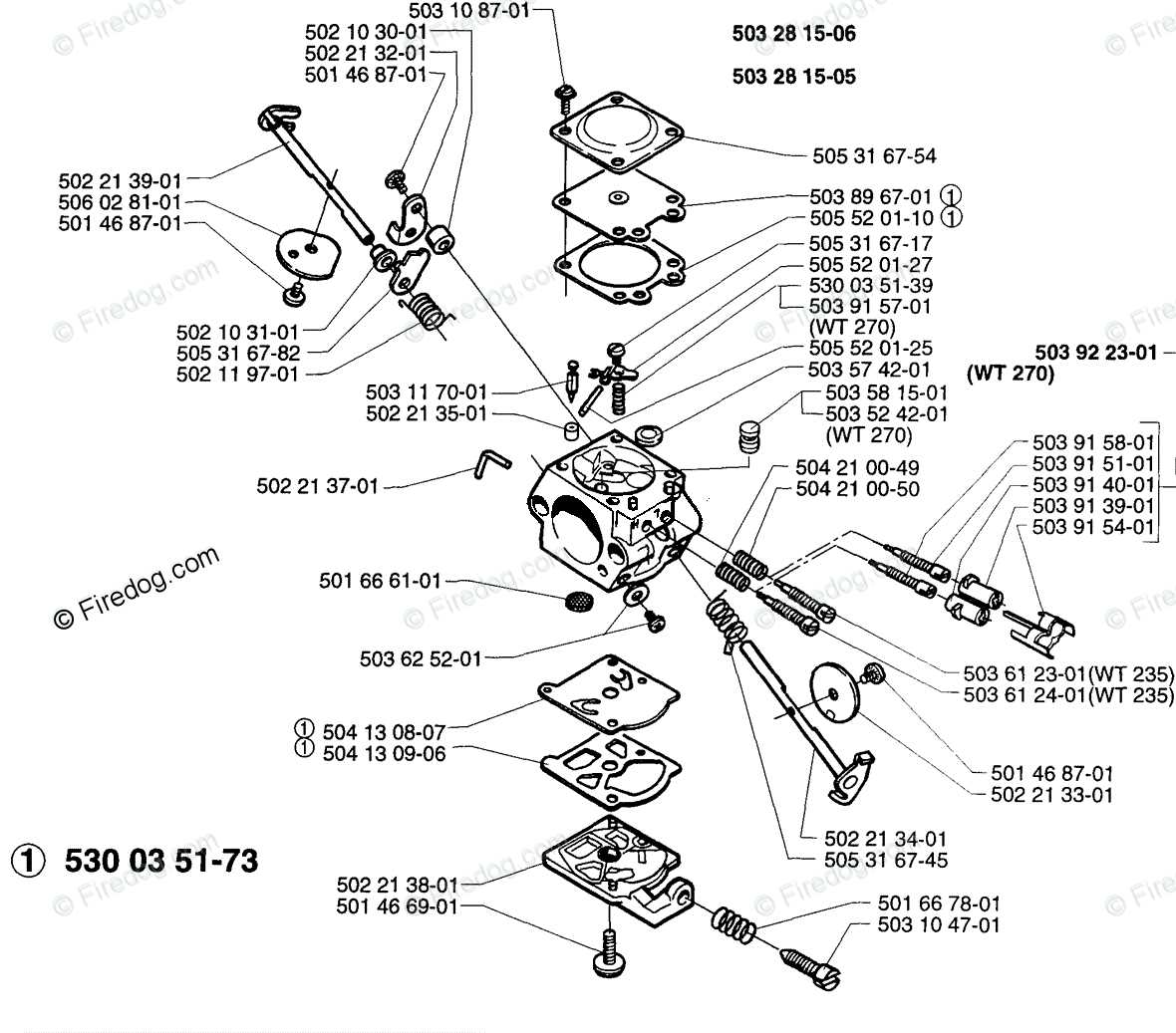

Fuel System Parts and Their Function

The fuel system is essential for ensuring that the engine runs smoothly and efficiently. By delivering the right amount of fuel to the engine, the system plays a crucial role in maintaining optimal performance. Understanding the components that make up this system can help identify issues and keep the machinery in top condition.

Key Components of the Fuel System

- Fuel Tank: Stores the fuel required for the engine, ensuring a continuous supply during operation.

- Fuel Line: Connects the fuel tank to the engine, allowing the transfer of fuel to power the machinery.

- Carburetor: Mixes air and fuel in the correct proportions before sending it to the engine for combustion.

- Fuel Filter: Prevents debris and impurities from entering the engine, protecting the system from damage.

How Each Component Functions

- The fuel tank stores the liquid, providing a consistent source for operation.

- The

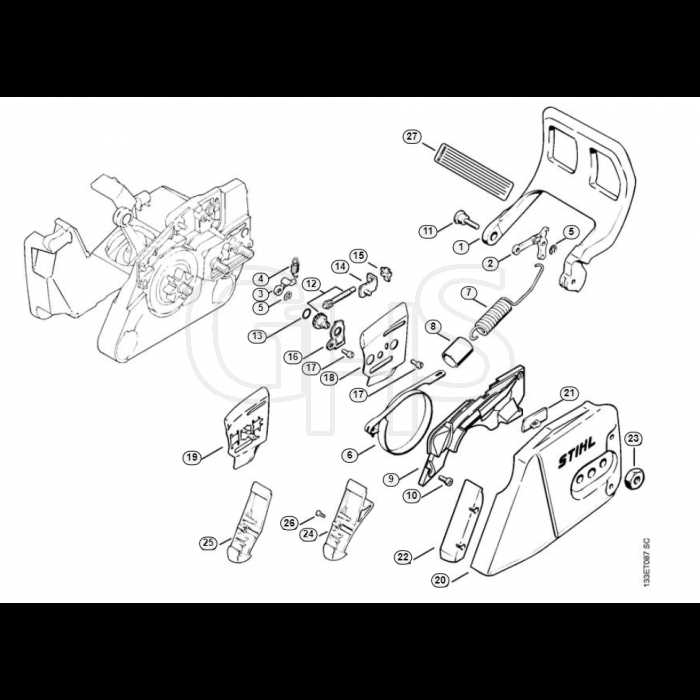

Detailed Look at the Chain Brake Mechanism

The chain brake mechanism is a crucial component that ensures safe operation by stopping the movement of the chain in specific situations. Understanding how this system functions provides insights into the overall safety features of your equipment. In this section, we will explore its structure and how it works to prevent accidents.

Key Components of the Chain Brake

- Brake Band: A metal band that tightens around the clutch drum to halt the chain.

- Activation Lever: This lever is responsible for engaging the brake when a sudden force is applied.

- Spring Mechanism: Ensures quick and efficient engagement of the brake when triggered.

How the Chain Brake Works

- Upon detecting a sudden movement or kickback, the activation lever is pushed forward.

- This force causes the brake band to contract around the clutch

Air Filter and Intake System Overview

The air filtration and intake mechanism plays a crucial role in ensuring optimal performance and longevity of the equipment. This system is designed to prevent contaminants from entering the combustion chamber, which can lead to reduced efficiency and potential damage. Understanding its components and functions is essential for maintaining the overall health of the machine.

The air filter serves as the first line of defense against dust, dirt, and debris, effectively trapping these particles before they can reach the engine. Regular inspection and cleaning of the filter are vital to maintain proper airflow and performance. A clogged filter can hinder the engine’s ability to breathe, resulting in decreased power and increased fuel consumption.

The intake system includes ducts and channels that direct air from the environment to the engine. The design of this system affects airflow dynamics, ensuring that the engine receives a sufficient supply of clean air for efficient combustion. Any blockages or leaks in the intake can disrupt the air-fuel mixture, leading to operational issues.

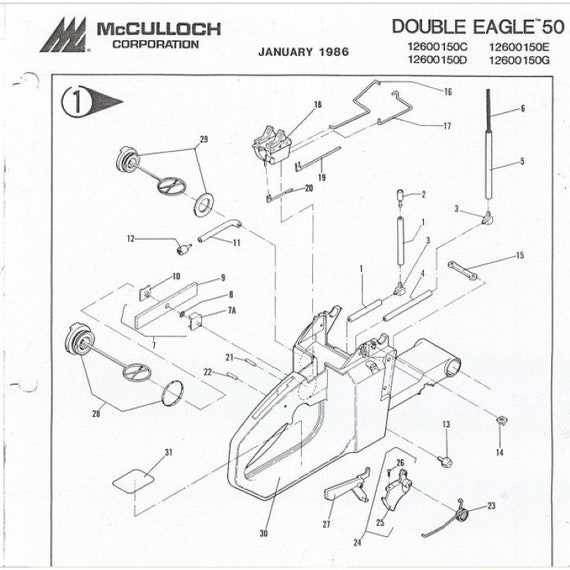

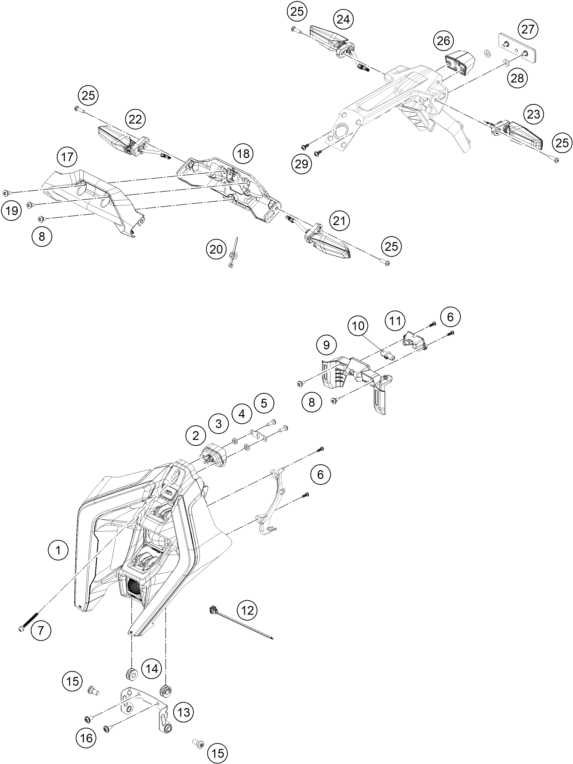

Examining the Starter Assembly and Mechanism

The starter assembly plays a crucial role in the operation of various power tools. This mechanism is designed to initiate the engine’s operation, ensuring that it runs smoothly and efficiently. Understanding its components and functionality is essential for proper maintenance and troubleshooting.

Key components of the starter assembly include:

- Starter Rope: This is the cord that the user pulls to engage the starting mechanism.

- Recoil Spring: This spring provides the necessary tension to retract the starter rope after a pull.

- Starter Pulley: The component that houses the rope and facilitates the pulling motion.

- Housing: The outer casing that protects the internal components and ensures their proper alignment.

Understanding how these elements work together can enhance the efficiency and longevity of the equipment. Regular inspection and maintenance of the starter assembly can prevent common issues such as:

- Difficulty in pulling the starter rope.

- Incomplete engagement of the starting mechanism.

- Wear and tear on the recoil spring.

By familiarizing oneself with the starter assembly and its mechanism, users can ensure optimal performance and address potential issues proactively.

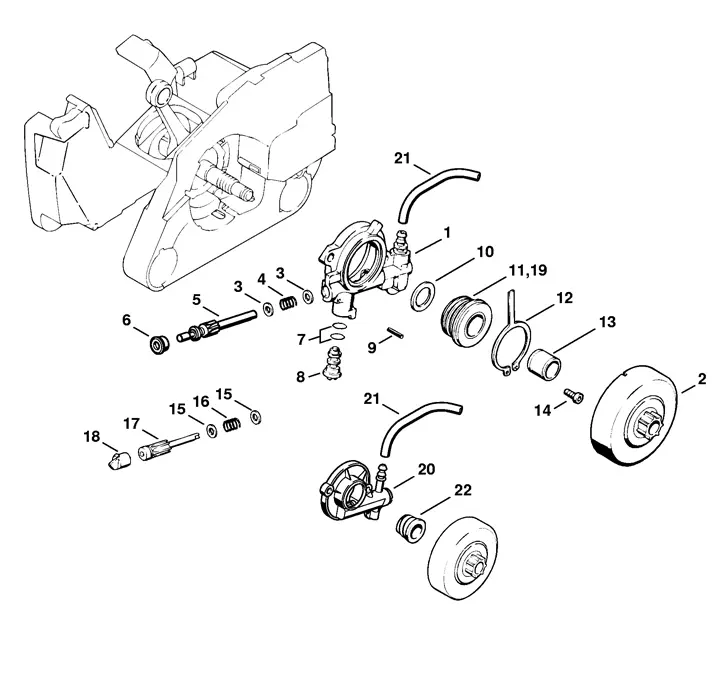

Understanding the Clutch System

The clutch mechanism is a crucial component in power equipment, responsible for engaging and disengaging the drive to the cutting tool. This system allows for smooth operation and enhances the efficiency of the machine, ensuring that it performs optimally during use. Understanding how this mechanism functions can help users troubleshoot issues and maintain their equipment effectively.

Component Description Clutch Drum This is the housing that holds the clutch components and connects to the drive shaft. Drive Springs These springs engage the clutch when the engine reaches a certain speed, allowing power to transfer to the cutting tool. Friction Discs These discs provide the necessary grip between the clutch components, ensuring effective power transmission. Brake Band This component slows down or stops the clutch drum when the machine is not in use, enhancing safety. Guide to Maintenance and Common Parts Replacement

Proper upkeep of your equipment is essential for ensuring optimal performance and longevity. Regular maintenance helps to identify potential issues early and prolongs the lifespan of key components. This guide will provide essential information on routine care and common replacements that may be needed.

Routine Maintenance Tips

Implementing a consistent maintenance schedule can significantly enhance the functionality of your device. Here are some key practices to consider:

- Regularly check and clean the air filter to prevent clogging.

- Inspect the spark plug and replace it if worn or dirty.

- Ensure that the fuel system is clean and free from debris.

- Lubricate moving parts to reduce friction and wear.

- Monitor chain tension and sharpness for efficient operation.

Common Component Replacements

Even with diligent maintenance, certain components will eventually need to be replaced. Here are some common parts that may require attention:

- Fuel filter – a critical component that ensures clean fuel supply.

- Bar and chain – essential for cutting performance; replace when excessively worn.

- Air filter – replace when it becomes clogged to maintain airflow.

- Drive belt – check for signs of wear and replace if frayed.

By following these guidelines, you can keep your equipment in excellent condition and ready for use whenever needed.