Maintaining machinery effectively requires a comprehensive grasp of its individual elements. Each component plays a crucial role in the overall functionality and performance of the tool. A detailed exploration of these elements can significantly enhance operational efficiency and longevity.

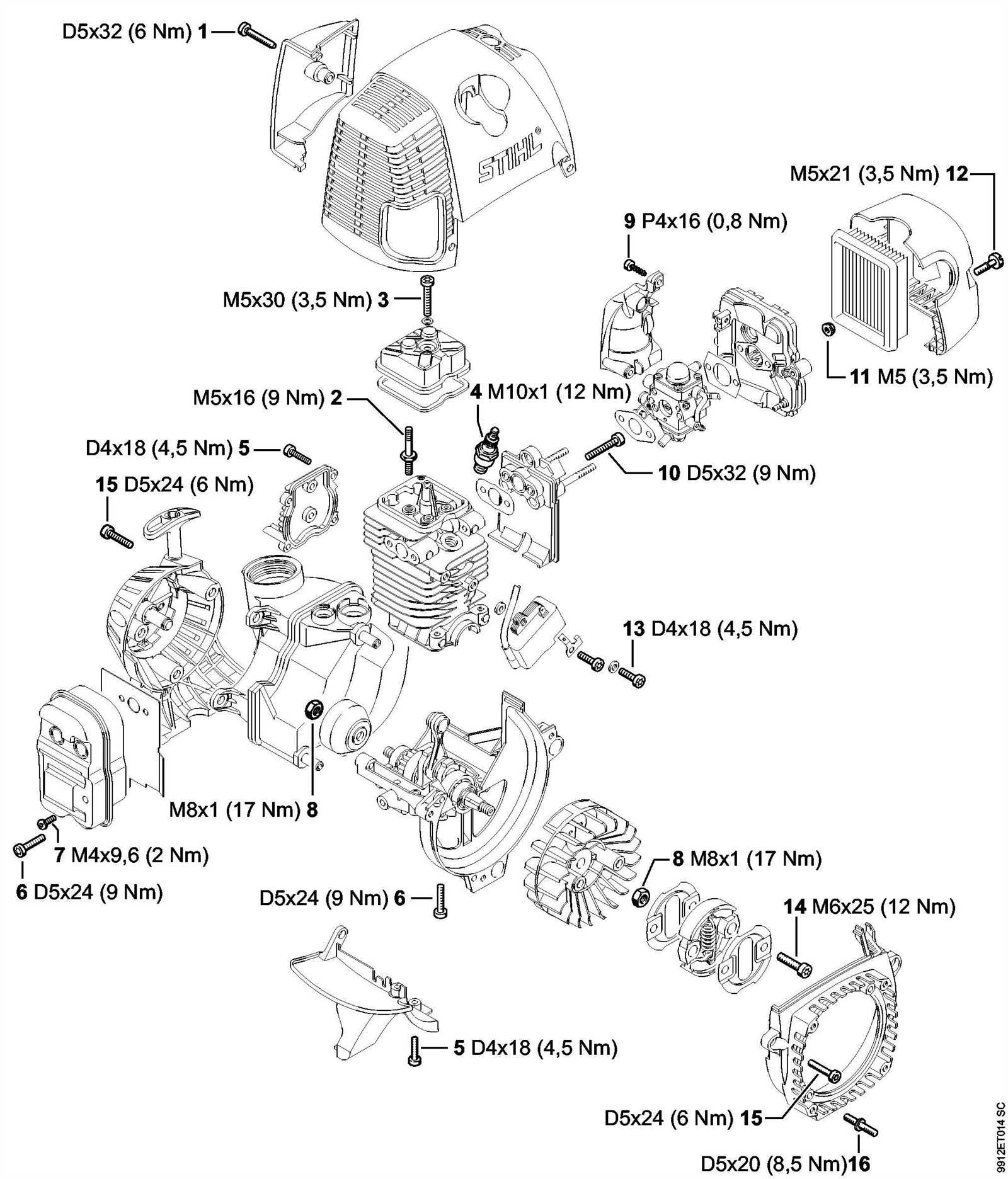

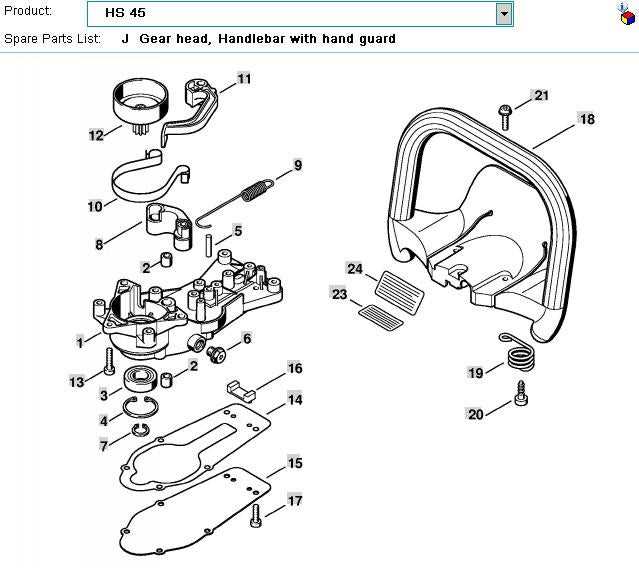

By examining a visual representation of these components, users can better identify potential issues and streamline maintenance procedures. This knowledge not only empowers operators but also fosters a deeper appreciation for the intricacies of their equipment.

Ultimately, understanding how each piece fits together enables more informed decisions regarding repairs and upgrades, ensuring optimal performance for years to come.

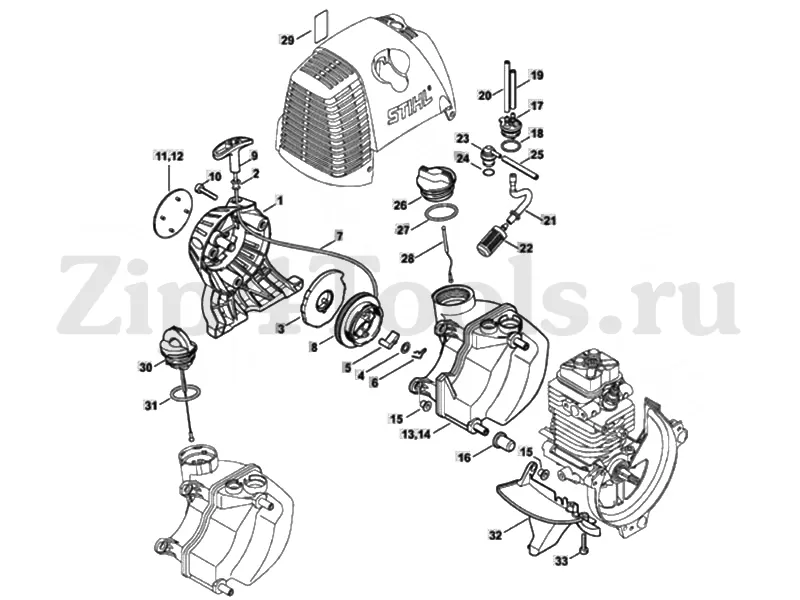

Understanding Stihl FS90 Components

Gaining a comprehensive understanding of the various elements that make up a string trimmer is essential for effective maintenance and operation. Each component plays a crucial role in the functionality and efficiency of the equipment, contributing to its overall performance. By familiarizing oneself with these essential parts, users can ensure proper care and troubleshoot issues more effectively.

Main Assembly Overview

The primary structure consists of the engine and handle system, which work in unison to provide the necessary power and control. The engine generates energy, while the handle allows for maneuverability during use. A thorough comprehension of these elements can enhance the user experience, ensuring both safety and efficiency during operation.

The cutting assembly is integral to the tool’s performance, featuring a line or blade that tackles vegetation. Understanding the differences between various cutting tools can aid in selecting the right option for specific tasks. Regular inspection and maintenance of this mechanism are vital to maintain cutting efficiency and prolong the lifespan of the device.

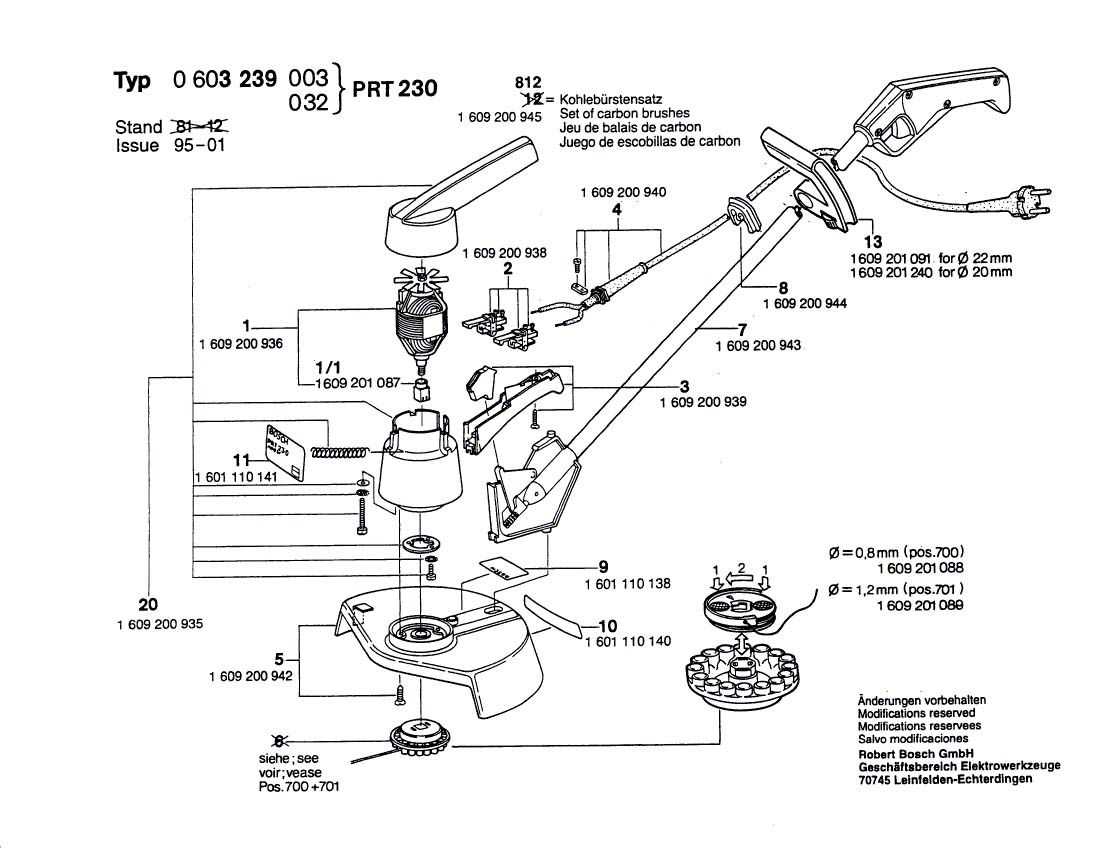

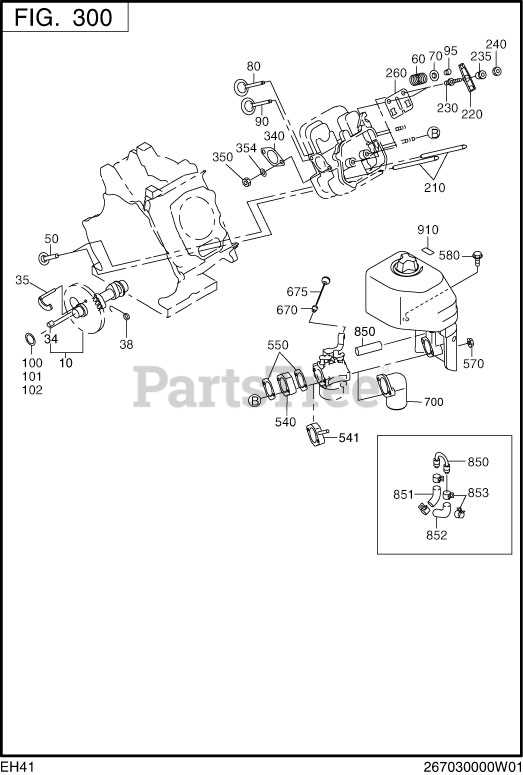

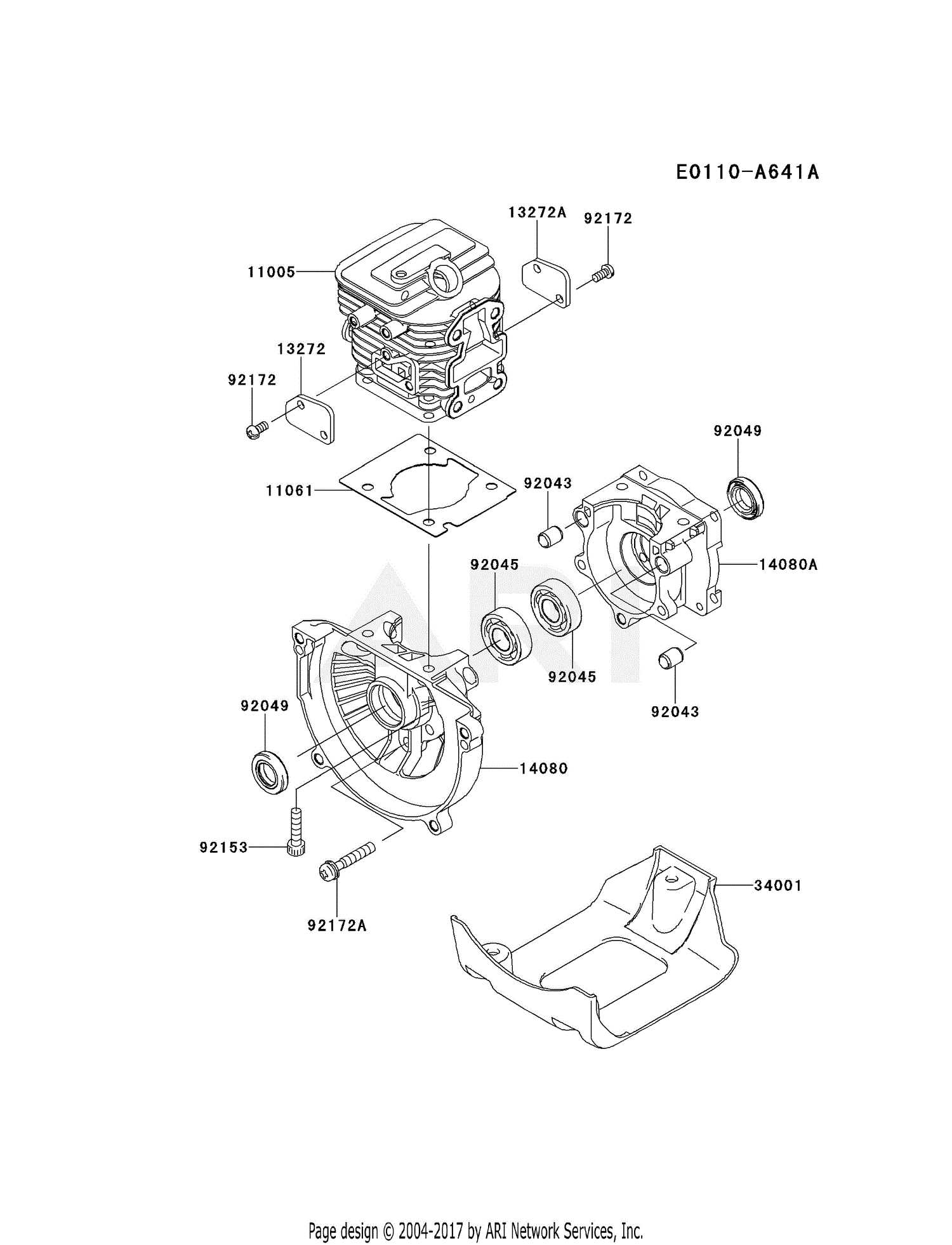

Importance of Parts Diagrams

Understanding the layout and components of any mechanical device is crucial for effective maintenance and repair. Visual representations serve as invaluable tools for users, enabling them to navigate complex assemblies with ease.

Benefits of Visual Representations

- Simplifies troubleshooting processes

- Facilitates accurate reassembly

- Enhances understanding of mechanical relationships

- Reduces risk of errors during repairs

Applications in Maintenance

- Guides users in identifying worn or damaged elements

- Helps in sourcing replacements effectively

- Aids in planning routine upkeep schedules

Common Issues with Stihl FS90

Users often encounter a variety of challenges with their equipment, which can impact performance and efficiency. Understanding these common problems is essential for effective maintenance and troubleshooting.

1. Starting Difficulties: Many operators report issues when trying to start their machines. This can be attributed to fuel quality, spark plug malfunctions, or air filter blockages.

2. Overheating: Overheating may occur due to improper lubrication or clogged cooling fins, leading to engine damage if not addressed promptly.

3. Vibration Problems: Excessive vibrations can indicate worn parts or imbalances in the cutting system, which can affect handling and safety.

4. Poor Cutting Performance: If the tool struggles to cut effectively, this may be due to dull blades or incorrect settings that need adjustment.

5. Fuel Leaks: Fuel leaks can arise from damaged lines or connections, posing safety hazards and requiring immediate repair.

How to Read Parts Diagrams

Understanding visual representations of components is crucial for effective maintenance and repairs. These illustrations provide detailed insights into the relationships and placements of various elements within a machine.

Identifying Key Sections

Begin by familiarizing yourself with the main sections of the illustration. Typically, you will find:

- Labels: Indicate specific parts or assemblies.

- Numbers: Correspond to a list for easy reference.

- Shapes: Represent different types of components.

Utilizing the Legend

A legend or key is often included to clarify symbols and notations. Pay close attention to:

- Symbols that represent particular features.

- Color codes that might indicate compatibility or function.

- Notes or tips that enhance understanding.

Maintenance Tips for Stihl FS90

Proper upkeep of your equipment is essential for ensuring longevity and optimal performance. Regular maintenance not only enhances functionality but also helps in preventing costly repairs in the long run. Here are some key strategies to keep your machine running smoothly.

Regular Cleaning

After each use, it’s important to clean the exterior and any accessible parts. This prevents dirt and debris from accumulating, which can lead to mechanical issues. Use a soft brush or cloth to remove residue, paying special attention to air intake and cooling vents.

Inspection and Replacement

Routine inspections are crucial. Check the cutting tool for wear and replace it if necessary. Additionally, ensure that all fasteners are secure and that the fuel lines are free of leaks. Regularly changing the air filter will enhance air circulation, contributing to efficient engine performance. Always consult the manual for specific recommendations on intervals and procedures.

Finding Genuine Replacement Parts

Ensuring the longevity and efficiency of your equipment hinges on the quality of the components you choose. Opting for authentic items not only guarantees compatibility but also enhances performance and reliability. Here’s how to navigate the selection process effectively.

Identifying Quality Components

- Check for branding and labeling that signifies authenticity.

- Look for reviews or testimonials from other users.

- Examine the material and construction quality.

Where to Purchase

- Official dealers and authorized retailers.

- Reputable online marketplaces known for their strict quality control.

- Manufacturer websites, which often provide direct purchasing options.

Tools Needed for Assembly

Assembling equipment requires specific instruments to ensure that every component fits perfectly and functions correctly. Having the right tools not only simplifies the process but also enhances safety and efficiency during the task. Below is a list of essential items that are typically needed for a successful assembly.

Essential Instruments

- Wrenches: Various sizes to accommodate different bolts.

- Screwdrivers: Both flat-head and Phillips types for versatile use.

- Pliers: For gripping and twisting components securely.

- Torque wrench: To apply the correct amount of force to fasteners.

- Hex keys: Necessary for screws with hexagonal sockets.

Additional Tools

- Measuring tape: For precise measurements during assembly.

- Level: To ensure that assembled items are properly aligned.

- Safety goggles: To protect your eyes from debris.

- Gloves: To maintain a good grip and protect your hands.

Gathering these tools beforehand will streamline the assembly process and contribute to a successful outcome.

Frequently Asked Questions

This section aims to address common inquiries related to maintenance and components of outdoor power equipment. Here, you will find helpful answers that can guide users in troubleshooting and understanding their machinery better.

What should I do if my equipment won’t start?

Check the fuel level, ensure the spark plug is in good condition, and examine the battery if applicable. Regular maintenance can prevent many starting issues.

How often should I replace the cutting line?

The cutting line should be replaced when it becomes frayed or worn. Depending on usage, this could be every few weeks or after several hours of operation.

Where can I find a list of compatible accessories?

Consult the manufacturer’s website or authorized dealers for detailed information on compatible add-ons that enhance performance and efficiency.

What type of fuel is recommended for optimal performance?

Using the recommended fuel type, usually a specific mixture of gasoline and oil, ensures maximum efficiency and reduces engine wear.

How can I ensure my machine lasts longer?

Regular maintenance, including cleaning, lubrication, and timely replacement of worn parts, will significantly extend the lifespan of your equipment.

Resources for Stihl Owners

For enthusiasts of outdoor power equipment, accessing reliable information and resources is essential for maintenance and optimization. Understanding the components and tools available can enhance performance and prolong the life of your equipment.

Online Forums and Communities

Engaging with online communities can provide invaluable insights. Users often share tips, troubleshooting advice, and experiences that can help others in similar situations. Websites and social media groups dedicated to outdoor tools are great places to ask questions and share knowledge.

Manufacturer Support and Manuals

Consulting official support from manufacturers is crucial. Comprehensive manuals and guides often contain detailed information on care and maintenance. Additionally, customer service can assist with specific inquiries, ensuring you have the right resources at your fingertips.