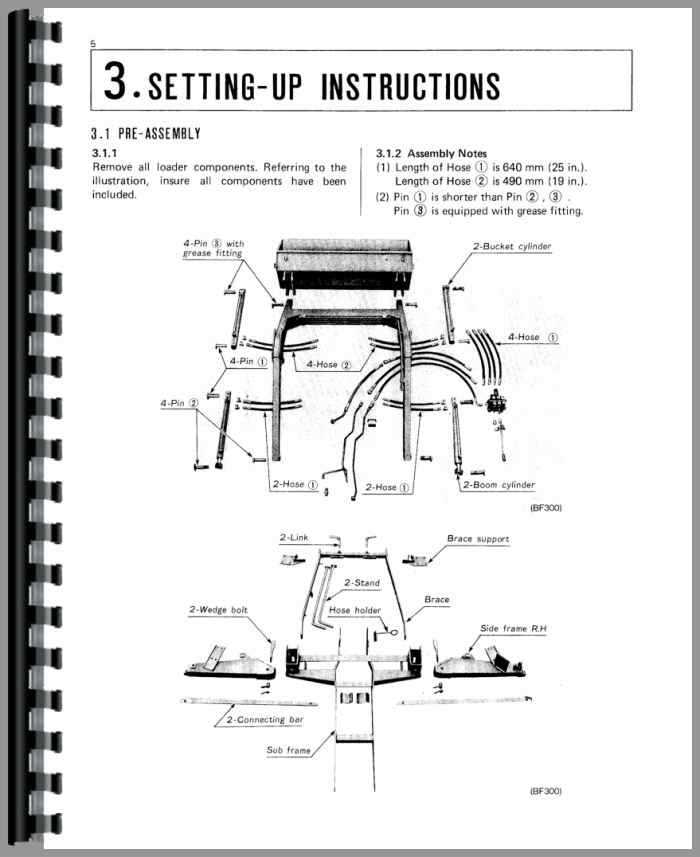

When it comes to machinery maintenance and repair, having a clear understanding of the component layout is essential. This knowledge not only facilitates efficient troubleshooting but also empowers operators to perform effective upgrades and modifications. A comprehensive representation of the assembly can be invaluable for both novice and experienced technicians alike.

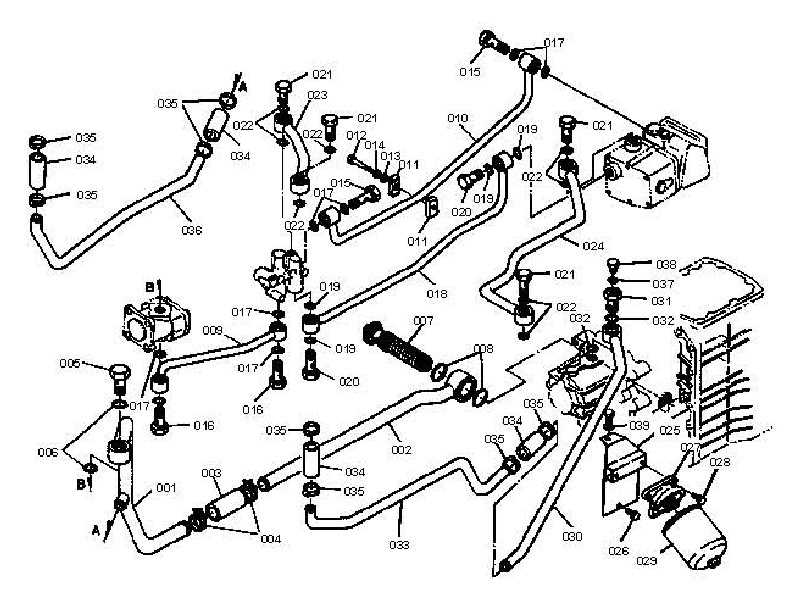

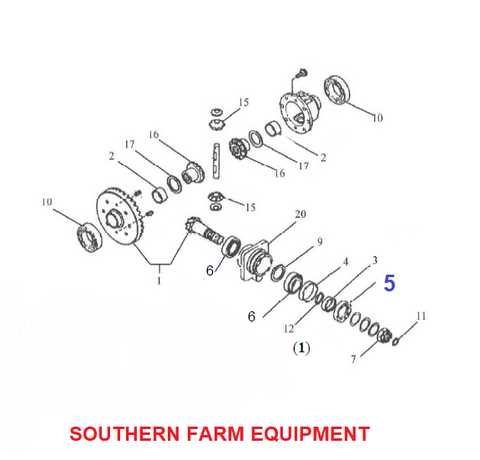

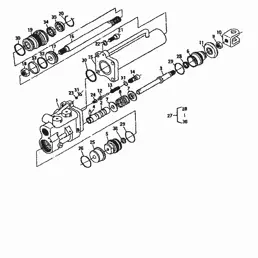

Visual aids play a crucial role in this process, offering detailed insights into how various elements interact within the system. These illustrations can simplify complex mechanisms, making it easier to identify individual components and their respective functions. Moreover, they serve as a reliable reference point during disassembly and reassembly tasks.

In this discussion, we will explore the significance of such visual representations in enhancing maintenance practices. By breaking down intricate systems into manageable parts, operators can better appreciate the intricacies of their machinery, leading to improved performance and longevity. Understanding these layouts ultimately contributes to a more efficient and informed approach to machinery care.

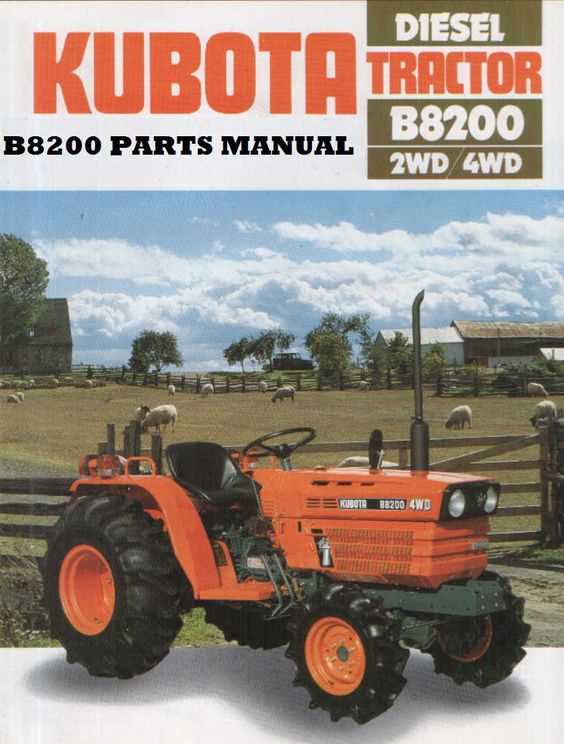

Kubota B8200 Overview

This segment provides an insight into a specific compact utility tractor known for its versatility and robust performance. Designed to cater to various agricultural and landscaping tasks, it combines efficiency with ease of use, making it a popular choice among enthusiasts and professionals alike.

Key Features

Equipped with a powerful engine, this machine offers remarkable reliability and torque. Its compact size allows for maneuverability in tight spaces, while the variety of available attachments enhances its functionality. Whether it’s mowing, plowing, or hauling, it stands out in numerous applications.

Performance and Usability

Featuring an intuitive control layout, operators can easily navigate and utilize the tractor’s capabilities. Its durable construction ensures longevity, even under challenging conditions. Additionally, regular maintenance can further extend its lifespan, making it a valuable asset for anyone in need of dependable equipment.

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools, providing clarity and organization when dealing with intricate assemblies.

- Enhanced Clarity: Diagrams simplify complex structures, making it easier to identify each element.

- Efficient Troubleshooting: Visual aids help quickly pinpoint issues, streamlining the repair process.

- Improved Communication: Clear illustrations facilitate better dialogue among technicians and operators.

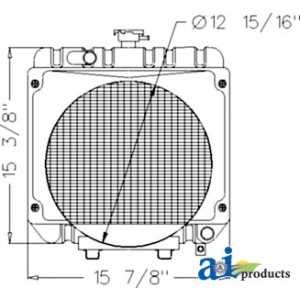

- Streamlined Ordering: Knowing exact specifications aids in procuring the right components without errors.

In summary, these visual tools play a vital role in ensuring smooth operations and longevity of equipment.

Key Components of Kubota B8200

This section delves into the essential elements that contribute to the overall functionality and efficiency of the machinery. Understanding these components not only aids in maintenance but also enhances performance and longevity.

Engine System

The heart of the machine is its engine system, which plays a crucial role in powering all operations. This component is designed for durability and reliability, ensuring optimal performance under various conditions. Regular maintenance of this system is vital for achieving maximum output and efficiency.

Transmission and Drive Components

Another significant aspect is the transmission and drive components, which facilitate the transfer of power from the engine to the wheels. These elements are engineered to provide smooth gear shifts and optimal traction. Proper care and timely repairs can prevent potential issues, thus extending the lifespan of the machinery.

Understanding these key components is essential for operators and technicians alike, as it enables them to identify and address any issues that may arise during operation. Proactive maintenance can significantly enhance the overall performance and reliability of the equipment.

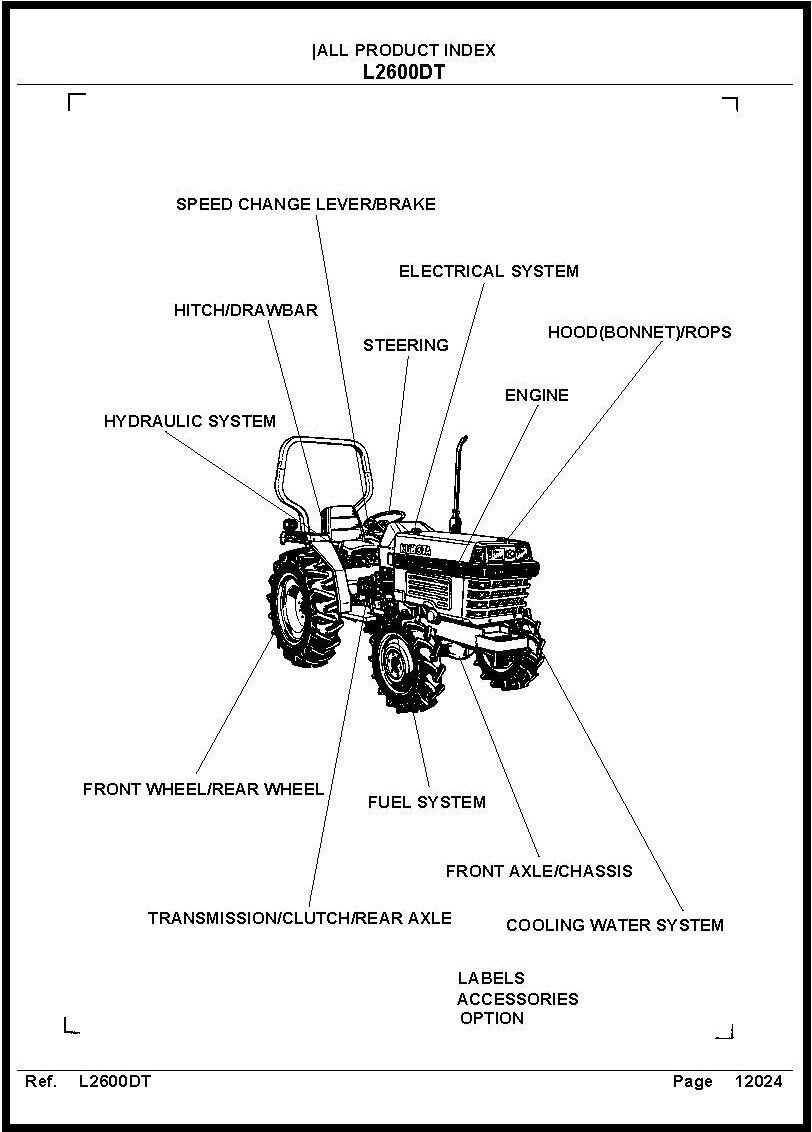

Understanding the Parts Catalog

The catalog serves as an essential resource for identifying and locating various components necessary for maintenance and repairs. It provides a comprehensive overview of individual items, allowing users to find the exact specifications needed for their machinery. By familiarizing oneself with this catalog, owners can enhance the efficiency of their equipment and ensure proper functionality.

Navigating the Catalog

To effectively use the catalog, it’s important to understand its layout and structure. Typically, components are organized by categories, which makes it easier to search for specific items. Each entry often includes part numbers, descriptions, and sometimes illustrations, aiding in the identification process. This systematic approach helps users avoid confusion and streamlines the procurement of necessary items.

Importance of Accurate Information

Having access to precise information is vital for successful repairs and maintenance. Accurate details help prevent costly mistakes and ensure that the right components are acquired. By referring to the catalog, users can compare different items and make informed decisions, ultimately extending the lifespan of their equipment and enhancing overall performance.

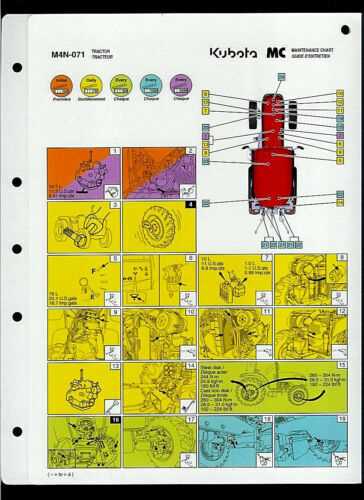

Common Repairs and Maintenance Tips

Regular upkeep and timely repairs are essential for ensuring the longevity and optimal performance of any machinery. Understanding basic maintenance techniques can prevent costly breakdowns and extend the life of your equipment. This section will explore key practices that can help you keep your machine running smoothly.

Routine Checks

Conducting routine inspections is crucial. Regularly check fluid levels, including oil, coolant, and fuel. Look for any leaks or unusual wear on belts and hoses. Keeping an eye on tire pressure and tread can also prevent accidents and improve efficiency.

Scheduled Servicing

Adhering to a scheduled service plan is vital. Change the oil and filters at recommended intervals to maintain engine health. Greasing moving parts helps reduce friction and wear. Additionally, clean air filters to ensure proper airflow, enhancing performance and fuel efficiency.

Where to Find Replacement Parts

Finding suitable components for machinery can be a daunting task. However, with the right resources and strategies, you can efficiently locate the items you need to keep your equipment running smoothly.

Online Retailers

One of the most convenient ways to source components is through online marketplaces. These platforms often provide a wide selection and competitive pricing. Here are some options:

- Dedicated machinery parts websites

- General e-commerce platforms

- Manufacturer’s official websites

Local Dealers and Distributors

In-person visits to local suppliers can also yield positive results. Building relationships with dealers may offer benefits such as:

- Expert advice on compatible items

- Access to exclusive deals and promotions

- Immediate availability without shipping delays

Utilizing these resources can significantly enhance your ability to find the right components for your machinery needs.

Using Diagrams for Troubleshooting

Visual representations play a crucial role in diagnosing issues effectively. They provide a clear overview of components and their interconnections, simplifying the identification of potential problems. By following these illustrations, users can systematically approach repairs and maintenance tasks.

| Step | Description |

|---|---|

| 1 | Identify the problem area by examining the visual guide. |

| 2 | Trace connections and locate possible faults in the system. |

| 3 | Refer to labeled components to understand functionality. |

| 4 | Make informed decisions on repairs based on the findings. |

Benefits of Genuine Kubota Parts

Using authentic components for machinery ensures optimal performance and longevity. These original pieces are engineered to meet specific standards, providing a seamless fit and function that enhances overall efficiency.

Quality Assurance: Genuine items undergo rigorous testing to guarantee durability and reliability, reducing the likelihood of unexpected failures.

Enhanced Performance: Authentic components work harmoniously with your equipment, ensuring peak operational capabilities and minimizing maintenance issues.

Warranty Protection: Utilizing original parts often helps maintain warranty coverage, safeguarding your investment against potential repair costs.

Long-Term Savings: While initial costs may be higher, the longevity and efficiency of genuine components can lead to significant savings in the long run.

Investing in authentic components is a wise choice for those seeking to maximize the lifespan and performance of their machinery.