Modern farming tools play a crucial role in efficient agricultural operations, helping to increase productivity and streamline essential tasks. A detailed understanding of how various elements of these machines connect and function can significantly enhance their performance and ease of maintenance. This section focuses on providing a general overview of these connections, enabling better familiarity with the equipment without diving into complex technical details.

When working with these machines, having a clear layout of their key elements ensures that users can efficiently identify and address any issues that may arise during their operation. Recognizing how the various components fit together helps to maintain the equipment in top condition and optimize its overall functionality. This is particularly beneficial when conducting repairs or routine inspections.

By exploring the arrangement of these components, farmers and operators can deepen their understanding of their equipment, leading to more informed decisions regarding care, upgrades, and replacements. Ultimately, this knowledge supports smoother and more effective farming practices.

Overview of Agricultural Equipment Components

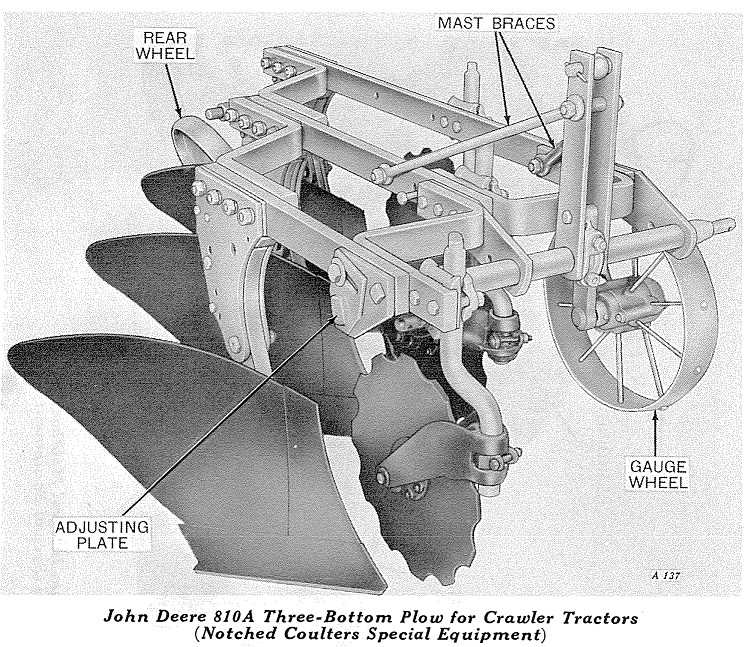

Agricultural machinery is composed of various mechanical elements designed to improve efficiency in farming operations. Each piece of equipment serves a specific role, enabling tasks such as soil cultivation, planting, and harvesting to be performed with greater precision and reduced labor. The structure and functionality of these machines rely on numerous components that must work in harmony to ensure optimal performance.

Key Functional Systems

- Engine systems provide the necessary power for a wide range of farming tools.

- Hydraulic mechanisms allow for smooth movement and control of attachments.

- Transmission parts ensure the transfer of energy to different machinery functions.

Common Mechanical Elements

- Frame structures offer stability and support for heavy-duty use in the field.

- Control systems allow operators to manage the precision and operation of the machinery.

- Cutting and tilling tools play a critical role in preparing the soil for planting.

- Standard Blades: These are versatile and often used for general-purpose work, offering a balance between durability and effectiveness.

- Serrated Blades: With jagged edges, these blades are ideal for cutting through tough materials or dense soil, providing extra grip during operation.

- Flat Blades: Known for their smooth edges, flat blades are perfect for tasks requiring clean, precise cuts, often used in soft soil conditions.

- Curved Blades: These blades enhance lifting and turning capabilities, making them suitable for tasks where material needs to be moved or reshaped.

- Pin-style connectors for heavy-duty towing

- Ball-and-socket joints offering flexibility

- Clevis hitches for enhanced durability

- Improved weight distribution for balanced towing

- Reduced strain on machinery with efficient couplings

- Enhanced safety through secure locking systems

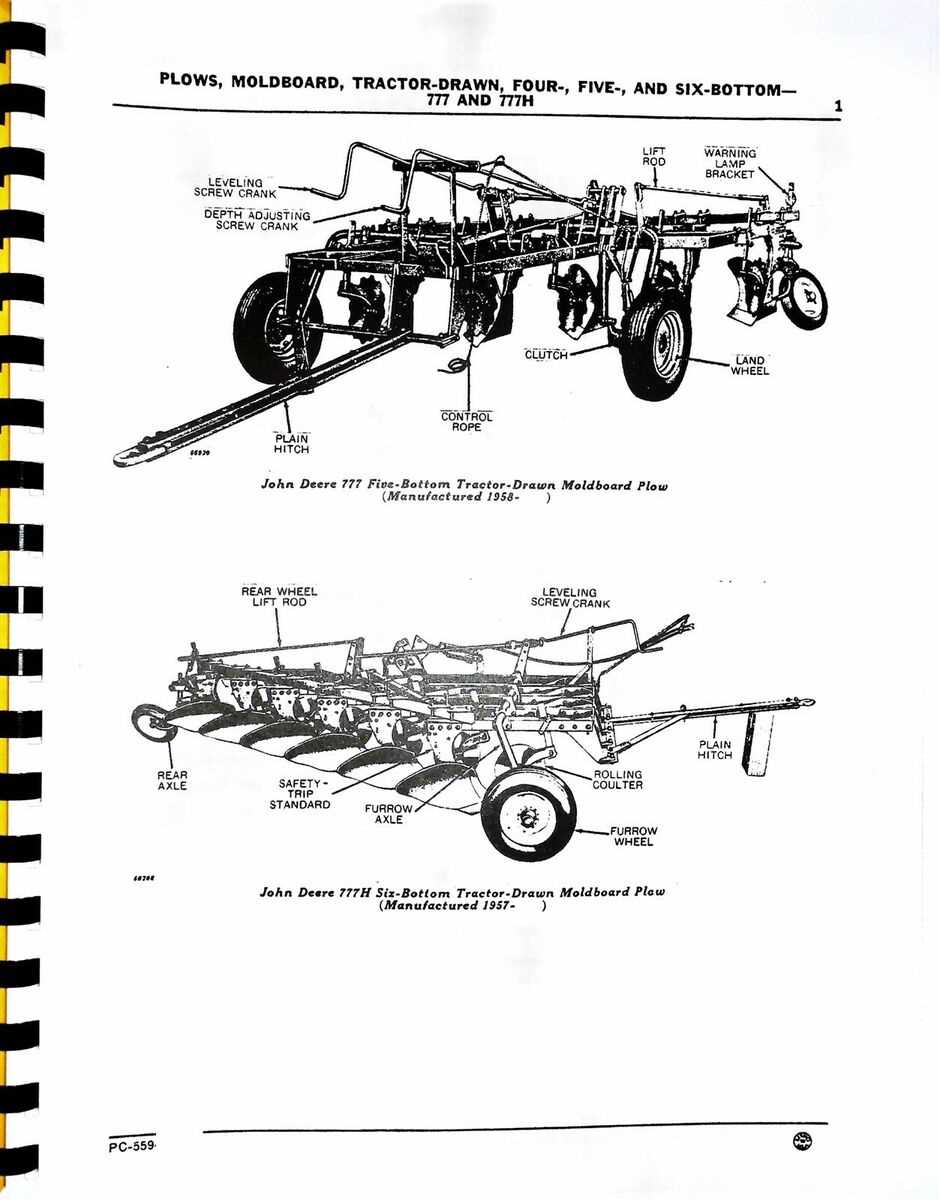

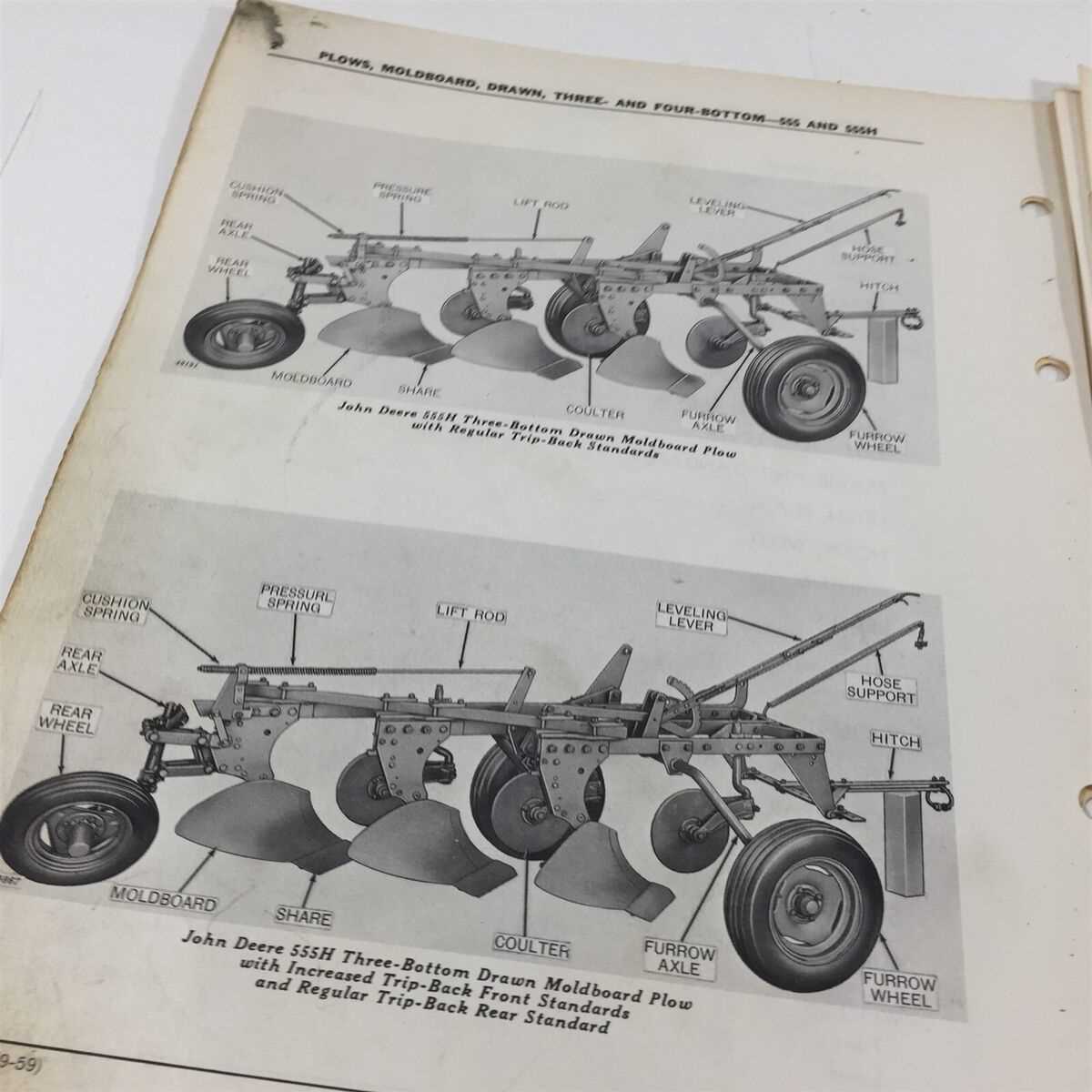

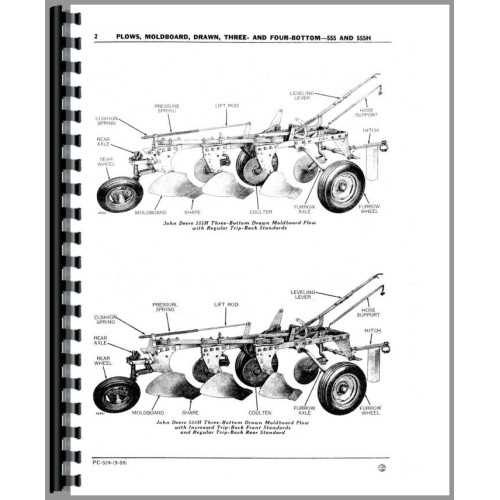

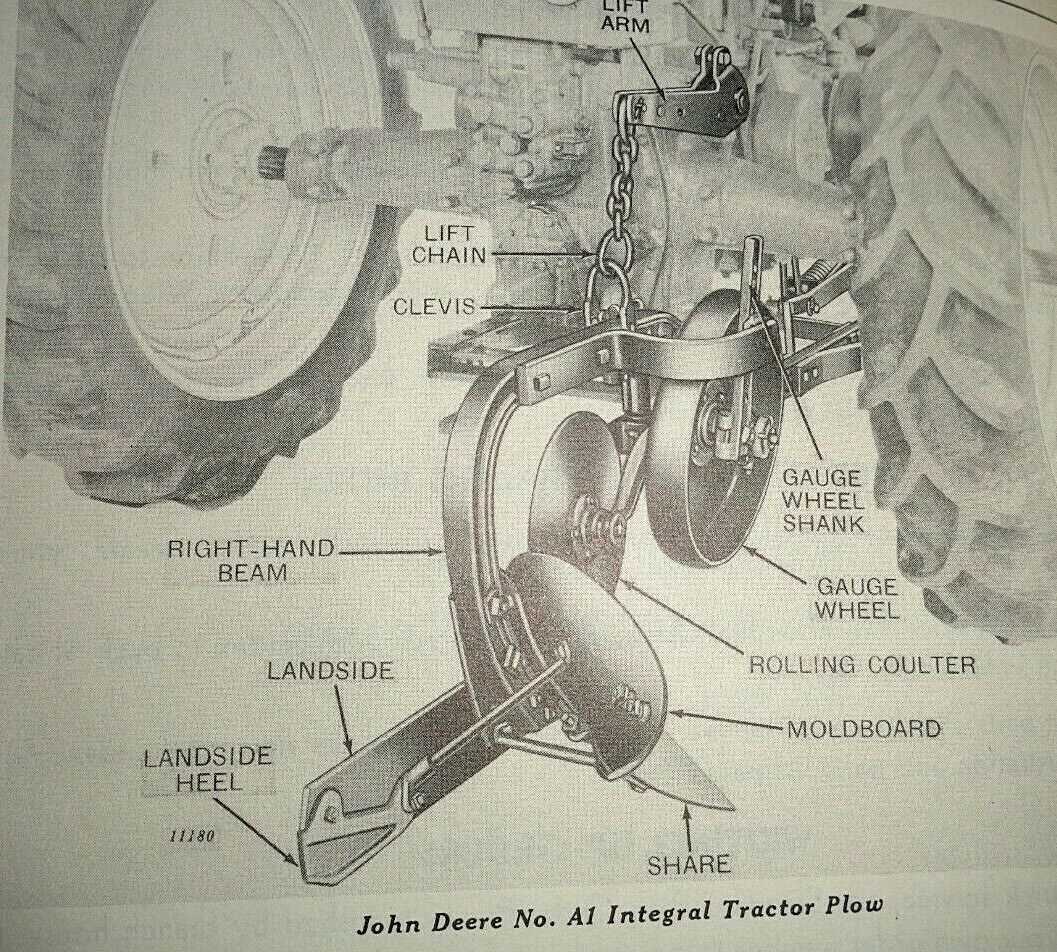

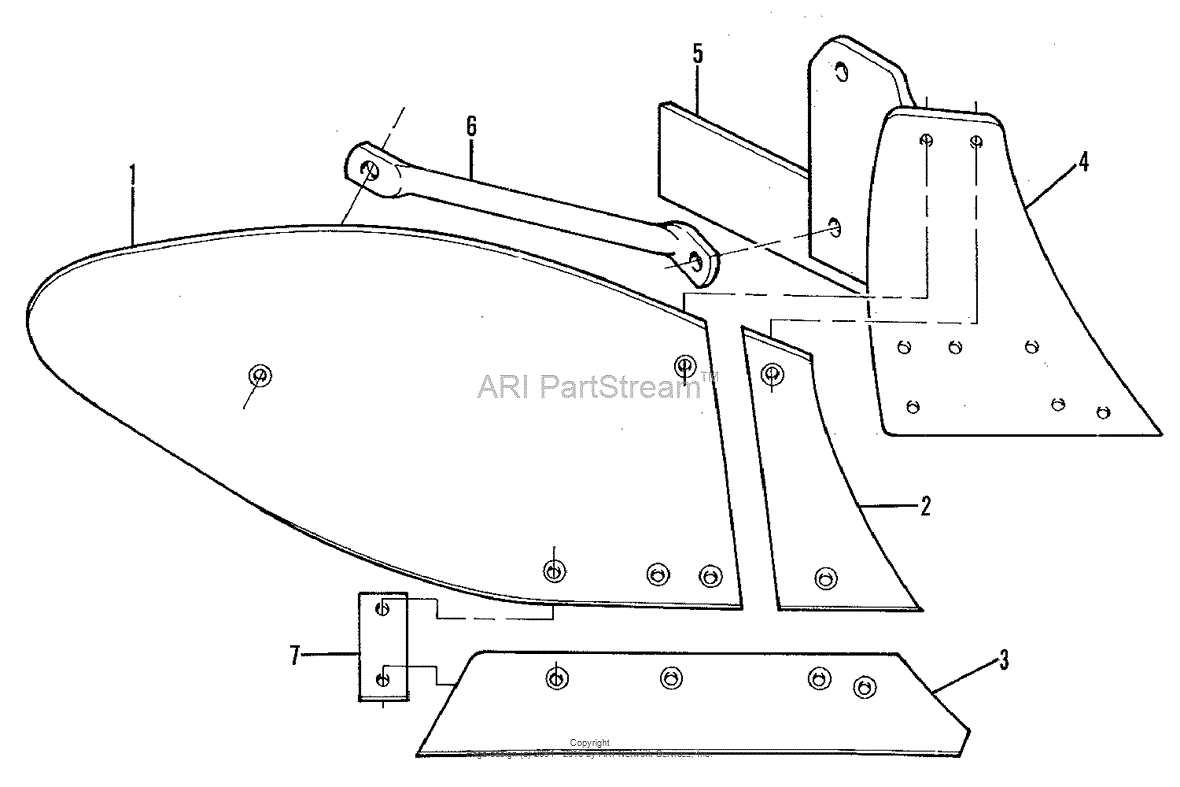

Main Parts of a Traditional Plow

The structure of traditional farming tools has remained relatively consistent throughout the years, designed to efficiently break and turn over soil. These tools consist of several essential components that work together to prepare the ground for planting. Understanding these key elements helps in maintaining and optimizing the tool’s performance.

The Blade

The cutting edge of the tool is crucial for slicing through the earth. This sharp, durable component is responsible for making the initial incision into the soil, allowing for further manipulation by the rest of the mechanism.

The Frame

The sturdy backbone supports all other parts and ensures proper alignment during operation. Made from strong materials, the frame provides the necessary stability and helps bear the load during usage.

Proper maintenance of these components is essential for the longevity and efficiency of the tool, ensuring it can handle various types of soil and farming conditions.

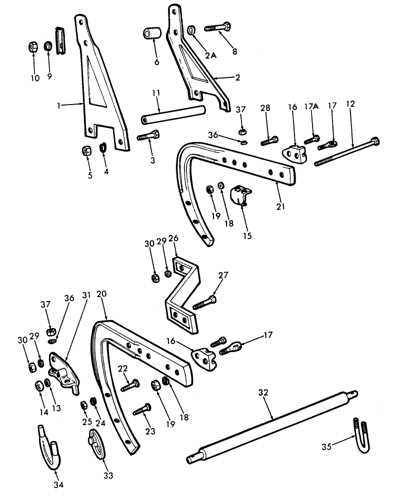

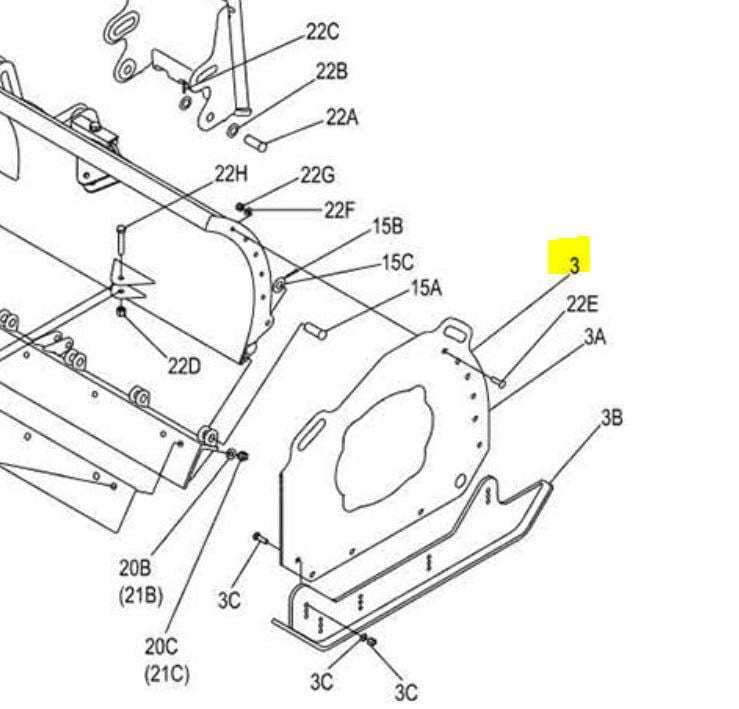

Identifying Key Sections of the Frame

Understanding the layout of the structural components is essential for maintaining and optimizing the overall performance of the equipment. The framework acts as the backbone, connecting different functional elements and ensuring stability during operation. Recognizing these critical sections helps in both troubleshooting and ensuring proper alignment.

Primary Support Structures

The main support areas consist of reinforced beams that provide the necessary strength to handle heavy loads. These beams are typically located at the central part of the framework and extend to the outer edges, forming the core foundation of the equipment. Proper maintenance of these sections is crucial for durability and efficient performance.

Attachment Points and Connections

Various attachment points serve to connect additional components or accessories. These points are often reinforced to handle stress and wear. Ensuring that these connections remain secure and free of damage is important for smooth operation and safety.

| Section | Description | |||||||

|---|---|---|---|---|---|---|---|---|

Main

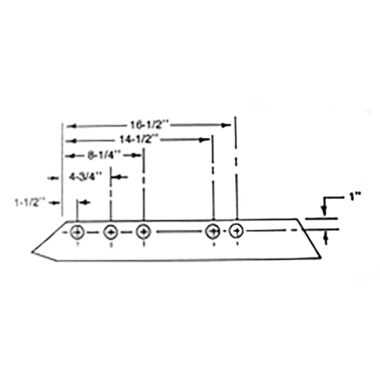

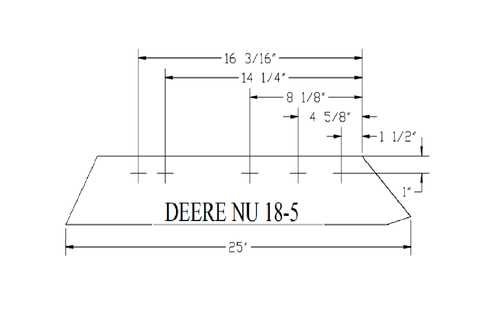

Understanding Blade Types and Their Uses

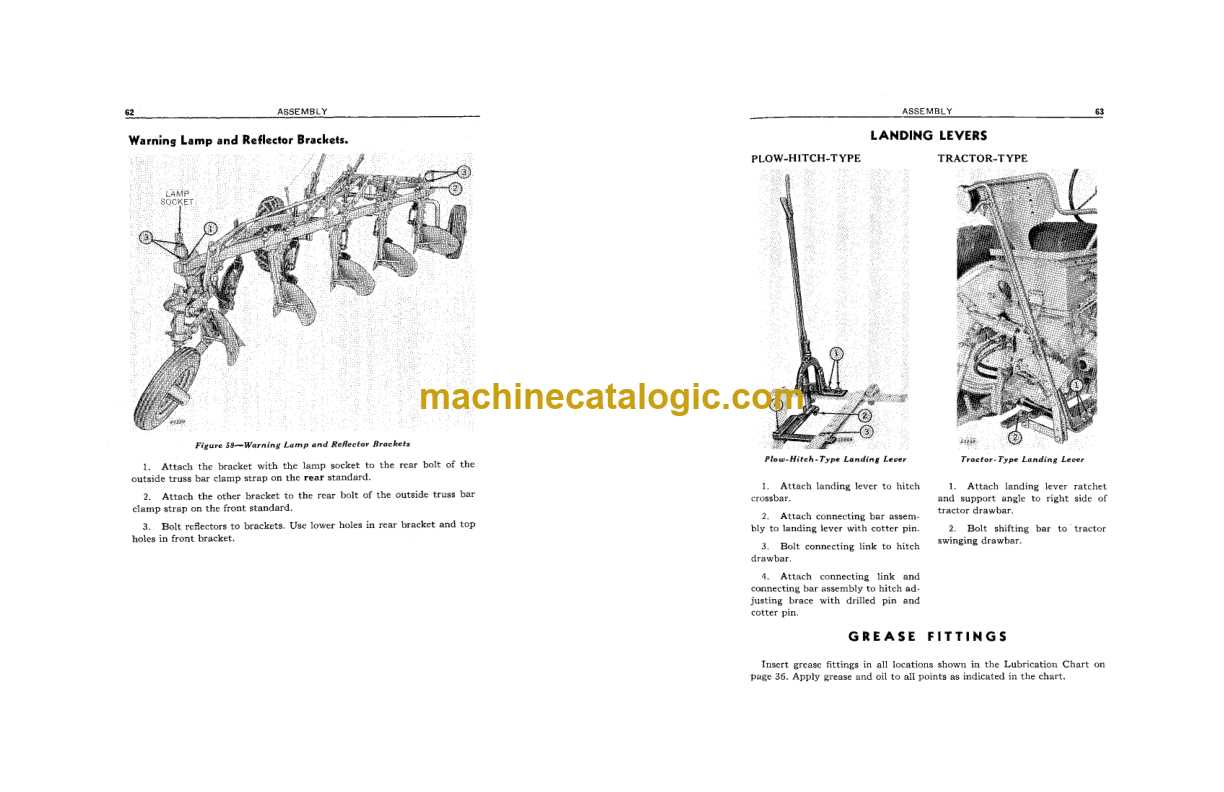

Blades come in various forms, each designed to handle specific tasks with efficiency and precision. Choosing the right type of blade can significantly impact the performance and durability of your equipment, making it crucial to understand the differences between them. Understanding the specific functions of each type ensures you can choose the most appropriate blade for the task at hand, enhancing both efficiency and longevity of Hitching Mechanisms for Efficient TowingConnecting a vehicle to towing equipment requires the right mechanism to ensure safety, stability, and efficiency. Various coupling systems are designed to handle different loads and provide seamless integration between the towing machine and the equipment being hauled. Proper alignment, secure latching, and ease of use are critical in achieving smooth operations, regardless of the terrain or weight. Key Types of Hitching Systems

Advantages of Optimized Hitching

By selecting the appropriate hitching mechanism and maintaining it regularly, operators can ensure consistent performance and avoid common issues related to misalignment or excessive Maintenance Tips for Plow Attachment PointsEnsuring the longevity and efficiency of agricultural implements requires diligent attention to the connection points. Regular inspection and maintenance of these crucial areas help in preventing wear and tear, thereby enhancing overall performance. Proper care not only extends the lifespan of equipment but also ensures optimal functionality during use. Regular InspectionsConducting routine checks on attachment points is essential. Look for signs of damage, rust, or any misalignment that could affect the performance of the implement. Early detection of issues allows for timely repairs, reducing the risk of more significant problems in the future. Lubrication and Cleaning

Keeping the connection points well-lubricated minimizes friction and wear. Use appropriate lubricants for the specific materials involved, and ensure that the surfaces are clean before applying any products. Regular cleaning helps prevent the accumulation of debris that could compromise the integrity of the connections.

Adjusting Depth Control for Better Performance

Achieving optimal results in tillage operations requires precise management of soil penetration depth. Properly setting this control can significantly enhance the effectiveness of agricultural tasks, ensuring uniform soil disturbance and maximizing crop yield potential. Understanding the nuances of depth adjustment is essential for any operator looking to improve performance. Fine-tuning the depth control involves several factors, including soil type, moisture content, and the specific requirements of the crop being cultivated. Adjustments should be made gradually, allowing the operator to monitor the changes in soil interaction and overall machine behavior. Consistent evaluation during operations will help in identifying the ideal settings for various conditions. Additionally, regular maintenance of the depth control mechanism is crucial. Ensuring that all components are functioning correctly will prevent unexpected failures and allow for smoother operation. By prioritizing these adjustments, operators can enhance the efficiency of their tillage implements and contribute to more productive farming practices. Replacing and Upgrading Worn ComponentsOver time, certain elements of agricultural machinery can experience wear and tear, affecting their efficiency and performance. Addressing these worn components is essential to maintain optimal functionality and prolong the lifespan of the equipment. Regular inspections and timely replacements can help ensure that the machinery operates smoothly and effectively, reducing the risk of breakdowns during crucial farming tasks. Identifying Worn Components

Recognizing signs of deterioration in equipment is the first step toward maintaining its performance. Look for visible wear, unusual noises, or decreased efficiency during operation. Components such as blades, connectors, and attachment points may show signs of fatigue and should be evaluated for replacement. Regular maintenance checks will aid in identifying these issues early, preventing further complications. Choosing Quality Replacements

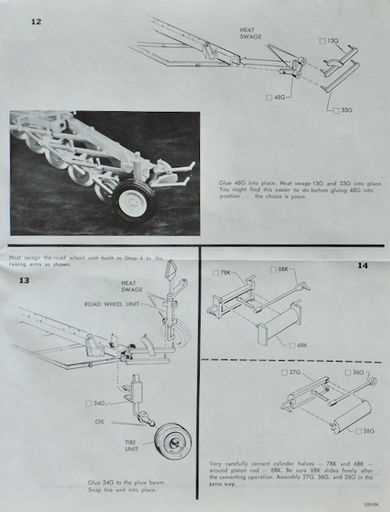

When selecting new components, prioritize quality and compatibility. Investing in high-quality replacements ensures durability and can significantly enhance the overall performance of the machinery. Consider consulting with knowledgeable suppliers to find options that meet the specific requirements of your equipment. Upgrading to improved versions of components can also provide additional benefits, such as increased efficiency or reduced maintenance needs. How Diagrams Assist in Equipment Assembly

Visual representations play a crucial role in the assembly of machinery, offering a clear roadmap for users. They simplify complex processes, breaking them down into manageable steps that enhance understanding and efficiency. This approach allows operators to visualize the components and their interconnections, ensuring accurate assembly. One of the main advantages of using these visual aids is the reduction of errors during the assembly process. When individuals can see how various elements fit together, the likelihood of misalignment or incorrect installation diminishes significantly. This leads to improved performance and longevity of the machinery. Moreover, these visual tools facilitate quicker learning for new users. By following the graphical instructions, even those with limited experience can grasp the assembly procedure effectively. This accessibility helps foster a more knowledgeable workforce, ultimately contributing to enhanced operational efficiency. |