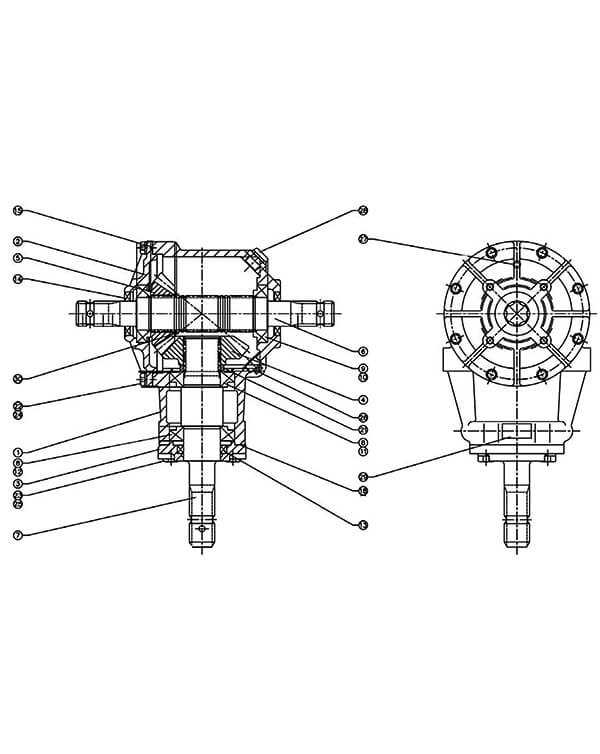

When it comes to mechanical systems, understanding how each element is arranged and functions together is key to ensuring smooth operation. A clear layout of every component can make it easier to identify any issues that might arise and aid in regular maintenance. Having a visual reference for how each part connects within the system can be incredibly valuable for both beginners and experienced users.

Each section of the system plays a specific role, and knowing the placement and function of individual elements allows for more effective troubleshooting. This approach also simplifies the replacement of any worn or damaged elements, ensuring the system remains in optimal condition. A detailed layout acts as a guide, offering a clear view of how the entire mechanism works together as a cohesive unit.

Understanding Key Components of the Predator Auger

To ensure smooth operation and longevity, it is crucial to be familiar with the major elements of this powerful tool. Each section plays a specific role in its overall functionality, contributing to its ability to perform demanding tasks effectively. Let’s explore the key elements that make this equipment robust and reliable.

Core Structural Elements

- Engine Unit: The central power source that drives the entire mechanism. This component delivers the necessary energy to perform intensive tasks.

- Transmission System: Responsible for transferring power from the engine to the rotating mechanism. It ensures seamless movement and controlled performance.

Functional Components

- Cutting Assembly: A vital part that directly engages with the material, facilitating efficient operation.

- Support Frame: This provides stability, keeping the equipment balanced and secure during use.

How to Identify Wear and Tear

Over time, mechanical tools and equipment are subject to natural deterioration due to constant use. Recognizing the early signs of degradation is essential for ensuring longevity and performance. This section will help you understand the most common symptoms of aging components, enabling timely maintenance and repair.

Signs of Mechanical Degradation

One of the first indicators is often a decline in operational efficiency. Tools may begin to function with less power or precision, signaling that internal components are wearing out. Additionally, unusual noises during operation, such as grinding or squeaking, often point to friction between parts that are no longer well-lubricated or aligned.

Visible Deterioration

Physical inspection can reveal various signs of wear. Look for cracks, rust, or excessive dirt accumulation on critical parts. Pay attention to areas that show discoloration, as it may indicate overheating or stress. Regularly check for loosened or warped components, as these can affect the overall stability and performance.

| Symptom | Potential Cause | Solution | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Proper Maintenance for Longevity

Regular upkeep is essential to ensure that your equipment remains reliable and performs well over time. Consistent care not only extends the lifespan of the machinery but also helps avoid unexpected malfunctions during use. By following simple preventive measures, you can maintain optimal functionality and save on costly repairs. Cleaning and LubricationAfter each use, it’s important to thoroughly clean the tool to remove dirt, debris, and residue. Proper lubrication of moving parts is crucial to reduce friction and wear. Make sure to use the appropriate type of lubricant as recommended for smooth operation and to protect components from rust and corrosion. Inspection and ReplacementRoutinely inspect all critical components for any signs of wear or damage. Tighten loose bolts, check for cracks, and replace worn-out parts before they lead to bigger issues. Staying proactive with part replacement ensures that the tool continues to function safely and effectively for year Common Replacement Parts and Their FunctionsWhen maintaining outdoor equipment, it’s crucial to know which components are most likely to wear out and how they contribute to the overall function. Regular maintenance and timely replacements ensure the longevity and reliability of the machine. Engine ComponentsThe engine is the heart of the machine, and several elements within it may need replacing over time. For example, spark plugs are essential for ignition, while air filters ensure clean air flows into the engine, improving performance. Keeping these in good condition helps the motor run smoothly and efficiently. Blades and Cutting Elements

Cutting edges or blades are prone to wear due to constant contact with hard surfaces. These components are critical for effective operation, as they are responsible for digging or cutting into tough materials. Replacing dull or damaged blades ensures precision and reduces strain on the motor. Step-by-Step Assembly GuideIn this section, we will walk through a detailed process of putting together the mechanical tool from start to finish. By carefully following these instructions, you’ll ensure that the equipment is correctly and securely assembled for optimal functionality. The steps below are designed to guide you efficiently through each phase of construction, with an emphasis on accuracy and safety. Begin by laying out all necessary components on a flat surface. Organizing your materials will help you easily locate each part as you move through the assembly process. Start by attaching the main frame to the base structure using the provided bolts, ensuring that all connections are secure. Tighten each bolt with the appropriate tool to avoid any loose joints. Next, connect the rotating mechanism to the central frame. Align the mounting holes carefully and fasten the screws to hold the structure in place. Make sure to double-check the alignment to prevent any operational issues later on. This step is crucial for ensuring that the device functions smoothly once it is fully assembled. After securing the rotating component, install the handles or grips, depending on the model. These are essential for maintaining control during operation. Use the supplied screws or clips to attach them firmly, and ensure they are positioned comfortably for the user. Finally, inspect all parts for proper alignment and tightness. Before using the tool, it’s important to make sure that all components are securely fastened and ready for use. A thorough inspection will help you Choosing the Right Auger Blade

Selecting the appropriate cutting tool for drilling can significantly impact efficiency and performance. Various factors influence this choice, including soil conditions, material composition, and the specific task at hand. Understanding these elements is essential for achieving optimal results. Factors to ConsiderWhen determining which cutting edge to use, it’s vital to evaluate the following aspects:

Conclusion

In conclusion, making an informed decision about the cutting tool can enhance productivity and ensure the success of your drilling tasks. Taking the time to assess soil conditions, required dimensions, and material quality will lead to better outcomes. Troubleshooting Performance IssuesWhen experiencing difficulties with equipment operation, it is essential to identify and address underlying factors that may hinder efficiency. Common performance problems can stem from various sources, including mechanical wear, improper maintenance, or environmental conditions. By systematically diagnosing these issues, users can enhance functionality and prolong the lifespan of their tools. First and foremost, ensure that all components are correctly assembled and securely attached. Loose or misaligned parts can lead to reduced effectiveness and even potential safety hazards. Regular inspections and adjustments can prevent such complications from arising. Next, evaluate the condition of the operational elements. Worn-out or damaged pieces may cause unexpected malfunctions. Replacing these components promptly can restore optimal performance and prevent further deterioration. Maintaining a schedule for routine checks and replacements is advisable. Additionally, assess the environmental factors affecting performance. Conditions such as soil density or moisture levels can significantly impact how well equipment functions. Adjusting operational techniques to suit varying environments may yield better results and improve overall efficiency. Lastly, keep a record of any unusual behaviors or recurring issues. This documentation can be invaluable for troubleshooting persistent problems and may help in identifying patterns that require attention. By taking a proactive approach, users can significantly enhance the performance of their equipment. Upgrading Your Auger for Better Efficiency

Improving the functionality of your drilling equipment can significantly enhance performance and productivity. By focusing on specific upgrades, you can optimize your device to achieve better results in various tasks. Here are some effective strategies to consider for enhancing efficiency.

By applying these upgrades, you can enhance the overall performance and efficiency of your equipment, resulting in better outcomes for your projects. Where to Find Compatible Spare PartsLocating the right replacement components for your equipment can be crucial for maintaining its functionality and performance. Various sources offer a range of options for acquiring the necessary items, ensuring that you can continue using your machinery efficiently. Online Retailers: Numerous e-commerce platforms specialize in selling aftermarket and OEM components. These websites often provide comprehensive catalogs that allow you to search by model or specific features, making it easier to find compatible options. Local Hardware Stores: Many local stores carry a selection of essential components for various types of machinery. Visiting these establishments can save time and shipping costs, while also giving you the chance to consult with knowledgeable staff. Manufacturer Distributors: Authorized distributors of the original manufacturer can be excellent sources for genuine components. They can ensure that you receive high-quality replacements that meet the exact specifications required for your equipment. Forums and Community Groups: Engaging with online forums or community groups dedicated to machinery enthusiasts can provide valuable insights. Members often share recommendations for reliable sources and may even have spare components available for sale or trade. |