In the realm of agricultural machinery, comprehending the intricate assembly of various components is essential for efficient operation and maintenance. This section delves into the essential elements that make up a specific type of equipment commonly used in farming and land management. By examining the interrelated parts, operators can enhance their understanding of functionality, leading to improved performance and longevity.

Moreover, having a clear visualization of the machinery’s construction allows users to identify any issues that may arise during operation. Recognizing how each segment interacts with others ensures that maintenance is conducted promptly, preventing potential breakdowns and extending the life of the equipment. This knowledge empowers users to make informed decisions regarding repairs and replacements, ultimately fostering a more productive farming experience.

Whether you are a seasoned professional or a newcomer to the agricultural field, familiarizing yourself with the essential elements of this machinery can significantly impact your operational efficiency. This exploration serves as a vital resource for anyone looking to optimize their use of such equipment in various agricultural tasks.

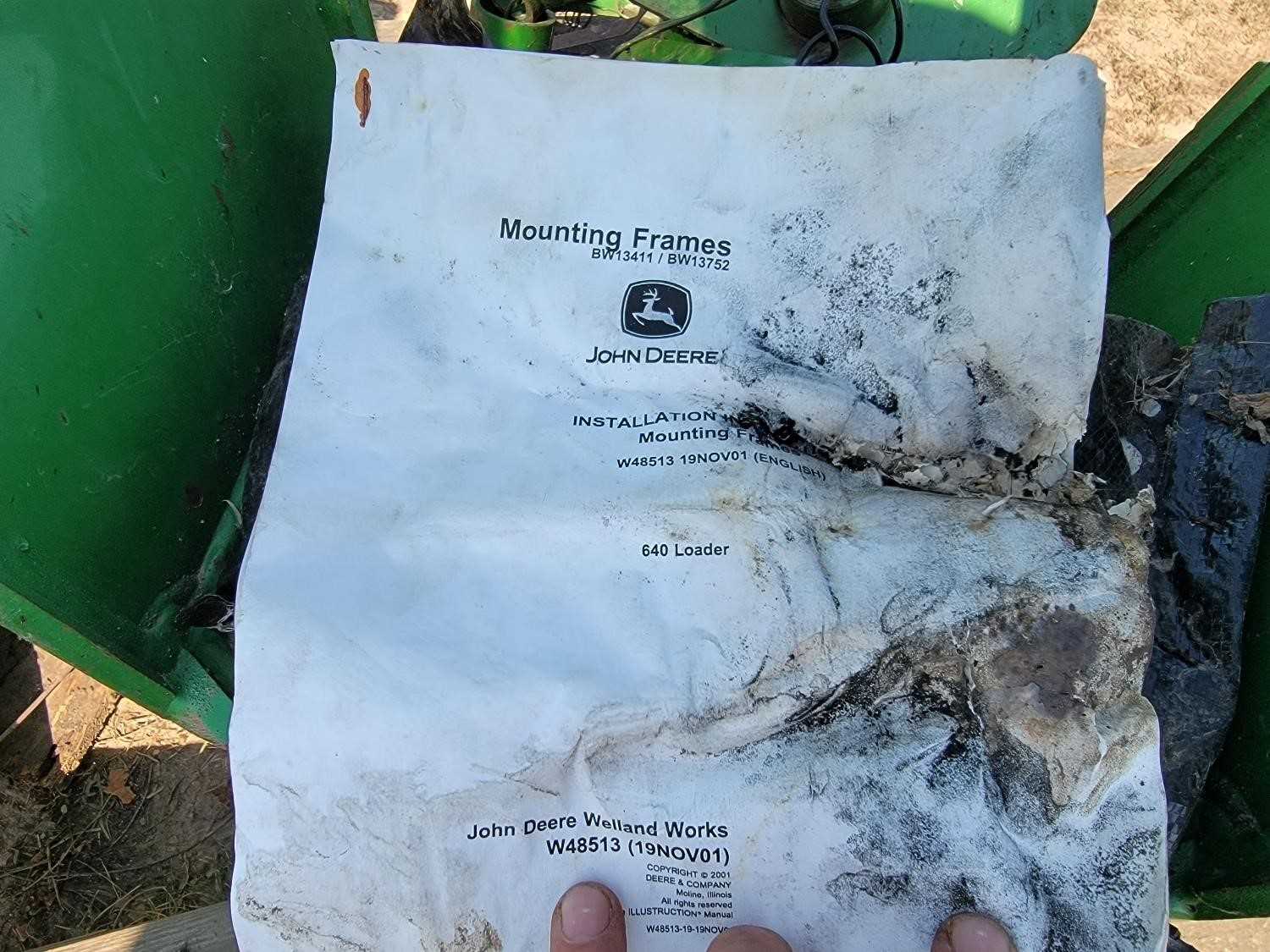

Overview of John Deere 640 Loader

This section provides a comprehensive examination of a popular piece of equipment designed for various lifting and digging tasks. Known for its versatility and reliability, this machine is commonly utilized in agricultural, construction, and landscaping operations. Understanding its components and functionality is essential for optimal performance and maintenance.

The equipment is engineered to enhance productivity, featuring a robust structure that supports a wide range of attachments. Its design allows for easy maneuverability and efficient operation, making it a preferred choice among professionals in various industries. Regular upkeep and familiarity with its features ensure longevity and effective use in demanding environments.

By exploring the intricacies of this machine, users can appreciate its role in streamlining tasks that require heavy lifting and material handling. Familiarity with the equipment’s assembly can significantly impact efficiency and operational success, making it a valuable asset in any fleet.

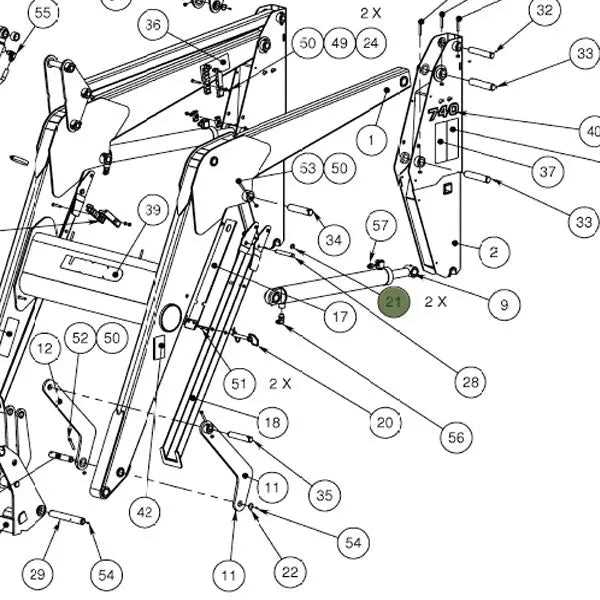

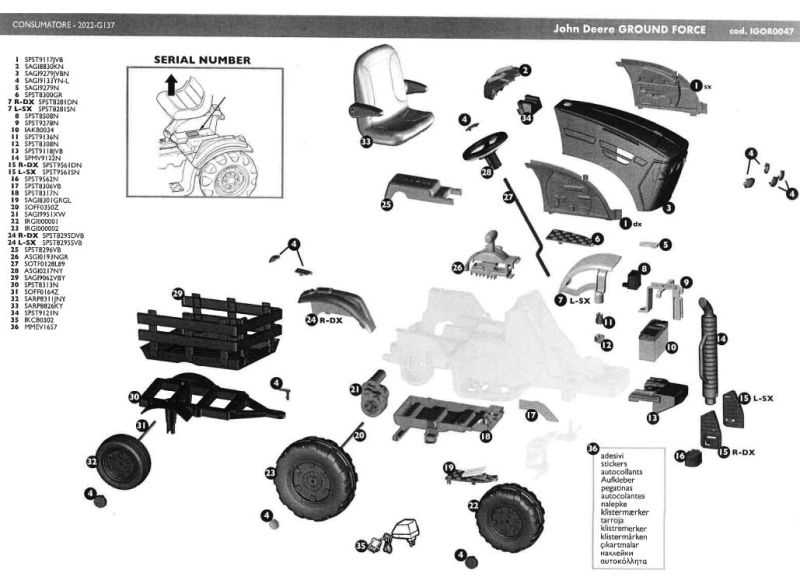

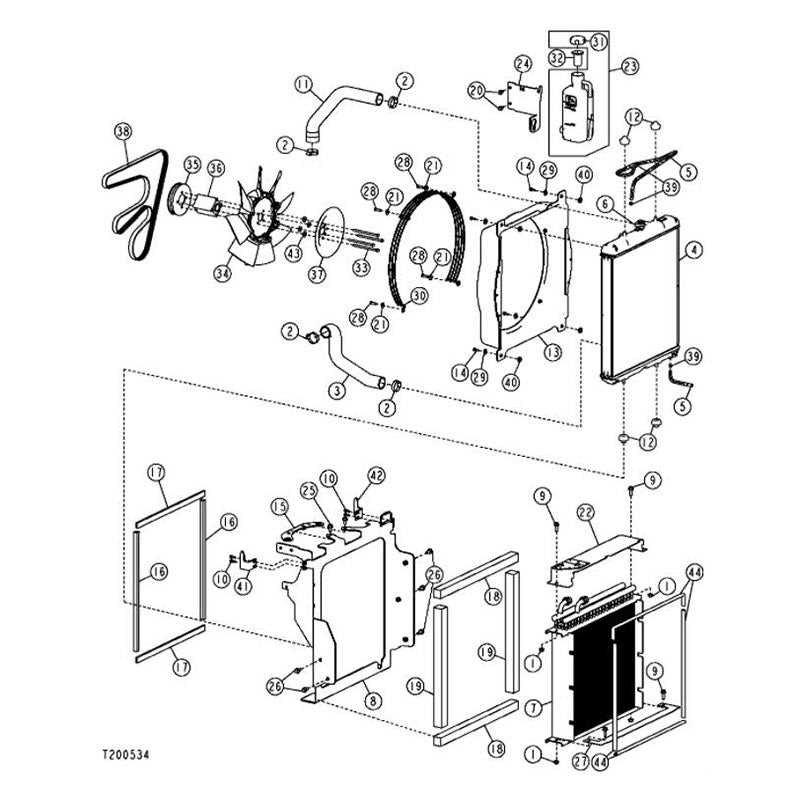

Key Components of the Loader

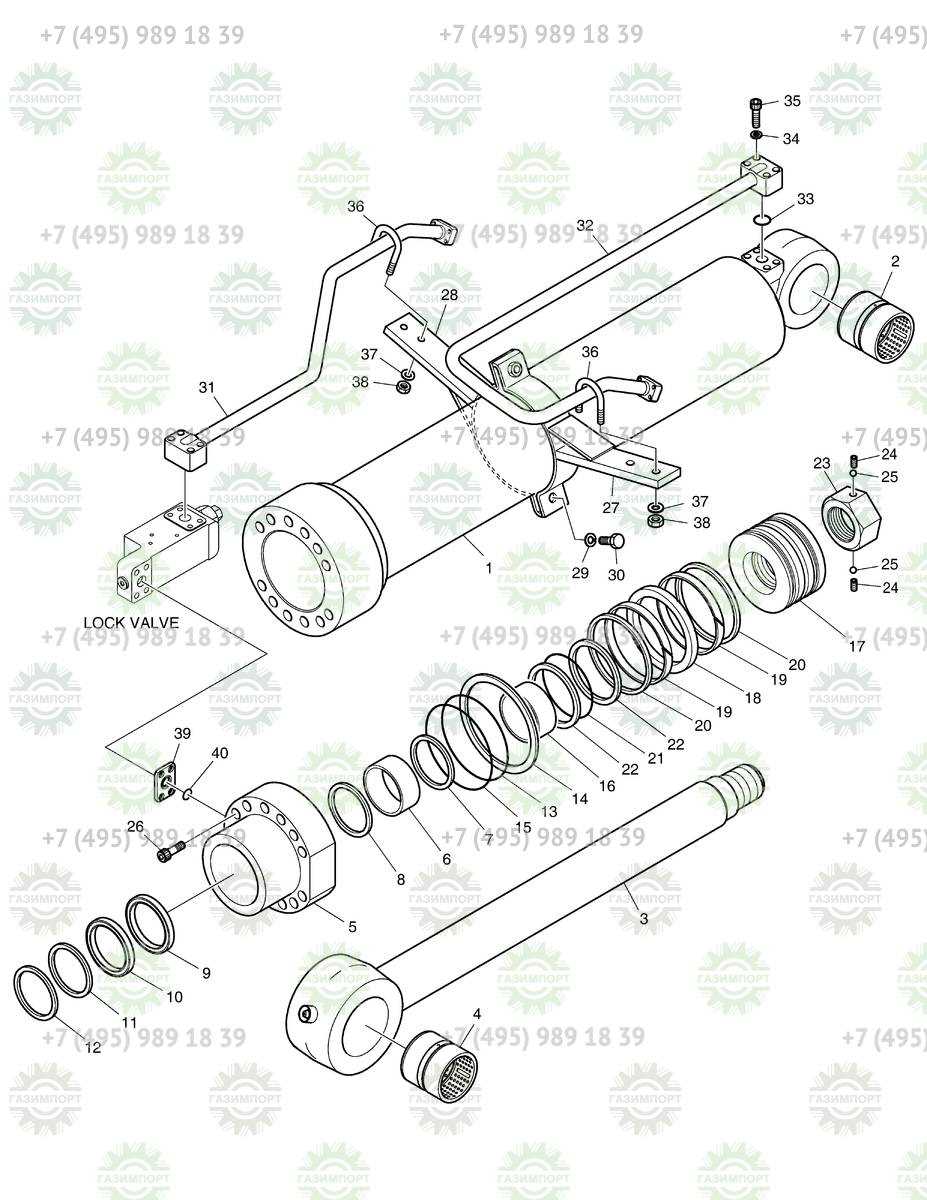

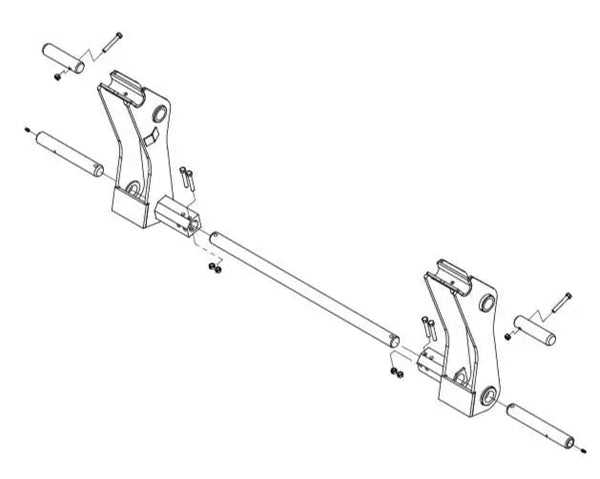

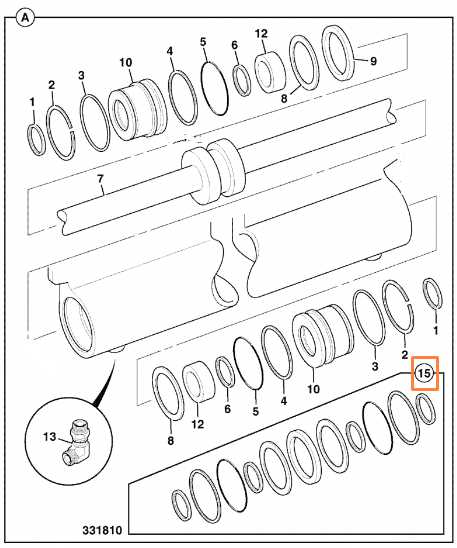

The functionality of any heavy machinery relies on a series of critical elements that work harmoniously to accomplish tasks efficiently. Understanding these essential components is vital for maintenance and operational effectiveness. Each part plays a significant role in ensuring the equipment operates smoothly, providing the necessary power and control for various applications.

One of the main structures includes the frame, which serves as the backbone, supporting various attachments and mechanisms. The hydraulic system is another crucial feature, responsible for lifting and lowering the apparatus. Additionally, the bucket or scoop serves as the primary tool for moving materials, while the linkage system facilitates the movement of these components, allowing for a range of motion and versatility.

Moreover, the power unit drives the entire system, providing the energy needed to perform demanding tasks. Other components, such as the steering mechanism, play an important role in maneuverability, allowing the operator to navigate different terrains effectively. Each of these elements contributes to the overall performance, ensuring the machinery meets the demands of various job sites.

Understanding Loader Assembly Functions

The functionality of a lifting mechanism is crucial for effective operation in various tasks. This assembly is designed to enhance productivity and efficiency, enabling seamless manipulation of heavy materials. Each component plays a significant role in achieving desired performance and ensuring safety during operation.

Key Elements of the Assembly include hydraulic systems, structural frames, and attachment mechanisms. The hydraulic system is responsible for generating the necessary force to lift and lower loads. Meanwhile, the structural frame provides stability and support, allowing the entire assembly to withstand the stresses encountered during operation. Attachments, such as buckets or forks, facilitate the handling of different materials, making the assembly versatile for various applications.

Maintaining proper functionality requires regular inspection and upkeep of all components. Ensuring that hydraulic fluids are at the appropriate levels and that connections are secure can prevent malfunctions. Additionally, monitoring for wear and tear on attachments is essential to maintain optimal performance and safety.

Understanding the roles of each part within the assembly can significantly improve operational effectiveness. By recognizing how these elements interact, operators can make informed decisions that enhance productivity and extend the lifespan of the equipment.

Maintenance Tips for Efficient Operation

Proper upkeep of equipment is crucial for maximizing performance and longevity. Implementing regular maintenance routines not only enhances functionality but also minimizes the risk of unexpected breakdowns. Adopting a proactive approach to care can lead to increased productivity and lower operational costs.

Routine Inspections

Conducting frequent assessments of the machinery is essential. Check for signs of wear, leaks, or any abnormalities that could impact performance. Early detection of potential issues can prevent costly repairs and ensure smooth operations. Pay close attention to key components, ensuring they are secure and functioning correctly.

Lubrication and Fluid Levels

Maintaining appropriate lubrication and fluid levels is vital for smooth operation. Regularly inspect hydraulic fluids and greases, replenishing them as needed to avoid friction and overheating. Proper lubrication reduces wear on moving parts and contributes to overall efficiency. Ensure that all reservoirs are filled to the recommended levels for optimal performance.

Common Issues and Solutions

Maintaining heavy machinery involves addressing various challenges that can arise during operation. Understanding these typical complications and their remedies can enhance performance and prolong the lifespan of the equipment.

-

Hydraulic System Failures:

Issues with the hydraulic system can manifest as inadequate lifting power or slow response times. Regular checks of fluid levels and ensuring no leaks are present are crucial.

-

Wear and Tear on Components:

Over time, mechanical parts may experience wear that affects functionality. Regular inspections and timely replacement of worn components are essential to prevent more significant problems.

-

Electrical System Malfunctions:

Problems within the electrical system may lead to starting issues or erratic performance. Checking battery connections and fuses can often resolve these issues.

-

Excessive Vibration:

Unusual vibrations can indicate misalignment or damaged components. Tightening bolts and ensuring proper alignment can mitigate this issue.

-

Fluid Leaks:

Leaks can occur in various systems and lead to performance decline. Identifying the source of the leak and replacing damaged seals or hoses is vital.

By addressing these common issues proactively, operators can ensure optimal functionality and reliability of their machinery.

Where to Find Replacement Parts

Locating suitable components for machinery repairs can be a daunting task. However, with the right resources and information, the process can become more manageable. Various channels are available for acquiring necessary replacements, ensuring the equipment remains operational and efficient.

When seeking out these essential elements, consider the following options:

| Source | Description |

|---|---|

| Authorized Dealers | Official retailers often provide genuine components that are compatible with your machinery, ensuring reliability and performance. |

| Online Marketplaces | Websites like eBay and Amazon offer a wide selection of aftermarket and used items, often at competitive prices. |

| Specialty Retailers | Shops focusing on heavy equipment may have a diverse inventory of essential items tailored to specific needs. |

| Local Salvage Yards | These facilities can provide used components at reduced prices, which can be a cost-effective solution for older machinery. |

| Manufacturer Websites | Many manufacturers offer online catalogs and direct sales for items, allowing for easy ordering and shipment. |

How to Read Parts Diagrams

Understanding the layout and components of machinery is essential for effective maintenance and repairs. A well-structured visual representation can provide valuable insights into the various elements of a system, enabling users to identify and locate specific items quickly. This knowledge can significantly enhance troubleshooting and facilitate smoother operations.

1. Familiarize Yourself with Symbols: Each illustration often includes unique symbols and notations that represent different components. Spend some time learning these symbols to interpret the visuals accurately. Recognizing these markers will help you understand the relationships between various elements.

2. Identify Key Sections: Typically, these visuals are divided into sections, each representing a specific area of the machinery. By breaking down the diagram into manageable parts, you can focus on one segment at a time, making it easier to comprehend the overall structure.

3. Use a Legend: Most illustrations come with a legend or key that explains the symbols and colors used throughout the visual. Refer to this legend frequently to enhance your understanding of the components represented and their functions.

4. Cross-Reference with Manuals: For deeper insights, cross-reference the visuals with your equipment manuals. This practice will provide additional context and clarify any uncertainties about the components and their functions.

5. Take Notes: While studying the illustration, jot down notes about the components and their locations. Creating a personalized reference can help reinforce your understanding and serve as a quick guide during future maintenance tasks.

Importance of Quality Parts

Utilizing high-grade components in machinery is crucial for maintaining optimal performance and longevity. Superior materials and precise manufacturing processes directly influence the efficiency and reliability of equipment. Investing in quality ensures that machinery can withstand rigorous demands and operate smoothly over time.

Durability is one of the primary benefits of using top-tier components. When machinery is subjected to heavy loads and challenging conditions, only robust materials can endure the stress without failing. This reliability minimizes downtime and enhances productivity, ultimately leading to cost savings in the long run.

Furthermore, compatibility plays a vital role in machinery operation. Quality components are designed to fit seamlessly with existing systems, reducing the risk of malfunctions. A proper fit ensures that all parts function together harmoniously, which is essential for achieving peak performance.

Additionally, employing authentic parts often comes with manufacturer support and warranties. This assurance can provide peace of mind, knowing that if issues arise, reliable assistance is readily available. Overall, the significance of using superior components cannot be overstated; it not only enhances machinery functionality but also promotes safety and efficiency.