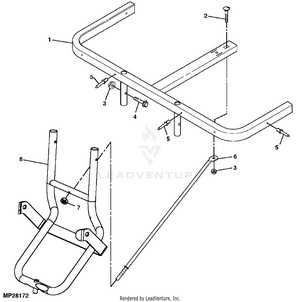

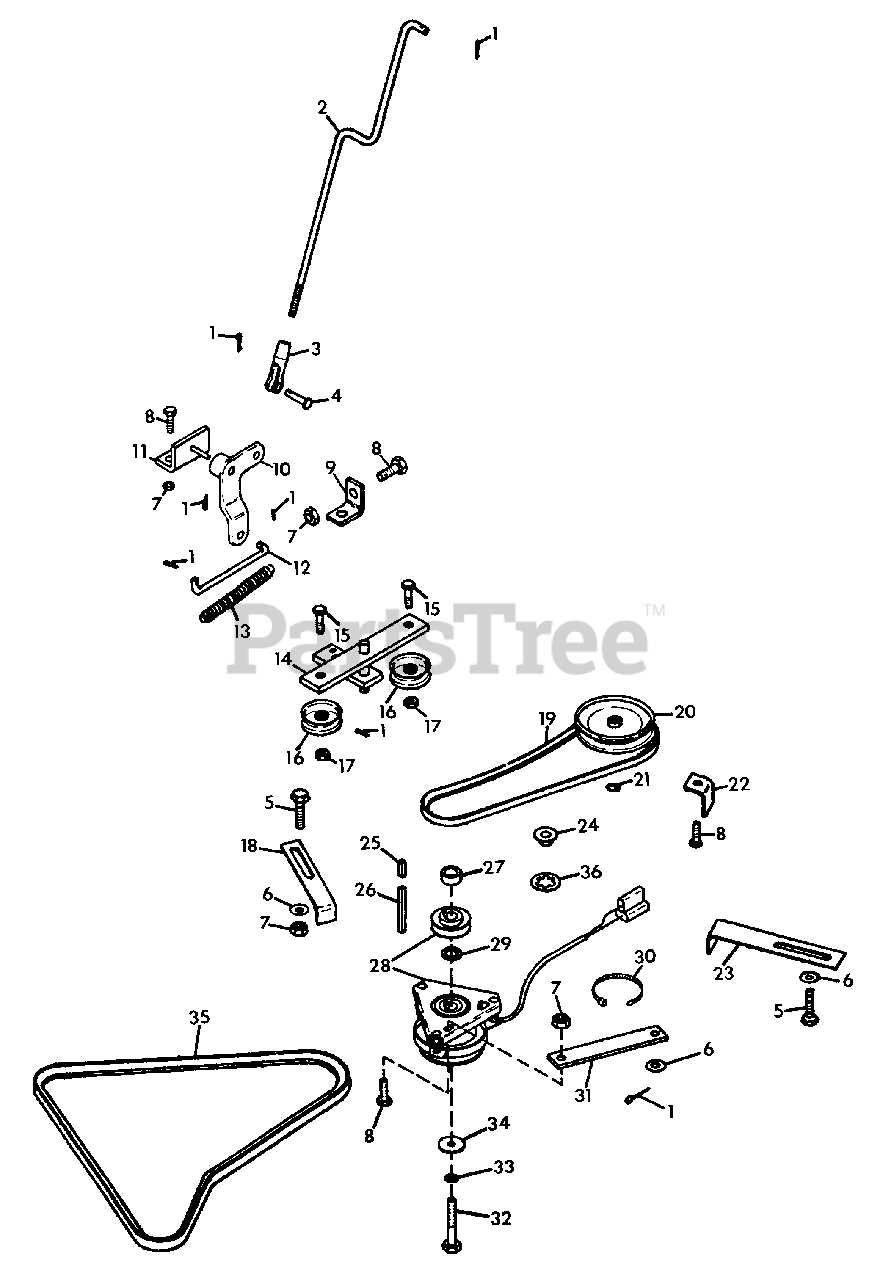

Understanding the layout and connection of various elements in your equipment is crucial for effective upkeep and seamless operation. With detailed schematics, one can quickly identify key areas that require attention, whether it’s for routine care or a more extensive repair. Proper knowledge of how each element is arranged ensures smoother handling during replacements or adjustments, enhancing both performance and longevity.

In this section, we will examine the structural makeup of essential elements, highlighting their arrangement and interdependence. This overview will help you easily navigate through the system, offering insights on how to maintain and optimize your machinery. The aim is to facilitate a clearer understanding of the core components, making troubleshooting and repair more efficient.

By analyzing the system’s layout, you’ll be able to pinpoint the location of specific elements, ensuring that even the smallest adjustments can be made with precision. This knowledge empowers users to address potential issues swiftly, reducing downtime and preventing costly errors.

Overview of the John Deere MC519 Cart

The versatile yard trailer is designed to help with various hauling tasks in residential and commercial settings. This tool is ideal for those needing an efficient solution to move materials like leaves, grass, and other debris, reducing manual labor and saving time during routine maintenance or clean-up jobs.

Main Features

- Spacious container for large volumes of material

- Durable construction for long-lasting performance

- Easy-to-use dumping mechanism

- Compatible with a wide range of equipment

Practical Applications

The cart is frequently used for yard maintenance, landscaping, and general property management. Its generous capacity allows for fewer trips, while the robust build ensures reliability during heavy-duty use.

- Collecting leaves and grass clippings

- Transporting soil, mulch, or garden waste

- Organize all components before starting to ensure nothing is overlooked.

- Refer to any available schematics or guides to understand the proper orientation and alignment of each part.

- Use the appropriate tools for each specific component to prevent stripping screws or damaging surfaces.

- Apply lubrication to moving parts as necessary to reduce friction and wear.

- Document the order of assembly by taking pictures or making notes to aid in reassembly.

- Carefully remove fasteners and keep them in a designated container to avoid loss.

- Handle components gently to prevent damage to delicate parts or surfaces.

- Clean each component thoroughly before reassembling to remove dirt or debris that may impede functionality.

- Visible signs of damage, such as cracks or breaks.

- Unusual noises or vibrations during operation.

- Inconsistent performance or response times.

- Fluid leaks or residue around connection points.

- Conduct routine visual inspections to identify any obvious issues.

- Refer to maintenance manuals for recommended service intervals.

- Utilize diagnostic tools to monitor performance metrics.

- Engage with professionals or community forums for shared insights.

Main Components and Their Functions

Understanding the key elements of any mechanical system is essential for ensuring proper maintenance and efficient operation. Each section of the equipment is designed with a specific purpose, working together to provide optimal performance. Identifying the role of each piece can simplify troubleshooting and repair.

Primary Structural Elements

The framework serves as the foundation, supporting the entire system. It ensures stability and durability, allowing the equipment to handle various workloads. Additionally, the framework connects other important assemblies and helps distribute weight evenly.

Drive and Transmission Systems

The drive mechanism is responsible for transmitting power throughout the machine, converting energy into movement. Components such as belts and gears play crucial roles in ensuring smooth operation, allowing the equipment to handle different tasks efficiently.

Understanding the Structural Layout

The overall framework of this equipment is designed with precision, ensuring all components work together efficiently. By examining the layout, one can gain a clearer understanding of how various elements are positioned and interconnected, forming a cohesive system.

Each section is carefully arranged to optimize functionality, allowing for easy maintenance and operation. From the frame to smaller attachments, understanding the spatial arrangement is essential for ensuring proper usage and addressing potential issues that may arise over time.

This overview will help you visualize the key areas of the machine, offering insights into how its foundational structure supports the entire system.

Maintenance and Replacement Guide

Proper care and timely component replacement are essential to ensure long-lasting performance and reliability of your equipment. Routine inspections help identify wear and tear, allowing you to address potential issues before they cause further damage. This guide provides a practical approach to maintaining and replacing various elements of your system.

Regular Inspection: Periodically check all essential mechanisms for signs of wear, rust, or loosened connections. Early detection of issues can prevent more complex failures down the line.

Replacement Procedures: When replacing parts, always follow manufacturer recommendations, ensuring that compatible components are used. Use proper tools to disassemble and reassemble any units, and double-check connections to avoid malfunctions.

Maintenance Tips: Clean critical areas regularly to remove debris and build-up that could interfere with smooth operation. Lubricate moving parts where necessary to reduce friction and prolong the life of the equipment.

Troubleshooting Common Issues

In the process of maintaining and repairing equipment, various technical problems can arise, often requiring a systematic approach to identify and resolve the root cause. This section provides essential guidance for diagnosing frequent malfunctions and offers potential solutions to help ensure the continued functionality of the machinery.

Identifying Operational Problems

Common issues can stem from wear, improper use, or environmental factors. Begin by checking key mechanical components for signs of damage, misalignment, or wear. If any abnormal behavior is detected, perform a step-by-step inspection to locate the source of the issue.

Resolving Performance Concerns

For performance-related problems, ensure that all connections and moving parts are functioning as expected. Lubrication, cleaning, and securing loose elements can help restore optimal operation. If problems persist, replacing worn or damaged elements may be necessary.

| Issue | Possible Cause | Solution |

|---|---|---|

| Reduced performance |