Wipe with a damp cloth

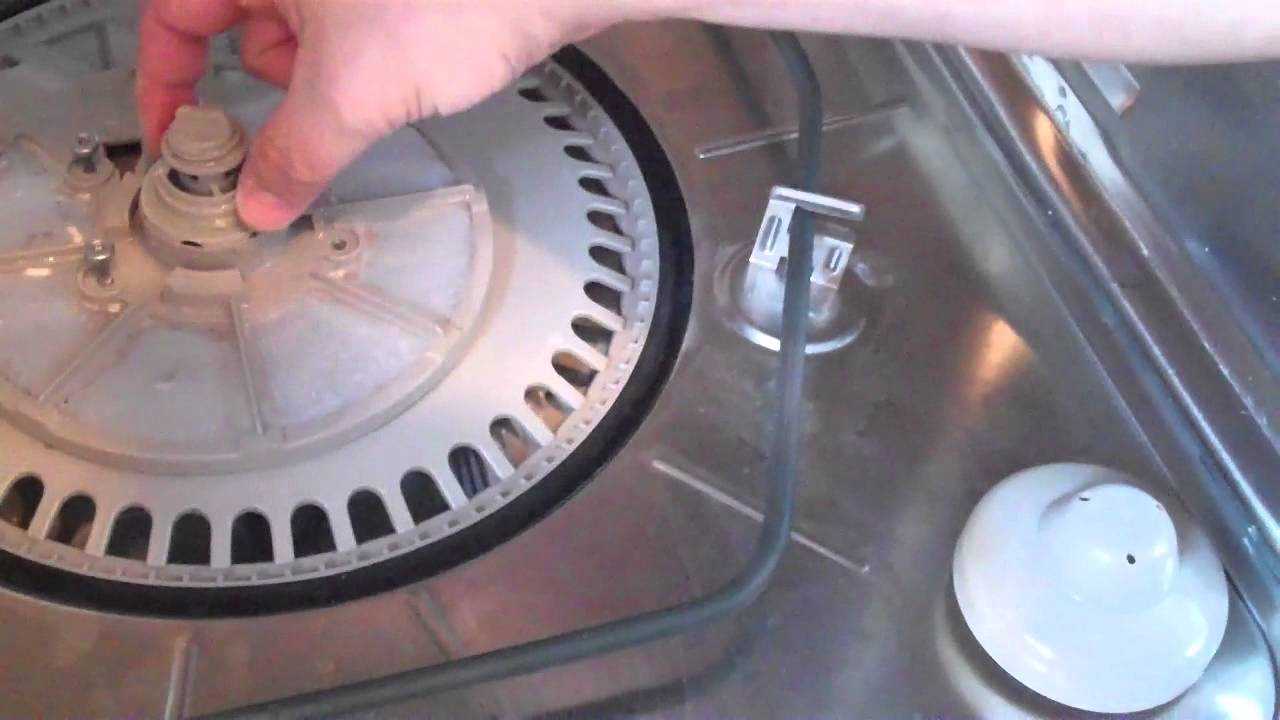

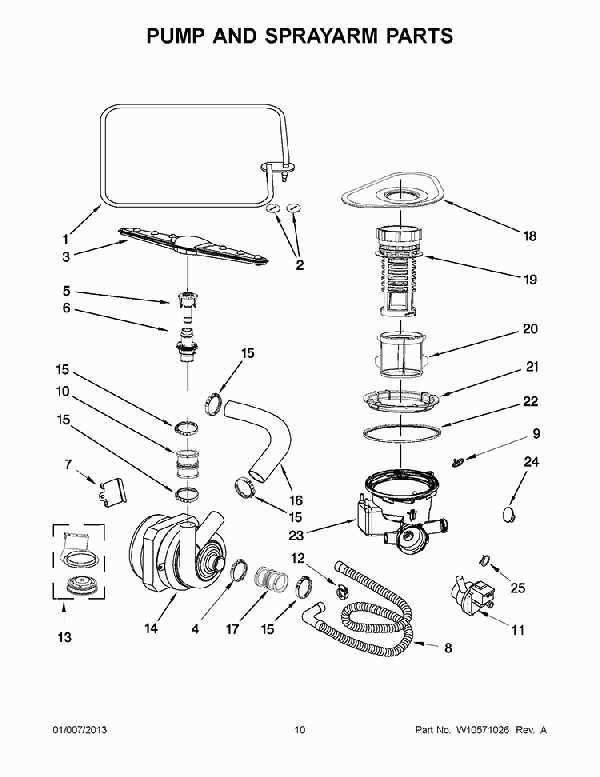

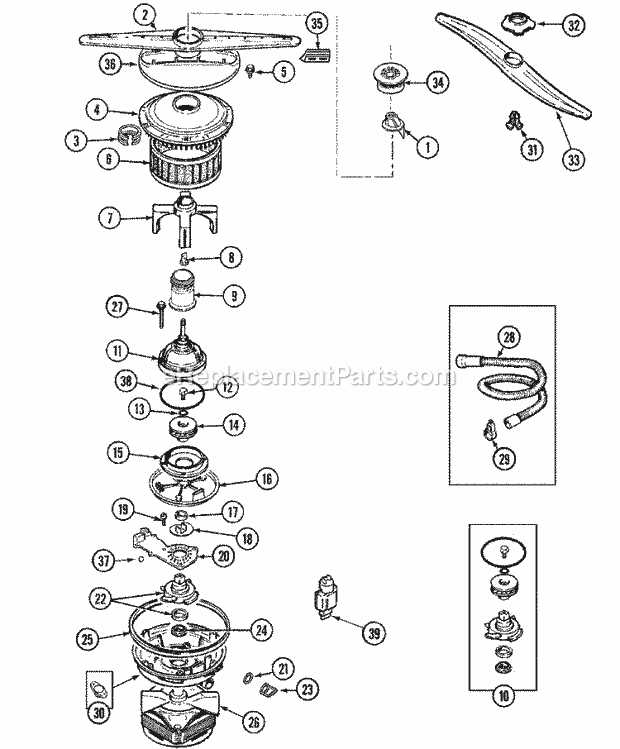

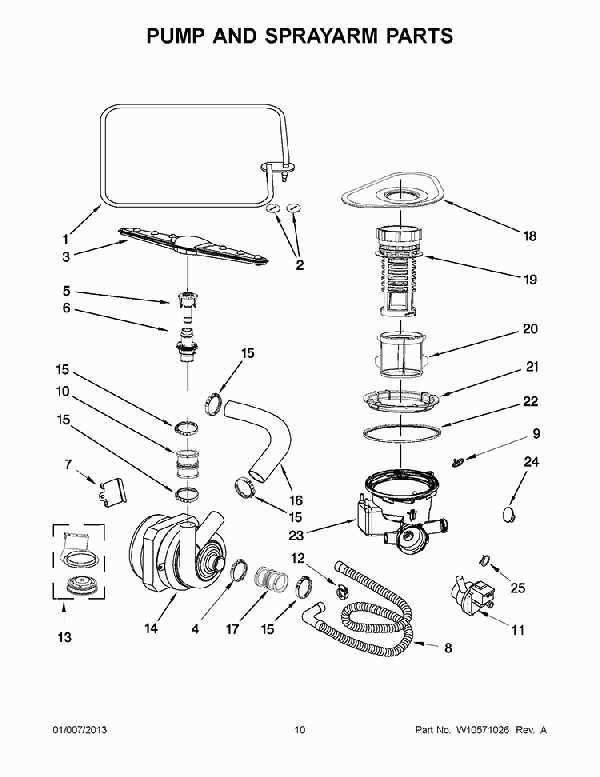

Exploring the Pump Assembly

The pump assembly is a crucial component responsible for efficient fluid circulation within the appliance. Its operation ensures the continuous flow of liquid during different stages of the cycle, making it essential for the overall system’s performance. Understanding its construction and the way it functions can help in maintaining the unit’s optimal working condition.

Main Elements of the Pump Assembly

- Motor: Powers the circulation process, driving the liquid flow through the system.

- Impeller: This rotating part pushes the fluid, creating the necessary pressure for the movement.

- Seals: Prevents leaks, ensuring the fluid stays within the designated channels.

Common Issues and Maintenance Tips

- Check for blockages in the impeller regularly to ensure uninterrupted flow.

- Inspect seals for wear and tear to avoid leaks.

- Ensure the motor runs smoothly by keeping it free from debris and checking connections.

By paying attention to these elements, you can extend the system’s lifespan and avoid frequent

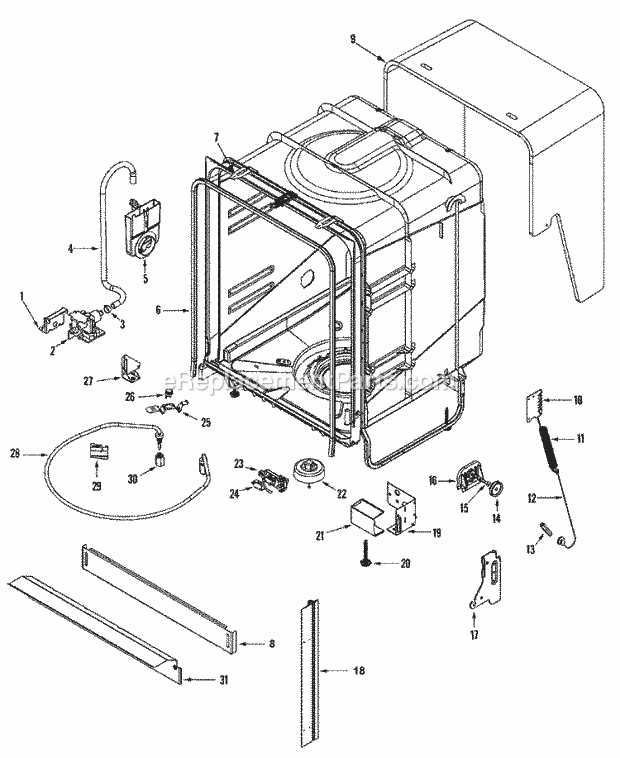

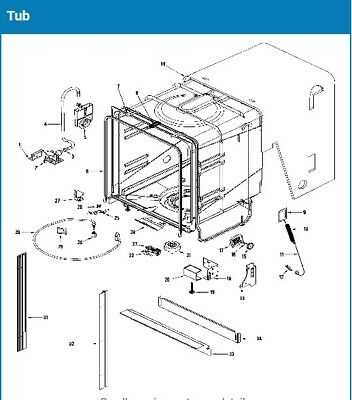

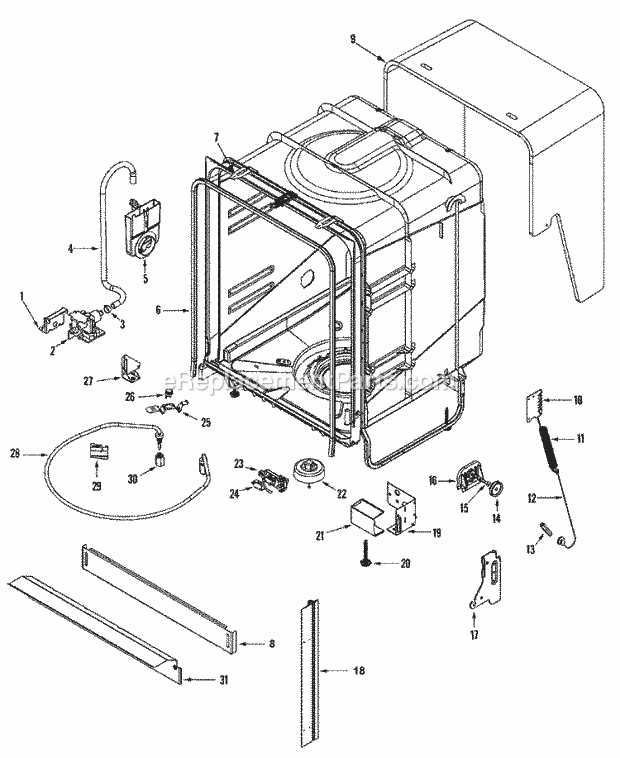

Understanding Its Role in Water Circulation

Effective management of water flow is crucial for optimal functioning in any cleaning appliance. This process ensures that every surface is adequately treated, enhancing the overall efficiency of the device. By examining the components responsible for directing and controlling water movement, one can gain insights into how this system contributes to performance and cleanliness.

The Importance of Flow Management

The primary function of the circulation mechanism is to deliver water where it is needed most. This involves a network of channels and nozzles that distribute liquid evenly throughout the interior. Without proper flow management, areas may remain untouched, leading to unsatisfactory results. Proper circulation not only improves cleaning effectiveness but also aids in drying processes, ensuring that items emerge spotless and dry.

Components Influencing Water Dynamics

Various elements work in harmony to facilitate fluid movement. Each component plays a unique role, from the pumps that generate pressure to the spray arms that disperse water in a targeted manner. Understanding these elements helps in troubleshooting issues and maintaining optimal operation. Regular inspection of these components can prevent clogs and malfunctions, ensuring consistent performance over time.

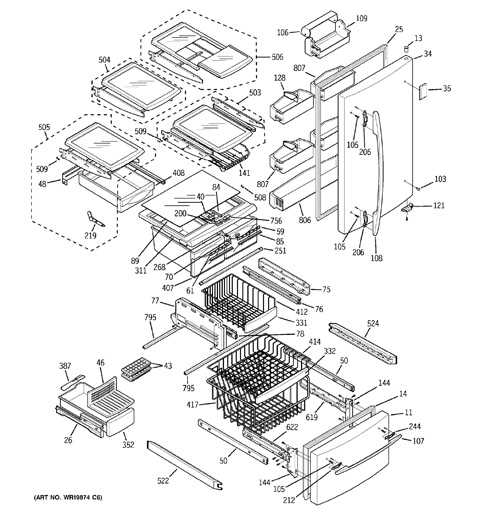

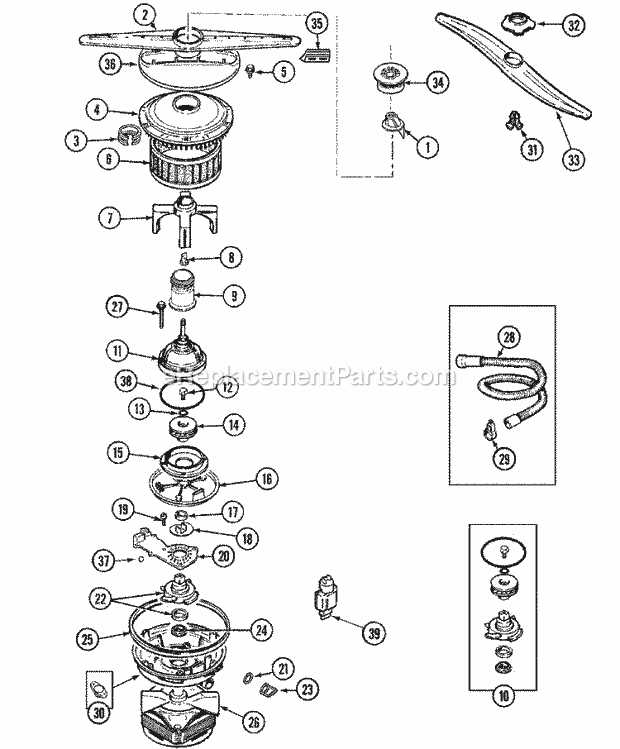

Spray Arm System in Amana Dishwashers

The spray arm mechanism is a crucial component that ensures effective cleaning within the appliance. This system is designed to distribute water evenly, reaching all surfaces of the items loaded inside. Proper functionality of this mechanism is vital for achieving optimal cleaning results.

Understanding the various elements of the spray arm assembly helps in maintaining and troubleshooting potential issues. Below is a breakdown of the key components that make up this essential system:

| Component |

Description |

| Spray Arm |

The rotating arm that disperses water during the cleaning cycle. |

| Support Bracket |

The structure that holds the spray arm in place and allows for rotation. |

| Water Inlet |

The entry point for water that feeds into the spray arm for distribution. |

| Nozzle |

The opening at the end of the spray arm that directs the water stream. |

| Deflector |

A component that helps redirect the water flow to enhance coverage. |

By familiarizing yourself with these components, you can better appreciate their role in the appliance’s cleaning process and address any maintenance needs effectively.

Efficient Water Distribution for Clean Dishes

Effective management of liquid flow is crucial for achieving spotless and hygienic kitchenware. Proper circulation ensures that every item receives adequate exposure to cleaning solutions, promoting optimal results. Understanding how water is distributed within the cleaning unit can significantly enhance its performance and longevity.

Several factors contribute to the efficiency of liquid distribution:

- Spray Arms: These components play a vital role in delivering water to various areas inside the cleaning chamber. Their design and positioning determine how well the liquid reaches all surfaces.

- Water Pressure: Sufficient pressure is essential for ensuring that water is effectively dispersed across the interior. This pressure allows the cleaning solution to penetrate and remove stubborn residues.

- Water Filtration: A clean filtration system prevents clogs, ensuring a steady flow of water. This helps maintain consistent performance over time.

- Load Configuration: Proper arrangement of items affects water circulation. Ensuring there is adequate space between items allows for better access to cleaning agents.

To maximize cleanliness, consider the following tips:

- Regularly inspect and clean the spray arms to prevent blockages.

- Ensure that the water pressure is within the recommended range for optimal performance.

- Clean or replace filters as necessary to maintain unrestricted flow.

- Load items according to guidelines to promote even exposure to cleaning agents.

By focusing on these aspects, one can significantly improve the efficiency of the cleaning process, leading to cleaner

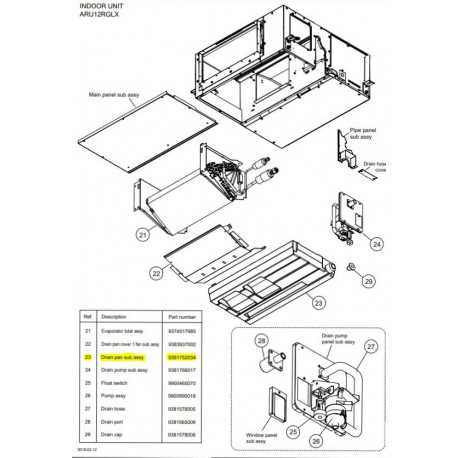

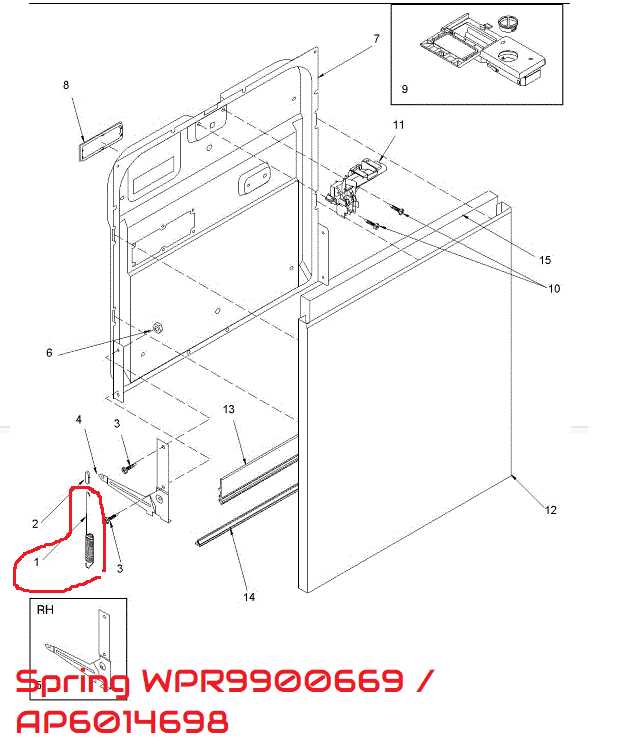

Understanding the Drain Valve Mechanism

The drain valve plays a crucial role in the efficient functioning of cleaning appliances by controlling the flow of water during the rinse and drainage cycles. Its operation is vital for maintaining the overall performance and longevity of the equipment. Understanding how this component works can aid in troubleshooting and ensuring optimal operation.

Key functions of the drain valve include:

- Regulating the release of water from the system.

- Preventing backflow, which could compromise cleanliness.

- Ensuring the appliance drains effectively after each cycle.

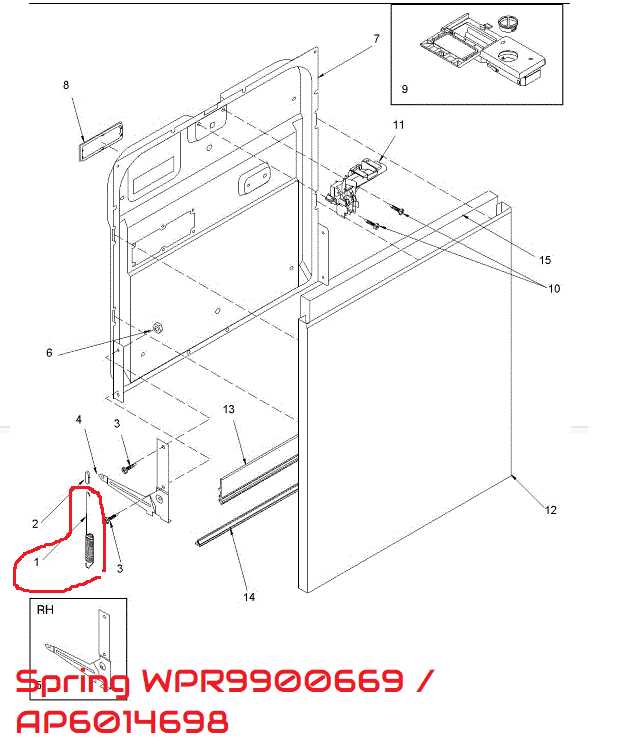

The mechanism typically consists of the following elements:

- Actuator: Engages the valve when it is time to drain.

- Seal: Prevents leaks and ensures a tight closure when not in use.

- Spring: Assists in returning the valve to its closed position after drainage.

Regular maintenance and inspection of the drain valve can help avoid issues such as clogs or leaks, enhancing the reliability of the cleaning unit. Understanding this component’s operation is essential for effective troubleshooting and ensuring efficient water management within the appliance.

Troubleshooting Drainage Problems

Effective management of wastewater is essential for optimal appliance performance. When drainage issues arise, they can lead to unsatisfactory cleaning results and potential damage. This section outlines common causes of drainage failures and provides solutions to address them.

- Clogged Hoses: Inspect hoses for blockages that may impede the flow of water.

- Faulty Pump: Ensure the pump is functioning correctly; listen for unusual noises during operation.

- Filter Obstructions: Regularly clean filters to prevent buildup that can restrict water flow.

- Improper Installation: Verify that the drainage system is installed according to guidelines to avoid kinks or elevation issues.

Follow these troubleshooting steps:

- Disconnect the unit from the power source for safety.

- Check all hoses for signs of wear or clogs, removing any debris found.

- Inspect the filter and clean it thoroughly if dirt is present.

- Test the pump by running the unit empty to see if it operates smoothly.

Should issues persist after these checks, consider consulting a qualified technician to assess more complex problems.

|