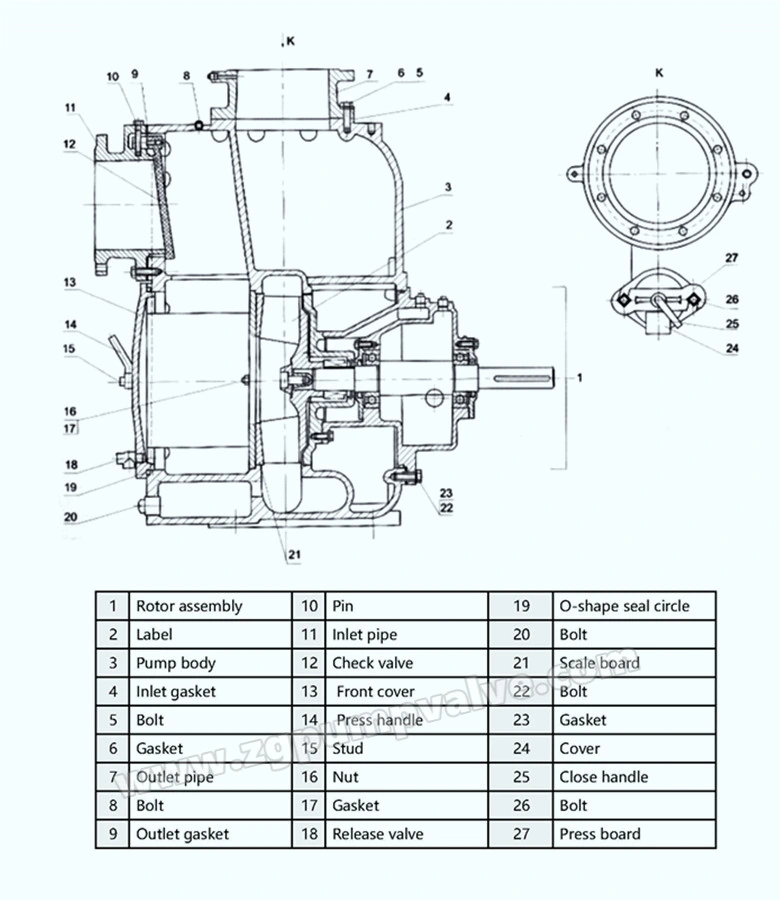

The layout and arrangement of individual elements within mechanical systems play a crucial role in ensuring efficient performance. Understanding how various components are interconnected can greatly enhance operational understanding and streamline maintenance processes.

Detailed breakdowns of various elements allow users to easily identify key sections and their functions within the overall structure. These organized layouts assist in simplifying complex technical information, making it easier to interpret and apply to real-world scenarios.

Regular assessment and clear visualization of these systems help to ensure long-term reliability. Comprehensive knowledge of how these parts work together will improve troubleshooting and enhance operational efficiency.

Overview of Key Pump Components

The functionality of any fluid transfer system is heavily dependent on the proper integration and operation of its essential elements. These components are designed to work together, ensuring smooth fluid movement and maintaining operational efficiency in various applications. Understanding the role of each part helps in maintaining optimal performance and addressing potential issues.

Primary Moving Elements

At the heart of the system are the main moving mechanisms responsible for creating the necessary flow. These elements are crafted to handle varying types of fluids and pressures, ensuring efficient movement through the system. Proper care and timely maintenance of these components are crucial for extending their lifespan.

Supportive Framework and Connections

The supportive structure holds all critical elements together, ensuring stability and minimizing vibrations. The connections between different parts are designed to be robust, allowing for secure fluid transfer without leaks or disruptions. Regular inspection of these connections ensures reliable operation and prevents damage.

Understanding the Functionality of Impellers

Impellers are crucial components in various mechanical systems, designed to transfer energy to fluids through rotational motion. Their unique design allows them to move liquids efficiently, altering pressure and flow in the process. The performance of these elements directly impacts the overall efficiency of the system.

- Energy Conversion: Impellers transform mechanical energy into kinetic energy, propelling fluids forward.

- Fluid Dynamics: The shape and size of the blades determine how the liquid moves, affecting flow rate and pressure.

- System Efficiency: Properly functioning impellers ensure smooth operation and reduce energy consumption.

Understanding these factors helps optimize the system’s operation, ensuring that energy is efficiently transferred and the required fluid movement is achieved.

Seals and Gaskets: Ensuring Leak Prevention

Seals and gaskets play a crucial role in maintaining the integrity of various mechanical systems. Their primary function is to create a tight barrier, preventing any unwanted fluids or gases from escaping, ensuring optimal performance and reducing the risk of leaks. Proper sealing is essential for both the efficiency and longevity of these systems.

Types of Seals and Their Importance

Different materials and designs are used to create seals tailored for specific applications. Whether it’s rubber, silicone, or metal-based, each type of seal is designed to withstand different conditions such as high pressure, temperature fluctuations, or chemical exposure. Choosing the right seal ensures that the system operates efficiently, with minimal risk of wear or breakdowns over time.

Gaskets: Key to a Leak-Free System

Gaskets are strategically placed between components to ensure tight connections. These flexible elements are designed to conform to the surfaces they seal, compensating for any imperfections and ensuring no gaps are left exposed. Regular inspection and replacement of gaskets are necessary to maintain a leak-free system, as they can deteriorate over time due to exposure to various elements.

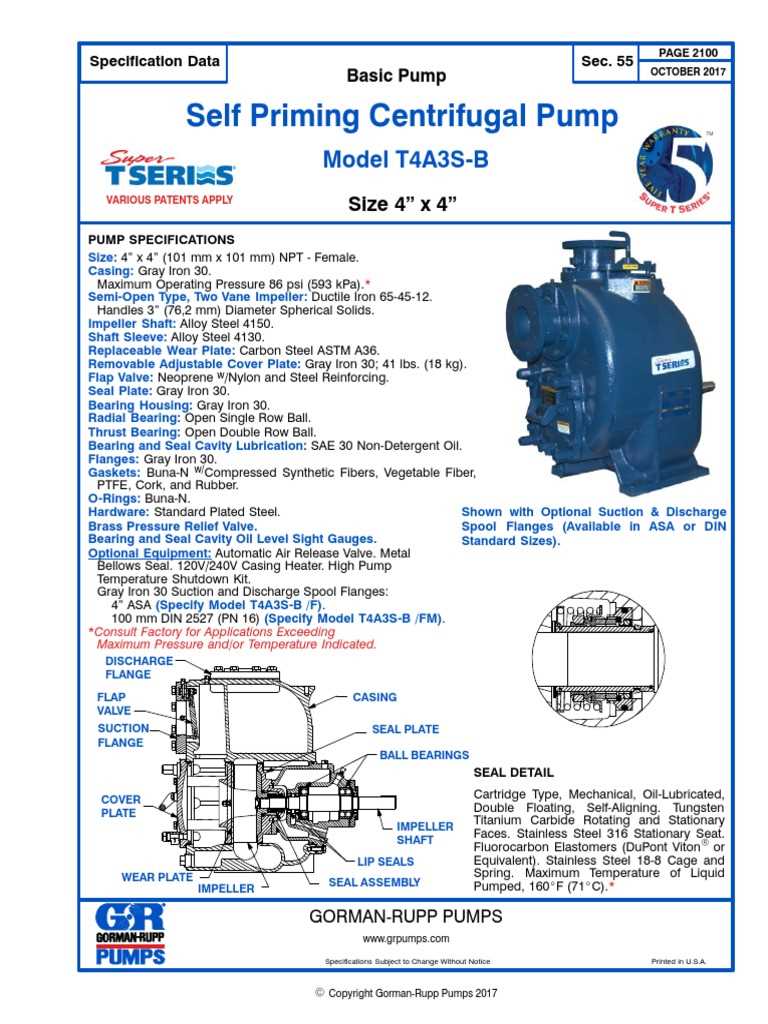

Pump Casing Structure and Durability

The outer shell of a hydraulic system plays a critical role in maintaining the internal integrity and protecting the essential mechanisms within. It is designed to withstand various environmental conditions, ensuring the longevity and effectiveness of the entire system. This section delves into the design considerations and material choices that enhance its reliability.

Material Composition and Design

Crafted from high-strength alloys, the casing is built to endure extreme pressures and resist corrosion. The use of advanced materials ensures that it remains robust even under challenging operational environments. The design typically incorporates reinforced sections to minimize wear and enhance durability over time.

Durability in Harsh Conditions

With exposure to abrasive substances and fluctuating temperatures, the structural elements are engineered to prevent damage. Durability features such as special coatings and optimized thickness help in minimizing the risk of erosion, ensuring continuous operation with minimal maintenance requirements.

Exploring the Role of Bearings

Bearings are essential components in many mechanical systems, as they reduce friction between moving parts, allowing smoother operation and increased efficiency. These elements help maintain the alignment of rotating elements and minimize wear, contributing to the longevity of equipment.

Types of Bearings

- Ball bearings: Known for handling both radial and axial loads, these are commonly used in various applications due to their versatility.

- Roller bearings: Designed for heavier loads, roller variants distribute weight more evenly across their surface, offering durability and stability.

- Thrust bearings: These are specialized for axial loads and are often used in systems requiring smooth rotation in a single direction.

Common Issues and Maintenance Tips

- Regular lubrication is crucial to prevent excessive friction and overheating.

- Bearings should be inspected periodically for signs of wear, corrosion, or misalignment.

- Prompt replacement of damaged bearings can prevent more significant mechanical failures.

Drive Systems: Types and Uses

Drive systems play a crucial role in various machinery, serving as the mechanism that transfers power and motion. Understanding the different types and their applications is essential for optimizing performance and ensuring efficiency in operations. This section will explore the primary categories of drive systems, highlighting their functions and specific uses in diverse contexts.

Electric Drive Systems

Electric drive systems utilize electrical energy to produce motion, offering precise control and efficiency. Commonly found in industrial machinery, these systems often feature electric motors that can easily be integrated into automated processes. Their adaptability makes them ideal for applications requiring variable speed and torque management.

Hydraulic Drive Systems

Hydraulic drive systems employ fluid power to generate movement, providing high force in compact designs. They are widely used in construction and heavy equipment, where significant power is needed in limited space. These systems are particularly effective for tasks that involve lifting or moving heavy loads, ensuring reliable performance under demanding conditions.

Valves and Their Importance in Flow Control

Valves play a crucial role in managing the flow of fluids within various systems. Their primary function is to regulate, direct, or control the movement of liquids and gases, ensuring efficiency and safety in operations. Understanding the significance of these devices is essential for maintaining optimal performance in fluid dynamics.

Types of Valves

- Gate Valves: Used primarily for on/off control, allowing for the full flow of fluid when open.

- Globe Valves: Ideal for throttling flow, providing precise control over the fluid’s passage.

- Ball Valves: Known for their quick operation and excellent sealing capabilities, suitable for both flow regulation and shutoff.

- Check Valves: Essential for preventing backflow, ensuring fluid moves in one direction only.

Benefits of Proper Valve Selection

- Enhances system reliability by preventing leaks and failures.

- Improves energy efficiency by optimizing flow rates.

- Facilitates maintenance by allowing for easy isolation of sections in a system.

- Increases safety by reducing the risk of overpressure and flow-related accidents.

Shafts and Couplings: Power Transfer Mechanics

The interaction between shafts and couplings plays a crucial role in the effective transmission of energy within mechanical systems. These components serve as the backbone for connecting different elements, ensuring that rotational power is seamlessly conveyed from one part to another.

Key Functions of Shafts

- Supportive Role: Shafts are primarily responsible for supporting rotating elements and maintaining their alignment.

- Torque Transmission: They facilitate the transfer of torque, enabling efficient operation of machinery.

- Material Integrity: The choice of material impacts durability and resistance to wear, crucial for long-term functionality.

Types of Couplings

- Rigid Couplings: These offer a solid connection with minimal flexibility, ideal for applications requiring precise alignment.

- Flexible Couplings: Designed to accommodate misalignment, these couplings enhance system resilience by absorbing shocks.

- Fluid Couplings: Utilizing hydraulic principles, these couplings facilitate smooth power transmission while minimizing wear.

Understanding the intricacies of these components not only enhances operational efficiency but also contributes to the longevity and reliability of mechanical assemblies.

Maintenance Tips for Pump Longevity

Ensuring the durability and efficiency of fluid-moving equipment requires consistent care and attention. Regular maintenance not only extends the lifespan of the machinery but also enhances its performance and reliability.

Here are essential practices to promote longevity:

- Regular Inspections: Conduct frequent assessments to identify any signs of wear or damage. Check for leaks, vibrations, and unusual noises.

- Lubrication: Keep all moving components adequately lubricated to minimize friction and prevent overheating.

- Cleaning: Maintain cleanliness by removing debris and contaminants that can impede functionality.

- Seal Checks: Inspect seals and gaskets regularly for signs of degradation to prevent leaks and ensure efficient operation.

- Fluid Quality: Use the recommended type of fluid and change it according to the manufacturer’s guidelines to prevent contamination and ensure optimal performance.

- Follow Manufacturer Guidelines: Adhere to the recommended maintenance schedule and procedures specified in the user manual.

Implementing these strategies can significantly enhance the performance and lifespan of your equipment, ensuring it operates at peak efficiency for years to come.