Modern kitchen machines are composed of various essential elements that work together to ensure smooth and efficient performance. Each component plays a crucial role in maintaining the overall functionality and longevity of the device, making it important to understand how these elements interact with one another. Whether it’s for maintenance or repair, being familiar with the internal mechanisms can save time and effort.

Recognizing the individual units that make up such machines allows users to quickly identify potential issues and take the necessary steps to resolve them. By exploring the inner workings, one can gain a deeper appreciation for the complexity and craftsmanship behind these household essentials.

Knowing how each part functions not only empowers users to maintain their equipment but also ensures that any required adjustments can be made with confidence. This knowledge is valuable when troubleshooting common issues or performing routine care to keep the device in optimal condition.

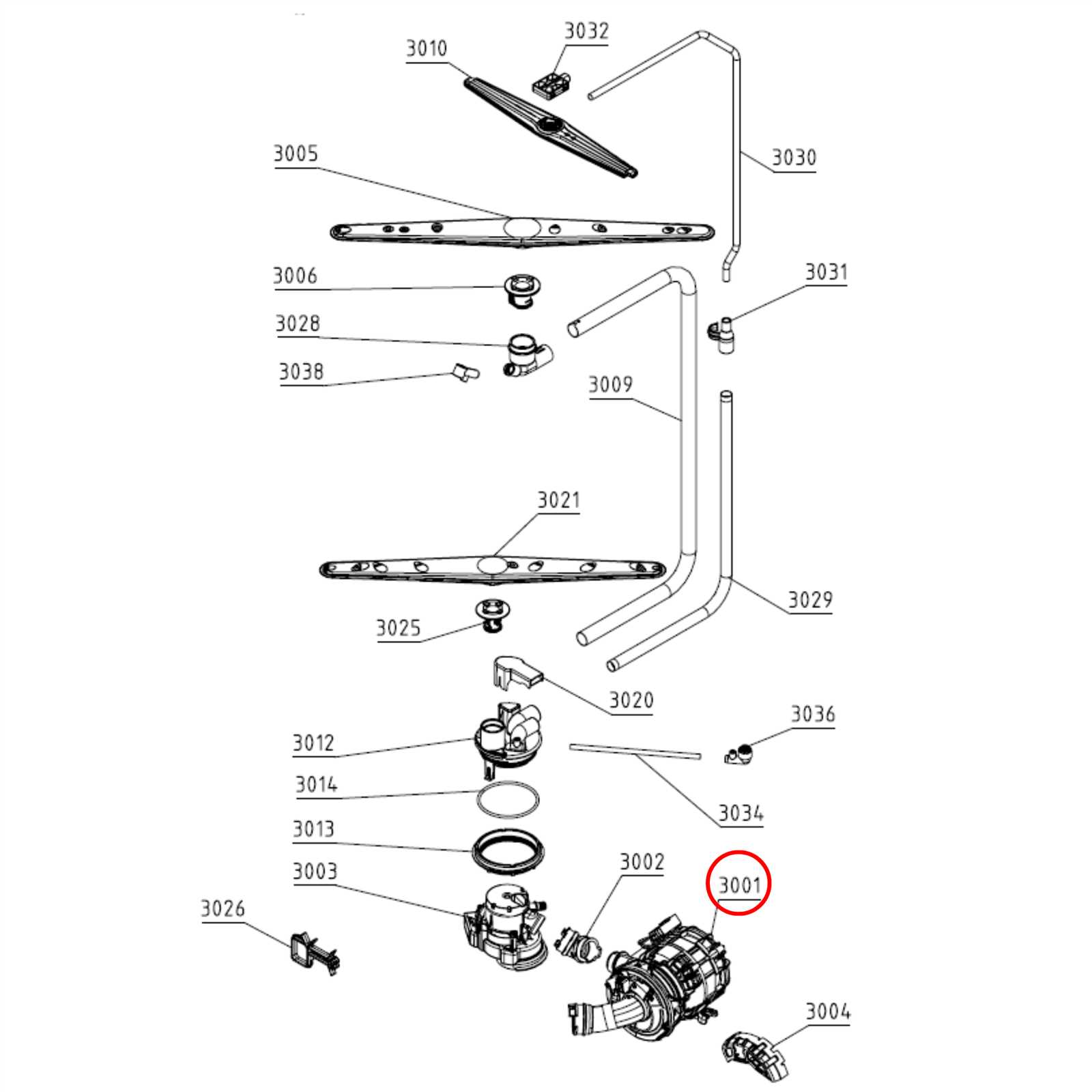

Asko Dishwasher Components Overview

The essential elements of this appliance are designed to ensure efficient performance and long-lasting durability. Each component plays a significant role in maintaining smooth operation, from cleaning cycles to drying features. Understanding the structure and functionality of these internal and external elements can help with troubleshooting and maintenance.

| Component | Function |

|---|---|

| Pump | Circulates water during wash cycles to ensure effective cleaning. |

| Spray Arms | Distribute water evenly across the items, reaching all corners of the machine. |

| Filter | Traps food debris to prevent clogs and maintain water flow. |

| Control Panel | Allows the user to select settings and monitor the cycle progress. |

| Heating Element | Responsible for heating water and aiding in the drying process. |

Key Internal Parts of an Asko Dishwasher

Understanding the essential mechanisms inside this kitchen appliance can help with its maintenance and efficient operation. These internal elements work together to ensure proper cleaning and drying of your dishes, making it a vital tool in your home. Below is an overview of the most important internal components that contribute to the smooth function of the machine.

Spray Arms

The spray arms are responsible for distributing water evenly throughout the unit. Their movement ensures that all surfaces are thoroughly cleaned by directing streams of water onto the dishware. They can vary in design, depending on the model, and often feature multiple nozzles.

- Upper and lower spray arms

- Rotational function for maximum coverage

- Multiple jet configurations

Water Inlet Valve

The water inlet valve is a crucial part that controls the flow of water into the system. It ensures the correct amount of water is used during each wash cycle, maintaining the balance between efficiency and performance.

- Regulates water intake

- Prevents overflow

- Operates in coordination with the electronic controls

How the Drain System Works

The drain system is a crucial part of the overall functionality of a cleaning appliance. It ensures that water is efficiently removed after each cycle, preventing any stagnation or overflow. Understanding the mechanism behind the drainage process allows for better maintenance and troubleshooting.

Water removal process begins once the washing stage concludes. The pump initiates the movement of the liquid, directing it through designated channels toward the exit pipe. These pathways are carefully designed to avoid blockages and ensure smooth operation.

Filters and valves also play a vital role in this system, acting as safeguards against debris. They prevent particles from entering the pump or the drainage pipes, which could cause clogs or other malfunctions.

Once the liquid is expelled through the outlet, the system resets, preparing for the next cycle. Proper care and regular inspection can help keep this essential component functioning without interruption.

Identifying the Main Control Panel Elements

The central control interface is essential for managing the device’s various settings and functions. It includes several key components that enable users to interact with the system efficiently. Understanding these elements ensures proper handling and smooth operation of the appliance.

Buttons on the interface allow users to select different modes and features. Each button is typically labeled, providing clear guidance on what action will be taken when pressed. These buttons often vary depending on the program or function needed.

Indicator lights offer visual feedback, showing the current status of the machine. These lights can signal if a cycle is running, whether there’s an error, or if certain functions are activated. Paying attention to these signals helps in monitoring the device’s performance.

Lastly, the digital display provides detailed information about the current settings or remaining time. This feature helps users track the process more accurately and adjust settings as necessary.

Exploring the Water Inlet Valve Function

The water inlet valve plays a crucial role in regulating the flow of water into a machine. It ensures that the right amount of water enters at the correct time, supporting the overall efficiency and operation of the system. This component opens and closes to allow water into specific areas when needed, making it essential for maintaining the device’s performance.

The Role of Timing and Control

One of the key functions of this valve is its ability to control water flow based on signals from the machine’s internal mechanisms. The valve responds to electronic or mechanical commands, ensuring that water is delivered at the precise moment required for optimal performance. Without this timely regulation, the process would become inefficient or even potentially damaging.

Preventing Overflows and Malfunctions

Beyond controlling water entry, the valve is also responsible for preventing overflows. By shutting off the water supply when it is no longer needed, it helps avoid leaks and other issues that could harm the system or lead to malfunctions. Ensuring that this valve operates correctly is vital for the overall functionality of the

The Role of Heating Elements in Dishwashers

Heating components play a crucial role in ensuring effective cleaning and sanitization of kitchenware. By elevating the water temperature during various cycles, these elements help to dissolve grease and food residues, leading to improved cleanliness and hygiene. Their functionality is essential for optimizing the overall performance of the cleaning appliance.

Functionality and Importance

The primary purpose of heating components is to raise the temperature of water, facilitating the breakdown of stubborn stains and contaminants. Higher temperatures not only enhance the efficacy of detergents but also aid in killing bacteria, making the cleaning process more effective. In addition, these elements contribute to drying cycles, ensuring that items emerge from the cleaning chamber free of moisture.

Common Issues and Maintenance

Like any other component, heating elements can experience wear and tear over time, leading to reduced performance. Common issues include inconsistent heating or complete failure, which can significantly impact the cleaning results. Regular maintenance and timely replacement of faulty elements are vital for maintaining optimal functionality and prolonging the lifespan of the appliance.

Understanding the Spray Arms Mechanism

The functionality of cleaning devices relies heavily on a specific component that effectively distributes water throughout the interior. This crucial element plays a vital role in ensuring thorough cleansing by delivering water to all surfaces, allowing for optimal results during each cycle.

At the core of this system is the movement of these arms, which rotate and pivot, creating a pattern that allows water to reach every nook and cranny. This mechanism not only aids in rinsing away residues but also contributes to the overall efficiency of the washing process.

Regular maintenance and inspection of this component are essential to prevent clogs and ensure smooth operation. Understanding how it works can help users identify potential issues early and maintain the effectiveness of their appliance.

Common Causes of Pump Failures

Pump malfunctions can stem from a variety of factors that hinder their efficiency and effectiveness. Understanding these common issues is crucial for maintaining optimal performance in appliances. By identifying the root causes, users can take preventative measures and address problems before they escalate.

Blockages and Clogs

One of the primary reasons for pump failures is the presence of blockages or clogs in the system. Debris, food particles, and other obstructions can accumulate over time, restricting the flow of water. Regular maintenance, including cleaning filters and ensuring proper drainage, can help mitigate this issue.

Wear and Tear

Another significant cause of pump failures is the natural wear and tear that occurs with regular use. Components may deteriorate, leading to decreased functionality. Regular inspection of parts and timely replacement of worn-out components can prolong the lifespan of the pump and enhance its reliability.

Replacing Racks and Baskets in Your Dishwasher

Maintaining the functionality of your appliance is essential for ensuring optimal performance. Over time, various components such as racks and baskets may wear out or become damaged. Understanding how to replace these elements can significantly enhance the efficiency of your cleaning machine.

Identifying When to Replace

Recognizing the signs that indicate a need for replacement is crucial. Look for the following issues:

- Visible damage or bending

- Rust or corrosion on metal surfaces

- Difficulty in sliding in and out

- Inadequate support for dishes and utensils

Steps for Replacement

Follow these steps to successfully replace the necessary components:

- Gather the required tools, including screwdrivers and pliers.

- Remove the damaged rack or basket by gently lifting it out of its tracks.

- Inspect the surrounding areas for any debris or damage.

- Install the new rack or basket by aligning it with the tracks.

- Test its movement to ensure it slides smoothly.